Fasteners for wooden structures: what are they? Ready projects of houses and cottages Fasteners for the construction of wooden houses

For building houses from a bar or building Bar from Brous Uses the following fasteners and accessories:

- Steel nails 150, 200, 250 mm as aggregates for the scribes of the crowns 1M step.

- Steel nails 100, 150 mm as connecting nodes in base structures (strapping), roofs, partitions, etc.

- Steel nails 50, 70, 100 mm for fastening numerous hidden and unisons of wooden structure structures.

- Galvanized nails 50, 60, 70 mm for fastening the lining inside the structure, floors and other visible structures (doors, windows, etc.).

- Steel and galvanized nails 10, 20, 30, 40 mm for fastening the staple, plinth, organity.

- Self-tapping screws from 16 mm to 120 mm for loops, window and door fittings, window and door blocks, many elements of wooden structures.

- Glukhari - large self-tapping screws for fastening different wooden parts, for example: wooden screened to piles.

- Bolts and studs of different lengths and diameter.

- Staples for fastening the base nodes (strapping) and a rafter base.

- Bracket under shrinkage (for terraces, veranda, etc., performed under one roof with a structure).

- The loops are produced by overhead, mortise. They can be hinged with a removable rod that are not removed from the loops. Length loops is different from 40, 60, 110 or more. The design of the loops provides the ability to remove the windows of the windows, the shells of the doors without unscrewing and with unscrewing.

- Handles - brackets mounted symmetrically.

- Falling handles with M-shaped handles without locks and with locks.

- Locking locks with keys for entrance doors.

- Locking devices: latches, decorating, valves of different types.

- Curling and overhead locks for doors.

- Self-tapping screws, Glukhary, roofing nails, slate nails - for the roof.

- Nog- This is a wooden cylindrical or square-shaped element used in the construction of houses and construction of a tree bathing, bar, logs.

Agel (spike, wanking) - fastening element of building structures, which

prevents displacement and shifts relative to each other wooden structures (houses, baths)

Magnifications are used in low-rise construction (construction of country houses, construction of wooden houses, bath construction).Begroes are:

- Metal - pieces of reinforcement of a certain length and diameter (nails 200mm)

Advantage: It is better to steal a bar with each other.

- wooden - From the solid wood (birch or oak), a diameter of about 25 mm., Installation is strictly perpendicular to the pre-drilled holes without effort.

Advantage: Uniform shrinkage at home, a tree in a tree is a homogeneous medium with a uniformly distributed moisture.

Disadvantages: Build houses longer, the process is more time-consuming, the price is more expensive.

- Metal - pieces of reinforcement of a certain length and diameter (nails 200mm)

The construction of houses from wood becomes increasingly popular and in demand. Buildings from logs and bars are easily and quickly erected. But in addition to the main material - wood, for the construction of a cut, it is necessary to purchase additional elements that will provide high-quality fasteners of his crowns. After all, the wooden materials installed on each other over time, simply break down under mechanical exposure. Fasteners for wooden houses There are most different and at different costs. Therefore, it is not easy to find among the large range of these materials.

Fasteners and what they need

With the help of fasteners, logs are firmly fixed or bars with each other. Walls are obtained in the most even and durable. They are not deformed, the wooden material itself does not twist, as a result of which large and dangerous slots are formed in logs or bars. Despite the solid fixation of the crowns, the fasteners do not prevent the inevitable process of shrinkage, and on the contrary, they help the cut to pass it more evenly and without unpleasant consequences.

For the construction of a wooden house, it is advisable to purchase the next set of fasteners, which make up the ducts, screw jacks, sliding supports, Spring nodes "force".

This is a mandatory fastening element, without which it is not necessary to build a wooden house. They are the so-called twist of various diameters and the size made of wood or from metal. Metal brazen use in the construction of wooden houses is not desirable. Even if they were pre-treated with powerful compositions, being inside a wooden material, still over time they fall corrosion. All this will inevitably lead to damning of wood. Yes, metal brazen is durable, but they are not combined with wood.

Wooden copper in strength are not inferior to metallic, because They are made of solid wood type oak, birch. Most often on the market there are birch shots, because in terms of cost they are most affordable than oak. You can use them for fixing all types of wooden houses. Wooden brazers will prevent crash, and strain timing or logs, while not interfering with a uniform shrinkage of a cut, without preventing the sliding of the crowns down.

Schedules are clogged strictly vertically, on top, in the center of the log, or a bar in the pre-drilled hole. One brave is capturing two logs at once, connecting the upper and lower crown among themselves. The distance between the brackets should be 1.5 or 2 meters. The first bell is clogged at a distance of 0.5 meters from the corner of the srub. Hello around the cut should be placed in a checker.

Screw jacks or shrinkage compensator

Screw jacks are needed to prevent the horizontal level changes that may occur during the shrinkage of the house. They are adjustable in height, installed on vertical logs, supports that are installed on the terrace, balcony, or upper floors. This element is a metal heel, nut and two steel plates. Screw jacks are made of high-quality steel and a zinc coating is applied on top to them, which prevents the formation of corrosion.

Sliding support

Sliding supports are intended to install the roofing rafting system. They consist of a sliding corner with a bracket and loop. Using this fastener allows you to protect against the possible displacement of the rafted elements that may occur during the shrinkage of the house. The thickness of the iron itself of the sliding support is 2 mm.

