How to fold a brick fireplace. Brick fireplaces

Creating a beautiful and functional brick fireplace with your own hands in a country house is a task that is not very difficult for an owner with ingenuity. Due to the material, the cost of a brick portal and chimney will not be high, especially compared to granite, marble and other exclusive minerals. cement mortar for masonry, necessary tools also not very expensive.

Before you make a fireplace yourself for a summer residence, you need to choose its design and shape, as well as decide on the calculation of the size of the firebox, chimney and portal.

A simple fireplace, depending on the location, is wall-mounted and corner. Its parameters are determined based on the area of the heated room: it is divided by 100 - as a result, the optimal area of \u200b\u200bthe furnace is obtained. The width of the furnace hole should be 1.5-2 times greater than the depth and approximately 1.5 times less than the height. In order to achieve sufficient draft, the area of the smoke hole should be 10-15 times smaller than the area of the furnace, and the straight section of the chimney should be 3 to 5 m long. With such proportions, it is possible to achieve efficient heating rooms and safe work fireplace.

A brick mini-fireplace for a summer residence is well suited for small spaces and require a minimum amount of building materials. With a firebox size of no more than 40 x 60 cm, it will completely cope with heating a room up to 20 square meters. m., and its height without a chimney will be approximately 1.1 - 1.2 m, width 0.5 - 0.6 m. Considering the entire lining with decorative ledges and the coating of the smoke tube, the structure will require 220 - 230 standard red brick .

The English fireplace differs from other models in its direct chimney, one-way heat flow and a trapezoid-shaped firebox. Such a device allows most of the generated heat to enter the room.

The side and rear walls of the firebox have a slight slope of about 20° and serve as a kind of reflector of heated air. The smoke collector has the shape of a pyramid, and the chimney pipe is also hidden under a layer of brick, which tapers slightly towards the ceiling. Another feature of English fireplaces is the base under the portal in the form of a platform, which is laid out of refractory bricks.

The depth of the firebox for English fireplaces is 0.4 - 0.5 m, the brick layer should protrude from the edges of the furnace hole by 0.3 m, and the protrusion of the horizontal base can reach 0.5 m. For effective traction and sufficient heating of the room, it is necessary that the cross-sectional area of the chimney and the area of \u200b\u200bthe furnace had a ratio of 1 to 8. The outlet pipe for the English version should be 3–5 m high. Subject to all these conditions, it is possible to achieve simple and uniform heating of the room, a beautiful flame in the hearth and the absence of harmful smoke in the room. Classic English fireplaces have a long history and will add to any Vacation home cozy atmosphere.

A barbecue grill is an option for outdoor use. This is a great way to decorate personal plot where you can comfortably spend your leisure time in good weather. A fireplace with a barbecue, in addition to a woodpile and a firebox, has a ledge on top, on which skewers with barbecue or a grill for roasting meat are placed. In addition, on such a device, you can cook other dishes in a frying pan, in a saucepan, in a roaster, and food cooked on the street with a natural fire is not only healthy, but will also give the family a lot of positive impressions.

The simplest barbecue fireplace without a roof is much easier to install than the home option, because it does not require the construction of a smoke box and a chimney - all combustion gases are vented directly to the street.

For the foundation, usually choose concrete base, whose thickness will depend on the mass brick construction future brazier, usually it is 20 - 30 cm. The portal is most often laid out in a U-shape with a recess, inside which there is a compartment for firewood, above the ceiling of the firebox with a tray for coals and a place for grating or skewers. You can show imagination and install more complex structures: with two fireboxes for cooking several dishes at the same time, with decor over bricks made of natural or artificial stone, with a table for cutting products or a sink with a tap and a sink.

A country gazebo can be built with a brick frame and a fireplace, and the walls and roof are made of other materials: profiled iron, wood or plastic. This will simplify the installation work and save on building materials.

There are a huge number of projects country arbors for the street, the most common of them:

- Open gazebo under the roof on 4 columns with brick barbecue, this option is suitable for calm, waterless weather, but in case of bad weather, you can build light walls made of fiberglass, PVC panels or other available materials. The roof can be tiled with metal or ondulin tiles, and electric lighting can even be installed inside.

- Lightweight construction gazebos made of wood, in which brick is used only for the fireplace itself with an arch-shaped firebox. On a cool evening, a small company can gather around the hearth, the heat from it will be enough. If necessary, you can equip the roof with a canopy made of light polymer materials.

- Finnish gazebos in Lately have become widespread in our country, as they are intended for a cold climate. They have a regular 6 or octagon shape in profile with closed walls and a sloping roof, from the center of which a chimney pipe emerges. They use a brick island fireplace, designed for both barbecue and space heating.

Since an ordinary clay brick is universal in its physical properties, then it can be used for both home and outdoor fireplaces. That part of the furnace, which is in direct contact with an open fire, is selected from a refractory grade.

purpose

The outdoor fireplace has many design projects, with home craftsmen coming up with new ideas every year. Outdoor fireplaces can perform the function of heating, cooking, or a combination of two tasks at the same time. Models can be island or wall, if they are attached to the gazebo, outer wall house or stone fence. The latter option is very interesting, it will save materials and construction costs if the site already has a strong and high brick fence. A corner or wall fireplace with a small hood can be attached to it.

A country fireplace made of bricks is most often made island type, a simple U-shaped design without a high chimney pipe. For this option, it is better to equip the foundation with a concrete platform in advance, street tiles or other durable non-combustible material. It will be convenient to place chairs for rest and other garden furniture. An island fireplace for a summer residence can be modernized over time, adding new details, in the end, having built a full-fledged closed gazebo with heating and barbecue.

decorative fireplace many are used in interior design so as not to use complex systems with a smoke box, hood and refractory materials. A false fireplace in a room can work on the basis of an electric, gas or water heater, and skillful paintings, electric light or candles are used to simulate a flame. This option will not replace the natural heat from burning firewood, but it will look very impressive and will cost much less, since it does not require the work of an experienced stove-maker.

