Examples of beautiful plastic wallpapers for walls

To date, building markets offer a large number. finishing materials For premises with such unfavorable conditions of the environment as sharp change temperatures and increased humidity. Having good properties are particularly popular, diverse color gamut and low cost plastic panels.

PVC wall panels can be applied as in the kitchen, in the bathroom and bathroom and in the corridor, on the balcony and loggia. Premises finishing options You can look at the photo.

The advantages of modern material

- Resistance to temperature drops and moisture effects.

- Easy to care: there will be enough surface just wipe with a damp cloth.

- Hygienicity.

- Easy installation: products are easily attached and for them you do not need to perfectly align the walls.

- Frost resistance.

- Ecology.

- Available cost.

- The ease of the product is provided at the expense of the cellular structure.

- The ability to install on any surfaces (wooden, brick, plastered).

- A variety of textures and colors of the material.

- Durability during operation due to the upper protective film of the product.

The protective layer of panels has many positive qualities, among which wear resistance, resistance to chemical preparations and impact ambient, antiseptic action.

Types of PVC wall panels with photos Examples

By the nature of the surface, the finishing material maybe matte, mirror, glossy. Wall mirrors (in the photo) are well bent and can be installed on uneven surfaces. Their minus is that they are unsuitable for bathrooms.

By the nature of the surface, the finishing material maybe matte, mirror, glossy. Wall mirrors (in the photo) are well bent and can be installed on uneven surfaces. Their minus is that they are unsuitable for bathrooms.

Plastic panels are three species.

Caption (photo).

- The products similar to the cladding are installed using the mounting brackets directly on the wall.

- To collect them, you can use the Schip-Paz technique.

- Plastic boardsMounted horizontally, visually make walls low and wide.

- Setting the panel vertically, you can get the effect of a high ceiling.

Leaf panels.

- In appearance, the product is similar to a piece of plywood with a pattern (see photo).

- Mounted sheets on the surface with nails or glue. The seams between them are closed with a rail or close by sealant.

- The material from plastic, having dimensions from one hundred and twenty to two hundred and three to six millimeters, is particularly popular with plastic sizes.

Panel under the tile.

- Products can be square shape or in the form of a mosaic (in the photo).

- When used, you can achieve an attractive aesthetic type of room.

- They are attached to the walls as well as robes. However, the effect of the result is completely different. The room decorated with such panels will look beautiful and cozy.

- Most often, products are used with dimensions from thirty centimeters to one meter.

Choose wall plastic panels

Not all products are equally high-quality, therefore choose panels follows carefully.

Not all products are equally high-quality, therefore choose panels follows carefully.

- Pay attention to the number of rigidity ribs that make material more durable.

- Choosing panels from PVC, their composition should be taken into account. The material must contain carbon, hydrogen and chlorine. Plastic products Move from bound lead, which is a stabilizer. When heated, such components do not distinguish harmful substances. In addition, plastic is well withstanding mechanical effects and does not burn.

- The surface of PVC panels should be smooth, not having damage and waves. Quality products will ensure the maximum attractiveness of surfaces.

- Painting panels must be uniform. It is recommended to purchase products from one batch.

- For a small room, it is best to choose a light color material.

- For spacious bathrooms, kitchens or loggias, you can pick up saturated dark colors. Finishing options can be viewed in the photo.

- If you wish to separate the bathroom with PVC panels with a pattern, it is necessary to choose products with an image applied by a thermocrying method. Such drawings are resistant to chemical and mechanical effects and are highly clarified. You can wash them using any detergents.

- When choosing, special attention is recommended to pay ornaments and panel protractions. When installing products indoors with high humidityEach irregularity and gap threatens the appearance of dirt and mold.

- Some plastic materials Can perform sound and heat insulating function. Choosing the panels, it also needs to be considered.

- Wide products from PVC are easy to implement. When they are used, less waste remains and there are few junctions on the surfaces.

Choosing a drawing and color of plastic wall panels, should not be afraid to experiment. This is dismantled construction material Easy enough. In the photo you can see the options for products with drawings.

Facing with PVC wall panels

To less waste, you should pick up optimal size Products in length.

To less waste, you should pick up optimal size Products in length.

Required materials and tools:

- panels;

- docking profiles (moldings);

- finish elements;

- plastic or metal profile;

- drill or perforator;

- marker;

- roulette;

- building level;

- extension;

- screwdriver;

- metal hacksaw.

