Furnace three-rotation laying scheme. How to fold the oven with your hands drawings and construction technology: step-by-step instructions, video. Chimney - how to ensure safety and good craving

© When using the materials of the site (quote, images), the source indication is required.

The old kind stove from the brick does not give up its positions under the onslaught of modern highly efficient competitors. Disputes - why? - Do not consider, but actually the reason is one: the brick stove breathes. Stone, by the way, no.

What does it mean - breathe? When heating the microporous body, the furnace sends a heated room with a pair of moisture into the air, and when cooled, absolves them into itself. As a result, the brick oven supports T. Naz. Point of dew in the room in optimal from the point of view of physiology limits. When they say that the brick oven "Healthier" any other, then, led or unknown, it is in mind that this factor.

In addition to the beneficial effect on health, the breath of the furnace gives another important consequence: in the medical and heat engineering calculation of the house, the lower limits of temperature in it can be reduced to 18 degrees in comfort and up to 20 degrees according to medicine, because The relative humidity in the heating season will be close to optimal. In wooden and brick buildings, it can give supercontamia: at 16-17 degrees in them over 80% of physically healthy people do not feel discomfort, and bed linen remains dry. And in a stone or concrete house, heated batteries, and at 18 degrees may be zyabko.

When heating with water registers, the lower temperatures must be taken at 20 and 22 degrees, respectively, and when heating IR emitters, electrical or gas catalytic, even on degrees above; IR appliances are strongly dried air. Therefore, the brick heating furnace with the efficiency (heat transfer coefficient) can be 50% in the cost of heating to be more economical to the super-modern metal componositis with efficiency in 70%, because the heat loss of the house is strongly, in a power law, depend on the difference in the inner and outdoor temperatures (temperature gradient).

Note: a small breathing can be achieved by overlooking it with a convection screen (see Fig.) A thickness of 30-40 mm of plywood, weathered wood hardwood or several layers of plasterboard. At the same time there will be uniform heating of the room in height. But the breath of such a furnace is deep and even will not be. Here modern technology to bricks are not yet reached.

The breath of the furnace in combination with physiology gives an economic investigation of the second order: the heating season can be started later, and finish earlier. In the middle strip of the Russian Federation, the difference in the year can reach the week, and in Chernozem and South - 2-3. Who will not need to buy fuel. And if you consider that a good brick stove works on everything that burns, including a throwing and cheap alternative fuel (pellets, etc.), then the savings are still increasing.

Note: on a global scale, brick furnaces still fit into the ecology - the production and production of materials for them causes damage to the environment greater than saving from furnace heating to losses in thermal highways and LPP. But in this case, demand does not give rise no longer, but the proposal dictates. In leading stoves, quiet, but hard work on improving the technologies for the production of furnace materials and the creation of brick furnaces allowing transportation in the finished form and install immediately at the place of use.

Wishing to fold the oven does not decrease. People's professionals also do not break the price: their work is in demand, competition is quite high, and, moreover, most of them are enthusiasts of their case. But to take over the stove or with knowledge of the case to consider the proposed project, you need to know the basic principles of the construction of furnaces, which this article is written.

Is it just in the house?

The brick oven on the farm will be useful not only for heating and cooking. Stationary can bring very good income, as or a barbecue IP, working in the field of catering.

First of all, the high heat capacity of the brick is primarily important, providing long-term heat transfer after the protest. Once the furnace is empty, you can sleep well, without fear of Ugon. For production furnaces to the fore, the low thermal conductivity of the brick, which gives the opportunity to create a high heat concentration in the working area. In this case, the breath of the furnace becomes an already harmful factor, and it is most often supplied by placing a stove into a gas-tight case.

Small businessmen specializing in handicraft industrial production, it is worth thinking about such types of industrial furnaces that may well do:

- Vagranka - on Hozdvor in it can be overpowered to 50 kg of scrap metal.

- - For hardening metal products with simultaneous cementing.

- Flaking oven for ceramics, etc.

Note: Brick furnaces are not recommended for heating, greenhouses, poultry houses, livestock courtyards. Breathable by mias, the furnace and the air will spoil, and the very spoil itself.

The fact is that the factory samples of small industrial furnaces are designed for transportation in parts or assembled. Therefore, prices for them are exorbitant. But, laying out the stove in place, you can get not the worst, without climbing in a beyond loan, and deploy a profitable business. We will still stop more details on: they were the first to appear in everyday life and the principles of fair and others embedded in them.

Note: a separate parsing requires a stove for a bath. Here the brick also turns out to be at the height, but for several other reasons. Bath furnaces will further be devoted to a special section.

Oven in the house

The house does not necessarily build from the stove, you can choose the stove to choose a suitable home. But first you need to carry out the heat engineering of the building, taking into account the factors described above and determine the place for the furnace in the house. It is also necessary to know that the insulation of the house outside increases the efficiency of furnace heating a lot more than heating registers. And, in turn, the slaughter of the house siding much simplifies and heshes insulation. Those., The optimal project of the house furnace initially must be comprehensive.

As for the planning, there are different options here, see fig. The house on the left is suitable for example, for example, for the Hermit Bachelor, but not ascetic or the childless family of convinced Sibarites, there will be a warm bed in the bedroom. The oven is a warm-cooking. Russian in such a house does not fit down, but the Swedish (see further) is suitable. Excellent. The winner is a budget housing for a small family, then the bedroom turns into a nursery or a zone in penthouse is distinguished for children.

In the middle the house is more and more consolidated. The living room comes out the furnace-fireplace with a finished cast cast iron furnace, see below; Heat-resistant firebox door. There are also different options here. If, for example, a kitchen with a bathroom to change places, the heating shield (see below) to deploy 90 degrees, and move the veranda with a hallway to the right side, then you can hide another 1-2 bedrooms at some decrease in the living room. At the same time, a corridor will take place to public areas.

Plan on the right is more suitable for giving. In the summer, opening the window in the kitchen, the hallway, it will not be too hot. Camin Point in the corner - for evening gatherings at the light; In it, it will be possible in the case of bad weather to prepare a kebab or barbecue on Rashaper.

Already at the stage of layout of the house with the furnace, you need to consider the following:

- For a high oven with its chimney, or for a furnace by 500 and more bricks, a separate foundation is needed that does not have a mechanical connection with the foundation of the building, even if they are designed and are built together;

- Low and wide hob and the heating shield to it on the floor, made according to the requirements of SNiP (i.e., capable of keeping the load at least 250 kg / sq. M. m) can be put without a foundation by making only thermal insulation; About her Next. Floor flooring under the shield is desirable to reinforce additional lags;

- Cutting the chimney (see below) should not come into contact with the ceiling beams, it is very desirable that the distance from the cutting to the blocks closest to it is approximately the same.

- The chimney should act over the ridge of the roof at least 500 mm and defend it from it by no less than 1500 mm.

Claim 1 allows exceptions. If the oven is 1000 or less bricks, and the foundation of the house is a liner section, then the foundation of the furnace can be constructed at the intersection or T-shaped tape connections under the inner walls. In this case, the distance from the foundation of the furnace to the nearest other tapes of the foundation of the building should be at least 1.2 m.

Note: Because Already at a small Russian oven requires 1500 bricks, then all Russian furnaces must be built on separate foundations. But here there is an exception - the small Russian can be built on the penetration of a wooden bar of 150x150 mm, permerating the floor to the boot in the foundation of the building or soil.

Furnace structure

Actually the furnace is sometimes called the body of the furnace. The body of the furnace is installed on the hydro and thermal insulation of the foundation of the furnace or floor and is completed by the chimney over the attic and the roof. All this together is called the structure of the furnace. The structure of the brick heating furnace is shown in Fig. on right:

- foundation;

- hydrometerproofing;

- shanses - a kind of legs, they are done for lower heating and saving bricks;

- confused;

- the inlet of the dryer - air canal, providing uniform heating of the room in height;

- paddle door;

- grate;

- the door of the furnace - worked - with the progress of fuel supply - gon;

- topki fuel, or just a firebox, or just a fuel;

- hide joints;

- the mouth of the firebox, or her Hailo. Sometimes Khail is called only the vertical mouth of the furnace with a narrowing (nozzle), and in the Russian oven Haulo - nozzle at the beginning of the chimney;

- clean door or just clean;

- flow (pass) - inflection of the air convector of the dryer;

- air convector dryers;

- furnace shift valve (see below, is shown conditionally);

- gas (smoke) convector, or convective furnace system;

- the view is a valve, which overlap the chimney after the protrusion so that the furnace does not speak naturally or wind tag;

- outlook outlook with its door. In the summer, the dryer's door is closed, and air convection in it stops;

- chimney chimney;

- overlapping oven;

- inner chimney chimney;

- ceiling overlap;

- fireborne cutting;

- flap, or otter - expanding the mouth of the chimney.