The fireplace in the house should, first of all, provide a normal smoke exhaust to the outside, so that the room does not have a strong smell and carbon monoxide. It is necessary to calculate its dimensions based on the area of \u200b\u200bthe room, and for cladding, materials with high thermal insulation should be used. If it is planned to make a false fireplace, then the usual one is used decorative brick without fire resistance.

Bath fireplaces use mainly coal for heating, they have small size and simple device. They have 2 working parts: a firebox and a chimney. Difference from traditional sauna stove in that the firebox is open and the heat for heating comes from it. brick options such fireplaces are usually wall or corner. Due to the large mass of building materials, they must be installed on a massive base, if the floor in the bath is not thick enough, then you need to take care of an additional foundation for the stove.

Fireplace device

Home fireplace consists of 4 parts:

- firebox where firewood is burned;

- smoke collector for a smooth transition of smoke into the chimney;

- a chimney that removes combustion products to the outside;

- portal around the firebox with decorative lining.

Stove options may be different, but it is best to choose a trapezoidal shape of an open firebox with inner walls at a slight angle. This will provide the greatest efficiency of such a fireplace. A very efficient fireplace model for a room with an air heat exchanger. This part can be made in the form of a snake-shaped pipe, which generates additional heat. Therefore, for the flow of hot air into the room, it is not necessary to maintain a constant open fire.

Outdoor fireplaces with a firebox can have chimneys, a barbecue, an oven, metal burners, and even a roof for cooking in the rain. Their device depends only on the imagination and capabilities of the owner. There are interesting models of fireplaces with a bread machine, with a woodcutter or several fireboxes.

materials

For the arrangement of fireplaces, red bricks are mainly chosen from clay or ceramics, plastic molding or pressing. The latter option is less durable, especially under high thermal loads, as it contains many pores. But ceramic bricks obtained by plastic molding have a smooth and durable surface and are no less strong inside.

There are 3 types of bricks for home and outdoor fireplaces. The usual building facing brick designed for inner layers of masonry that are not visible. He doesn't need protection from open flame and a smooth beautiful surface, and therefore it is the cheapest. In the manufacture of refractory bricks, pressing and high-temperature firing of workpieces from fireclay mass or quartz are used. Such building materials are installed in places of contact with open fire, i.e. in the furnace and smoke box. Facing and shaped bricks for decor have a smooth, uniform surface with different colors, textures or luster.

For masonry use mortars, which include cement, sand, water, sometimes chemical fillers for heat resistance. To not count on your own the right combination components for building a furnace, you can purchase special dry building mixes that only need to be diluted with water and mixed before use.

In addition to brick and binder mortar, when building fireplaces, metal parts are used for the grate, heat exchanger, chimney, barbecue and charcoal trays.

With or without foundation

The arrangement of the foundation for the fireplace is best done during the construction of the building itself. But if the house has already been built, then the floor is cut out and a concrete or brick base is made under the fireplace facade. Depending on the size of the fireplace, the foundation deepens 30 - 50 cm below the floor level. The brick base should be laid on a mortar of cement grade 400 or 500 with sand in a ratio of 1 to 3. In the case of a poured foundation, a wooden formwork is constructed from concrete.

A foundation for a home fireplace is not needed if it has a high brick base, such that the distance from the bottom of the firebox to the floor is at least 0.3 m. In this case, it must be taken into account that the floor structure can withstand the existing weight of the stove with a chimney. Also, false fireplaces do not need a foundation.

An outdoor fireplace in any version must be erected on a concrete base of at least 20 - 30 cm, so that the structure is stable in the backyard soil.

For the manufacture of home fireplaces, it is customary to use materials that are widely used in home construction at all times. At the same time, fireplace stoves are made today not only from bricks, but can also be mounted from concrete or ceramic blocks. And yet, brick fireplaces are the most popular these days.

In the course of solving the question of how to fold the fireplace yourself, you will certainly encounter a number of technical problems. To make a brick fireplace, for example, you will need to purchase the following building materials and components:

- high quality brick (400-450 pieces);

- special ("blowing") door;

- protective (grate) grate;

- a piece of roofing iron for covering the floor in front of the stove;

- welded firebox;

- smoke box made of steel sheet;

- consumables (sand, cement, clay, copper wire, strip iron, roofing material for foundation waterproofing).

Preparatory work

Having wondered how to properly fold the fireplace, you, first of all, must decide on the type of brick used. It is well known that only the following types are suitable for the manufacture of fireplaces:

- clay brick, which usually goes to the lining of the firebox and withstands high temperatures;

- refractory white brick(Gzhel);

- refractory fireclay brick.

Preparatory work begins, as a rule, with the preparation of a clay mixture cleaned of unnecessary impurities and well rubbed, which is then soaked in water for 1-2 hours (before laying).

Sand for the manufacture of the solution should also not contain large impurities, which is ensured by simply sifting it through a fine-grained sieve.

Mixing clay with sand should be done in batches. In exactly the same way, you need to add water to the mixture until you get the consistency you need. Properly prepared solution should easily slide off the working blade (trowel) and not spread over its surface.

Depending on the fat content of the clay used, the ratio of sand and clay in the solution should be set in a ratio of 1:2 or 1:1.

Main works

Foundation

To equip the fireplace foundation in the area allotted for the fireplace, a small pit is dug right in the ground (to a depth of 30-40 cm), the bottom of which, after leveling, is carefully rammed.

The first layer of the foundation is usually filled with brick or broken stone, thoroughly compacted, and then poured on top with a liquid cement mortar. The base of the foundation must exceed the dimensions of the fireplace by at least 5 cm on each side, and its upper cut must be located below the floor level (approximately two bricks thick). A layer of waterproofing is usually laid on the penultimate row of bricks, which is necessary to reliably protect the furnace from dampness.

Chimney arrangement

The most important part of the brick fireplace construction, which ensures the creation of the draft required for the normal operation of the furnace, is the chimney. To equip the chimney, you can use both bricks and special ceramic or metal pipe modules.

Chimneys used in brick fireplaces according to their design features are divided into the following types:

- built-in;

- suspended;

- based on a fireplace (if there is a link to the building).

Brick chimneys, which are designed to support the fireplace, transfer the latter part of their weight and therefore require the arrangement of a separate foundation.

