A strong fence to the country house with our own hands: we use proven and improvised materials. Construction of a fence and ideas for its design How to make a fence with your own hands

The garden has been dug up, the seedlings are ready for planting, but in addition to vegetables and useful crops, I would like to pay attention to the beauty of the garden, namely the fencing of the flower beds. Flowers growing one by one or in pairs, descending in garlands from balcony boxes, or arranged in a single composition under the windows of your beloved home, will give joy after a hard day and allow you to take a break from work. But how to keep this beauty? How to protect flowers from the ubiquitous line of a lawn mower, from children always running somewhere, from dogs who strive to lie down on them? Consider a few examples of making fences using improvised materials and minimal amount tools.

natural stone border

Stone is not an enemy to plants. Many people know that the sculptures created from durable granite, after centuries, have conveyed to this day the beautiful faces of ancient women and the muscular torsos of men. Frozen in stone, they still amaze with their beauty.

And why not use this durable material to decorate adorable petunias, lupins, cosmos, marigolds. Granite and marble, of course, not the most cheap option, but you can resort to the help of improvised representatives of the stone world, for example, cobblestones, which can be found almost everywhere. Having made a considerable margin, you can impose a fairly large one, thereby protecting it from lawn mowers and other cutting tools.

Variants of the forms of a natural stone fence depend only on the author's imagination and the amount of source material. The advantage of this fence is durability, and the disadvantage can be considered a small height and, over time, natural subsidence deep into the soil.

Fence for a flower garden made of wooden pegs

Tired of the old plinth, why throw it away? Miniature, up to 20 centimeters, wooden fences look very unusual and pleasant, enclosing plants of medium height. The construction of such a fence will take several hours of time and a couple of meters of the old plinth.

- First of all, you need to decide on the height, mark it on the base, and saw off the pegs that will make up the fence.

- For the convenience of inserting such blanks into the ground, it is advisable to make an acute angle from one edge, and leave the top straight.

- Pegs are either dug in or driven into the ground by 5 - 10 cm, for greater strength. Thus, the workpiece is a peg 30-35 cm long.

The advantage of such a fence is its original shape. The disadvantages include the difficulty of setting a straight line, but using the level, you can achieve greater accuracy.

Glass bottle fencing - simple and affordable

Glass is not a new material, and certainly not expensive. After all, for sure in your house there is sometimes a bottle of beer, champagne, Coca-Cola or lemonade by the trash can. They will serve as an excellent basis for a decorative fence. All you need to do is collect the required number of glass bottles. For an average-sized flower bed, approximately 20-30 pieces will be required. Per winter period It won't be too hard to get that many.

The construction technology is extremely simple, tearing out a small hole, you need to stick a glass bottle upside down and dig it in for greater strength. keep straight horizontal line the usual building level will help.

Glass bottle fences are durable and look great next to low plants.

Considering possible ways improvement of a flower bed, each owner is looking for the most simple and affordable option. It's easier than building a fence out of crushed stone, wood, or glass bottles. Let's analyze a few more options for decorating floral splendor:

Wooden rods and tree branches as a decorative fence

Rods and branches - to the fire or to work? To build original barriers from the branches of an old tree that fell under an ax - there is nothing easier! Naturally, branches are taken as the basis, but their selection is very important.

To decorate a flower bed, it is advisable to use straight or slightly curved rods. Branches that have knots or shoots are not suitable for work, because with the growth of green spaces, the stems will hang on them and cling. It is advisable to clean straight branches from the bark and dry. An ideal option is also to impregnate them with antifungal agents, but not necessarily.

The construction of such a fence is as follows:

- Straight base stakes are driven into the ground at a distance of 10-15 cm, rods or branches are laid out between them;

- Fastening, for greater stability, is carried out with twine or fishing line. The height of the structure depends on the number of rows thus laid.

The advantages of the design are ease of execution and natural appearance. The disadvantages include a small durability, in general, from 2 to 3 years, and the possibility of curvature under the influence of weather conditions.

Another option for wicker fences is a wicker fence. It looks very aesthetic. The method is similar to the construction of branches and rods, only due to the length of the base material in the process of laying out the rows, the main pegs-supports are intertwined.

The advantages of this version of the improvement of the flower bed is its excellent combination with the landscape and aesthetically simple appeal. The downside is that the short life and possible corrosion of the material. Wood processing tools will help to correct these shortcomings.

Macrame in garden design

The macrame technique, which is based on a special weave of threads, can be a wonderful and unusual option for decorating a flower bed. Naturally, strong twine will serve as the main material. Any drawing can be taken. Detailed diagrams can be found online or in craft magazines.

Wooden pegs will serve as fasteners for the original baubles, which can also be braided to match the main motif. The advantage of this work is its originality. The disadvantages include a fairly long duration of work and a short service life.

A fence of dishes (photo)

Dishes beat fortunately. There are three plates left from your favorite service, which are not only embarrassing to put on the table, but also insulting to tears. The saucer cracked or split in half, it doesn’t matter, we collect fragments for the fence, they will serve as an excellent basis for creative design flower bed.

Simply stuck into the ground or embedded in cement mortar, once a work of ceramic art, today will become an original decoration flowering plants. The simplicity, durability and unusualness of such a fence is a definite plus, only some danger to children can be attributed to the minuses, because it can split and injure.

DVDs playing in the sun

Many video and audio lovers in the house often have a fairly large number of unnecessary discs that have already played their contents millions of times and have lost their freshness and quality. By combining them with a paper clip, wire or fishing line into a single canvas and fixing them on the pegs, you can give the flower bed an unusual, bright and shiny look in every way.

The disadvantage of such an undertaking is only a short period of operation of this fence. For the rest, she can become original solution v landscape design any area.