This is a more modern fastener. It is a screw with spring. When it turns into a log or bars, presses them firmly to each other, preventing the formation of cracks and gaps between the crowns. The spring assembly "force" will prevent the deformation of wooden materials and their twist.

Also, this element provides logs or bars the necessary load. If the lower crowns are tested by a sufficient load, which is carried out upper wooden materials. That for logs in the upper ranks, the load is only from the roof, this is not enough for them. The spring assembly "force" is most often used precisely to fix the upper crowns. Thus, the built house becomes durable, warm and sealed.

Building a wooden house is necessary using fasteners, such as the spring node "force", sliding supports, ducts and screw jacks. These elements will build a durable, durable wooden house in which it will be warm and safe. Collect the same wooden house on nails or onto the reinforcement is a violation of the cutting technology, which can lead to unpleasant consequences.

Where in Moscow to buy fasteners for the construction of a wooden house?

All listed fasteners, designed for wooden house-building you can buy in the company "Progress". Fare scheme to the warehouse - the store of our company is located

Most of the preserved wooden architecture monuments are erected without a single nail, with the help of an ax alone, and this fact still causes admiration. But after the centuries, the fasteners used for the construction are made from metal, they have changed a lot, so today it makes no sense to repeat the "feats" of the ancestors. It is easy to build, quickly and reliably. Consider the metal fasteners offered by manufacturers on the example of nodes and elements that allow much to simplify and speed up the connection of the floor lag with beams or, and at the same time some other operations.

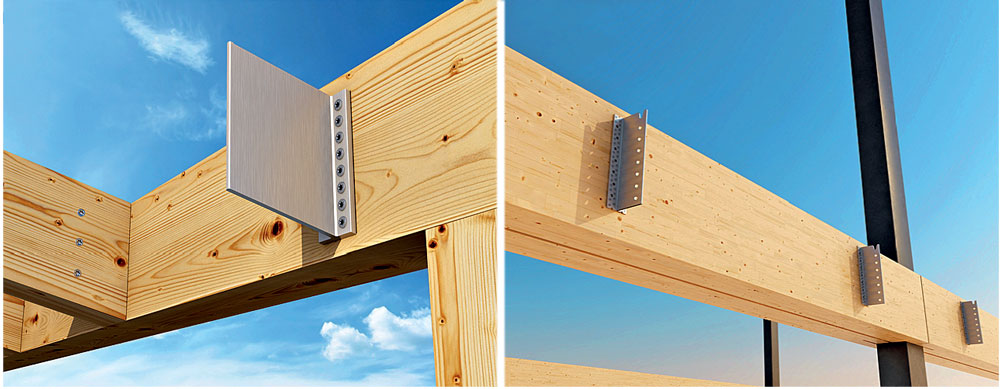

Photo: Essve. The beam shoes are equipped with holes with a diameter of 5 mm (located both on the flange and on weapons) for nails / screws and holes with a diameter of 9 or 11 mm for bolts or coarse screws. On the bottom surface of the flange there is a hole with a diameter of 7 mm for an additional fastening of lags

1. Connecting elements with perforation

Photo: Eurutec. Special elements for performing distributed in wooden housekeeping operations: Adjusting screws for window boxes or dooms (a); tightening self-tapping screw (b); Hobotec selflessness for fastening a massive board, blockchausa or imitation of a bar when wearing a wooden house (B)

If the beams and lags are invisible in the interior, they can be connected using the so-called beam shoes manufactured, for example, Essve. These elements are suitable for fastening the tree not only to the tree, but also to concrete or brickwork (when using the appropriate). They are made mainly of hot-dip galvanized with a thickness of 1.5 or 2 mm, but there are in the market and more expensive products from stainless acid-resistant steel A4. Shoes are available in two versions: with challenges, crushed out or inside. Price: from 50 to 500 rubles. For 1 pc.

The manufacturer recommends mounting the beam shoes to the connected elements with special anchor screws with a diameter of 5 mm (depending on the load, the latter can be inserted into everything or into some holes), and with a very large load or fixation to the "stone" material also use bolt holes. In addition to the anchor shoes, perforated universal locks (a), rafter mountings (b), corners (B), plates (g), shown in the figure, and so on is presented on the market.

Advantages of anchor screws

Why do the perforated fasteners manufacturers offer to use the anchor screws? What is the latter better than ordinary self-tapping screws or anchor (frant) nails used to fix the beam shoes and other metal perforated elements?

Advantages are caused by the features of the design of anchor screws.

First, their flat hat tightly presses the fixed metal element to the wood.

Secondly, the smooth cylindrical part under the screw screw has the same diameter of 5 mm as the holes in perforated metalloelements. It fully fills the hole and therefore completely transfers the load, and also works well on the cut. In addition, thanks to the cone head rest, the screw is better centered.

The usual self-sufficiency does not always transmit the load completely, it works much worse on the cut. Well, the anchor nail cannot be dismantled without destroying the part of the wooden element in which it is drunk.

But the anchor screw is easily twisted and can be wrapped in a wooden element in a new place.

2. Metal Schip-Paz systems

The Nodal Connector "Atlas" is made by the German company Eurotec. The element is made of aluminum and consists of two parts, one of which is equipped with a spike, the second - appropriate groove. They fasten with each other on the principle of "Lastochka Tail", which allows to ensure reliable transmission of vertical and horizontal efforts, perceive efforts when tensile and compression and even bending moments. The compound can be both visible and hidden, for which both metal pieces are combined into pre-erected grooves. The length of the nodal connector "Atlas" - 70-200 mm. Price - 1500-5500 rub. For 1 pc.