Mount the products on the crate

Bathrooms used plastic or Metal Profile. The drying of the tree in the premises of high humidity does not apply, since over time the bar, which has absorbed moisture, is deformed.

Bathrooms used plastic or Metal Profile. The drying of the tree in the premises of high humidity does not apply, since over time the bar, which has absorbed moisture, is deformed.

- On the plastic profile Installation is made using clips.

- It is not recommended in the bathroom to install wall products from PVC horizontally. They will accumulate moisture.

- For sewer pipe It is recommended to install a box from an aluminum profile.

- The profile for the crate should be mounted perpendicular to the panels.

- Moldings are installed on the finished crate. Such PVC profiles hide the connection location along the length and joints in the corners.

- The products are trimmed with hacksaw at the desired length and are attached to the frame using self-tapping screws.

- The edges of the sheets are inserted into the starting profiles.

- A narrow shelf is started in the groove of the angle and the vertical of the installation is checked.

- A wide shelf is fixed with a bracket or self-tapping screw.

- The next sheet is inserted into the groove. It is necessary to ensure that they are tight pressed to each other.

- The last wall panel is mounted near the opening and is cut into width. It is inserted into the grooves of the previous one narrow shelf, and the cut side is hidden by molding.

- The last installed sheet is not fixed.

Thus, making installation in a rather short period of time, you can get high-quality and beautiful walls.

The photo shows the results of wall cladding panels from PVC.

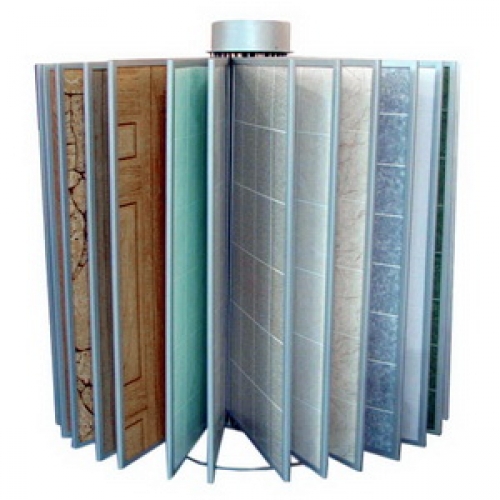

Several options for plastic panels

MDF panels - this is sheet Materialmanufactured from woodworking waste and used for decorations.

How decodes abbreviation MDF? Literally from English "MEDIUM DENSITY FIBERBOARD", translated as "medium density of fibreboard".

What is the difference between MDF from similar plates of DVP and chipboard? The production technology of conventional wood fiber plates (DVP) was developed even at the beginning of the twentieth century. The Fiberboard is made of technological chips, wood wood and other side products of wood sawmills, fragmented to separate fibers by heat-molded mass with the addition of synthetic resins as hardening substances. In the 60s of the last century, the production technology of DVP was improved, as a result of which the construction market appeared plates MDF.which differ from the fiberboard plates in the composition of the feedstock, the method of production and properties. In the manufacture of MDF plates, the initial mass is crushed into particles a much smaller size, and the main binder is Ligninwhich is distinguished from wood when heated (as a binder in the Fiberboard, harmful to health epoxy resins). MDF plates are more environmentally friendly, durable, easy to handle and aesthetically attractive material compared to conventional Fiberboard plates.

In everyday life, this finishing material has different names: decorative wall panels, veneered panels, MDF.

Today, MDF plates produce many manufacturers of building materials. The global leaders of production include the following companies:

- P.

- SONAEINDUSTRIA;

- ErnstKaindl;

- Gruponueva.

These companies have productions located in North America, Europe and the Asia-Pacific region, and almost half of world production is in the PRC. MDF is also produced in Russia, three companies can be attributed to the largest manufacturers:

- CJSC "Plitepichprom";

- CJSC "Russian Laminate";

- LLC "Kronostar".

MDF panels

Modern industry produces MDF plates of various types and destination. Plate thickness varies from 6 to 60 mm, while plates 6-12 mm thick for the manufacture of wall panels are used, which are divided into three types of size:

- tile - Square or rectangular shapehaving a length and width within 1000 mm, a thickness of 7-10 mm. With their help, you can create original mosaic compositions on the walls, combining various textures and color schemes;

- rachetresembling wooden "lining" having a height from 2500 to 3000 mm, a thickness of 8-12 mm;

- large leafy Panels that can be up to 3000 mm high, up to 1500 mm wide, the thickness of them is 3-12 mm.