Plastic bottles - a flight for fantasy

Remaining after feasts can also be useful to a decorator flower beds. Inserted like glass bottles, carefully painted in different colours, illuminate the green space with bright notes.

However, it is worth remembering that plastic is subject to deformation when the temperature changes, therefore, before directly inserting the bottles into the ground, it is worth carefully filling them with sand. Possible deformation, under the influence of weather conditions, is a minus of these fences.

Decorative fences enclosing your flower garden

Items such as an old fence, remnants of roof tiles or wall plastic, unused metal tape in a roll, forged products and other improvised material can be an interesting basis for creating a flower fence.

Their presence, in various configurations, will bring a touch of chaos and modern colors to the green ornament of plants, forcing the owners and guests of the summer cottage to look at the classic forms from a different angle.

A variety of design options for flower beds, at times, amazes the most experienced grower. Wood, glass, stone chips, knitting, weaving and many other materials reveal countless creative ideas owners of summer cottages and simply lovers of aesthetics and beauty.

Consider a few more ideas aimed at fencing for flower beds, which use improvised non-standard materials.

Stone border - a classic version of the fence flower beds in the country

The creation and design of flower beds is undoubtedly an exciting creative activity, and the flight of fancy here is hardly limited to the usual forms and materials.

Creating, against the backdrop of favorite plants, an object of landscape art, each owner will be able to feel like the creator of something new, unusual, original. The main thing is a positive attitude and focus on a truly grandiose result.

Each owner adjoining territory tries to ennoble it as far as possible or according to his aesthetic idea. Not the last role in decorating the site is played by fencing fences and borders. They will help to carry out zoning, for example, to separate part of the space for rest with a barbecue, benches, gazebos. With the help of them, you can select beds for vegetables or berries, as well as beautifully and originally arrange flower beds, preserve the geometry of flower beds. In the article we will consider different kinds decorative fence and methods of their manufacture.

Such fences will not only give a neat appearance to the site, but will also cope with their direct purpose - they will protect the plantings from careless guests and serve as a barrier to domestic animals. And here it does not matter at all whether it is a summer cottage where only a few seasons are held, or a private house for year-round use.

It should be noted right away that all of the following options for fencing can frame absolutely any form of paths, flower beds and draw up dividing zones. There is no limit to the imagination in these works, they are mounted in the form of strict geometric shapes or non-standard lines.

Plastic decorative fences

This kind of fences on the market are presented in a huge assortment, due to the technical characteristics of the material from which they are made. Its thermoplasticity makes it possible to produce borders for paths and fencing of flower plantations, front gardens of various shapes, and a special laminating method - in various colors.

- Here you can give preference to a border of a tape or sectional type, which will serve as a designation of the boundaries of garden paths, and will also become an additional decoration for plant compositions.

- Each section is equipped with pegs, so the installation process consists of light pressure - until the supports are completely in the ground. Installation can be carried out both on absolutely flat surfaces and on the ground with a slight slope.

- Decorative fences for summer cottages made of plastic can imitate wooden picket fence, wattle, clinker or masonry, forged items. Usually such sections are produced in height from 13 to 20 cm.

Decorative wooden fences

The most popular material for giving a well-groomed appearance to the yard is still wood. Such fences look quite relaxed in the landscape and do not create any disharmony.

Availability should also be attributed to the benefit of the material, because any lumber is suitable for finishing, for example, flower beds: boards, battens, pegs, logs and even branches. This refers to the manufacture of standard fences, only miniature sizes.

Before carrying out any work, wood requires mandatory processing:

- the lower part of the supports entering the ground must be fired or dipped into liquid roofing material;

- all other structural elements are impregnated with special solutions that slow down the process of decay and protect against insects.

"Wood Fence"

For the manufacture of a structure 40 cm high to frame a flower bed 70x70 cm, you will need:

- 4 beams 50x50x700 mm;

- 8 boards 20x100x700 mm (here, if desired, you can use both edged and raw lumber);

- 32 wood screws or the same number of nails;

- screwdriver, hammer.

Stages of work

- Drive the supports into the ground 700 mm apart, check the vertical and adjust their height.

- A board is attached to the upper part of the beam in two places, where its end part should not protrude beyond the edge of the peg.

- The second crossbar is mounted, stepping back 100 mm from the bottom edge of the board.

- The same manipulations are performed on the other sides of the flower garden.

"Lattice"

With this light fence made of slats, you can enclose a flower bed with tall plants, for example, such as: a window sill or cornflower. If you run it over large sizes, then it is perfect for separating the recreation area.

For its implementation, one section with dimensions of 900x630 mm will require:

- for supports 2 bars 30x30x950 mm;

- for crossbars 2 pieces 20x30x900 mm;

- 12 rails 10x20x520 mm;

- 12 wood screws 3x25 mm, 4 screws 3x40 mm.

Stages of work

- Section assembly is performed on any flat surface. 30 mm recede from the upper parts of the supports, and the logs are fastened with 3x40 mm screws.

- Stepping back 500 mm from the attachment point of the upper crossbar, a similar installation is made for the lower log.

- The rails are fastened first from left to right, using 3x25 mm screws. The first rail is mounted at the attachment point of the upper cross member and the support, to the lower frame - stepping back 150 mm from the support. Their subsequent installation to the purlins is carried out in increments of 150 mm from the previous attachment points.

- In a similar way, the mounting of the rails is now done from right to left. The result is a diamond pattern.

- To protect any site, even if it has the wrong contour, you can make the required number of such sections.

- Important: when making a square fence or rectangular shape, material consumption will be much less than in the construction of a multifaceted structure.