A built-in chimney is a special channel located inside the bearing (enclosing) masonry and serving to remove smoke. According to most experts, chimneys of this type are the most economical and most suitable for private construction. Located inside the masonry, such chimneys do not need a separate foundation and can be mounted directly during the construction of the house.

Suspension-type chimneys are used, as a rule, for equipping autonomous fireplace structures, but can also be used in heating systems of another class.

The outlet of suspended chimneys is attached to the ceiling and to load-bearing structures roofs of the house by means of the so-called cable-stayed stretch marks or special brackets.

Regardless of the type of chimney design used, the following circumstances must be taken into account in its manufacture:

- when calculating the height and flow section of the chimney, it is necessary to proceed from the dimensions of the furnace;

- since the visually perceptible part of the chimney structure above the roof (chimney) is partly involved in the formation of the silhouette of the building, special attention should be paid to it when developing the roof design.

For a beginner without practice in the furnace business, immediately laying out a brick fireplace with his own hands is a very difficult task. But three components - the availability of time, patience and a great desire - will help you succeed and make a wonderful home, a source of comfort and warmth in the living room. We will provide all theoretical information and we will tell you about the procedure for conducting masonry work in the form of a simple instruction.

General information and device

In fact, a traditional English fireplace is a stove of a simplified design, consisting of the following main elements:

- open firebox large sizes in the form of a rectangular niche (portal), lined with solid ceramic bricks;

- the straight chimney shown in the diagram is equipped with a special protrusion - a chimney tooth and a tapering part - a smoke box;

- the pre-furnace frontal platform plays a decorative role and at the same time protects the floors from sparks from the firebox;

- valve for adjusting thrust.

Note. In simple designs, grates and an ash chamber are not provided; firewood is burned directly on a brick hearth.

In the current conditions, fireplaces are built solely to create a unique atmosphere of comfort in private houses and cottages, and not to organize heating. The fact is that open hearths are extremely ineffective, even for more complex models with two smoke circuits, the efficiency does not exceed 20%, since the lion's share of the heat simply goes outside through the pipe.

Scheme of a complex fireplace with two smoke circuits

The room is heated by infrared radiation emitted by an open flame. As soon as it decays, the heat transfer stops. Convective heating does not work here - the draft of the chimney, which has large section, literally sucks heat out of the room along with the air flow. Decrease transverse dimension pipes are not allowed - the fireplace will smoke into the room. For the same reason, brick walls practically do not accumulate heat.

Tip for calculating the size of the hearth. When building fireplaces with your own hands, it is important to achieve a compromise between the smoke in the room and too much draft, which helps to remove heat along with the air. The flow area of the chimney should be 1/9 of the area of the open part of the firebox (portal). In turn, the dimensions of the front opening are taken in the ratio of 1/50 to the area of the room, and its height is 1.5-2 times the depth of the firebox.

So that you can choose the right dimensions for the fireplace without delving into calculations, we present a table with the dimensions of the main elements tied to the area of \u200b\u200bthe room.

Instructions for laying a fireplace

On various Internet resources and in the technical literature, it is easy to find a variety of projects for home and outdoor hearths, accompanied by orders and photos. But at the heart of all the proposed designs is a traditional English fireplace, which we offer to lay for beginners. As an example, let's take a look at a relatively small model shown in the drawing and designed for a room of 20-25 m².

Note. If your room differs in dimensions, then the dimensions in the drawing can be changed in accordance with the table, only more accurately fit them to the length and thickness of the brick (taking into account 5 mm joints).

The step-by-step work steps are as follows:

- Preparation - choosing a place for the future hearth and purchasing building materials.

- The device of a reliable foundation - reinforced concrete or brick foundation.

- Mortar preparation and laying.

- Trial ignition and warm-up.

By design, fireplaces are divided into wall, corner and built-in. We chose the first option because of the ease of execution - the building is being built next to the existing wall. Do corner model without proper experience, it is much more difficult, and to embed the structure in the partition, the latter will have to be disassembled.

The optimal location of the hearth is near the inner bearing wall or partitions, closer to the center of the room. At the same time, try not to complicate the passage of the chimney through the roof - make sure that it does not get into the ridge. On both sides of the fireplace, you need to provide free space along the walls of at least 1 m. The worst place for a hearth is near the outer fence or next to the doors.

Advice. It is not recommended to place fireplaces in too small rooms up to 12 m². Moreover, it is not allowed to build them in apartments of multi-storey buildings. The way out is to install a gas or electric fireplace insert and make a lining of decorative bricks and drywall, as shown in the diagram.

Necessary building materials

To independently fold the fireplace according to the above drawing, you need to prepare the following materials:

- ceramic solid brick - 300 pcs.;

- fireclay (refractory) brick - 120 pcs.;

- chimney damper;

- dry mortar for refractory masonry - 150 kg;

- ready-made clay-sand mixture for laying out stoves - 250 kg;

- metal equal-shelf corner 50 x 3 mm - 2.5 m;

- revision oven door.

Red ceramic brick grade 150-200 is the main material used in the furnace business. Choose a solid stone of standard dimensions 250 x 120 x 65 mm without cracks, preferably with smooth sides. Building materials of low quality and used materials cannot be used for laying fireplaces.

Fireclay bricks used to form fireboxes for wood and coal stoves are produced different sizes. A stone 250 x 124 x 65 mm of the ShA brand will suit you, laid on a special solution of refractory clay and mortar.

Material saving advice. Ordinary ceramic brick calmly withstands temperatures of 700 ° C, which corresponds to heating when burning firewood. Refractory stones, whose price is much higher, are designed for a maximum temperature of 1690 ° C. Hence the conclusion: if you do not plan to heat the fireplace hot every day, then feel free to make a combustion chamber from cheaper red brick.

Furnace craftsmen know how to prepare a masonry mortar from individual components - sand and clay (cement is not added!), Intuitively selecting the exact proportions. For beginners, there is nothing left but to build a fireplace based on ready-made dry mixes sold in stores. If you want to make the solution yourself, then we strongly recommend that you first get your hands on simpler designs. For example, add outdoor grill or barbecue, choosing the proportions experimentally to feel all the nuances of working with clay.