The main competitors of Eurotec in the Russian market are the Austrian companies Pitzl and Sherpa Connection Systems, which produce a similar range of connecting elements. The SHERPA system is more known, providing the carrying capacity of compounds from 5 to 280 kN -

Special program for calculations allows you to pick up fasteners for each specific case. Any connector consists of two aluminum parts, which are also fastened by the "Lastochka Tail" principle. The cost of SHERPA elements is from 800 to 12 thousand rubles. For 1 pc.

Photo: BB Stanz-und Umformtechnik, Pitzl. SHERPA connectors (a - d) made from superproof aluminum alloy, and steel elements of BB (E - H) allow you to create not only high-strength and reliable building structures, but also very aesthetic stairs and even furniture

Another Eurotec competitor is the German company STANZ-UUND UMFormTechnik, which has developed a connecting node. It is made of a galvanized sheet steel with a thickness of 4 mm and consists, as well as its aluminum beans, from two parts that are fixed to each other on the principle of "Lastochka Tail". Both halves are attached to wood with self-draws, the number of which depends on the size of the element. BB connectors have a width of 70 mm and a length of 90, 125, 150 and 190 mm. The price is one of the most accessible today: 180-800 rubles. For 1 pc.

Connectors allow in a few minutes to solve the tasks, which in classical construction technologies are required hours and even days.

3. Three-dimensional rails

Photo: Rotho Blaas. Three-dimensional perforated aluminum rails for creating secret connections: Alumaxi (a), alumini (b) and Alumidi (B)

The Italian company Rotho Blaas proposes to connect the details located both perpendicular to each other in the same plane and at an angle of vertical, using T-shaped rails, which are made by extrusion from aluminum alloy high strength EN AW-6005A. They are produced in three modifications designed for different levels of loads: ALUMINI, ALUMIDI and ALUMAXI. Each presented rails both with holes at the base and perpendicular to it the shelf and without holes in the shelf. Rakes may have a fixed length (from 80 to 768 mm), and in modifications without holes, rails are available with a length of 2176 mm with cuts every 64 mm, which allows you to make fasteners of any length.

When installing, the base of the rail is attached to the beam by self-drawing, then a groove of which corresponds to the rack shelf is made on the end to the labia beam. If the latter has perforation holes, then using the shelf as a conductor, the holes are drilled in the lag, they put it on the shelf and insert metal pins into them. If there are no perforations, a lag is put on the shelf and a compound is fixed with a screw with a drill. Price Raking Fasteners: 1230-18 425 rub. For 1 pc.

The connecting system should be selected in accordance with the sizes of the cross sections of the connectable beams, as well as the static and dynamic loads acting on them.

4. Hanging elements like "Yozh"

Photo: Rotho Blaas. Installation of elements "Hedgehog" is simple. In the end of the lags, a deepening is made, into which the connecting element is invested and fixed with screws twisted at an angle. Next, lag through a predetermined hole is attached to the beam with a threaded element screwed into the central hole of the connector

Rotho Blaas Disc connections are a carbon steel washer with galvanic galvania. At the base of the washer, there are drilled holes for self-tapping screws, in the central part - a hole with carvings. In the latter, the stud is screwed, they make it a free end in a pre-drilled hole in the beam and fixed from the opposite side of the beam with a wider washer with a wide wash. The resulting connection is successfully operating both on the shift and extrusion. With a large load in the end of the lags, you can simultaneously install up to three DISX elements with the base diameter of the washer 50, 80 and 120 mm (the diameter of the threaded holes - M12, M16 and M20, respectively). Price: from 4145 to 9044 rubles. For 1 pc. (Screws are included).

An alternative to Disc connectors serve EUROTEC IDEEFIX elements. Fastener is made in the form of a hollow cylinder with an external diameter of 30, 40 or 50 mm made of aluminum alloy. At the bottom of the cylinder there is a hole with M12 thread, M16 or M20. In the upper - cone recess with the screws under the self-tapping screw, drilled at an angle of 45 °. An ideefix element is attached almost the same as the previous connector, but the lag to the beam is fixed not with a pin, but a powerful bolt with a wide hat (included with the kit with the screws). Price - 1500-4500 rub. For 1 pc.

5. Self-tapping screws Konstrux

These unusual products allow you to save not only the time required for assembling the node, but also means, because the connecting metal elements are not needed. The self-tapping screws have a complete thread that creates high resistance to pulling out, and is completely twisted into wood at an angle of 30, 45 or 60 °, which radically changes the usual scheme of their work. In this case, the screws operate only for pulling out that it allows them to make a significant part of the efforts acting on the connection. Thus, it is possible to connect the parts at an angle (a), to allocate the elements, reducing their deflection (b), enhance the places of cutouts in beams and lags (c) (see figure below).

Photo: Eurotec. Choose a suitable screw konstrux, element bonding scheme, and also calculate the required number of screws helps a special ECS program, which can be freely downloaded on the site of the manufacturer of self-tapping and large seller

There are self-tapping screws with cylindrical (screw diameter - 6.5; 8 and 10 mm) and counted (screw diameter - 8 or 11.3 mm) head. Length - 65-1000 mm. Price - 20-800 rubles. For 1 pc. For the installation of screws with a length of less than 245 mm, the pre-drilling is not required, but for longer (in order to prevent an entry to the side) it is recommended to drill holes in advance for the samp of the depth to ⅓ from its length.