Rectangular panels can be attached to the walls vertically, horizontally, as well as diagonally. Facing panels are made with fastening to the crate of wooden rail, metal profiles Or directly on the wall in case the surface is perfectly flat. The edges of the panels, depending on their purpose, are curved smoothly or they give a pinned form for the convenience of docking. For the installation of the MDF panel, they are equipped with special fasteners - self-pressing, nails, curmmers, finish corners for the design of external and internal angles.

If we talk about installing sections in relation to a friend, there are two options here:

- installation of jack, that is, without gaps;

- installation with spacerspanels are connected to each other additional elements (From the same MDF or tree), thanks to which there is a permanent clearance between the sections to 1 cm.

In addition, wall panels may have relief. For example, in advance carved on the surface of the groove, it is quite well imitated appearance Walls, decorated wooden clapboard. Products with more complex reliefs refer to the category of 3D panels, which will be discussed below.

External texture of wall panels from MDF

The main types of finishing surfaces of wall panels Three:

- color;

- nipping;

- lamination.

For color The surface of the panels, pre-engine and prostrum, is covered with paints or enamels having good fluidity and elasticity. Veneered panels are covered with veneer - a thin layer of natural wood, so after such a finish of the MDF panel do not differ in appearance from natural tree. Laminating panels It is carried out by sticker on the surface of a polyvinyl chloride film using a formaldehyde resin. Film can be matte or glossy, painted in different colors and with drawings under wood or a natural stone. It is the laminated panels that are made with photo printing, thus you can apply a pattern imitating absolutely any material. Popular image is quite popular ceramic tile or brick masonry.

Unusual options. In some cases, with the original design decoration Interiors, panels can be finished and exclusive materials, for example, by natural mother-in-law (the most expensive finish type - the cost of one such panel reaches 25 thousand rubles.)

Examples of finishing apartments MDF panels

MDF panels in the interior of the apartment can be used in the decoration of walls of any premises: living rooms and bedrooms, hallways, loggias and balconies, and even kitchens due to the rather high stability of the laminated or painted surface of the panels to the moderate exposure to moisture. Of course, in premises with high humidity - in bathrooms and bathrooms, the use of MDF is minimized. Although there are moisture-resistant models. Most of them produce furniture for rooms with high humidity.

Walls can be covered with MDF panels completely, from floor to ceiling in places such as holles, hallways and corridors, or partly, focusing on one of the walls or part of it residential rooms.

Some designers love the panel for the fact that of them you can quickly and easily make a wall panel and add a bright touch into a boring interior. This technique is regularly used in bedrooms for the design of the wall behind the bed (see examples). Another common designer reception This is a special in the living room. The veneered surface can become a good tv background.

Another common way of application is kitchen apron (See the gallery, including from MDF) The color and texture of wall panels must be harmonized with the type of finish of the facades kitchen furniture and equipment. Some furniture factories Complete your furniture ready-made apron with MDF.

Photo with interiors of MDF wall panels in the apartment are presented below. As you can see, in the overwhelming majority of cases.

Decorative panels in classic style

IN classic style, it is also called English, usually finish low part walls combined with framing door openings, design of stairs, fireplaces and other elements of the interior. There are various varieties of this finishing material. Learn more and see other photos with all possible options Designs in the appropriate gallery about classic panels (reference below).

Decorative 3D panels from MDF

The MDF panels with a bulk pattern are manufactured by processing on special milling machines. 3D drawings are created by individual sketches created by artists. The use of panels with volumetric patterns allows you to create really original, unique interiors. More details are examples of wall cladding are considered in a separate gallery.

Interiors of offices and other public spaces

We reviewed many options for applying decorative panels in the interiors of residential apartments. But it is impossible to bypass the party and the topic of office interiors. The fact is that in such spaces it is important to use inexpensive materials having high wear resistance and simple technology Installation-dismantling. After all, office and public areas (hospitals, government agencies) have high permeability and need regular cosmetic repairs. Constructions from MDF can be mounted very quickly, easily renovated (replacing the desired section) and, if necessary, also quickly disassemble. At the same time, such a finish looks quite solid and expensive. That is why manufacturers of wall panels are oriented, first of all, to the commercial real estate market.

Advantages and disadvantages of materials from MDF

| pros | Minuses |

|

|

Modern wall panels are a wonderful decoration of any room. Thanks to the infinite number of options for this kind of products, you can create interiors in different styles and directions. The high popularity of wall panels is due to their practical and aesthetic value.