Note: the side of the furnace with Classroom (in the Russian oven, sometimes called Zev) are called a brow furnace, and its side walls - mirrors or cheeks.

Let's give some explanations. The foundation is a solid reinforced concrete; For the oven on the chances - ribbonly concerned. The ending of the foundation is at least 50 mm. Isolation - 2-3 layers of rubberoid, on top of them - 4-6 mm asbestos or basalt cardboard, then a sheet of roofing iron, and on it a litter under the masonry - a sheet of felt or basalt cardboard, painted in a very liquid masonry solution for a furnace, see it . Further. The litter is put on the iron wet and give it to stop before starting the laying.

The first rows of the masonry of the body of the furnace (oblique hatching in Fig.) - from the usual ceramic red brick (not facial!) On the cement-sandy solution, this is a sub-level part of the furnace. Next comes the heat, or heat part (hatching in the cell), it is placed from ceramic chimney bricks in combination with chamoten, about bricks are also further on the clay-sandy solution.

The roofing iron sheet on the asbestos or basalt cardboard of a pillow of 4-6 mm is stacked in front of the underwear door and workl on the floor on the floor, its root edge is immutted into the nearest top seam of the masonry. Leaf removal forward is at least 300 mm, and on the side of the chela - at least 150 mm. The free edges of the sheet are separated and naked to the floor.

The clay masonry solution is not captured, but dries. With an irregular furnace during the cold season, he gradually squeezes from moisture. In this case, part of the body of the furnace, the temperature in which does not rise above 200-250 degrees, lay out from the chimney brick, but on cement-sandy solution, it is also much cheaper than the clay, bowing hatching with a gray fill in fig. The solution for this part of the masonry is portland cement from M400 and mountain sand without inclusions. Replacing decorative analogues is unacceptable!

The lower transitions from the channel to the gas convector channel (flowing) must be 30-50% more in the height of the upper (pass). This will ensure the accumulation of soot at the bottom of the convector (on his faith), from where it is easy to remove it. With the same purpose, the edges of the pass are performed rounded.

Starting from 80 degrees in chimney, the masonry lead again from simple brick on the usual cement-sandy solution. The inner cutting of the chimney is necessary, it keeps on itself a fire cutting (at least 50 mm of asbestos or basalt cardboard in a metal cable) and, most importantly, in the event of a sunbathing, the soot will take part for a time sufficient to take the necessary measures.

The role of the roller (otter) aerodynamic. It dissects the wind stream, forcing its upper part of it to jump out the mouth of the chimney, so the thrust does not matter much from the wind. The height of the roller is at least 2 rows of bricks, removal on the seal of the mouth - in Pollikirpich. Neglecting Flying is a very frequent cause of smoking furnaces.

Choosing a furnace scheme

The main circuits of convection of household brick furnaces are presented in Fig. Left - Channel oven with a serial gas convector, the simplest with the version. The consistent channel scheme is built and similar to them. In addition to simplicity, the advantage of the channel circuit is that it is very plastic constructively. The furnace convector is mechanically connected only by Hail, so the channel furnace can be developed under any finished room, see the next. Fig.

However, the efficiency of purely channel stoves rarely exceeds 40%, and it is very difficult to embed the water to the water: in the body of the furnace circulates a powerful inner stream of heat, and any of its violation leads in a drop in the efficiency and reinforced soot.

In the center in fig. With schemes the most perfect heating and cooking furnace of bricks -Her efficiency reaches 60%. It is a chamber furnace (the role of an air chamber, a streamlined flow of hot gases, plays an oven 1) and stretched from the floor to the ceiling of the channel convector behind it. In the chamber portion, the gas is warm the cooking surface in the cooking niche 2, and part of the heat convector enters the dryer 3. The benefits of the Swedish furnace:

- The convector and oven do not have an energy feedback with the furnace part, so in the oven you can embed a U-or W-shaped heat exchanger of the DHW system with a cumulative tank, and the tank is placed or in the drying niche, or on the covered oven.

- Roaking flue gases occurs in the chamber part of the furnace. In convector, they leave with a temperature below 800 degrees, so it can be made from the usual brick on the cement-sandy solution.

- The high narrow convector gives a uniform heating area in height.

- Part of the flue gases from the camera output can be reinforced, for example, in a laying, and then return to the convector, without worsening the furnace parameters.

- The size of the convector can be varied, move and rotate it relative to the chamber part, so the Swede also fits well into the finished house and can hear up to 3 rooms, see the trail. Fig. (after channel stoves).

- If you open the oven door, the powerful flow of thermal radiation will go out of it, which will allow you to quickly warm up and dry by people who come with hard work in the cold.

The main drawback of the Swedish furnace is high requirements for the quality of materials and work for the chamber part of the furnace. In addition, it necessarily needs a foundation, without it a high and narrow structure, parts of which are loaded in different due to thermal stresses in different ways, will be fragile and unstable. Make a Swedish-type furnace can only an experienced cook.

Finally, on the right in fig. With the schemes - the coat oven. Its efficiency may exceed 70%, because It is self-regulating: the flue gases will not go into the chimney, until they store under the arch of the cap and will not give their heat the body of the furnace. In addition, the cap has a property of a gas type: if you forget to close the standard, hot gases under the cap will not be allowed to dock heavy cold air from High, and the oven does not work. This guarantees from Ugon because of not on time a closed view.

However, the cap is just just in the diagram, and in version it is very complex due to the high loads in the design. Then, the cap is exclusively heating, it is impossible to embed a cooking surface into it. The heat selection for the water was possible only in two-collous furnaces, even more complicated, so the cap ovens in everyday life are common. Exception -, but such talented burns on the world rarely appear.

Plate and shield

The development of the idea of \u200b\u200bthe Swede gave rise to a very promising design: a conventional hob with a separate heating shield-convector, see fig. Everything that this needed is to refuse the cooking and drying niches, it made it possible to disconnect the chamber and channel part mechanically, i.e. build them separately; Perhaps even in turn.

What do we get in return? Lower load on the floor. The slab in most cases can be built directly on the wooden floor, putting the insulation on it as the foundation under the oven. And under the shield just just damping cushions from basalt cardboard. The problem of the sustainability of a high narrow panel remains, but it is solved by creating its mechanical connection with the wall, even if the partition in the Polkirpich, see fig. left.

Next, the shield can be shifted and deployed relative to the stove, then the plate can warm the kitchen with a bathroom, and the shield is still up to 4 rooms. To do this, insert into the horizontal section of the chimney between them a flexible link from the heat-resistant corrugation with good thermal insulation to avoid sedimentation of soot. In general, the price of refusal from almost unnecessary in our time the niche turned out to be a fundamentally new and very practical design.

Seasonal strokes of the furnace

In the summer, when it is hot, to warm the room to nothing. But the meager amounts of fuel will not be laid in the furnace: the limits of adjusting the power of the fuel supply of all furnaces is small. Heat from a small bookmark will fly into the pipe, the remainder is not enough for the scrambled eggs. But getting a summer kitchen with a slab the opportunity is far from all.

At such a case, the design of furnaces with switching stroke with summer on the winter is invented. The easiest way to switch in the channel furnace parallel diagram, two left poses. In fig. below. However, the maximum efficiency of the channel-parallel furnace can be achieved only at its power of more than 20 kW. There is a law of a square Cuba, and in a too small furnace, the heat "worst" into the pipe, without having time to heat the convector. In addition, all two-way furnaces are potentially dangerous: if it is not enough to close both valves, a volunteer will go. Finally, on the summer, the blocker and part of the cheeks of the furnace are still heated.