We arrange the foundation

Since the total mass of the brick hearth exceeds 1 ton, a reliable foundation is indispensable. It must be arranged separately from the foundation of the house, maintaining a minimum indentation of 5 cm. If the fireplace is supposed to be built in a lived-in room, then you will have to open the floor in a section that exceeds the dimensions of the future structure by 100 mm in each direction. For our example, the dimensions of the site will be 137 x 124 cm (according to the diagram above, the dimensions of the building are 127 x 114 cm).

The device of the foundation for the fireplace follow the following step-by-step instructions:

- Dig a pit and carefully tamp the bottom. The depth is determined by the existing foundation of the house.

- Lay sand on the bottom and compact again. The final thickness of the pillow is 100 mm.

- Lay the pit to ground level with a rubble stone. In the process of backfilling, fill all cavities with liquid cement or lime mortar mixed with clay.

- Form a flat top concrete pad and after hardening, lay on it 2 layers of waterproofing from ordinary roofing material.

Note. As a backfill, fragments of concrete, old brick, shell rock and other piece materials will fit.

The second stage of laying the foundation can be done in two ways: pour iron concrete slab or lay out the base of red brick. The first option, shown in the drawing, is more reliable and convenient for further construction, since a solid slab allows you to lay a wall anywhere on the site. It is implemented like this:

- Fabricate and install wooden formwork to the height of the finished floor of the building in such a way that foundation slab advocated for the dimensions of the future fireplace by 50 mm in all directions.

- Tie a mesh of iron reinforcement with a diameter of 12-16 mm and set it at a height of 5 cm from the roofing material, using small wooden linings.

- Prepare concrete grade 150 by mixing M400 cement, sand and gravel in proportions 1: 3: 5. Lay concrete mix into the formwork and level the site with the rule according to the building level.

After 7 days of concrete hardening, remove the formwork and process the foundation walls bituminous mastic. Wait until it is completely dry before laying out the fireplace. reinforced concrete slab(another 3 weeks), then cover it with 2 layers of roofing material and proceed to the masonry itself. To avoid mistakes when building the foundation, watch the video from the furnace master:

Fireplace Rules

Submit ordinary wall and the body of a brick fireplace are two different things. So before you build a home, read the general rules for its construction:

- in the manufacture of refractory and clay mortar strictly observe the ratio of the dry mixture and water indicated on the packaging by the manufacturer;

- first lay out the stones of each row dry, adjust and file according to the order, and only then put them on the mortar;

- soak the red brick in water for 3-5 minutes before laying in place until air bubbles stop appearing;

- observe the maximum joint thickness of 5 mm;

- do not tie sections of masonry made of ceramic and fireclay bricks together;

- constantly check the vertical in different points plumb and horizontal building level;

- when installing metal corners, a number of stones resting on it must be laid without mortar.

Note. It is not recommended to soak refractory stones, but only rinse with water from dust, because the material gives off moisture for a long time and may burst after kindling.

During operation, bricks can be tapped, but moving in a horizontal plane is highly undesirable. Remove protruding excess mortar with a trowel, and from the inside, wipe the entire wall with a damp cloth to form a smooth surface. For a detailed description of the process, see the next video:

Work order

First of all, the foundation slab is covered with a sheet of galvanized roofing iron, and on top - with basalt cardboard. However, according to experts, the latter is successfully replaced by felt soaked in liquid clay. Required set masonry tool shown in the figure.

The first two rows of ceramic bricks form the base of the fireplace and the pre-furnace platform, the 3rd and 4th - the hearth part of the furnace. Please note: in order, red and fireclay stone are indicated in different colors. The fifth and subsequent rows (up to the 11th) form the walls of the combustion chamber and the outer contour of the portal.

After laying the 12th row of stones, install the steel corners that serve as a support for the front wall. The next levels form a smoke box and a chimney tooth, which is shown in the ordinal diagram. On the 16th row, a cleaning door is built into the back wall.

Rows of bricks from the 17th to the 23rd form the body of the fireplace, and the remaining 3 levels form the chimney. On the 26th row, a valve is built into it.

Further laying of the chimney is carried out before desired height in the same way, excluding the node of the passage through the floor. Here it is necessary to lay out a special extension - a cut, whose task is to protect wooden structures from hot flue gases. According to the rules fire safety combustible floor material must be protected by a brick wall 38 cm thick. All requirements for the chimney pipe, including its height, are reflected in the diagram:

In conclusion - trial kindling of the hearth

After the solution has dried, which will take 10-14 days, make the first kindling. It is important to follow one rule here: the entire masonry should warm up gradually so that cracks do not occur. Put a small pile of brushwood or wood chips on the hearth, open the damper fully and set fire to them. Then lay firewood in small portions for several hours, watching the walls of the hearth and chimney. Fix the appearance of cracks - then close them with the same solution.

The finished fireplace can be decorated in various ways - plastered, decorated with tiles with tiles or painted. Of course, provided that after a full warm-up it functions properly and the masonry did not give large cracks. If you did everything according to the instructions and without haste, then commissioning will certainly be without problems.

Structural engineer with over 8 years experience in construction.

Graduated from East Ukrainian National University them. Vladimir Dal with a degree in Electronic Industry Equipment in 2011.

Related posts:

Creating a beautiful and functional brick fireplace with your own hands in a country house is a task that is not very difficult for an owner with ingenuity. Due to the material, the cost of a brick portal and chimney will not be high, especially compared to granite, marble and other exclusive minerals. Cement mortar for masonry, the necessary tools are also not very expensive.

Before you make a fireplace yourself for a summer residence, you need to choose its design and shape, as well as decide on the calculation of the size of the firebox, chimney and portal.

A simple fireplace, depending on the location, is wall-mounted and corner. Its parameters are determined based on the area of the heated room: it is divided by 100 - as a result, the optimal area of \u200b\u200bthe furnace is obtained. The width of the furnace hole should be 1.5-2 times greater than the depth and approximately 1.5 times less than the height. To achieve sufficient draft, the area of the smoke hole should be 10-15 times smaller than the area of the firebox, and the straight section of the chimney should be 3 to 5 m long. With such proportions, it is possible to achieve efficient heating of the room and safe operation of the fireplace.