6. Special self-tapping screws

With the help of the Hobotec self-train, massive boards, blockchas or timber imitation are fixed. The product cap is equipped with milling ribs and is easily comfortable in wood, and the tip is made in the form of a drill. The mill in the middle of the short-length screw increases the diameter of the hole, allowing you to make the fastest element densely. The screws with a diameter of 3.2 mm and a length of 20 to 60 mm are made of conventional steel coated (price - 1100-2200 rubles. For packaging of 500 pcs.) Or stainless steel (price - 3500-7500 rub. Per pack of 500 pcs .).

The tightening selflessness is also equipped with a cutter, but its tip is different - it has a special groove that turns the screw in the tree drill. A flat hat has a large diameter and is equipped with an independent head and a hex sliced. A special wax coating is applied to the self-sufficiency, reducing friction when screwing. Product diameter - 3-12 mm, length - 30-600 mm. Price - from 300 to 5 thousand rubles. For packing out of 500 pcs.

Photo: Eurotec. Self-tapping screw - Flyugel for fastening wooden sheat to a steel base. Equipped with a tip-drill and special "wings" (located above the tip), which expand the hole in the wood and break when the metal drilling. As a result, cutting the thread in metal, the screw is fixed in it, and the wooden element attracts the hat to the metal. Length: 32-125 mm. Price: from 500 to 2500 rubles. For packing out of 500 pcs.

Adjusting self-adjustment is useful, for example, for fastening window and door boxes or a wooden drying to a tree, concrete, brick or metal (an element can be equipped with a drilling tip of two types). Self-tapping screws into the box and the wall or power element behind it. At the same time, the ring cone "spikes" arranged under the head of the screw are firmly fixed in the box (almost like a fishing hook), due to which its position relative to the wall is easily adjusted by further screwing or unscrewing the fastener element. Length - from 60 to 125 mm. Price - from 2000 to 3,500 rubles. For packing out of 500 pcs.

Special tapes make it possible to significantly speed up and facilitate the implementation of those operations that are necessary when creating wooden structures.

What should be fastened for sawn timber? Wood is a sufficiently soft material, especially if you compare it with other types of arrays. However, the physical properties of the wooden parts used in construction can be very different depending on the percentage of their humidity, the breed, the conditions of growing trees ... The structure is not homogeneous even on different sites of the same logs. A fastener element in any case should well hold on to the fibers and reliably fix any details. To increase the strength of friction, the nails are very often the rolling or the bonus, and the self-repair screws have a major thread.

Fastener reliability

Most fasteners for wood in Moscow are made from galvanized and phosphatated steel or metals that do not rust (for example, there are nails from aluminum, copper). Only some types of products are made of black metal, but only those that are used in draft structures - Construction nails, roofing staples. The protective coating makes it possible to increase the service life of the fasteners, but, in addition, the aesthetic properties of products improve the aesthetic properties, because red spots and rust flips will be excluded.

The design of modern fasteners is thought out to the smallest detail. So, there are dozens of types of self-samples, which are intended for certain works, each of them has its own characteristics. Suppose the roofing fastener on the edge there is a boring, which can drill sheet metal, and a large rubberized washer. And the structural yellow self-tapping screws - complex body carving (sometimes incomplete) and a special tip. The finishing nail has a very small head, and the galvanized nail for the fastening of the OSB - on the contrary - is quite large. There are fasteners with a conical head under say, and there is flat. A lot of variants are available in length.

Almost all of these fasteners (including perforated) are operated under load, so they must have resistance to bending and cutting effects. High-quality fasteners for wood does not break, as a last resort, it can only bend. For certain works, it is possible to choose products of different thickness, it concerns both nails / self-tapping and perforated plates / corners.

Types of fasteners for wood

Nails

This is perhaps one of the most famous and verified types of components for construction work. At this tree fastener, the price is the most democratic, but it is distinguished by practicality and functionality. The nail is a metal rod, sliced \u200b\u200bfrom the wire, which at one end is the edge, and on the other - a flat hat.

When using the product is clogged with a conventional hammer, or can be combined into tapes and boot into the neutile gun. Nails can be used independently or in a complex with perforated mounting elements.

The size of the cap differs in size, depending on whether the nail must be comfortable or reliable to press the part. There may be notches on the rod to increase the friction forces, because it is with their help nails hold on wood. The length (actually, like the thickness), the nail is selected by the character of the connection and the type of load tested by the unit.

Depending on what purpose of nails are intended, they are divided into several basic types. If we talk about construction, then this is:

- Black nails construction,

- Galvanized with a large hat,

- Stormy

- Screw

- Finish

- Tolly

- Slavic.

Selfless

This modern fastener has high efficiency and is also very practical. The cost of fasteners for the tree of this type is greater than that of nails, but also a lot of benefits.

The hewing of the self-seed screw is that it uses wood ductility. That is, allows you to screw off without prior drilling. Due to the wide step of the thread and its increased altitude (for example, the metal screws have more frequent and lower threads), this fastener is tightly included in any wood fibers and is perfectly held there. At the same time, such a connection remains collapsible, while wooden details shot down with nails, separated without damage, it is extremely rare.

The design of the thread and tip is focused on a light ride in a tree. The car at the end of the wood screws is usually not applied. The hat is made with a cone for consuming invested, either flat, in the types of "pressshab", "roofing selflessness". The thread can be solid or partial. There are many variants in the thickness and length of products.