- The finished structure is painted alkyd paint one color or covered with a protective varnish. To give the fence a more “joyful” look, it will turn out if you paint it in multi-colored tones.

"Wattle"

This kind of fence can be done in a fairly short time.

- Willow, birch or apple twigs for its manufacture are best cut in spring or autumn, the thickness of which should not exceed 2 cm.

- Quantity consumable determined by the height and length of the structure. In general, for the implementation of this idea, stakes or bars, rods, wood screws, wire are needed.

Tip: Instead of a vine, you can use old multi-colored hoses or wires with a rubber sheath.

Stages of work

- As a rule, vertical supports are installed in increments of 0.5 m.

- Weaving starts from the bottom row. The vine is fastened to the first support using wire or screws. Further, the rod is passed in a horizontal direction, bending around each bar. It is recommended to fix the joints of the rods with wire.

- If there is no desire or opportunity to engage in independent production of such fences, then you can purchase ready-made version. For example, modular fences up to 0.5 meters high from natural pine are offered. Treatment with antiseptic solutions and painting with varnish to give an attractive appearance to the lamellas is carried out at the factory.

- Those who care not only appearance fence, but both its strength and resistance to atmospheric precipitation can opt for products made of wood-polymer composite. This material allows to produce sections of any complexity and configuration.

Decorative fences for flower beds made of stone

For masonry, cobblestones of various shapes are selected, thus, a fence of the "medieval" period will be obtained. Here, the rough texture of the stones will create a wonderful contrast with delicate flowers and greenery. It will literally last forever.

Stages of work

- The material can be sandstone, dolomite, shungite, both round and bedded. As a rule, the first row is laid out on a concrete mortar, trying to use a tiled type of but.

- They are selected in such a way that the same row height is observed. In this case, the laying is carried out "in a run", where the seams between the upper and lower layers should not coincide.

- To give additional reliability to such a masonry, a sand-cement mixture will help.

Metal decorative fence

Any product made of such material has a rather long service life, but at the same time it requires maintenance - annual painting. The fence can be purchased at ready-made or order according to an individual sketch.

But it is quite possible to make it on your own, for one section (900x550 mm) you will need:

- supports - 2 fittings Ø 12 mm and length 950 mm;

- crossbars - 2 fittings Ø 12 mm, length 900 mm;

- horizontal crossbars - 5 rods Ø 10 mm, length 39 cm;

- decorative elements - 6 rods Ø 10 mm, 14.5 cm long;

- welding machine.

Stages of work

- Step back 50 mm from the top of the supports and weld the cross member, measure 40 cm from it and mount lower part frame.

- With a step equal to 150 mm, horizontal crossbars are attached.

- Next, decorative vertical elements are welded in a checkerboard pattern. To do this, a twig is first welded, stepping back from the lower crossbar 100 mm, and in the next section it is attached, counting the same distance, but already from the upper crossbar.

- Such a fence is installed by pressing its supports into the ground, while leaving a distance of 100 mm from the ground to the bottom of the frame.

Manufacturers also offer galvanized bumpers, designed not so much to enclose flower beds, but to create them. They are produced with a height of 17 cm and a length of 25 to 100 cm, which allows you to design flower beds quite original way. Thanks to the universal connection, there is a great opportunity to assemble a flower bed of different sizes from them and in the form of any geometric figure.

Decorative concrete fences

Of course, for many, at the mention of such material, it evokes the association of a massive, gray fence. But do not rush to abandon concrete products, there are various options borders designed for garden paths, lawn fencing and flower beds.

- These products have not been produced in a dull color for a long time, now they can be of different shades and have a pattern on the front surface.

- It will not be difficult to make this kind of fence with your own hands if you use molds for a decorative fence made of polyurethane or plastic.

Stages of work

- All work consists only in lubricating the matrix and pouring it with a concrete mixture.

- Next, you need to let the solution harden (24 hours is enough) and you can take out the finished section. Thus, the required number of curbstones is prepared.

Some Tips

- matrix lubrication can be carried out with ordinary vegetable oil;

- for the solution, one part of M250 cement and two parts of sand are taken, so much water is added so that the mixture becomes thick;

- the more sand in the mixture, the darker the product will turn out

- if it is planned to paint a concrete fence, then before that it is necessary to treat it with a deep penetration primer.

Decorative brick fence

This material firmly holds a leading position as a fence for lawns, flower beds, lawns and paths in the garden and in the country. This is due to its characteristics, availability and ease of installation.

Stages of work

- Usually, the brick is laid around the perimeter of the flower bed at an angle to its end side, creating a kind of "toothed" fence.

But there are several other ways to perform masonry:

- lay out the clinker around the flower bed, forming a circle or oval. The second row is carried out in the same way, making sure that the seams do not coincide with the previous layer. Masonry is done without concrete mortar, so the design is unreliable. But it can also be done using a sand-cement mixture;

- the first two rows to perform the usual masonry using concrete mortar. The clinker in the next row is placed on a spoon (this is the narrow and long side of the brick). Since here the width of this layer is greater, alignment is performed on the inside of the masonry;

- the brick can be put on a poke (on its narrow, short side). The seams between them can be quite wide - about 2 cm.

Photo of decorative fences made by hand

- Car tires are most often used to create flower beds and flower beds. They also separate beds, paths, lawns, simply digging them into the ground;

- beer bottles can serve as a mini fence by dripping them upside down. To give even more originality to this design, the use of bottles made of white, green, brown glass will help;

- with the same success, plastic 5-liter bottles from under the water will do. They are filled with colored pebbles or sand so that they do not lose their shape, and are painted on top with any color;

- logs Ø 15-20 cm are dug in or driven into the ground close to each other, any lumber left from the construction site is also suitable for this purpose.