Meanwhile, there is a two-way scheme, especially suitable for heating flaps: a diagram with two chimneys, summer and winter, two pos. Right in fig. For it, only one catch is needed, so it is completely safe - with any position of the thrust switch will be. The position of the valve is not immediately felt on the heat transfer, but you can switch the move during the firebox. And smoothly adjust the heating, partially shaking the damper.

In the summer, gases in the winter movement will not be shattered: the aerodynamic resistance of the convector labyrinth is much more than that of a straight pipe. And the laboriousness of the chimney structures is not at all double: gases in the winter chimney go cooled below 80 degrees, so the winter tube may be lightweight and simplified, for example. asbetic. The only small minus of the system with two chimns - for each pair of convector channels is needed.

Special ovens

Before switching to a more detailed analysis of ordinary furnaces, we will focus on several special high-demand structures.

Barbecue oven

This is an ancient open source, see fig. Build it either in the open air under a canopy or indoors under a cap-smoke. Laying without any wisdom: in a pollipich with a spoonful dressing. 3-4 rows need to lay out the tilers so that the strubel and lattices are supported. However, for more about the laying, see below.

The foundation for the outer barbecue is the simplest, slab made of ready-made concrete monoliths or stone blocks on a sandy-choggy pillow. The room barbecue is built directly on the floor on the combined insulation described above.

Barbecue has one subtlety: a firing side, he warm in the right focus warming up with sides. Therefore, 2-3 of the upper rows are desirable to lay out of chammed bricks, he very well absorbs heat and slowly gives it. In order for imperative brazier to warm up faster, bricks need to take faceted shaped, as shown in Fig. below. According to the wedge-shaped varnishes between them, heat will be fast in the masonry. You can also make shaped bricks for a barbecue, but then you have to work with a grinder.

Bannaya

How the furnace is based in ordinary order; Here is the main secret - the device of the heater. A closed heater, through the flue gases pass (on the left in Fig.) Quickly heats up and gives the most useful dry pairs. But it is impossible to "pass" water or kvass to it, you will have to reap the oven again. In addition, the slightest flaws are incorrectly selected stones, poor fuel, the violation of the fire mode - leads to precipitation in the heater of the underworked organic organics, and dry steam can be toxic and carcinogenic.

Open heater (second left in Fig.) Safe, but long heats up. To bathe with the "Nadach", the furnace need to trample all the time, so it was created to go to the pre-banker: the avgar is especially dangerous at high air temperature. Fighting too much, the Kamenka can be taken at all, and the whole sauna will go to the pump.

The third left oven with a side closed heater is perfect: the bunker with stones is washed by hot gases from all sides, except for the front, therefore the Kamenka and heats up faster, and you can take it more. But the most perfect bath oven is a cap, extreme right. The Kamenka is arranged on the coat of the cap, the temperature under which is very high, there is the main floor of the heat dissipation, and there is nowhere to go to this warmth except in stones. Therefore, the Kamenka warms up in minutes and you can take almost without restrictions. It is not necessary to pour the furnace, the "Cap" itself will select myself a mode looking at heat consumption, if only fuel in the firebox was.

This furnace has 3 disadvantages. First, the overall complexity and high cost, like in caps in general. Secondly, the cap from the usual steel quickly roars, and from heat-resistant roads. Finally, you can only go to the chair of this furnace only from the built-in soul, and I will not refuel it.

Flowing furnaces

Flowing furnaces do not have convectors, but with a fire in a pipe or cave, they only have external similarities. Flowing furnaces can be very effective. The most popular species are the English fireplace and the Russian oven.

Fireplace

The scheme of the structure is shown in Fig. To obtain the maximum efficiency, comparable to the DOLLECA efficiency, the fireplace firebox must be pressed back from all sides to the right in Fig.

The main proportions of the fireplace are as follows:

- The portal area is 2% of the room area.

- The height of the portal - from 2/3 to 3/4 of its width.

- The area of \u200b\u200bthe erection is 1.5-1.8% of the area of \u200b\u200bthe room.

- The area of \u200b\u200bthe fuel is 70% of the portal area.

- The depth of the fifthly - 1/2 2-2 / 3 of the height of the fiber opening.

- The ohow of the rear wall of the fuel is - on 1/3 of its height.

- The angle of inclination of the "mirror" of the back wall - 20-22 degrees from the vertical.

- The angle of convergence of the side walls is 45-60 degrees, i.e. 22.5-30 degrees per each.

- If the fireplace is with a deaf bottom, then its rise is back - 4-7 degrees.

- The height of the podium above the floor is about 50 cm.

- Spectacle area of \u200b\u200bchimney - 7-13% of the field of firebox. A smaller value refers to a round chimney, more to a rectangular with 1: 2 sides. For chimney square section - 10%

Russian oven.

(Fig. But the design of the Russian oven is very conservative, to make changes to it, not risking to spoil the oven, can only a cook with extensive experience in Russian furnaces.

From the point of view of construction mechanics, the Russian oven is also a mansion. It is not a solid working as one, the module (hollow column, wall), but almost a complete analog of the building: a connected construction, parts of which interact through the angles. Therefore, the angles of the Russian oven need to post all the rules. Records in order is not enough, you need to constantly recover in a plunder. The key points of the masonry of the Russian furnace shows the markup.

Preliminary calculation of the furnace

Before choosing a furnace project, it is necessary to do its preliminary calculation. It is usually carried out on the basis of the heat transfer furnace in the kcal / hour. In the process of cooling the furnace, the heat transfer is reduced, but also the loss of heat is falling, because It also cools. The task of calculation is to withstand the temperature in the room until the next furnace.

This calculation is theoretically complicated, and on ready-made coefficients and simplified formulas requires greater experience. But for homes with good outer insulation, quite reliable results gives the proposed by I. V. Kuznetsov method for calculating the averaged thermal power unit of the furnace surface (TMEP). For normal firebox, it is possible to take 0.5 kW / sq. m, and for overgrowths in a heavy frost - up to 0.76 kW / sq. m for 2 weeks.

Using the TMEP, the capeful calculation of the furnace becomes completely simple. Suppose we have a furnace 1.5x1.5 m in the plan and a height of 2.5 m. The area of \u200b\u200bits walls is 3.75x4 \u003d 15 square meters. m, plus 2.25 square meters. m overlap. Only 17.5 square meters. m. Pay this furnace from 8.75 to 13.3 kW of heat. Taking into account the features of the chimney heating, this is enough for a house of 80-100 square meters. m.

Flak

To calculate the firebox, you must first determine the maximum fuel bookmark. It is found along the required thermal power, the calorific value of fuel, its specific weight and the intended KPD of the furnace. The calculation is carried out for all types of fuel for which the oven is intended, and choose the largest value. The volume of the fuel chamber of the furnace (combustion chambers) is charged 2-3 times more than the maximum volume of the fuel mass, calculated on the passage. In general, the maximum load of fuel into the combustion chamber is 2/3 of its volume.

The full calculation of the fireboxes - the lot is not lovers and even far from any heat engineer. Take at least such a "trifle" as a grate grille. She misses too much air - fuel will burn faster than the body of the furnace will take it warm, the residue will fly into the pipe. Little air - fuel to burn completely, and unrequided heat again in the pipe with smoke. And soot, and ash, scoring coopers? And all this needs to be linked to other, no less significant hubs of the furnace, and for different types of fuel.

Fortunately, there are now on sale there are many finished furnaces for different thermal power, under different fuel, with a deaf or transparent, for fireplaces, created. And the finished firebox will be cheaper than any self-made. It is only necessary when choosing to pay attention to the following:

- The size of the furnace and its fasteners (pins, mustache) must be consistent with the size of the brick. Chimney bricks are available multiple sizes (see below), and the same firebox can be on sale of several modifications for different bricks.

- For a furnace of long-term use, the furnace must be taken cast iron. Welded from sheet - for furnaces used episodically.

- It is also necessary to pay attention to the depth of the narrowing of the combustion chamber to the grinders - the ash mine, the ash well, or just the ash bar.