For the use of screws, drill or screwdriver is needed, although, theoretically, small products in small quantities can be screwed using a screwdriver. To transmit rotation from the tool, there are slots on the head screw. The shape of the slot may be varied. As a rule, pH or pz formats are used, it needs to be considered by choosing a bit.

Among the many types of tree self-samples, the most demanded were:

- phosphatated (black);

- galvanized (yellow);

- roofing (white and painted);

- screws with a hexagon or profile head (including: Ceremonic, with a ring, with a hook, L-shaped screw-crutch, deaf with a spring).

Threaded Metric Types of Connection

Nails and self-tapping screws are not the only components that work out wooden structures. The most loaded or the most volumetric nodes are twisted by bolts and studs. Together with nuts and washers, these hardware make it possible to obtain the most reliable fixation, because you can very tightly press the details to each other, to apply the rods of the increased diameter (and therefore very durable). The obvious plus is to disassemble and collect designs several times.

Studs and bolts are installed through a through hole that must be drilled in each of the fastened parts. Direct fixation is carried out by twisting nuts. Large washers allow you to increase the support area and prevent the immersion of nuts / heads into the wood.

Perforated fasteners

This type of fastener is designed to speed up the installation of wooden building elements. Thanks to such products, it was possible to avoid complex technically (and time-consuming) manufacturing in the rugster tree and castles. If the wood of wood actually lowered the cross section of the details, then the perforated products allowed us to assemble the jack, and with an increase in the reliability of the node. Therefore, there is no need to increase the secess of lumber, as before. Accordingly, it will turn out to unload the house and save money, although it seems to be calculated that it is a perforated to buy a perforated fastener - a rather cost solution.

Another advantage of such products lies in increasing construction speed. Connections using corners and plates can easily perform non-professionals, because everything you need to cut off the bar or the board more or less exactly in length.

Perforated fasteners are presented in a wide range. They are combined and overlap all the needs of modern wooden and general construction. They are made of sheet metal thick from one and a half to 5 mm, in which there is a large number of holes (round small, large under anchors, long slots for moving fixations). All products are galvanized, fully prepared for use. Among the entire fasteners with perforations, several types of design and the scope of use are distinguished, first of all, it is corners, plates, supports, tapes.

Price list

Prices for fasteners on wood

| Nased product | Nased option | The price of the product | ||

|---|---|---|---|---|

| Glue for plywood and parquet Artelite 21 kg | Bucket 21 kg | 4,200.00 rubles | ||