Every owner of a summer house, garden or garden dreams of creating an ideal design on his land space. And for this it is not at all necessary to purchase expensive factory-made fences, it is quite possible to make them, for example, from the material left after the construction of the house, and using all your wild imagination. You can take one type of material or combine them, thereby giving the surrounding area an amazing and rather original look.

A beautiful and reliable fence will decorate and secure any land plot. When its construction is only planned, the question arises - what is the best way to make a fence so that it fully performs its functions? To do this, consider the location and purpose of the structure. If the fence will protect the site from the street, then it is made of more durable materials. For example, from stone, corrugated board, concrete, brick, wood. To protect from neighbors or zoning your site, you can build a fence made of chain-link, plastic, picket fence. Sometimes such a structure is made of two different materials, successfully combining them with each other.

Combined fence options are practical and often economical without losing "presentability"

Let's take a closer look at what to make a fence from. We list the most popular building materials for the fence, from which durable and presentable structures are made.

concrete blocks

Concrete block fence

Concrete block fence If you make a fence of two elements, concrete pillars and blocks, then it will last longer than a cottage can stand. It is a symbol of impregnability and reliability. The main advantages of concrete include:

- Easy and fast assembly.

- High strength to all kinds of influences.

- It can be built on any soil.

- There are many options for block designs. Their sizes can also vary.

- Durability.

And now a few drawbacks:

- High construction cost.

- The area will not be adequately ventilated.

- To do it, you need to involve construction equipment.

- If the manufacturing technology is not followed, the fence may warp after the winter season.

profiled sheet

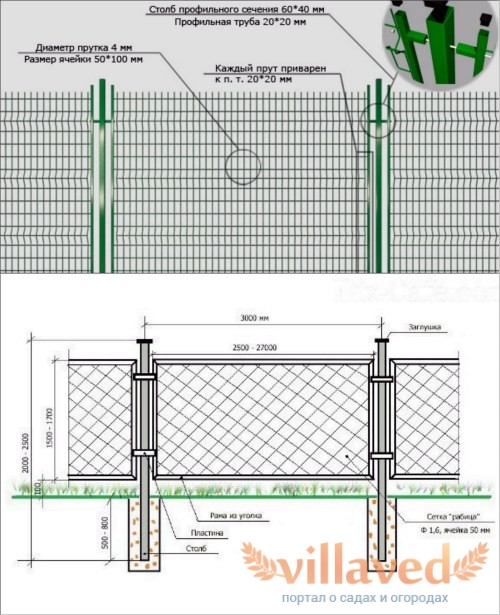

Fencing made of profiled sheet with pillars made of profile pipe

Fencing made of profiled sheet with pillars made of profile pipe Often the choice of material for the fence often rests on the availability of those on the local market. Profiled sheet is one of the most common materials for arranging a fence, especially for a fence in a country house. It combines ease of installation, affordable cost and durability of the structure. Completely covers the visibility of the area. There is a lot of material on sale, and the dimensions of the sheets allow you to make fences various heights. It is recommended to use sheets not just galvanized, but also coated with a polymer layer, as a result of which the service life of corrugated board increases significantly.

Advantages of a fence from a profiled sheet:

- Rising quickly. You can build a fence yourself.

- The light weight of the sheets, which eliminates the need for the construction of a powerful foundation.

- Combines well with stone and brick pillars, but sheets can also be installed on a frame made of metal pipes.

- Resistant to moisture, frost and heat.

- Does not fade in sunlight.

- To new fence was beautiful, it is better to make it from figured corrugated board, the upper part of which resembles domes or peaks.

- Relatively inexpensive

Curly profile

Curly profile Cons of the material:

- An impenetrable wall is formed on the site, which the plants do not really like.

- The fence looks monotonous, in the form of a solid plain wall.

Forged metal fence

This fence looks very stylish. It can be done in combination with or stone pillars. Usually consists of two elements: an overestimated foundation and directly forged gratings.

Advantages:

- Presentable look.

- The fence can be made according to an individual drawing, taking into account the desired section sizes.

- Variety of manufacturing options.

- The area is well ventilated.

- At proper processing metal provides high-quality protection against corrosion.

Flaws:

- The site will be fully visible inside. In some cases, some facing materials are mounted on the section, due to which the visibility of the site is partially blocked.

- Periodically, metal elements must be tinted.

wooden fencing

Horizontal checkerboard fence made of wood - a completely modern version

Horizontal checkerboard fence made of wood - a completely modern version It is advantageous to make a wooden structure if there is an excess of wood or there is an option where to get it, substandard, it can be of decent quality,. In all other cases, the cost of its manufacture will be quite high (with the exception of the picket fence). There are the following types of wooden fences:

- Fence. May be sparse or solid.

- Boards. Can be mounted horizontally, at an angle or vertically.

- Wood lattice. Planks are usually placed at an angle.

- board fence.

Which better fence to do, each owner of the site decides for himself. The location of the fence and the need to ventilate the area are taken into account.

Wood benefits:

- Eco-friendly material.

- Nice appearance.

- Ease of installation.

- It can be successfully entered into the design of the site.

- Compatible with any other materials.

- It is light in weight, so it does not require a strong foundation.

Fencing disadvantages:

- High price.

- The need for periodic treatments from pests and dampness (pillars in the ground are especially affected).

- The service life of wood is not too long.

Brick

Brick fencing is considered traditional. It has already been used successfully long years. Brick is a symbol of constancy and reliability, it emphasizes the taste of the owners.

Advantages:

- Reliable fencing.

- Harmonizes with almost everyone building materials: stone, metal, wood, glass.

- Durability.