Let's explain the last item. If the furnace is predominantly high-calorie minor fuel in large slices (stone coal, peat), then the roller need to take deeper, to 1/3 of the height of the combustion chamber. In the small ashnik, such fuel too quickly prohibit. If the oven is under low-calorie wood fuel, including pellets, the depth of the ashtar should be no more than 1/5 height of the combustion chamber, otherwise the bottom of the fuel mass will quickly break ash, the air flow will decrease, and the fuel will not do the fuel.

As you can see, the plug of the depth of the ashbar is large. Therefore, it is better to overpay and take multi-fuel furnace. In such complete combustion of all fuels listed in the certificate are provided by special structural measures.

Note: raw firewood can be completely burned in a deep ash splash, and coal - on the smooth hill, correctly choosing the magnitude of the fuel laying. But this requires the experience of an expiratory and intermediate subtopers with shining that night is not suitable at night.

Chimney

The calculation of the chimney is a separate topic, hardly more complicated than the calculation of the entire furnace. Even the computer accounts for 2-3 times to restart the CAD, manually adjusting the initial data before everything does not happen. But for conventional conditions (the cross section is rectangular, the stroke vertical without fractures, the height of the mouth of the chimney over the grate 4-12 m) can be immediately given the finished values \u200b\u200bof the transverse dimensions for furnaces of different power:

- Up to 3.50 kW - 140 × 140 mm.

- From 3.50 to 5.20 kW - 140 × 200 mm.

- 5.20-7.20 kW - 140 × 270 mm.

- 7,20-10.5 kW - 200х200 mm.

- 10.5-14 kW - 200x270 mm.

These values \u200b\u200bare minimal. They are designed to avoid the "priceist" when the cold air is counted in the oven for too wide chimney. "Consistency" is fraught not only by heat loss, but also a lot of other serious trouble.

If the oven in the chimney chosen by the chimney smoke at least occasionally, it should be increasing, just 0.25-0.5 m. Once upon a time, for this, the protruding bucket turned to the pipe, now you can put a piece of asbotic pipe with a cross section not less than in chimney.

But the best way is not to be lazy and put another 2-4 row of bricks, not forgetting to make a new flush. Have you ever seen a pipe with two otters? This means that the initially short chimney according to the results of the proturters increased to the norm.

Note: increasing the pipe is often accounted for when the aerodynamics of the area changes. Let's say the forest around the rose or high-rise buildings set up.

Chimney materials and appliances

Brick

In sources are often confused with refractory chamoten. In general, they only have dimensions: if the single building bricks are 250x125x65 mm, then the oven 230x114x40 mm (standard) or, sometimes, 230x114x65 mm. In general, the chimney brick is a high-quality red M150. From it, it is entirely to build a Dutch and a Russian oven. In heat resistance (up to 800 degrees), he would go to the fireplace, but absorbing little heat and quickly cools, so only for the fireplace of the summer cottage, in which only admire.

Note: the dimensions of the furnace brick have developed historically in the old days so that anyone can distinguish it from the construction. The firing brick then cost large works and expenses, there was no concrete, and the field of good clay was rare. Therefore, the then wandering burns often halted, launching a weakly burned brick from unimportant clay.

Chamotte brick goes to the masonry of the furnaces of furnaces with a sufficiently stressful thermal regime: Swedish, baths, caps. The main dignity for household furnaces is not a heat resistance, 1600 degrees in household furnaces does not happen. It is more important here a large thermal conductivity of a chamot in combination with high heat capacity: chammed laying is an excellent heat accelerator.

Due to the large thermal conductivity, it is impossible to build a furnace entirely from the chamota: it will be unacceptable at first, and then too quickly gives it warmly radiation. Outside, the chamotte masonry should be covered with ceramic, at least in the Pollipich.

To judge the quality of chamotte brick only in the depth of his color is not entirely correct, because Chamotte clay from different deposits is very different outwardly. Almost black brick can be bad, but light yellow - excellent. The main sign of quality is a fine-grained structure without a variety of visible pores and inclusions (on the left above in fig; next to suspicious). The next stage of checking is the climbing light hammer. A good brick gives a ringing or clear ripple sound, and a bad - deaf stretched. Finally, if the knock really did not clarify anything, check on the scope, or, in modern, the crash test is carried out: the brick is broken or dropped from height on the solid floor. A good brick and spikes are good, it splits on large pieces with a grainy break. Bad gives more dust and crumbs than large fragments.

The sides of chamotte brick are called the same as construction, this is also shown in Fig. Like the construction, Shamot is in the case of full, in 3/4 lengths (three-rigs), halves and quarters. As they are designated in laying schemes, shown in Fig. Left below.

For the masonry of the internal responsible parts of household furnaces, clinker brick is well suited, or just a clinker (right in Fig.) It is the same ceramic brick, burned at high temperature. The view of him is non-fried, but the strength and heat resistance are increased. There is a clinker somewhat more expensive than ordinary red brick, but the chamot is significantly cheaper.

Note: Silicate brick on any parts of the furnaces is unsuitable absolutely. On the clay solution, it does not hold, and from the signage heat loads pulls moisture as a sponge.

Sand

Sand into a solution for laying furnaces requires special consideration. For a furnace designed for more than 10 years of regular use without repair, mountain sand is needed without inclusions. In other types, too many organic organic, due to which the laying seams are sharpening over time and crack.

Pure mountain sand roads. But the main thing is now on sale there is generally the perfect replacement: clay sand for ceramic masonry and chamoten for chamotte. Do not be surprised by the phrase "clay sand", it, like a chamoten, the ground battle of the corresponding brick species. Brick sand most often turns out to be cheaper than good mountain, and the laying on the solution with it is exceptional quality.

Masonry solutions

For masonry brick furnaces apply. Recipes know a lot, we give the simplest and high-quality. For the chamot, you need a chamotte mergel or white kaolin. For ceramic brick - any refractory threshing clay; Best of all Gray kaolin, blue or gray Cambrian. And in that, in another case, 100 pcs. Bricks will need 40 kg of clay.

When buying immediately check the clay on the smell: any clearly tangible, pleasant or unpleasant, indicates the impurities of the organicists, for the masonry of the furnace, this clay is not suitable. Next, it is necessary to determine the necessary stake of sand in the solution, because The clay of different fields of one quality has different fat content - a combination of adhesive ability with viscosity. It takes 0.5-1 kg of clay powder on the sample, poured with water in the dishes to the top of the backfill and give a day to cry, gain moisture. Chamotted Mergel completely pops in 1-2 hours, the overexposure is not terrible.

Thinning clay, adding a little water, was mixed up to the consistency of a very thick dough or plasticine. Then the chambers are separated on 5 parts and sand: 10%, 25%, 50%, 75% and 100% by volume. All samples are carefully, until complete homogeneity, again smear and dried 3-4 hours.

Now the samples are rolled into the sausages with a diameter of 1-1.5 cm, a length of at least 30 cm. Each sausage is turned around around any round item with a diameter of about 5 cm and look the result:

- The solution for a sample that is easy to absolutely without cracks is suitable for any furnace, including the fuel part.

- The frying crust was broken by forming a grid of small cracks - the solution is also suitable for all furnaces, incl. For the relief of Russian and the furnaces of Dutch.

- The cracks were departed by 1-2 mm - the solution is suitable for the parts of the furnace, heated not higher than 300 degrees, for the barbecue and the country fireplace.

- Deep cracks, foes, breaks - sand too much, the solution is not suitable.

The main meaning of the sample for the proportion of sand is to reduce the maintenance: brick sand is much cheaper than high-quality clay. Accordingly, the more it goes into the solution, the more it will be cheaper.

Note: this test is suitable only for the solution on the brick sand. For solutions on natural sand, other samples are used.

The working solution is prepared on the same principle as the sample, but already in the required volume:

- Clay soaked a day; Chamotted Mergel - hour.

- Mix the mass to the dough.

- Wipe through a sieve 3x3 mm.

- Add sand according to the results of the sample.

- By adding a little water, they smeared sour cream.

- Check the fat content of the solution in the usual way, for wetting the Kelma.

- If necessary, clay or sand are added (very little!), Smear and proceed to the masonry.