| Bit roofing | 6 mm | 60.00 rubles | ||

| 8 mm | 65.00 rubles | |||

| 10 mm | 70,00 rub | |||

| 12 mm | 75.00 rub | |||

| 13 mm | 80.00 rubles | |||

| 17 mm | 90,00 rub | |||

| 25 mm | 220.00 rubles | |||

| 30 mm | 220.00 rubles | |||

| 40 mm | 220.00 rubles | |||

| 50 mm | 220.00 rubles | |||

| Foam assembly | Macroflex (prof.) | 360.00 rubles | ||

| Macroflex | 300,00 rub | |||

| Titan (prof.) | 380.00 rub | |||

| Titanium | 320.00 rubles | |||

| Wooden nape | with bitch | 14,00 rub | ||

| without bitch | 18.00 RUB | |||

| Yellow Tree Self | 3x25 mm | 380.00 rub | ||

| 3x30 mm | 350,00 rub | |||

| 3x35 mm | 350,00 rub | |||

| 3x40 mm | 350,00 rub | |||

| 3.5x16 mm | 350,00 rub | |||

| 3.5x40 mm | 350,00 rub | |||

| 4x35 mm | 330.00 RUB | |||

| 4x50 mm | 330.00 RUB | |||

| 4x60 mm. | 330.00 RUB | |||

| 4x70 mm | 330.00 RUB | |||

| 5x40 mm | 330.00 RUB | |||

| 5x50 mm | 330.00 RUB | |||

| 5x60 mm. | 330.00 RUB | |||

| 5x70 mm | 330.00 RUB | |||

| 5x80 mm. | 330.00 RUB | |||

| 5x100 mm | 330.00 RUB | |||

| 5x120 mm. | 330.00 RUB | |||

| 6x40 mm | 330.00 RUB | |||

| 6x50 mm | 330.00 RUB | |||

| 6x60 mm. | 330.00 RUB | |||

| Saws on a tree black | 3.5x16 mm | 240.00 rubles | ||

| 3.5x19 mm | 240.00 rubles | |||

| 3.5x25 mm | 240.00 rubles | |||

| 3.5x32 mm | 240.00 rubles | |||

| 3.5x35 mm | 240.00 rubles | |||

| 3.5x41 mm | 240.00 rubles | |||

| 3.5x45 mm | 240.00 rubles | |||

| 3.5x51 mm | 240.00 rubles | |||

| 3.5x55 mm | 240.00 rubles | |||

| 4.2x64 mm | 240.00 rubles | |||

| 4.2x70 mm | 240.00 rubles | |||

| 4.2x76 mm | 240.00 rubles | |||

| 4.8x90 mm | 240.00 rubles | |||

| 4.8x95 mm | 240.00 rubles | |||

| 4.8x100 mm | 240.00 rubles | |||

| 4.8x127 mm | 240.00 rubles | |||

| 4.8x140 mm | 240.00 rubles | |||

| 4.8x150 mm | 240.00 rubles | |||

| Black carnails | 1.8x20 mm | 98.00 rubles | ||

| 1.8x25 mm | 98.00 rubles | |||

| 2.5x40 mm | 98.00 rubles | |||

| 2.5x50 mm | 98.00 rubles | |||

| 2.5x60 mm | 98.00 rubles | |||

| 3x70 mm | 98.00 rubles | |||

| 3X80 mm. | 98.00 rubles | |||

| 3.5x90 mm | 98.00 rubles | |||

| 4x100 mm | 98.00 rubles | |||

| 4x120 mm | 98.00 rubles | |||

| 5x150 mm | 98.00 rubles | |||

| 8x250 mm | 98.00 rubles | |||

| 8x300 mm | 98.00 rubles | |||

| Sliding support for rafters | 40x120 mm | 70,00 rub | ||

| 40x160 mm | 80.00 rubles | |||

| 40x200 mm | 90,00 rub | |||

| Staples for timber, Kalenny | 6x150 mm | 20.00 rubles | ||

| 6x200 mm | 22,00 rub | |||

| 6x250 mm | 24,00 rub | |||

| 8x200 mm | 26,00 rub | |||

| 8x250 mm | 28,00 rub | |||

| 8x300 mm | 30.00 rubles | |||

| Metallic perforated corner | 20x40 mm. | standard | 8.00 rubles | |

| 40x40 mm. | standard | 14,00 rub | ||

| 50x35 mm | reinforced | 15,00 rub | ||

| 50x50 mm | standard | 20.00 rubles | ||

| 70x55 mm | reinforced | 26,00 rub | ||

| 90x40 mm | reinforced | 32,00 rub | ||

| 90x65 mm | reinforced | 34.00 rubles | ||

| 105x90 mm | reinforced | 47.00 rubles | ||

| 130x100 mm | reinforced | 102.00 rub | ||

| 140x140 mm | reinforced | 120.00 rubles | ||

| Perforated mounting plate | 100 x 35 x 2 mm | 18.50 rubles | ||

| 140 x 55 x 2 mm | 29.00 rubles | |||

| 180 x 40 x 2 mm | 39.00 rubles | |||

| 180 x 65 x 2 mm | 49.00 rubles | |||

| 210 x 90 x 2 mm | 59.00 rubles | |||

| Support Bruus | 110 mm | 50 mm | 80.00 rubles | |

| 140 mm | 50 mm | 90,00 rub | ||

| 165 mm | 50 mm | 100.00 rubles | ||

| 180 mm | 50 mm | 110.00 rubles | ||

| 100 mm | 100 mm | 120.00 rubles | ||

| 160 mm | 100 mm | 130.00 rubles | ||

| 200 mm | 100 mm | 140.00 rubles | ||

| 150 mm | 150 mm | 150.00 rubles | ||

| Screw for fastening Lag and Retakes (Ceremonary) | 60 mm | 6 mm | 40.00 rubles | |