- Does not require repair and maintenance.

Flaws:

- When a brick fence is made, a powerful foundation is poured due to the significant weight of the structure.

- The cost of such a structure is considered one of the highest.

- Masonry requires the involvement of qualified craftsmen.

A rock

Exterior of a fence made of wild natural stone

Exterior of a fence made of wild natural stone For the manufacture of a fence, stone can be used both and artificial. The latter option is much cheaper. Benefits of stone fence:

- Excellent appearance.

- Durability.

- Reliability.

- Lack of care.

Flaws:

- High price, especially if you make a fence from natural stone. You also need to consider the cost of shipping materials.

- Its production time can be extended for a long time.

Gabion - a fence made of stones in a grid

Gabion - a fence made of stones in a grid Rabitz

Green mesh fencing

Green mesh fencing For fencing, a galvanized or polymer-coated mesh is used. It is better to use a material with a polymer layer, if possible. The mesh sizes are selected depending on how high the fence is made.

Benefits of a chain link:

- The whole area is well blown.

- Inexpensive price - is the lowest among all materials used for the construction of fences.

- Simplicity and speed of installation - it is important at their summer cottage.

- You can choose the cell size you want.

- Ease of construction.

Flaws:

- The site is fully visible.

- With the help of a special tool, the mesh can be cut and penetrated into the area.

- The grid can be stolen from the site in your absence.

Plastic

Dark plastic picket fence

Dark plastic picket fence Plastic fencing is not suitable for fencing a site from the street, but it is successfully used for zoning the territory, as well as for establishing boundaries between neighboring sites.

Pros of plastic:

- make the site more aesthetic.

- Functional areas are well defined. For example, flower beds, playgrounds, recreation areas.

- Plastic is resistant to temperature changes, is not afraid of moisture, does not rot.

- Over time, plastic fencing will not change color.

- There are many design options from which you can choose the most suitable type of fence.

- The sizes of plastic sections give even more choice for creativity.

Disadvantages of plastic:

- Insufficient resistance to mechanical damage.

- Preferably for indoor use only.

- The service life usually does not exceed 12-15 years.

We have analyzed the most popular materials for the construction of fences. Which one is better to choose and from what the fence can be made is decided on an individual basis, taking into account many related factors. Consider the purpose of the fence, the location of the site (house or cottage), your financial capabilities, possible labor costs.

The fence of the site plays not only a protective, but also a decorative role. Due to the variety of materials on the modern market, it is possible to build a fence not only from wood or chain-link mesh, but also from brick or corrugated board.

You can find instructions, ideas and drawings for building a fence with your own hands in this article. It provides useful information for those who want to make a solid and beautiful fence for the site.

DIY fence

Permanent fences are subject to both general and statutory requirements. Among the common ones are:

- Reliability of supports, their resistance to wind loads, as well as to rain and melt water;

- Lack of shading of residential buildings and green spaces;

- Neat appearance;

- The erection of deaf fences is allowed only from the side of the street.

Guided by these requirements, you will be able to independently create a project and build a fence on the site, choosing the most suitable material for this.

How to make a wooden fence

V Lately wooden fences are becoming less and less common, because wood is being replaced more modern building materials with high quality. However, a picket fence structure is often erected on summer cottages, because it combines ease of construction with an attractive appearance and low cost.

Installation materials

To build a wooden picket fence, you will need the following materials:

- Wooden poles for supports;

- Trimmed or planed boards, the length of which depends on the estimated height of the future structure;

- A beam, 2 - 2.5 m long and 40x40 in section;

- Cord and stakes for marking;

- Construction nails (screws);

- Crushed stone (concrete) for mounting pillars;

- Ruberoid (roofing felt) for waterproofing supports.

In addition, you will need an antiseptic or bituminous mastic to process the pillars. Without this, the supports can quickly fail, and the integrity of the structure will be compromised.

Construction of a wooden fence

With the budget cost of a wooden fence, it can serve its owner from 10 to 15 years. In addition, its construction does not require special building skills, so it is quite possible to do all the work yourself without spending money on the services of professional builders.

Stages of building a wooden fence

Consider the sequence of work in the construction of a wooden picket fence:

- Performing markings with determining the locations of the pillars (2-3 meters apart);

- Training wooden poles to installation in the soil: treatment with an antiseptic and bituminous mastic. Alternatively, wrapping the ends of the supports with roofing paper or roofing material can be used;

- Digging recesses for supports in accordance with the markings. In this case, the depth of the submerged support must be at least a quarter of the total height of the structure;

- Arrangement of a sand and gravel cushion at the bottom of the recesses. Its thickness should be from 10 to 25 cm. It is mandatory to spill the layer with water and thoroughly compact it;

- Installation of supports and their concreting;

- Fastening wooden beam to the installed supports after the concrete has set;

- Fence fastening to cross bars. In this case, the minimum distance from each picket fence to the ground surface should be at least 5 cm.

At the final stage, the wooden structure is treated with colorless mastic, impregnation or oil paint.

How to make a chain-link fence with your own hands

In the conditions of small summer cottages, due to the risk of shading, it is impossible to build fences from corrugated board, slate or brick. In this case, the chain-link mesh becomes indispensable, the fence from which does not prevent the sun from entering the site and passes air well.

In addition, the netting is inexpensive, but it lasts a long time. Let us consider in more detail the features of the construction of a structure made of this material.

Construction of a chain-link fence

by the most in a simple way construction of a chain-link fence is to fix it between posts made of various materials(metal, wood, concrete). Wherein optimal distance between the supports is 2.5 meters, and their height is calculated in a special way.