A brick mini-fireplace for a summer residence is well suited for small spaces and requires a minimum amount of building materials. With a firebox size of no more than 40 x 60 cm, it will completely cope with heating a room up to 20 square meters. m., and its height without a chimney will be approximately 1.1 - 1.2 m, width 0.5 - 0.6 m. Considering the entire lining with decorative ledges and the coating of the smoke tube, the structure will require 220 - 230 standard red brick .

The English fireplace differs from other models in its direct chimney, one-way heat flow and a trapezoid-shaped firebox. Such a device allows most of the generated heat to enter the room.

The side and rear walls of the firebox have a slight slope of about 20° and serve as a kind of reflector of heated air. The smoke collector has the shape of a pyramid, and the chimney pipe is also hidden under a layer of brick, which tapers slightly towards the ceiling. Another feature of English fireplaces is the base under the portal in the form of a platform, which is laid out of refractory bricks.

The depth of the firebox for English fireplaces is 0.4 - 0.5 m, the brick layer should protrude from the edges of the furnace hole by 0.3 m, and the protrusion of the horizontal base can reach 0.5 m. For effective traction and sufficient heating of the room, it is necessary that the cross-sectional area of the chimney and the area of \u200b\u200bthe furnace had a ratio of 1 to 8. The outlet pipe for the English version should be 3–5 m high. Subject to all these conditions, it is possible to achieve simple and uniform heating of the room, a beautiful flame in the hearth and the absence of harmful smoke in the room. Classic English fireplaces have a long history and will add a cozy atmosphere to any country house.

A barbecue grill is an option for outdoor use. This is a great way to arrange a personal plot, where you can comfortably spend your leisure time in good weather. A fireplace with a barbecue, in addition to a woodpile and a firebox, has a ledge on top, on which skewers with barbecue or a grill for roasting meat are placed. In addition, on such a device, you can cook other dishes in a frying pan, in a saucepan, in a roaster, and food cooked on the street with a natural fire is not only healthy, but will also give the family a lot of positive impressions.

The simplest barbecue fireplace without a roof is much easier to install than the home option, because it does not require the construction of a smoke box and a chimney - all combustion gases are vented directly to the street.

For the foundation, a concrete base is usually chosen, the thickness of which will depend on the mass of the brick structure of the future barbecue, usually it is 20–30 cm. for coals and a place for the location of the grate or skewers. You can show your imagination and install more complex designs: with two fireboxes for the simultaneous preparation of several dishes, with decor over natural or artificial stone bricks, with a table for cutting food or a sink with a tap and sink.

A country gazebo can be built with a brick frame and a fireplace, and the walls and roof are made of other materials: profiled iron, wood or plastic. This will simplify the installation work and save on building materials.

There are a huge number of projects of country gazebos for the street, the most common of them:

- An open gazebo under the roof on 4 columns with a brick barbecue, this option is suitable for calm, waterless weather, but in case of bad weather, you can build light walls made of fiberglass, PVC panels or other available materials. The roof can be tiled with metal or ondulin tiles, and electric lighting can even be installed inside.

- A lightweight construction of a wooden gazebo in which brick is used only for the fireplace itself with an arch-shaped firebox. On a cool evening, a small company can gather around the hearth, the heat from it will be enough. If necessary, you can equip the roof with a canopy made of light polymer materials.

- Finnish arbors have recently become widespread with us, as they are designed for a cold climate. They have a regular 6 or octagon shape in profile with closed walls and a sloping roof, from the center of which a chimney pipe emerges. They use a brick island fireplace, designed for both barbecue and space heating.

Since an ordinary clay brick is universal in its physical properties, it can be used for both home and outdoor fireplaces. That part of the furnace, which is in direct contact with an open fire, is selected from a refractory grade.

purpose

The outdoor fireplace has many design projects, with home craftsmen coming up with new ideas every year. Outdoor fireplaces can perform the function of heating, cooking, or a combination of two tasks at the same time. Models can be island or wall, if they are attached to the gazebo, the outer wall of the house or a stone fence. The latter option is very interesting, it will save materials and construction costs if the site already has a strong and high brick fence. A corner or wall fireplace with a small hood can be attached to it.

A country fireplace made of bricks is most often made of an island type, a simple U-shaped design without a high chimney pipe. For this option, it is better to equip the foundation in advance with a platform of concrete, street tiles or other durable non-combustible material. It will be convenient to place chairs for relaxation and other garden furniture on it. An island fireplace for a summer residence can be modernized over time, adding new details, in the end, having built a full-fledged indoor gazebo with heating and a barbecue.

A decorative fireplace is used by many in interior design, so as not to use complex systems with a smoke box, exhaust hood and refractory materials. A false fireplace in a room can work on the basis of an electric, gas or water heater, and skillful paintings, electric light or candles are used to simulate a flame. This option will not replace the natural heat from burning firewood, but it will look very impressive and will cost much less, since it does not require the work of an experienced stove-maker.

The fireplace in the house should, first of all, provide a normal smoke exhaust to the outside, so that the room does not have a strong smell and carbon monoxide. It is necessary to calculate its dimensions based on the area of \u200b\u200bthe room, and for cladding, materials with high thermal insulation should be used. If it is planned to make a false fireplace, then an ordinary decorative brick without fire resistance is used.

Fireplaces for baths use mainly coal for heating, are small in size and simple in design. They have 2 working parts: a firebox and a chimney. The difference from the traditional sauna stove is that the firebox is open and the heat for heating comes from it. Brick versions of such fireplaces are usually wall or corner. Due to the large mass of building materials, they must be installed on a massive base, if the floor in the bath is not thick enough, then you need to take care of an additional foundation for the stove.

Fireplace device

Home fireplace consists of 4 parts:

- firebox where firewood is burned;

- smoke collector for a smooth transition of smoke into the chimney;

- a chimney that removes combustion products to the outside;

- portal around the firebox with decorative lining.