Note: on average, 3-4 buckets of the finished solution take place from the selling packaging of clay.

Oven

The furnaces (doors, valves) are attached to the body of a furnace either by a mustache on the seams of masonry (on the left in Fig.), Or the heat-resistant steel skirt, wrapped before installing a 5-mm asbestos cord, right there. The first, is understandable, cheaper, but for worked out the furnaces, ovens and heat dampers are not suitable: during the furnace service, they have to change several times, and break the masonry, pulling the mustache from the seams, badly. And, of course, the installation dimensions of the devices must be consistent with the size of the bricks, taking into account the thickness of the seam.

Laying and dressing

Brickwork is spoonful and twitch, depending on which side of the brick looks outward. Bricks are stacked by bed. "Bed" masonry, when bricks put on a margin or spoons, it is extremely fragile and a snip is prohibited, but in exceptional cases it is used for the external finishing of unloaded structures.

The masonry is led by dressing seams, i.e. Seams of individual bricks should have a dissemination (offset) in a row of masonry (in one or two directions horizontally) and between rows (vertically). In unsecured masonry, any microcrack, which cannot be avoided, will inevitably crawl further, destroying the design.

The methods of dressing seams are known only in construction are dozens, and they also have to change them in the bary to lay out complex smoke. However, check the finished furnace project either designed independently can be guided by simple principles:

- The masonry begins and ends with tiley rows.

- Any brick should be relying at least 2 others.

- Bricks of neighboring rows should be overlapped at least 1/4 in length or width.

- All vertical seams must be filled with mortar, otherwise the masonry will decrease on vertical layers.

- Vertical seams of tychk and spoon rows should not coincide.

- Protruding thresholds, areas under beams and liners must be tiley.

- Substainable parts of bricks should not appear out. Exception - bricks treated with a grinder with a diamond circle.

The normal width of the seam when laying the furnace - 3 mm, minimal - 2 mm. Permissible broadening up to 5 mm; At the subtopic rows and in the arch - up to 13 mm. In places of conjugation of chamotte and ceramic masonry and around inserts from any other material (furnace devices, concrete beams, pins under the cooking surface, etc.) The masonry is carried out with a seam of maximum width - 5 mm. Colonsets are stacked in the nest on the surface of the furnace to dry so that they can be removed for cleaning.

All rows of laying must be tied up vertically. In the extensive internal spaces of the rows, an incomplete tissue is allowed to row (see Fig.), Or the laying by the method of forceding, i.e. Filling them with bricks without dressing. Dressing between similar rows (for example, underlying) is convenient to make a mirror reflection method, like the intake poles are laid out, on the right in Fig.

Convector and shield laying

When laying partitions of convectors, it is necessary to leave the overlap windows at the top (passes) and at the bottom (flow). There are no problems with passages - not enough to report 2-3 bricks, and that's it. But the flow is so impossible, it turns out a hanging wall. Partitions above the flows are laid out, as shown in Fig. Supports from the chokes alternate through 3-5 rows. The windows of a spoonful row near the chips are closed with halves of bricks.

The walls of the furnace convector are laid out at its order, and the walls of the heating pad - spoons with a simple spoofing dressing. Its walls for the walls in the Polkirpich, in the brick and a half of the brick are shown on the trail. Fig. The latter uses the bandage to the method of mirror reflection.

Laying archives

In household furnaces, semi-curvous (as part of the cylinder) and flat vaults are used, see Fig. below. In the best Russian furnaces, very experienced cooks sometimes make a corner of the oval four-centrov, and in Pompiana furnaces, the arch is domed, but also the other requires high mastery and experience. In the mechanically slightly loaded chicken semi-curvous arch, the extreme stones of the wings - heels - and the central stone - the lock - do not differ from others.

The semi-curvous arch is laid out in the following order:

- Prepare drawing of the arch on the scale of 1: 1.

- According to him, the scales are pianked - bricks, which will be relying the wings of the arch.

- Putting the scales and masonry of the furnace interrupt until complete drying of the solution.

- In templates - circles - lay the wings of the arch, observing the dressing between the rows.

- Abundantly apply a solution in the groove of the lock and insert the castle stones into it in turns, inserting a wooden sledgehammer or polen. A sign of properly completed masonry will be uniform extrusion of the solution from seams on wings.

- It is waiting for a complete drying of the solution in the arch, cleaned circles, continue the masonry of the furnace.

Vertical locks of the castle should not coincide with the seams on the wings. For this, at the stage of drawing, the wings must be performed in the mirror reflection, and not a simple shift of one to the other side. The maximum discrepancy of bricks in the arch - 17 degrees. With standard size bricks, internal seam in 2 mm external 13 mm, this angle will be set aside.

The flat arch is laid out on a flat pan instead of circling from the shaped bricks, ready-made purchased or independently manufactured. The laying technology is the same, but consider - the flat arch does not tolerate the slightest asymmetry! A little shifted the whole to the side - it goes to collapse by itself. Therefore, the flat arch, even experienced masters are laid out of the shaped bricks along the template pattern.

How much do you need bricks?

What is the number of bricks on the oven? After all, the amount of solution is tied to it and, consequently, the main costs of building.

Sometime, the number of bricks was considered by empirical coefficients for typical projects. The method gave up to 15% of the battle (and on theft), which at the current prices is unacceptable.

Now the furnaces are calculated in computer systems of automated design (CAPR). The program immediately gives out how many fulfillment, dolly and shaped bricks need. But, since the houses are not built at home or the roasting furnace for the plant, and the Mastering of the CAD requires considerable work, time and special knowledge, then the home owl does not have anything other than just count the bricks in the furnace's friend. It will take it for the middle house stove hour-and-and-and-and-and-and-a half, but, believed carefully, you can reduce the fight to 2-3%

Note: A propulsion indicating the number of bricks, other materials and a complete list of devices with the indication of their type and variety, is required to the properly executed furnace project.

Tool

The tool for furnace work is generally the same as for other masonry (see Fig. Below): Hammer-Kirchka (training) with a wedge in the form of a wedge on the bricks of bricks, Kelma (trowel), cutting for convex and concave seams, dissolved shovel. But order is necessarily added. In this case, this is not a laying scheme, separated by its ranks, but a tool for checking its correctness.

The fact is that the laying of the furnace with uneven stones in the thickness of the seams soon cracks from temperature deformations. On the other hand, the laying on the clay will dry for a long time, not less than a week, and even dried seams can be twisted and rebuilt the design.

The order-tool (right in Fig.) - A flat wooden slack 50x50 mm, on the sides of which the numbers are applied for different types of bricks, taking into account the thickness of the seam. The furnace needs at least 4 coaches, and one for each additional angle, internal or external. Enjoy friends as follows:

- Podputy rows are laying out in the formwork.

- The corners are fixed by coaches, 2 brackets with pointed ends each. Staples are pressed in laying seams.

- The cozers are fascinated to the coaches, according to which the masonry leads. For the Russian oven, the corners are additionally imposed by plumbing.

- As the top bracket is calculated, shaking, remove from the seam and insert into the next one.

- Holes from the bracket in the previous seam are sealed with a masonry solution.

Working principles

In all sorrows, mechanical ties are relatively weak, and the loads are high. Therefore, "Brick on a brick - Goney, grandmother, Mogorch!" It does not take place unequivocally. The furnace has not yet been brought to the blockers, as described in Makarenko in the Pedagogical Poem. When laying the furnace, the following rules must be observed:

- Bricks are put only one by one. The newcomers are preferably postponed to put on dry, align, and then put stones for the solution.

- Each brick before laying Schwawruts (not to be confused with shabby!): Thoroughly clean from crumbs and dust with a hair brush.

- Ceramic brick for a second or two dip in clean water and shook well, then he immediately sticks to the solution.

- Shamotny brick do not "bathe" in no way!

- Apply a layer of solution exactly in 3 mM Kelma is difficult, so experienced masters are applied with a solution with hand. But this also requires a certain skill.

- Brick put in place in one movement, it is impossible to fit and tidy!

- If the stone does not immediately lie as it should, it is removed, it is cleaned with a solution with a brick and his bed and put it again.