To the width of the grid add the height of the clearance from the fence to the ground (5 - 10 cm) and an additional meter and a half. The resulting number will indicate the average height of the column. At the same time, the length of the corner posts exceeds the rest by 20 cm, since these supports carry a large load, and therefore they need to be buried deeper.

If you are using wooden posts, do not forget to treat them with an antiseptic before installation. It is also recommended to concrete the bases of all installed supports for greater stability.

Further, hooks for mounting the mesh are attached to the supports with the help of screws, nails, wire, welding. The grid begins to be installed from the corner post, straightening it from post to post and hanging on hooks with a rod. Then, reinforcement is threaded into the grid from above and below, located horizontally, at a distance of 5 cm from the edges, and the rods are welded (attached) to the poles. Construction work is completed by bending the hooks and painting the supports.

Stages of work in the sectional construction of the fence

Another option for building a chain-link fence is to attach it to sections. As in the case of the tension model, work begins with the marking and installation of pillars. Then proceed to the manufacture of the frame. For him, you need a corner measuring 40/5 mm.

Chain link fence construction plan

Next, you need to calculate the right dimensions frame. To determine the length of the section, it is necessary to subtract 10-15 cm from the distance between the posts, and to calculate the width, the same number is subtracted from the height of the support above the soil level. In accordance with the calculations, the corners are welded into a rectangular structure and the mesh is fixed, forming sections. Then, between the pillars, it is necessary to fix metal strips, 15-25 cm long, 5 cm wide and 5 mm in cross section. Finished sections are welded to these strips. The work is completed by painting metal elements.

How to build a fence from corrugated board

Fences from a professional flooring enjoy wide popularity thanks to a number of advantages. Profiled sheets are reliable and durable, and their colors and various sizes able to satisfy even the most demanding consumer. Such a fence protects well from dust, wind and noise, it is easy to install, and the service life is quite a long time.

This material is great for building a stepped fence on a site that gives a slope. With some building skills, it is quite possible to build such a structure from corrugated board on your site. Let's see how it's done.

Fence Installation

The construction of a fence from a profiled sheet begins with precise marking and installation of pillars. You should know that in this case, the supports are installed at a distance of no more than 3 meters from each other. For these purposes, pipes with a square or round section can be used. In the first case, their size should be 50/50 mm, in the second - at least 76 mm. The upper holes of such supports must be welded to prevent moisture from entering them.

Stages of erecting a fence from corrugated board

To install the pillars, you will need pits with a depth of 1 to 1.5 meters and a width of 15 cm, which depends on the height of the fence and the diameter of the supports themselves. The bottom of the pits must be covered with gravel of the middle fraction, then the pillars must be strictly vertically installed and concreted. In the case of soil, where ground water come too close, to install the pillars, you will have to build a strip foundation. It consists of a box, 20 cm high, the boards of which are fastened with bars or wire. The walls of the box are covered with a layer waterproofing material and filled with concrete. After the solution has completely solidified, they proceed to the installation of the lag - transverse strips, to which the profiled sheets will be attached. As a log, you can use a profiled pipe with a cross section of 40/25 mm. At the same time, the number of logs depends on the height of the future fence: with a height of up to 1.7 m, you will need to install two logs, with a higher height - three.

The upper and lower lags are attached at a distance of 4 cm from the top of the sheet and the edge of the earth. Metal structures mounted in this way must be treated with a special primer to protect against rust. Sheets of corrugated board are attached to the logs with the help of metal screws. In this case, the joining of the sheets is overlapped.

What is needed for construction

For self-assembly, you will need the following materials and tools:

- Sheets of corrugated board;

- Pipes for supporting pillars;

- Pipes for log;

- Cement, crushed stone, sand for the preparation of concrete mortar;

- Rope, level;

- Primer;

- Welding machine;

- Solution container;

- Drill and drill;

- Riveter with rivets or self-tapping screws

- Antiseptic and bituminous primer for wooden poles.

How to make a brick fence: video

Brick fences retain their popularity due to their strength, durability and decorative effect. However, this type of fencing is expensive and requires special construction skills. Therefore, most often the canvas is made combined using various materials.

Construction stages include:

- The choice of material and the calculation of its quantity

- Drafting

- Marking on the ground

- Foundation laying

- Bricklaying

- Plastering

Since the construction of a brick fence requires certain skills, we recommend that you familiarize yourself with the video, which shows the main stages of this process.

A foundation is needed to build a fence. At the same time, its appearance depends on several factors: the type of soil, the type of supporting structures, and the material of the canvas. It should be borne in mind that the foundation must withstand the loads applied to it from the side. environment, soil and the fence itself. Therefore, it is so important to choose the right type of foundation. For example, a tape type is required for brick and concrete fences. Under the fence of corrugated board, it will be enough to lay a point foundation at the installation sites of the supports. Let's take a closer look at the construction technology different types foundation.

The laying of the strip foundation is preceded by marking along the perimeter of the site with the help of pegs and twine. This is followed by digging a trench according to the markings. At the same time, its depth reaches half a meter, and the width should not be less than the thickness of the future fence. The bottom of the moat is covered with a mixture of sand and gravel, after which it is rammed.

The main components of the foundation

This is followed by the execution of formwork from boards, the height of which above the ground level is about 15 cm. At the same time, you should know that its inner surface must remain smooth, therefore all fastenings of the boards are made from the outside. Reinforcement is laid inside the box: cuttings of pipes, metal, reinforcing mesh. In the places where the supports are installed, the reinforcement should form a three-dimensional structure.

The next step is to fill the formwork with concrete mortar, level it and remove air bubbles. At the end of the concrete hardening (after 1-2 weeks), the formwork is removed, however construction works do not continue, since the foundation will still gain strength for about a month and cannot be disturbed. Only after the final installation, you can proceed with the installation of the fence itself.