Use of decorative wall panels in the interior

- panels on the bottom of the wall. This location of wall panels is not only a spectacular aesthetic, but also a practical design solution. Thanks to the proportion of proportions when decorating the wall, you can create a high ceiling effect and visually increase the room.

- Panels on the whole wall.Panels out natural materials Or with imitation of wood often use for the facing of all walls in the office, the private library or billiard room. This decision is designed to make the strictness of the interior and demonstrate the status of its owner.

- Panels as a decorative element.Panels out different materialsMade to the interior as a light accent look stylish and harmonious in every room. A variety of textures allows you to implement any designer idea. Plates can be completely lined with one of the walls, and on other walls - only small sections.

Types of decorative wall panels - Photo

Tile type panels Allow the wizard to embody fantasies and create all sorts of drawings, combining colors, sizes and textures. Manufacturers offer square-shaped plates with dimensions from 300 * 300 cm to 980 * 980 cm. For installation, glue or klyamimers are used, connecting the plates due to special grooves.

Rush type panelseffectively apply B. small rooms. Rakes are mounted on the crate of brackets or self-drawing. Thanks to the grooves and spikes of the panel, they are easily connected, and the gap between them looks neatly and does not require additional cladding.

Sheet wall panels allow you to create a spectacular decor without significant costs. Panels 122-244 cm long and 0.3-0.6 cm thick, mimic the structure of the tree, stone or tile. They glue directly on the wall, and the gaps between them are closed with molding.

![]()

Materials used for the manufacture of decorative wall panels

- Panels for Szden - natural tree. Oak, cedar and alder - the most popular wood for the manufacture of panels. The panels from natural materials are environmental and used to cover walls in residential rooms. Wooden water-repellent waxing panels can serve for a long time In the bathroom or in the kitchen.

- Panels for Szenn - chipboard and fiberboard. Panels from these materials are used in dry rooms. Such plates are quickly deformed when moisture exposure.

- Panels for Szenn - MDF.These plates are distinguished by high strength, moisture resistance, heat and sound insulation. The shelves and cabinets can be installed on the MDF panel.

- Panels for Stenen - Glass.Decorative glass plates have a good aesthetics, but require careful use. Manufacturers use technologies that can increase glass strength, but it also increases the cost of panels.

- Panels for Szenden - Gypsinyl. The surface of the panels from such a material is covered with vinyl, decorated with drawings or texture.

- Panels for cotton plastic. Plastic wall panels have high characteristics of moisture resistance, strength, refractory, hygienicness. These qualities allow them to apply them for decoration of walls in any room.

Decorative wall panels will help to transform any room or create absolutely new interior in as soon as possible. A wide range of design options and materials will allow you to carry out any of your imagination.

Wall Panels - Photo Ideas

Scheduled redecorating in Pain country house Or the apartment, come across the choice of finishing material for the walls. And if another 15 years ago, the choice of materials was limited, today it appeared quite large number of them. One of these modern materials for finishing are wall panels. They are easy to install, have a rich selection of colors and textures, are created based on both artificial and natural raw materials. How to choose wall panels, from which material they are, and the advantages of this type of panels will be discussed in this article.

Types of wall panels

To date, the wall panels are produced in three main modifications that differ in size, shape, structure and installation method. The presence of a choice of one or another type of wall panels gives certain advantages when creating an interior. From what type of wall panel will be used, the final appearance of the walls will depend on. The following types of wall panels exist:

This type of wall panels is a bar length from 240 cm to 370 cm, a width of 12.5 to 30 cm and a thickness of 8 - 12 mm. Due to its sizes, the panels are most popular in cases where it is required to seize the room with a small area or large quantity Corners. To mount the roll panels requires creating a crate of metal or wood. To connect to each other, the panels have a spike and grooves, or only the grooves. In the second case, tabs connect two panels with each other. With this embodiment, the connection remains a small gap between the panels. The fixation of the panel to the crate is carried out with the help of special brackets or by fastening the screw in the groove. Rush type panels are made of DVP, Chipboard, MDF and PVC. In addition to the panels themselves, various corners, plinths, plugs, and so on are produced.

In contrast to the roll panels, tile are made in the form of a square with parties from 30 cm to 98 cm. Such panels are attached mainly to the surface of the wall on glue or with the help of curmmers. Another important difference of tiled panels is that only grooves and inserts in them are used to connect together with each other. Tiled panels are made from DVP, Chipboard, MDF, PVC. Perhaps the main plus of tile panels is the possibility of combining multi-colored panels at different angles, which creates a unique pattern on the wall.