- The removed solution is thrown into, it is no longer suitable!

Examples of structures

For example, consider a pair of structures from which you can start moving from theory to practice. In fig. - Scheme and order of the simplest brick furnace: a hob that does not require the foundation. It will take no more than 130 ordinary red bricks, given the fight from the hands of a novice master. It is possible to build a U- or W-shaped DHW heat exchanger with a cumulative tank from a metal tap, can be built into the chimney output (marked in red.).

Despite the simplicity and small sizes, the heat transfer of this stove is about 650 kcal / hour, which allows you to skip flue gases through a heating flap heating 20-25 kV. m. Living Square. The cooking surface of standard size 1 is laid free on the mustache 2 of 3-4 mm steel laced in the seam between 11 and 12 rows of masonry. Its thickness - 6 mm.

On the trail. Fig. - a small friend with a single-mounted hob. It is also performed from the simple red brick M150. They are taking into account the amateur battle will be needed 270-280 pcs.

The cast iron stove lies freely on the mustache, as in the previous stove. It can be removed and insert a rushper for a barbecue into her nest for a barbecue, or put skewers with kebabs on the opening. With an open (or transparent) coaching door oven turns into a fireplace.

It is no longer impossible to put this furnace on the floor, it is too high and narrow. But on the soils with sufficient carrier ability (loam, soup, forest land, etc. "Country" soils) The foundation for it can be a solid slab on a sandy-rubble pillow, as for a barbecue heart.

Video: An example of laying a simple brick oven

The most important principle

Finally, we will give the most important principle of construction of brick household furnaces: the furnace and the house are closely interconnected, they can be friends and enormous. Perform the stove with the house is very simple: any of them will show all their advantages only in a good, well instended house.

The construction of a brick furnace - the process is quite complex and time consuming. You can build it with your own hands, but in this case you should be extremely attentive and accurately observe the climbing scheme of bricks (order). If for you, this is the first masonry of a brick furnace with your own hands, it is better to get a detailed consultation of a specialist or lay the oven under his leadership.

Choosing a brick oven

In large private houses and cottages for heating, boilers with water heating are most often used. For the heating of the same buildings with 2-3 residential premises, it is enough to build a brick oven. It is not only much longer kept warm, but also creates a special microclimate indoors and can become a real decoration of the house. However, a brick oven has a significant disadvantage: this construction is very overall and takes too much space.There are several types of brick stoves:

in the ranking of such structures swede Honored ranks first; It is compact, has a cooking panel and equipped three-channel shield (heat exchanger that allows for a long time to maintain heat in the form of a wall with chimneys inside, can simultaneously perform the role of the carrier wall or located separately); their varieties include the designs of Kuznetsov, Buslaev, etc.;

Exterior view of the Swedish furnace and the construction of a wall with a three-channel shield

Despite its name dutch oven from vertical chimneys (channels in which heat remains and on which the smoke is derived) was invented by Russian masters; has high heat transfer; Usually has 2 channels: summer and winter, which simplify the extracts after a long break; In classical versions, the cooking panel is not provided, but there are variations of furnaces with an integrated fireplace and a hob;

Classical Dutch stove with vertical chims

Chimneys with vertical (like the Dutch) and the horizontal location of the channels

Russian oven. Hold heat for a very long time: up to 2-3 days; It has a gas threshold (the wall between the chamber and the mouth of the furnace); It warms it for a very long time, and there is plenty of space, its size is such that several people can simultaneously fit on her lament; That is why in recent years, such structures are rarely applied.

Russian stove

Through the walls of the walls All furnaces are divided into:

Thin-walled: in one brick, ideal option for country buildings;

Tolstown: Earls in rooms designed for permanent residence, long stored heat;

Combined: Thick walls are laid out only in the fuel cell; The chimney has thin walls.

Same and two-kip furnaces Kuznetsova is one of the most common variations of the Swedish furnace. In contrast to ordinary channelThe yield of hot gases in chimels is carried out not only by traction, but also naturally due to the special design of smoke channels. Smoke in them at first rises up, and when cooled downs down. Since the heat leaks in them are significantly smaller (after all, warm air, until it cools, can not find output), such furnaces are able to store heat for a long time.

Scheme of the cap chimney

The brick oven may not have finishes or watrated with a metal, plastering, put out the ceramic tiles or a facing stone or fit under the extension (with sealing and giving the seams of a special form).

Fishing stove seams

Preparation options

Do you need a foundation for the furnace?

Brick is a rather heavy material. The weight of a folded furnace can reach 8-10 tons, so the foundation for the furnace is needed solid. Otherwise, due to the movements in the ground and its expansion during the freezing, cracks may form or it can completely collapse. Sometimes for a more uniform shrinkage in the house there are several furnaces or fireplaces in the house, separate bases are made not only for them, but also for the root (located in a separate section) of the chimney.

Foundation for the furnace

Since the dummon drawdown under the furnace and the house will be different, the foundation for such a design should be erected separately from the base of the structure itself. Between the main and furnace foundations is necessarily a gap of 50 mm, which is filled with sand.

If the furnace is built in the already constructed building, it is allowed to install a structure weighing up to 1200 kg (300-350 bricks) on the overlap panel. On the wooden floor, it is permissible to build structures up to 700 kg.

Better for a massive heating furnace is concrete. For cement M400, the ratio of cement, sand and rubble will be 1: 3: 5. When using the M250 brand, the proportions change: 1: 2: 4. The depth of the mixing of the concrete pillow depends on the weight of the furnace, the density of the soil and the depth of the soil. In each region of Russia, it will be different (see photo).

Depth of soil freezing

1. The foundation should speak from the edges of the furnace in each side of the brick (10-15 cm). At the firebox, this distance can be slightly large - up to 30 cm.

2. The bottom prepared for the foundation is trambed. Then the layer of waterproofing is placed on it.

3. A 10-centimeter cushion from crushed stone and 15 cm of boob stone is falling asleep before laying a solution in the recovery. All free space between the stones is also filled with rubble and poured with a solution.

5. In order for the solution in the process of drying, it is filled with the layers, it should be no less than a day.

6. After removal of the formwork, the formed gaps are filled with sand, shed water and thoroughly tram.

Bookmark Foundation for the Furnace at the Stage Study of the Building

Important! It should be erected only after complete soloing of the solution. The foundation is gaining 50% of the strength in 15 days. Final consolidation occurs only in 28 days.

Tools for masonry

To work will be required:Kelma for scamping and laying the solution; most convenient to work a tool with a slightly shifted by a handle;

Kirk or Hammer - Kirk: For the Test of Incompact Bricks;

Bulgarian with a diamond disk for sawing them on halves and quarters;

Molding with a rubber tip for bricks picking in laying;

Twisted moor cord;

Plumb to check vertical surfaces;

Building level;

The coal to which the corners will be recovered;

Roulette.

Furnace Masonry Tools

For alignment of walls and angles, you can use the cord-moor and metal corner.

Masonry solution

The cement mixture under the action of high temperatures is quickly cracking, so it is used to lay out furnaces only clay-sandy solution. For a device, a limestone or lime-cement solution is used for the device under the attic. The cement-sandy mixture is used only for masonry pipes above the roof.The ratio of clay and sainted sand is experimentally selected. It depends on the type of clay. Most often mixtures 1: 2 or 1: 3. And the fatty clay, the less should be in solution. Initially, the clay is soaked, filter through the sieve, and only then add sand.

The solution must have a consistency of sufficiently thick sour cream. It is possible to determine the viscosity of the mixture as follows. Wooden stick or trowel lowered into the solution and shake. If it remains a layer of less than 2 mm thick, clay is added, more than 3 mm - sand is added. Too fatty solution will lead to cracking of the seam of masonry, with a lack of clay, sand from the seams will be poured.

Secrets of brick masonry

Baking better lay out fireproof chamotte bricks. To save funds, you can put it only to the furnace, for the rest of the furnace, use the usual silicate. However, combine them in one bundle, as well as bricks from different manufacturers, it is not recommended: at temperature drops, their extension will be different, so such a furnace can "lead". Effect hollow brick for masonry is not used.