For light types of fences use pile foundation, raising it in the following sequence:

- Site marking;

- Drilling wells for supports, with a depth of 0.8 m for the fence and a diameter of about 20 cm;

- Laying a sand and gravel cushion in wells, from 10 to 15 cm high;

- Installation of supports with their preliminary processing (if necessary), their fixing with props;

- Concreting of pillars from the outside;

- Concreting of wells from the inside to the ground level;

- Further construction of the fence after the concrete mortar has completely solidified.

fence posts

Support posts play an important role in the process of arranging any fence, because they not only increase the strength of any structure, but also complement it in style. Therefore, it is so important to choose the most optimal type of supports during the construction of the fence.

Types of pillars

Most often, wooden, brick and metal poles are used as supports. The choice of material depends not only on financial capabilities, but is also determined by the expected load that is created by the sections, as well as mechanical and wind loads.

So, metal poles are universal, since they can be mounted on both sections of a chain-link mesh, as well as a wooden picket fence and corrugated board. In addition, metal poles have long term operation (up to 50 years). Wooden supports, on the contrary, can last no more than 20 years even with proper processing due to the tendency to rot. Therefore, wood poles are recommended for use in the construction of temporary fences, front gardens, or low hedges. Brick (concrete) pillars are erected during the construction of heavy fences, however, in some cases they are used for decorative purposes.

Installation methods

The installation of pillars can be carried out in several ways, the choice of which depends on the design features of the fence and the nature of the soil. So, metal, reinforced concrete and wooden structures on soils with low level groundwater deposits, mount universal way. This means that a hole of the appropriate size is drilled (dug out) under each support, a pole is installed, and the remaining space is filled with concrete mortar.

The easiest and cheapest way is to drive poles with the help of the so-called "headstock". In this case, the supports are installed on a strip or column foundation. Another option is to use piles, which are easily mounted by hand and serve as a reliable support for heavy fence structures.

Materials for building a fence

As mentioned above, you can build a fence from almost any material. For small areas, a chain-link mesh is most often used, but if the design needs to be more reliable, preference should be given to wood products.

Brick fences are considered the most reliable, but their installation requires special construction skills or the involvement of specialists. One of the simplest and most modern is considered to be a fence made of corrugated board, which is easy to install, but has a long service life.

Payment

Performing the calculation of the foundation for the fence is a rather complicated process and requires special knowledge. In addition, you should know the features of the soil on which the fence will be located, the prevailing direction and strength of the wind. Therefore, if you are building a fence yourself, it would be best to resort to a combined tape-point foundation, which is considered the most reliable. With this design, any type of load will be distributed over the entire length of the fence.

Let's give a simple calculation of the fence from corrugated board. With a span length of 2.5 meters and a height of 160 cm, the area of \u200b\u200bthe sheet of corrugated board will be 4 sq.m. Taking into account the value of the aerodynamic coefficient for flat vertical surfaces (1.4) and the value of the velocity pressure of the wind (about 40 kg), the wind load will be 224 kg for each support. Having distributed the load evenly over the entire surface of the fence, and taking into account the coefficient of resistance (225), we obtain the depth of the foundation, equal to 80 cm.

However, it should be noted that this calculation was made without taking into account the characteristics of the soil. Therefore, in practice, the foundation is buried to the depth of soil freezing for each specific area. Most often it is 120 cm and guarantees a solid installation of the pillars.

What boards to choose for sheathing

As the lining of the fence most often choose inexpensive not edged boards. They can be placed vertically or horizontally. The first option is considered the simplest. In this case, horizontal crossbars are attached between the supports, and pickets from boards are attached to them.

It is worth considering that a wooden fence can be through or deaf. In the first case, a certain distance is left between the boards, and in the second, they are nailed tightly on both sides of a horizontally located beam.

Before installation, the boards must be carefully inspected and cleaned. A width of 20 cm is considered optimal, since in this case the material will not dry out or crack.

Fence sheathing calculation

The main structural elements of any fence are the foundation, supports and materials that will be used to sew up the spans. But if to calculate wooden planks the calculation is simple (the width of the span and the board is measured, and the distance between the pickets is determined), then for products from corrugated board it is necessary to calculate the required number of sheets more carefully.

An example of calculating materials for building a fence

First of all, you should decide how the sheets will be attached, and what brand of corrugated board you will use. The last point is especially important, since the sheets of different brands have different widths.

Consider a few common calculation options:

- Horizontal placement without gaps for supports: in this case, the brand of the sheet does not matter. The only thing to consider is the overlap on the poles (subtracted from the length of the sheet). This indicator should be half the width of the support plus 10-15 mm.

- Horizontal fastening with gaps for supports: with this arrangement, the calculation is carried out similarly to the first example, with the only difference being that no margin for overlap is left. In other words, you need to measure the width of the span, and buy sheets 10-20 mm less than the figure obtained. This will allow you to build a smooth and symmetrical fence, even if support pillars there are irregularities.

- Vertical fastening without gaps for poles requires careful calculations. First of all, it is necessary to determine the working width of the sheet, since the width of one span will depend on this indicator. Further, depending on this indicator, sheets of suitable width are selected and multiplied by the number of spans. For example, if 3 sheets are required for one span, then 15 sheets are required for a fence of 5 spans.

However, with a vertical mounting method, there is a risk of uneven material consumption and the formation of a large number waste, so when buying a profiled sheet, you should make a small margin.

construction tool

To build a fence, you will need a standard set of tools. First of all - a tape measure for taking the necessary measurements, as well as a drill for digging holes for supports.