| 80 mm | 6 mm | 50.00 rubles | ||

| 100 mm | 6 mm | 60.00 rubles | ||

| 50 mm | 8 mm | 50.00 rubles | ||

| 60 mm | 8 mm | 70,00 rub | ||

| 80 mm | 8 mm | 85,00 rub | ||

| 100 mm | 8 mm | 100.00 rubles | ||

| 120 mm | 8 mm | 120.00 rubles | ||

| 130 mm | 8 mm | 140.00 rubles | ||

| 160 mm | 8 mm | 160.00 rubles | ||

| 180 mm | 8 mm | 195.00 rubles | ||

| 200 mm | 8 mm | 240.00 rubles | ||

| 60 mm | 10 mm | 120.00 rubles | ||

| 70 mm | 10 mm | 140.00 rubles | ||

| 80 mm | 10 mm | 160.00 rubles | ||

| 100 mm | 10 mm | 180.00 rubles | ||

| 120 mm | 10 mm | 220.00 rubles | ||

| 160 mm | 10 mm | 260.00 rubles | ||

| 180 mm | 10 mm | 290.00 RUB | ||

| 200 mm | 10 mm | 320.00 rubles | ||

| 220 mm | 10 mm | 350,00 rub | ||

| 240 mm | 10 mm | 390.00 rubles | ||

| 260 mm | 10 mm | 420.00 rubles | ||

| 120 mm | 12 mm | 290.00 RUB | ||

| 160 mm | 12 mm | 370.00 rubles | ||

| 180 mm | 12 mm | 390.00 rubles | ||

| 200 mm | 12 mm | 410.00 rubles | ||

| 240 mm | 12 mm | 480.00 rubles | ||

| 260 mm | 12 mm | 500.00 rubles | ||

| 280 mm | 12 mm | 580.00 rubles | ||

| 300 mm | 12 mm | 720.00 rubles | ||

| Screw (dehahric) with spring | 10x200 mm | 124.00 rubles | ||

| 10x220 mm | 134.00 rubles | |||

| 10x180 mm | 116.00 rub | |||

| Screw-ring | 8x120 mm | 25,00 rub | ||

| 8x160 mm | 30.00 rubles | |||

| 10x220 mm | 50.00 rubles | |||

| Bolt | M6 | 180.00 rubles | ||

| M8. | 180.00 rubles | |||

| M10. | 180.00 rubles | |||

| M12. | 180.00 rubles | |||

| M14 | 180.00 rubles | |||

| M16 | 180.00 rubles | |||

| M18 | 180.00 rubles | |||

| M20 | 180.00 rubles | |||

| M22. | 180.00 rubles | |||

| M24. | 180.00 rubles | |||

| Washer | M6 | 195.00 rubles | ||

| M8. | 195.00 rubles | |||

| M10. | 195.00 rubles | |||

| M12. | 195.00 rubles | |||

| M14 | 195.00 rubles | |||

| M16 | 195.00 rubles | |||

| M18 | 195.00 rubles | |||

| M20 | 195.00 rubles | |||

| M22. | 195.00 rubles | |||

| M24. | 195.00 rubles | |||

| Nut | M6 | 190.00 RUB | ||

| M8. | 190.00 RUB | |||

| M10. | 190.00 RUB | |||

| M12. | 190.00 RUB | |||

| M14 | 190.00 RUB | |||

| M16 | 190.00 RUB | |||

| M18 | 190.00 RUB | |||

| M20 | 190.00 RUB | |||

| M22. | 190.00 RUB | |||

| M24. | 190.00 RUB | |||

| Threaded hairpin | M6 | 1m | 39.00 rubles | |

| M8. | 1m | 58.00 rubles | ||

| M10. | 1m | 70,00 rub | ||

| M12. | 1m | 90,00 rub | ||

| M14 | 1m | 129.00 rubles | ||

| M16 | 1m | 155.00 rub | ||

| M20 | 1m | 245.00 rubles | ||

| M22. | 1m | 310.00 rubles | ||

| M24. | 1m | 380.00 rub | ||

| M6 | 2 M. | 78.00 rubles | ||

| M8. | 2 M. | 116.00 rub | ||

| M10. | 2 M. | 140.00 rubles | ||

| M12. | 2 M. | 180.00 rubles | ||

| M14 | 2 M. | 258.00 rubles | ||

| M16 | 2 M. | 310.00 rubles | ||

| M20 | 2 M. | 490.00 rubles | ||

| M22. | 2 M. | 620.00 rubles | ||

| M24. | 2 M. | 760.00 rubles | ||

| Finish nails | 30 mm | 1 kg | 200.00 RUB | |

| 40 mm | 1 kg | 200.00 RUB | ||

| 50 mm | 1 kg | 200.00 RUB | ||

| 60 mm | 1 kg | 200.00 RUB | ||

| 30 mm | 5 kg | 1 000.00 RUB | ||

| 40 mm | 5 kg | 1 000.00 RUB | ||

| 50 mm | 5 kg | 1 000.00 RUB | ||

| 60 mm | 5 kg | 1 000.00 RUB | ||

| 100 mm | 1 kg | 200.00 RUB | ||

| 120 mm | 1 kg | 200.00 RUB | ||

| 150 mm | 1 kg | 200.00 RUB | ||

| 32 mm | 5 kg | 1 000.00 RUB | ||

| 40 mm | 5 kg | 1 000.00 RUB | ||

| 50 mm | 5 kg | 1 000.00 RUB | ||

| 60 mm | 5 kg | 1 000.00 RUB | ||

| 70 mm | 5 kg | 1 000.00 RUB | ||

| 80 mm | 5 kg | 1 000.00 RUB | ||

| 100 mm | 5 kg | 1 000.00 RUB | ||

| 120 mm | 5 kg | 1 000.00 RUB | ||

| Saw roofing galvanized | 4.8x29 mm | Metal + tree | 21,00 rub | |

| 4.8x38 mm | Metal + tree | 24,00 rub | ||

| 4.8x51 mm | Metal + tree | 26,00 rub | ||

| 4.8x76 mm | Metal + tree | 28,00 rub | ||

| 5.5x19 mm | Metal | 21,00 rub | ||

| 5,5х25 mm | Metal | 23,00 rub | ||

| 5.5x32 mm | Metal | 26,00 rub | ||

| 5.5x51 mm | Metal | 28,00 rub | ||

| 5,5х76 mm | Metal | 34.00 rubles | ||

| Selfless roofing painted | RAL 8017 brown | 4.8x29 mm | Metal + tree | 26,00 rub |