Among the three main types of panels are the largest. They are produced in the amount of 1.22x2.44 m and a thickness of 6 mm from DVP impregnated with resins, or PVC. The working surface of the sheet panel is a multilayer structure with a drawing or imitation of a tile, wood and stone. Sheet panels are mounted on glue, and the seams between the panels are hidden using moldings. The main advantage of sheet panels is the coating of large areas in the minimum time.

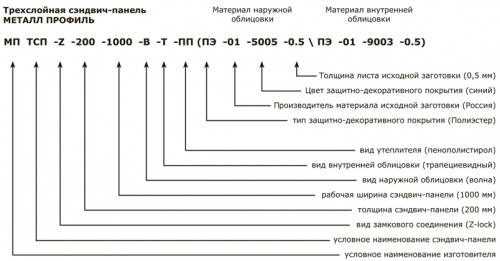

It should be especially noted that in addition to decorative panels, which are also separated by the walls, there are also constructive wall panelsfrom which they take interior walls and partitions. It can be panel Wall PS. from various concrete, as well as modern panels for modular homes - wall Sandwich Panels. If the above species are decorative, the sandwich panels are essentially ready Walls With insulation, steam and moisture insulation inside. When searching and selecting such wall panels, you must pay attention to the labeling. So, for example, wall panels PS 30.9.3.0-6ldecoded as follows:

PS. - wall panel;

30 - Length in dm;

9 - Height in DM;

3,0 - width in dm;

6l - Serial number and material (in this case, lightweight concrete).

In addition to the photo demonstrated sandwich panel marking:

These panels are used during construction. country house Or cottages, so they stand a mansion from the main types of wall panels. The bright representative of the sandwich panels in our market is the wall panels of Vental-Ruuki, which differ high quality and affordable price. Wentall-Ruuk wall panels are produced in Russia finnish technology and meet all the requirements of GOST.

Wall panels

It's no secret that the materials used in the finish directly affect the atmosphere in the house. In the production of wall panels, a large number of different raw materials apply. Starting with ordinary wood and ending with glass and plastic. Most often in the panels are combined by several materials. But you can find the panels of only one, for example, from wood, PVC or glass.

Natural wood panels

Those who seek to create a healthy and welcoming atmosphere should be chosen on wooden wall panels. Woods use as raw materials duba, klena, alder, cedra or bamboo. The room decorated with wooden wall panels looks particularly attractive and cozy. Wooden panels are mostly produced with rubber and slab. The exclusion is the wall panels of the mosaic, which are based on their dvp and covered with pieces of wood different breeds or shades.

For those who seek to create an expensive and respectable interior, a veneered wall panels are suitable. They are famous for their luxurious views. Those who love the exotic and want to issue their interior in eastern styleYou should use wall panels from bamboo. These manually woven from bamboo pieces and soaked mats that are impregnated with special melting, as it is impossible to give the whole atmosphere of Asia. Mosaic wall panels made on the basis of DVP with pieces from different breeds Woods will allow creating a unique and attractive panel of wood. One of the bright representatives of mosaic panels are canifor wall panels. Their feature is the magnificent imitation of the stone from the pieces of wood treated in a special way.

Unfortunately, the tree has its drawbacks that limit the scope of its use. To a greater extent, it applies to rooms with high humidity. But this deficiency is easy to correct. For this wooden panels Covered with a layer of wax or special varnish.

Panels from chipboard

Woodworking industry was found in the so-called plates of chipboard. As wall panels, they are largely inferior to wall panels from wood, but simplicity in production and low cost compensate for this flaw. By themselves, the chipboard panels are unspeculent and therefore covered with plastic. Such a coating made it possible to implement a wide selection of colors and various textures, which perfectly demonstrates the wall Scyth panel.

Despite harmful adhesive compositionsWall panels from chipboard are widely used in the design of the premises. Such popularity is due to an artificial coating that makes the scope of using panels from DSP practically unlimited. But these panels have one serious lack of use - they are extremely poorly tolerated high humidity indoors. In addition, the large weight of the wall panels from the chipboard imposes certain restrictions on the way they are installed, so they are available only in the stoves. Such panels are best to sow such rooms as an entrance hall or corridor.

Panels from DVP

Perhaps the most common wall panels are from fiberboard. This material is obtained as a result of hot pressing of wood fibers, which allows you to create wall panels of any type. Fiberboard is a material that combines modern technologies and natural purity. And in combination with low cost and various options The work surface finishes makes them the leaders of the wall panel segment.