The options for the stove may be different, but it is best to choose a trapezoidal shape of an open firebox with inner walls at a slight angle. This will provide the greatest efficiency of such a fireplace. A very efficient fireplace model for a room with an air heat exchanger. This part can be made in the form of a snake-shaped pipe, which generates additional heat. Therefore, for the flow of hot air into the room, it is not necessary to maintain a constant open fire.

Outdoor fireplaces with a firebox can have chimneys, a barbecue, an oven, metal burners, and even a roof for cooking in the rain. Their device depends only on the imagination and capabilities of the owner. There are interesting models of fireplaces with a bread machine, with a woodcutter or several fireboxes.

materials

For the arrangement of fireplaces, red bricks are mainly chosen from clay or ceramics, plastic molding or pressing. The latter option is less durable, especially under high thermal loads, as it contains many pores. But ceramic bricks obtained by plastic molding have a smooth and durable surface and are no less strong inside.

There are 3 types of bricks for home and outdoor fireplaces. Ordinary building non-facing brick is designed for inner layers of masonry that are not visible. It does not need protection from an open flame and a smooth, beautiful surface, which is why it is the cheapest. In the manufacture of refractory bricks, pressing and high-temperature firing of workpieces from fireclay mass or quartz are used. Such building materials are installed in places of contact with open fire, i.e. in the furnace and smoke box. Facing and shaped bricks for decor have a smooth, uniform surface with different colors, textures or luster.

For masonry, mortars are used, which include cement, sand, water, and sometimes chemical fillers for heat resistance. In order not to calculate for yourself the correct combination of components for building a furnace, you can purchase special dry building mixes that you only need to dilute with water and mix before use.

In addition to brick and binder mortar, when building fireplaces, metal parts are used for the grate, heat exchanger, chimney, barbecue and charcoal trays.

With or without foundation

The arrangement of the foundation for the fireplace is best done during the construction of the building itself. But if the house has already been built, then the floor is cut out and a concrete or brick base is made under the fireplace facade. Depending on the size of the fireplace, the foundation deepens 30 - 50 cm below the floor level. The brick base should be laid on a mortar of cement grade 400 or 500 with sand in a ratio of 1 to 3. In the case of a poured foundation, a wooden formwork is constructed from concrete.

A foundation for a home fireplace is not needed if it has a high brick base, such that the distance from the bottom of the firebox to the floor is at least 0.3 m. In this case, it must be taken into account that the floor structure can withstand the existing weight of the stove with a chimney. Also, false fireplaces do not need a foundation.

An outdoor fireplace in any version must be erected on a concrete base of at least 20 - 30 cm, so that the structure is stable in the backyard soil.

Order-schemes

The ordinal diagram of the fireplace contains drawings of the location of the bricks from the lowest to the top row. There can be several images, they contain orders with different parties. Via finished projects such drawings, you can properly assemble the oven with your own hands, the builder is only required to lay bricks on a horizontal level and add mortar. Ready-made schemes in rows allow you to immediately calculate the required amount of building materials.

masonry

If the owner suburban area does not have experience in laying bricks for a fireplace, then he will be helped to build a structure from scratch step-by-step instruction. There are many variants of such plans, but they all have approximately the same structure. A manual laying lesson for a home or outdoor fireplace usually consists of 5 - 7 stages, each of which describes the installation of 2 - 3 rows of bricks and its features. Along with this, other necessary issues are considered: how to properly reinforce a brick or concrete base, how to make a smoke box and an air heat exchanger, how to decorate a fireplace facade.

Basic Mistakes

Experienced stove-makers identify the most common mistakes in the construction of brick fireplaces:

- incorrect proportions of the sizes and shapes of the firebox, smoke box, section and height of the chimney and the area of the heated room;

- too thick or thin width of the seam between the rows, the wrong combination of concrete mortar components;

- not using heat-resistant and refractory bricks;

- too small height of the foundation or base under the fireplace;

- the dimensions of the facade, decorative parts are incorrectly calculated, the rows are not evenly mounted and decorative details, laying bricks must be done with the utmost care and professionalism.

In addition, there are operational errors immediately after construction. Many do not know how many days after laying the fireplace you can heat the fireplace. A complete firebox can be made only after 2 - 4 weeks.

Before this, forced drying is carried out: every day not a large number of dry wood. Start with 2 kg, every 2 days increase the weight by 1 kg.

The fireplace is usually placed in the living room. Where else to admire the fire, if not in a room for relaxing and receiving guests. It is far from possible to use it as the main source of heat with all designs, but as an additional one, in the autumn-spring period it is very comfortable. The fireplace will also help in especially severe colds, when the main heating is insufficient in terms of power. You can fold a simple fireplace with your own hands. It's far from easy, but possible.

Although much less brick is required to build a fireplace, it is very important to correctly lay out all the elements. Due to design errors, the fireplace may work inefficiently or not work at all. In addition to the function of heating, the fireplace performs in many ways also aesthetic functions, therefore it is often chosen also in appearance, not forgetting about the technical features.

Dutch fireplaces

This heater, although it has a large-format firebox traditional for fireplaces, is in fact a stove - it has a multi-turn chimney. So this is a heavy, difficult-to-implement massive structure. It has only two key differences from the furnace - the size of the furnace portal and the absence of a blower. If you know how to fold a Dutch stove, with a few simple adjustments, you can turn it into a fireplace. Moreover, if there is an old Dutch woman in the house, even demanding overhaul, it easily turns into a fireplace. It is only required to disassemble the front furnace part, insert a ready-made metal furnace of a suitable size, connect it to the smoke circuits and decorate it.

This is the type of open-fired units that can be used as the main heater. The Dutch have long been forced to save on fuel and do not allow themselves to release heat into the chimney.

Open or Alpine (Swiss)

This type of fireplace has become popular recently. In fact, this is also not a fireplace in pure form, but for a different reason. It is, rather, just an open or semi-closed hearth, over which a cap is made, turning into a chimney.

It fits perfectly into chalet-style interiors, because it was from there that he came to us. The device, in general, is simple, but not very efficient in terms of heating. But very decorative.