Views, sizes and weight of bricks

1. For the device furnaces, the furnaces are used: detailed schemes in which the process of masonry of each row is indicated. The location in the furnace chamotte refractory brick in such schemes is indicated by hatching or highlighted by color. Change the order without the need is urgently not recommended: deviations in the scheme can lead to narrowing channels of flue moves.

Laying chamotte for firebox and chimneys and silicate bricks

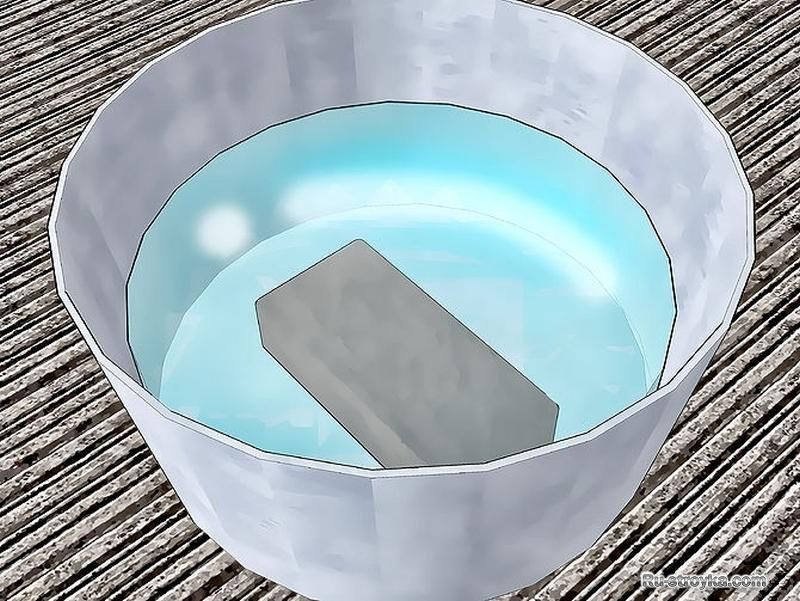

2. Before laying bricks on the basis of 2 layers waterproofing: Tol or rubberoids impregnated with mastic. To protect the solution from dehydration, the brick is pre-for a couple of minutes soaked in water.

3. The first of its number is laid out dry without a solution. Next, the statement is conducted with overlapping junctions previous series. Each seam should be completely filled with a solution, without voids and shells.

4. Laying of the row is made from the corners (see photo). After that, between two angular bricks, a report is made of the entire row.

Laying row

5. Each row is checked by a building level for compliance with horizontal and vertical.

6. In order to avoid errors, the number first is laid out without a solution. Then the sequence number of each of the bricks is signed with chalk, they are removed and started fine laying. Not only horizontal, but all vertical seams with a layer of 3-5 mm are missing.

Important! When laying chimneys should not use halves and a quarter of bricks. In case of their loss, get them from the chimney will be problematic. Use parts of bricks better in the top rows of facilities.

7. The cooktop and the grate is laid with a gap of 5 mm to compensate for temperature expansion.

8. Fire doors and pondered insulated asbestos and are additionally attached to the wire, which is laid in the laying seams. For its attachment in the cast-iron frame, special holes are required.

Fastening the door of the furnace

9. The walls of the chimney must be perfectly smooth and smooth. Say lumps will accumulate in the joints and chips of bricks, so only perfectly smooth bricks without defects are used to arrange smoke moves. The residues of the solution in such places should immediately be climbing climber or rag.

10. If the pipe is erected, a plot passing through an attic overlap. The walls in this place increase so that their width exceed 38 cm, while the chimney cross-section remained unchanged.

At the following schemes provided order Little Furnace-Swedets with 570 bricks with a cookbook. For the device such a furnace will also be needed:

Cast iron plate with two burners;

Cast iron doors for firebox and devices pondered;

3 Clean soot removal doors;

2 valves;

Metal oven;

Corner

Steel band for the overlap device over a cooking recess.

Video: Laying a brick furnace with their own hands

Despite the fact that in very many today are those or other heating systems, brick heating structures do not lose their popularity. On the contrary, engineers and folk crafts are being developed by all new furnace models, more compact, including various functions. Indeed, the furnace heating will never be superfluous for a private house, as it will be able to rescue the owners in different situations. For example, in the fall or in the spring, when the nights are cold, but it seems to include autonomous heating, the drowning oven will create a cozy atmosphere in the rooms and relieve them from excessive humidity. The oven will help maintain the optimally favorable atmosphere and the temperature balance, comfortable for a person.

Therefore, a search query about how to fold the oven with your own hands the drawings of which will tell in detail about the correct sequence of masonry work, does not come down from the pages of the Internet. Today, even those people who do not have the experience of the liver, show the desire to try their strength in this craft. If it is decided to install the furnace in the house with its own forces, then beginners it is recommended to choose a simple version of this facility with an understandable order.

In addition to the availability of the design, when choosing, you should pay attention to its heat capacity, that is, it is designed for heating. It is important to take into account the functionality of the structure and decide what I would like to get from it.

Varieties of brick stoves

There are several main types of furnaces - some of them perform only one main task - this is heated at home, others are used only for cooking, and the third includes several functions in their "set of features". Therefore, in order to decide on the desired model, you need to know what is each of the species.

- The construction is capable of not only to warm one or two rooms, but also help cook food and boil the water. If the model is equipped with a brass cabinet and drying niche, then the possibility of bake bread appears, and peel vegetables and fruits for the winter.

The heating and cooking furnace is often embedded in the wall or itself performs the role of the wall - for this it is rotated by a slab and a firebox in the direction of the kitchen, and the back wall in the residential area of \u200b\u200bthe house. You can solve two problems immediately - the heating of the premises and the possibility of cooking in a separate room.

If the design is additionally equipped with a fireplace, the furnace will work not only as a functional structure, but it will become a decorative decoration of the house.

- The heating variety of furnaces is designed only for the heating of the rooms at home. Some models have not only a fiber chamber, but also a fireplace. Thus, the furnace can function in two modes - when only one of the functions is used, or they are involved both simultaneously. Most often, the heating stoves are embedded in the wall between the rooms or are installed in the middle of one large hall, separating it into zones.

Such a building is being built for both the main heating of the house and as an additional, which is used in the spring and autumn period to maintain normal temperature and humidity in the rooms. The heating furnaces are usually established when the kitchen has already implemented its ability to prepare food, or in a large total area of \u200b\u200bthe house, where several furnaces perform various functions.

In the country area in a small house, it is better to establish a multifunctional structure that can help immediately in several situations.

- The cooking furnace is erected in the kitchen, and its design is designed for quick cooking. However, this function does not deprive it and heating capabilities, since its entire body, the rear wall and the cast iron stove are well warmed, giving heat and room.

The main function of this stove - cooking

The main function of this stove - cooking The cooking furnace is usually compact, so it is perfect for installing it in the country or in a small kitchen of a private house.

Having such a compact, but functional unit, one can exclude the risk to frozen or remain without dinner and hot tea, even if the electro- and gas supply is turned off.

A lot of different models of all listed types of furnaces have been developed. They can be completely miniature, and occupy a large area. Therefore, stopping at one of the models before stocking materials for its construction, you need to measure and draw it the base on the floor of the room in which it is planned to install it. Thus, it will be possible to visually determine how much the free space will remain in the room.

How to choose the right place to install the furnace?

So that the furnace worked effectively and maximally gave heat into the premises of the house, and was also a fireproof, it is necessary to choose the right location for it.

It is especially important to think about this moment if the furnace is embedded in the finished building, since the chimney pipe must pass between the ceiling overlap beams, and accidentally do not stumble upon them, so the installation option must be calculated as accurately as possible.

The furnace brick structure can be installed in different places of the room or between two rooms. What place it is better to choose - will be considered further.

- To get the maximum effect from the furnace, you should not install it near the outer wall of the building, as it will cool quickly and can hardly be able to heat more than one room.

- Some stove models are installed in the center of the room or shifting it from it in one or the other side. This location is selected if the room is required to divide into separate zones. Moreover, different sides of the furnace structure can have a different decorative finish, made in the style corresponding to the design of a particular area of \u200b\u200bthe room.