| RAL 6005 green | 4.8x29 mm | Metal + tree | 26,00 rub | |

| RAL 3005 Cherry | 4.8x29 mm | Metal + tree | 26,00 rub | |

| RAL 8017 brown | 4.8x38 mm | Metal + tree | 28,00 rub | |

| RAL 6005 green | 4.8x38 mm | Metal + tree | 28,00 rub | |

| RAL 3005 Cherry | 4.8x38 mm | Metal + tree | 28,00 rub | |

| RAL 8017 brown | 4.8x51 mm | Metal + tree | 35.00 rubles | |

| RAL 6005 green | 4.8x51 mm | Metal + tree | 35.00 rubles | |

| RAL 3005 Cherry | 4.8x51 mm | Metal + tree | 35.00 rubles | |

| RAL 8017 brown | 4.8x76 mm | Metal + tree | 45.00 rubles | |

| RAL 6005 green | 4.8x76 mm | Metal + tree | 45.00 rubles | |

| RAL 3005 Cherry | 4.8x76 mm | Metal + tree | 45.00 rubles | |

| RAL 8017 brown | 5.5x19 mm | Metal | 27,00 rub | |

| RAL 6005 green | 5.5x19 mm | Metal | 27,00 rub | |

| RAL 3005 Cherry | 5.5x19 mm | Metal | 27,00 rub | |

| RAL 8017 brown | 5,5х25 mm | Metal | 32,00 rub | |

| RAL 6005 green | 5,5х25 mm | Metal | 32,00 rub | |

| RAL 3005 Cherry | 5,5х25 mm | Metal | 32,00 rub | |

| RAL 8017 brown | 5.5x32 mm | Metal | 37,00 rub | |

| RAL 6005 green | 5.5x32 mm | Metal | 37,00 rub | |

| RAL 3005 Cherry | 5.5x32 mm | Metal | 37,00 rub | |

| RAL 8017 brown | 5.5x51 mm | Metal | 43.00 rubles | |

| RAL 6005 green | 5.5x51 mm | Metal | 43.00 rubles | |

| RAL 3005 Cherry | 5.5x51 mm | Metal | 43.00 rubles | |

| RAL 8017 brown | 5,5х76 mm | Metal | 50.00 rubles | |

| RAL 6005 green | 5,5х76 mm | Metal | 50.00 rubles | |

| RAL 3005 Cherry | 5,5х76 mm | Metal | 50.00 rubles | |

| Fastening corner sliding | 40x120 mm | 60.00 rubles | ||

| 60x220 mm | 90,00 rub | |||

| Staples for a construction hand-made stapler | 6 mm | 40.00 rubles | ||

| 8 mm | 50.00 rubles | |||

| 10 mm | 60.00 rubles | |||

| 12 mm | 70,00 rub | |||

| 14 mm | 80.00 rubles |

To apply various wood compounds in the construction area, it is not easy without a tool, but also without relevant experience. That is why inexperienced masters have such connections not always carefully. One of the best options is to use professionals a variety of fasteners for the massif, which are made of metal.

Many preserved architectural monuments from wood are constructed without nails, by means of an exclusively ax. This fact causes true pleasure to today. However, after a century, the fasteners made from metal used to build buildings from the massif, radically changed, it is for this reason that it is meaningless to repeat the experience of our ancestors.

It is preferable to raise quickly and without difficulties. Let's talk more about the proposed fasteners manufacturers, taking the part to the example, which make it possible to maximize the connection of the beams with floor lags, or the wall surfaces from the array.

Fixing with perforation

When the beams, as well as the lags of the floor surface are hidden in the interior space, it is possible to connect them through the shoes of the beam. This fastener for wood structures is suitable for fixing an array not just to the tree, and to concrete, a brick laying. It is created from durable steel.

Manufacturers advise secure similar attachments to the parts connected by special screws, and with excessive load, or fixing the material from the stone, use the holes for the necessary bolts. In addition to the anchor shoes today, you can purchase special locksters, and much more.

Schip-groove

This galvanized fastener for wood consists of a part with a spike and part with a groove that are connected to provide better transmission of horizontal, as well as vertical effort.

The connection is visible, either hidden, for these purposes the part of the steel is completely intermedied in special grooves.

Three-dimensional rails

The modern Italian firm produces fasteners that are placed perpendicular and vertically at an angle, by means of a T-shaped type, created by extrusion from high-strength steel alloy. They are produced in several modifications provided for multi-level loads.

The fastener system must be selected according to the dimensional row of sections of the combined beams and affect them dynamic, as well as static loads.

During the installation, the rack base is attached to the beam by means of screws. Then on the end part attached to the base of the lags, the grooves the same size as the rush shelf is created. In the absence of perforation, the shelf is equipped with a lag and a connection is fixed with self-tapping screws.

Secret details of Yozh

These connectors are steel washers, the base of which is equipped with holes drilled under the slope. These holes are designed for self-tapping screws. In the center of the washer, there is a hole with a thread, in which the stud is inserted. Its free end is done in a special hole and fastened on the back side of the beam with a detail with a fledged washer.

The established connection perfectly functions not only to highlighting, but also on the shift. With excessive load in the field of the end of the lags, it is possible to install several elements at the same time.

Fastening with a carving complex

Unusual self-tapping screws that make it possible to save time, money, since in this embodiment metal parts are not required. Self-tapping screws are equipped with a thread that helps to create a high degree of resistance when pulling out, and also tightly twisted into an array, which completely changes their traditional operation.

In this case, the operation of the screws occurs exclusively to twitching, which gives them the opportunity to take most of the efforts that come to the connection. So, you can mount the elements at an angle, combining the parts, cutting into a minimum of their deflection, as in the photo fastener from the wood below.

Self-tapping screws

Using similar elements, sufficiently massive wooden products fasten. The hat has a milling rhyres and is easy to sleep in the product, while the tip is created by type of drill. In the middle of the screw, the cutter makes more hole, helping to attract the element as thick as possible.

The self-adjustable type will be useful for fastening the door boxes, window openings, an array of wood to wood, metal. The self-tapping screw is screwed directly into the box, as well as the wall surface located behind it, or the power item.

The self-tapping screws for the high-quality fastening of the masses from the array to the base created from the steel. There is a tip in the form of drill and placed over it wings to expand in the tree of the hole.

When drilling products from metal, the wings break. As a result, having done the thread in the metal part, the self-sufficiency is firmly adjacent to it, while the element of the array is attracted by a metal cap.

Photo of wooden fasteners

Why you can not postpone the pregnancy

Why you can not postpone the pregnancy Effect from regular use of home recipes

Effect from regular use of home recipes Features of the structure of the neck

Features of the structure of the neck