The option that you see in the photo above is made in the rustic style - from natural processed stone. Such work costs a lot of money: you have to adjust, trim hard rocks of stone, which requires a high level of skill.

Classic English

A traditional looking fireplace just the way we imagine it. Open wide portal firebox in which firewood burns. Moreover, its decoration can be any, both artsy for the corresponding interiors, and restrained, which fits into high-tech and minimalism.

Despite the fact that it does not seem to take up much space, it will take about 800 bricks to make a classic fireplace, along with an average length of the chimney. The total mass of such a structure is in the region of a ton. The smallest classic fireplace requires a solid separate foundation, like what is arranged for the stove - to the same depth as the foundation of the house, and in size it should be at least 15 cm larger on all sides. They bring it to the same level with the floor.

Device and how it works

If you look at the photo, it seems that there is nothing complicated: a box with a pipe and that's it. But what looks simple is actually far from simple. Firstly, there is a smoke tooth in the upper part of the firebox. And not just some kind of ledge, but with a reflective surface. It narrows the cross section of the pipe, twisting the flame inside the firebox.

Secondly, the hearth part of the fireplace insert does not have a blower, and the front wall is made with an inward slope. These two components make it possible to ensure that the flame spins in the furnace for a long time, giving off heat as much as possible.

Thirdly, there is a damper in the pipe, which effectively, and, very importantly, safely regulates the intensity of combustion. Safe - because a properly built fireplace under no circumstances forms carbon monoxide in hazardous quantities. After all, it is formed with a lack of oxygen, and with an open portal of a classic fireplace, there is always enough air and oxygen.

Another point of the fireplace view is that, like in a gate valve, a hole is cut out in it, equal in area to 10% of the chimney cross section. This gap is necessary for a minimum draft, which in any case will not allow the flame and smoke to “fall out” of the furnace. Even with the damper closed, the fire spins inside, and the smoke goes up the chimney.

This design allows efficient use of heat even when burning high-calorie fuel. A long spinning flame heats the walls of the furnace as much as possible, and they perfectly heat the room.

If we talk about the possibility of heating water, then it is not possible to put anything in the furnace: the whole dynamics is disrupted. But above the tooth on the pipe, you can put a heat exchanger. Another question is that the temperatures there are already far from being so high and it will not work to heat water for heating, but for hot water in a small volume (storage type boiler), there will be enough heat.

In the earliest English fireplaces, the hearth was without grates, sloping outwards. At the same time, the slightest inaccuracy in execution led to the fact that the flame began to rotate in the other direction. At the same time, coals could fly out of the furnace, which is not good at all. Therefore, in the Middle Ages, they began to make small grates and a blower, which was opened only when kindling. When the firewood flares up, the blower closes, which gives impetus to the formation of a fiery whirlwind in the furnace.

Modern English fireplaces are made with both a solid hearth and grates. When kindling deaf models during ignition, liquids are used for kindling. They themselves give sufficient momentum for the formation of a vortex.

Ordering a classic fireplace

Traditional English fireplaces are structurally different from each other in the form of a smoke tooth. For its exact reproduction, only “straight hands” are not enough. It takes a lot of experience. But there are models that are not so critical to this detail. You can fold such a fireplace with your own hands if you know how to handle a trowel and a level.

In this embodiment, the grate is small and located at the very end of the firebox. This made it possible not to be smart with the tooth, but to make it ordinary, stepped. But in this fireplace, during kindling, the blower cannot be closed. The fire "spins" precisely due to the flow of air into the back of the firebox.

Rumford fireplace

One of the varieties of the classic is called the Rumfod (Rumford) fireplace. The principle of operation is the same, only it is not the smoke tooth that provides the swirl, but the narrowed neck of the chimney, the shape of which repeats one of the branches of the hyperbola.

Rumford fireplace. The key node is the neck of the pipe

Structurally, it is simpler and requires less space - the firebox may be less deep. All the problems are that the neck must be made with a very high precision. A deviation of only 5% from the required shape leads to inoperability. This is the main difficulty, therefore we do not recommend making this fireplace with your own hands.

With factory firebox

If there are metal stoves, why not metal fireplaces? And they are. Fireplace inserts are made of complex alloys - organosilicon, composite and special. The processes occurring in the fireplace insert are simulated by special programs, therefore the efficiency of these heaters is high, the installation complexity is medium. Another advantage is that you can connect an ordinary metal chimney.

Another nice point: the weight of the firebox is about 100 kg. If the finish will weigh a little, you can put such a fireplace on a reinforced concrete slab. If you want natural stone, you still have to make a foundation for a fireplace.

When installing a fireplace with a firebox, it is necessary to observe whole line requirements:

- the walls near which the heater will be mounted must be covered with non-combustible materials and thermal insulation with a reflective layer;

- the distance from the firebox to the wall is at least 10 cm, to the insulation - less than 5 cm;

- the ash pan should facilitate cleaning, and its inlet should be as close as possible to the firebox;

- the chimney must match the parameters of the furnace;

- chimney joints are sealed with high-temperature sealant;

- the gap between the furnace wall and the lining must be at least 1 cm;

See the video for the principle and procedure for installing a fireplace insert.

Getting permission

A little about ordering the installation of a fireplace in a company or doing it yourself. The point here is not only technical side question. Usually, difficulties arise long before this - even during the execution of documents. Firefighters do not like to give permission for fireplaces. And permits are required when installing a fireplace in any residential area. The difficulty is that there is no legislative framework that would prescribe the installation rules. There is a similar document for stoves, but not for fireplaces. But there is a phrase in SNiP 2.04.05-91 (on the construction of heating and cooking stoves) that it is forbidden to install heaters with an open firebox in any residential area. From this point of view, you are lucky if you plan to make a fireplace in a country house located in a holiday village - it is not considered a living space.

As often happens, there is another document (MGSN 3.01-96), which in Moscow allows the installation of fireplaces on upper floors if there is only one owner. So in the capital, there is a chance to get permission, albeit not for everyone.