In addition, you need to prepare a drill, a screwdriver and fasteners (self-tapping screws) for fixing structural elements to each other. It is better not to use a grinder for cutting profiled sheets, as it leads to heating of the metal and a violation of the integrity protective coating. For this purpose, it is better to use electric shears for metal.

How to make a budget fence

There are situations when the site must be protected, but there are no extra financial resources for the construction of a brick or corrugated fence. In this case, it is better to give preference wooden products or chain-link fences.

It should be borne in mind that a wooden fence needs to be painted regularly, and a mesh fence performs more decorative than protective function, and can only serve as a temporary structure or delimiter for several sites.

So, you are the proud owner of a new land plot! Work - no end, but it is a very pleasant job. Where will you start? From construction, of course! If you have enough funds, it is better to hire specialists (although it is not a fact that they will do it qualitatively and “for centuries”). But if the budget is limited, and you are full of energy and enthusiasm, then it is quite possible to build a fence yourself. The process is quite laborious, but quite feasible - you are not the Great Chinese Wall build in the end))

In this article I will talk about the advantages and disadvantages of certain types of fences, and about building a fence with my own hands.

What kind of fence to build?

So, after consulting with your wife (and most importantly, with your mother-in-law)), you are finally “ripe” for construction. Now you need to decide: what kind of fence do you need? If you want to completely "hide" from the outside world in your country oasis, then build a fence from, concrete slabs or long boards. If you just need to protect your property - consider creating a palisade, a metal lattice, a fence on the basis, a low fence made of boards, or even make a beautiful fence.And do not forget: in addition to its main purpose - to protect the territory and protect it from outside penetration - the fence must also perform an aesthetic function. Therefore, pay attention to its appearance. Before I talk about building country fence with our own hands, let's make a brief comparison of the most common types of fences.

Advantages:

- the availability of the material;

- low cost.

Flaws:

- short-lived;

- requires regular maintenance: repair, tinting, and so on.

brick fence

Advantages:- very durable (it will serve you faithfully for more than 50 years), the most durable of all types of fence;

- does not require special care;

- looks solid and respectable.

Flaws:

- very high material cost;

- you will need a solid foundation, the construction of which is very expensive.

Advantages:

- availability and variety of material: different sizes wave, different color, coating and other parameters;

- ease of installation (does not require a special foundation);

- low price;

- practical;

- durable: will last you about 30 years.

Flaws:

- very unattractive appearance (especially from the inside).

It turns out durable and aesthetically pleasing.

Advantages:

- reliability of the material: a concrete fence is 5-6 times stronger than a brick fence and can last more than 100 years;

- undemanding care;

- an impressive variety of decorative concrete slabs for fences - you can choose any model you like.

Flaws:

- it will not be possible to build it with your own hands from beginning to end, because for the installation of such a fence you will have to involve special equipment and workers.

Metal mesh fence

Advantages:- reliability: modern metal mesh for fences consists of galvanized iron rods with PVC coating;

- sufficient durability (service life up to 30 years);

- does not create a shadow on the garden plot.

Flaws:

- does not close your site from the immodest glances of passers-by))

We build a fence in the country with our own hands

And now I present to you two ways to build a fence with your own hands, the most popular among summer residents and do not require serious financial investments.Building a wooden fence

A detailed master class on building a wooden fence with your own hands, so now I will only briefly recall the main points.

- We define the boundaries of the site.

- We drill holes for supporting pillars with a depth of 0.7-1.0 m at a distance of 2 or 2.5 m from each other.

- We insert poles into the pits, using a level (or plumb line) we check that they stand strictly vertically.

- We strengthen (can be concreted or cemented).

- We nail or fasten a timber with a section of 50x50 mm or more onto the pillars from above and below or fasten it with self-tapping screws.

- Install cross bars.

- TO finished construction we fix edged boards (you can take boards with a section of 85x145 mm) at a distance of 1.5-2 cm from each other.

- Let's start painting.

For example, modern preparations are effective, they cover such a wide range of wood protection that after processing them for a wooden fence, you can not worry for many years.

For example, I really like wooden fences, and not necessarily painted: the wood grain always looks good, it will be in place everywhere. And modern impregnations will help to do without painting.

We build a fence from corrugated board

So, you bought the metal sheets you liked in the store and are ready to build a fence from corrugated board with your own hands. Start with a trivial markup of the site, and then follow the instructions:

- Along the perimeter of the site, drill holes in the ground with a depth of 1-1.2 m.

- Fill each hole with a layer of crushed stone or gravel 20-25 cm thick.

- Install metal poles with a section of at least 50x50 mm in the pits and set them strictly vertically.

- Strengthen the posts or cement mortar.

- Weld transverse logs (2-3 pieces) from a profiled metal pipe to the posts at an equal distance from each other.

- On the resulting base, fix the sheets of corrugated board (usually they are mounted on self-tapping screws).

It is worth noting here that it is undesirable to fix sheets of corrugated board on self-tapping screws, because cunning attackers can easily twist such fasteners in your absence and steal sheets. Alas, such cases are not uncommon. Therefore, it is better to use special rivets for metal, which no thief can unscrew.

A few important nuances:

The quality factor and durability of any fence depends on the supports - the pillars on which it rests. Therefore, experts advise using strong metal supports even for wooden fences- so the fences will last much longer.

Consider where and how you will mount

Diseases transmitted through the blood of a sick person to a healthy person What infections are transmitted through the blood

Diseases transmitted through the blood of a sick person to a healthy person What infections are transmitted through the blood What you don't know about okroshka Where and when did you come up with okroshka

What you don't know about okroshka Where and when did you come up with okroshka Colostomy closure - reconstructive coloplasty

Colostomy closure - reconstructive coloplasty