- Quite often, the furnace is built into the wall between two or even three rooms, which makes it possible to use the heat generated as efficiently as possible. In this case, for the purpose of fire safety, it is very important to provide reliable insulation of the walls, the ceiling and the attic overlap at the location of the passage

- When choosing a place of installation, it is necessary to envisage that each of the sides of the foundation under the furnace should be 100 ÷ 150 mm more than the base of the furnace itself.

- To accurately determine the size of the base and height of the furnace, it is recommended to always select the model to which the order scheme is applied.

By choosing and place for its installation, you can acquire all the necessary materials and prepare the necessary tools. The amount of materials will depend on the size and functional features of the furnace model, and masonry tools are always the same.

Tools required for masonry work

To work it will be necessary to prepare a very "solid" set of tools.

To work it will be necessary to prepare a very "solid" set of tools. From the tools for masonry brick and fill the foundation, you will need:

- Rule - This tool is used to align the surface of the basement with concumen.

- Kirk's hammer is necessary for splitting and trimming bricks.

- Veel is a wooden blade, which is used for rubbing the clay and lime solution.

- The furnace hammer is used to split the brick and removing the dried, speaking outside the masonry of the solution.

- Makeup made of urine is intended to clean the internal furnace channels from sand and solution in them.

- The lead drain is needed for marking in the event that the furnace is separated by tiles.

- The construction level is necessary to control the levels of rows and the surface of the walls.

- The diaper is the rod applied for marking.

- The plumb is a cord with a load, designed to check the verticality of the output surfaces.

- Building corner with a ruler to verify the correctness of external and internal angles, as they must be perfectly straight.

- Pliers are used to bend and bite the wire for fixing the cast-iron elements of the furnace in the seams of masonry.

- Raspil - This tool is used to remove the influx and wrecking lumps in the dried masonry.

- The chisel is used to split the brick and the parsing of old masonry.

- The rubber hammer is necessary for the alignment of the brick-labeled solution.

- (Trusks) of different sizes are used to apply a solution when laying bricks and removing the mixture speaking from seams.

- Fishing - a tool for aligning the solution in the seams of masonry. It is used if the laying is produced "under the extection", without further lining.

- Manual tamping will be required to seal the soil and layers of frustration in the pit for the foundation.

- Capacities for kneading the solution and pure water.

- Sieve with a metal mesh for sand sifting.

- Stand for the convenience of working at height, called "goats". The surface of this device has sufficient size not only for comfortable movement of the wizard, but also for the installation of a container filled with a solution.

Foundation arrangement for brick stove

The foundation for the furnace is usually preparing together with the foundation of the house, but they should not be in contact with each other, and even more so - to be combined into a single design. New foundations, as a rule, give a shrinkage that can lead to deformation of one of them, and this will pull the damage to the other. That is why they should be installed necessarily separately from each other.

In the event of an end of the oven in the already built house with a wooden floor, you will have to do a fairly large-scale work. In the place where the furnace will be installed, the floorboards will have to be removed, drinking the hole to the size of the future foundation.

If the foundation under the house is monolithic, and the selected furnace model is not too massive, then the design can be erected on it, the material for waterproofing is pre-installed.

The foundation should be in the form of the base of the furnace, however, as mentioned above, each of its parties is made greater than the furnace at 100 ÷ 150 mm.

- If the floor in the wooden house, it makes the markup on which the boards will be peeling.

- Then in the soil of the sample in the form of the future foundation rotates, the depth of which can vary from 450 to 700 mm, depending on the composition of the soil.

- The bottom of the pit is rambling, and its walls are lined with a polyethylene film or rubberoid.

- Then, a sand pillow is 100 ÷ 150 mm thick on the bottom, depending on the depth of the pit, and is well compacted with a manual tamper.

- The next layer, on top of the sand, is falling asleep rubbing, which, too, if possible, is rambling. This layer can be from 150 to 200 mm.

- Next, a wooden formwork in the form of a box is installed along the perimeter of the pit. Moreover, polyethylene or rubberoid remain inside it, and then fixed on the walls using a stapler and brackets. This waterproof material will keep the solution flooded into the formwork, not giving to leave it moisture, which will give the plate the opportunity to dry and harden evenly.

- The foundation should have a height of approximately 250 mm below the level of "clean" floor, that is, the finished base will need to put two rows of bricks so that it rises to the floor with the floor.

- Some wizards in order to save brick, on the contrary, raise the foundation above the floor by 80 ÷ 100 mm. The convenience of such a solution consists also in a simpler docking of the side walls of the foundation with the surface of the floor coating.

- The next step in the formwork, for its entire height, the reinforcement grille is installed, made of 4 ÷ 6 mm thick with a thickness of 4 ÷ 6 mm. The bars are associated with a wire twist.

- Further, in the lower part of the formwork, a rough concrete solution, mixed from cement and gravel, can be pouring into a thickness of 250 ÷ 300 mm in the proportions of 1: 3, or cement, rubble of the middle fraction with the addition of sand in a 1: 2 ratio: 1. But, In principle, a conventional concrete solution from sand and cement can be used.

- If the coarse mixture is poured down, then immediately, without waiting for its setting, the thinly mixed solution is laid on top.

- The flooded is aligned with the rule on the upper facets of the formwork boards, after which it is recommended to put and drown on 15 ÷ 20 mm into the solution of the reinforcing mesh with cells of 50 mm.

- The surface of the foundation is resurrected again, and, if necessary, a concrete solution is added to the formwork, on top of the grid.

- Further, the foundation leaves to stick and recruit strength - this process will take from three weeks to a month, depending on the thickness of the layer of the flooded solution. So that concrete is more durable, recommended daily during the first week, starting from the second day, spray it with water.

- From the top of the frozen foundation, waterproofing, consisting of two or three rubber carriad sheets, which are stacked by one to another.

- To start laying the first row, it is recommended to make marking on the waterproofing material, denoting the location of the base of the furnace. Due to the outlined perimeter of the base, it will be much easier to assemble the first row of bricks and observe the solidity of the parties and the corners.

After these preparatory work, you can go to the masonry.

Dry masonry

Even experienced masters, starting the laying unfamiliar to this design, first produce it dry, that is, without a solution. This process helps to figure out the intra channels of the furnace and do not make mistakes during the main masonry. Every majority rises dryly, each of the rows should be posted in accordance with the furnace applied to the model.

Performing dry masonry, it is necessary to observe the thickness of horizontal and vertical rows. In order for this parameter to withstand the same throughout the masonry, you can use 5 mm thick racks. Of course, the vertical seams will be difficult to measure with small segments of the ridges when drunk dry, so they will have to be determined visually, but for horizontal seams, the rails need to be used. Applying them, after laying out the last row of the design, you can see the real height of the furnace.

As an example of using the RESEK, you can consider this photo.

It is especially important to adhere to a single thickness of the seams if the masonry is performed under the extection, and will not be further separated by additional decorative materials.

Mastering dry, it is important to understand the channel configuration through which the smoke will go from the furnace, and climb the pipe. If, when laying out this passage, an error will be made, you will have to shift a part or even the entire design of the furnace, as the reverse thrust can be formed, and the room smoke will go.

Having lifted the oven dryly before the laying of the chimney pipe, the design disassemble. Moreover, if the ranks used not only as well, but also their small fragments, then when disassembling, each of the rows can be folded in a separate stack, putting a number of rows on one of the bricks. Sometimes, additionally, the brick number is also affixed in each of the ranks. Such a system will accelerate the work, since all the material will be fitted and decomposed in the right order, and will remain only to soak it alternately and put into the ranks of the furnace, but already per solution.

Performing basic masonry, two rails are installed on the edges of the previous series, between which the solution of 60 ÷ 70 mm thick is applied. Then the brick of the top row is put on it, aligns and embarrassment until it is stored in the rail. It is necessary to have such calibration devices into three rows, since it is possible to pull it out of the seam only after grapping the solution. So, laying out three rows, the rails pull out of the lowest seam, clean and laid on the fourth - and so on. If there is no confidence that the vertical seams are the same thickness, for them you can also prepare a short rail, which will be rearranged in the next seam immediately after aligning two adjacent bricks.