There is a loophole for the residents of old brick stalins and Khrushchevs, in which, in addition to ventilation ducts, each apartment also has chimneys. Houses of modern construction, which also have smoke channels, fall under the same category. In all these buildings it is allowed to put heating equipment on the flame. In general, the oven is meant, but this fact is not prescribed anywhere.

One of the possible options for decorating a fireplace in a modern style

You can “push through” the permit by issuing papers and a complex redevelopment with the transfer of heating appliances. An example is the transfer of walls, walls, association with a balcony or loggia. Do not write about registers or batteries in papers central heating. It is in this general formulation - heating appliances. In the same document, you enter that you are going to put the heater on a flame, attaching a project made in a design organization. In this case homemade paper do not pass. There is a chance. But in general, the owners of houses and apartments will be driven long and hard. And do not try to argue, otherwise you will never get permission. Redo whatever they require. No other way. It will be a little easier for homeowners. The logic is clear - if problems arise, you will burn yourself. They talk harshly with the owners of apartments, but you can still get permission.

Now, if you don’t want to get involved with all this, you can order the installation of the same fireplace with a firebox in a specialized organization. As a rule, they provide documentation services. Their paths have already been trodden, the chances are much greater. In addition, when accepting your heater, they may (and most likely will) require certificates for all materials, including bolts, screws and stove fittings. This also needs to be known and remembered. And with such a task, the purchase of materials turns into a difficult quest.

Corner fireplace - ordering and video

Very often, fireplaces are made in the corner. It is convenient and practical: this way it occupies the most difficult area for decorating and serves as an excellent decoration itself. When choosing a place for a fireplace, consider such a nuance as the height of the pipe. When laying a fireplace, almost half of the material and time is spent on the formation of the pipe. On the one hand, a tall pipe - that's good - will good traction. On the other hand, there are high costs. To reduce them, the fireplace can be placed in the corner where the roof slope is located, and not its ridge. The height of the pipe should still be enough to provide traction, and the costs will be less.

How to make a protective screen

If the fireplace will stand in wooden house the walls need to be protected. Ideally it should look like this:

- wooden walls are sheathed with thermal insulation (you can use cardboard from basalt wool with an operating temperature of up to 800 ° C, 1.5-2 cm thick);

- on top of it, on ceramic insulators with a height of 3 cm, attach a metal screen.

The walls of the fireplace can be located 5-7 cm from the screen. The dimensions of the metal sheet are 15-20 cm larger than the dimensions of the firebox. Such a multi-layer system will prevent heating wooden walls to any significant temperature.

Materials, ordering, comments

This fireplace has dimensions of 890*890*1610 mm (excluding pipes). To make it you will need:

- red oven brick 356 pcs (without pipe);

- refractory bricks SHA-8 - 55 pcs;

- smoke damper 250*130 mm;

- steel corner with a wall thickness of 5 mm: 50 * 600 mm - 1 piece; 50*800 mm - 2 pieces;

- steel sheet 3 mm thick 400*600 mm.

The above layout is one of the types of a classic fireplace to install it in a corner. The scheme is quite simple, but in it a large number of bricks require trimming. For laying this brick fireplace, you will definitely need a good grinder and a large number of stone disks.

When forming a tooth in the furnace (10-13 rows), fireclay refractory bricks are hewn. The upper edge of the brick of each subsequent row should protrude 30 mm above the previous one. This edge is hemmed so that it is inclined and even. As a result of laying all 4 rows that form the tooth, the surface should be even and smooth. It will “twist” the flame and reflect heat into the room, so pay maximum attention to this moment.

Sufficiently detailed instructions for laying this fireplace are given in the video.

Masonry conditions and materials

It is necessary to start laying a fireplace with your own hands in the autumn-spring period, when the temperature is kept within 15-20 ° C. Under other conditions, it is difficult to work and requires solid experience.

The brick is taken from the stove, red, full-bodied. Facial and smooth does not fit - it will not withstand temperature changes and will crumble. When choosing a stove brick, pay attention to the geometry and color. Burnt "iron ore" does not suit us, as well as swollen and warped bricks. Only smooth, of the same color, emitting a clear sound when tapped.

Masonry is carried out on a clay-sand mortar. Clay - purchased construction, as well as sand - river, not quarry. The clay soaked to a pasty state is mixed with sand in a ratio of 1: 3, water is added until a solution of medium plasticity is obtained. Be sure to check the fat content of the solution: take the solution on a trowel, tilt it. The solution should fall, leaving a layer of 1.5-3 mm on the metal. If the layer is thinner, metal is visible, clay is added, if the residue is lumpy and thick, sand and a little water are added. As a result, a solution with the specified conditions should be obtained.

You can knead it all at once. At night, the container with the solution is covered with wet burlap, and mixed several times before work.

When laying, the thickness of the joints is 6-13 mm. Ideally - 8-10 mm. If you are laying a fireplace with your own hands for the first time, constantly use a level and a plumb line. Check every row and even every stone. Fireplaces are tall and narrow devices with a high center of gravity. Such structures do not forgive even the slightest deviations. Therefore, the level must be good quality, ideal if you have a calibrated .

Drying and accelerating furnace

The finished fireplace is dried for at least 20 days, in a well-ventilated area. You can arrange a draft, but the walls should not fall Sun rays. For shading windows and doors, you can hang sheets or tighten the openings with gauze.

After three weeks of drying, you can carry out an accelerating furnace. They take slow-burning fuel (coal-seed, blacksmith's coal). If the oven was dried in good conditions, melt, add fuel in small portions, heat for a while. After three days, you can use "to the full." If the conditions were “not very good”, they start with 3/4 of the bookmark, gradually bringing it to full in a few days.

Basic Techniques for Cropping a Photo in Photoshop How to Uncrop a Photo in Photoshop

Basic Techniques for Cropping a Photo in Photoshop How to Uncrop a Photo in Photoshop Which acrylic brushes are better to choose: little secrets of choosing the right one Using different piles

Which acrylic brushes are better to choose: little secrets of choosing the right one Using different piles What are the sizes of business cards?

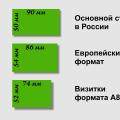

What are the sizes of business cards?