The mounting of the DVP panels can be both on the crate and directly on the wall itself. The basic condition is the absence of large drops, dry and clean surface. The connection of the panels is performed either with a locking method or using a groove compound. In independence, on whether robes, slab or leafy, Fiberboard panels can be easily fixed and replaced if necessary. These advantages give huge opportunities in their use. As such serious disadvantages of DVP practically no. The only thing that DVP is poorly tolerates, this is high humidity. Reiki under the action of moisture expands, and the sheets and plates unscrew the propeller.

Separately, it is worth noting the options for finishing the working surface of the Fiberboard panels. In addition to conventional lamination, the surface can be covered with a cloth, wooden mosaic, veneer or just painted. IN huge selection Flowers and textures can be seen by looking at Isotex wall panels. This company is one of the production leaders in this segment.

Panels from MDF.

Brother Twin DVP is MDF, but in contrast to the first, MDF we have less density. Wall panels from MDF have a number of significant advantages over usual. For example, ISOTEX wall panels from MDF or as it is also called soft fiberboard, they have sound and thermal insulation qualities. Such universalism makes wall panels from MDF very attractive for interior decoration. In addition to insulating properties, MDFs in the manufacturing process can also be given other useful qualities, such as fire and moisture resistance, as well as resistance to biological effects. It is these qualities that are owned by the wall panels of the Union, which are positioned as fire and moisture resistant. Unfortunately, advantages of MDF. Before DVP have their price, which affects the cost of these panels. But if you compare with huge opportunities for their use, the price will be quite justified.

PVC panels

As material, PVC is quite widely used in various building structures and products. And the wall panels are no exception. Thanks to its operational qualities, such as moisture resistance, durability, the possibility of drawing and creating various textures, wall PVC Panels have a wide range of applications. Combined with simplicity of installation and affordable price, PVC panels quickly won the market, becoming one of the most used finishing materials. As for the form of release, the panels are produced in all three modifications - rush, tile and leafy.

It should be noted that PVC allows you to implement a huge spectrum design solutions. So, thanks big selection Colors and textures, you can create wall panels mosaic with imitation under a tile or stone. In addition, the panel with the basis of the Fiberboard or MDF coated with PVC layer can easily create a simulation of a marble plate or wood. The bright representatives of this segment are DPI wall panels, which in addition to classic Fiberboard and MDF panels, can boast panels with imitation of stone and wood. The only and most serious disadvantage of PVC. Panels are their artificial origin.

Glass panels

To create durable unique photographic patterns on wall panels, a durable and durable basis can protect and save the drawing. Under such requirements, ordinary MDFs or PVC foundations are not suitable. The solution was the use of glass in wall panels. Such panels possess many shortcomings inherent glass, but with neat operation and proper care Glass wall panels will serve quite a long time. In addition, manufacturers strive to apply modern technologies to this industry, which is reflected on the strength and protection of the glass surface. The most striking representative of this category of panels is the wall panels skinali.

Gypsinyl panels

Today the popularity of drywall is difficult to underestimate. From this material, walls, partitions and even ceilings are created. With the development of technologies of drywall converts to a new generation of finishing materials - gypsinyl wall panels. In essence, it is the same plasterboard, but instead of a layer of cardboard covered with vinyl. Initially, this type of panels was intended for public rooms with big passability. But gradually the gypsumnile wall panels moved to ordinary houses. These panels are beneficial from ordinary plasterboard. They are much stronger and more reliable, have ready working surface With a defined color or pattern. Durafort wall panels are one of the most visible on this rapidly growing market.

Features of the selection of wall panels

Various types of wall panels and materials from which they are made in advance determine the place of use. For example, glass panels will perfectly fit in the kitchen and in the bathroom, and the wooden is ideal for living rooms, bedrooms and children's. The same applies to the size of the panels. Thinner and long panels will allow visually expanding small rooms, and large slab or leaf panels will be suitable for large premises. These simple rules Already known for a long time. Difficulties begin when when looking at the description and labeling of the panel itself there are even more questions.

When considering labels, note that they indicate characteristics and sizes, as well as the correspondence of a certain wall panel SNiP. In the Russian market, all wall panels must correspond to the following SNIPM:

- SNIP 2.08.0289 " Public buildings and facilities ";

- SNIP 2.09.04-87 "Administrative and household buildings",

- SNiP 31-03-201 "Production buildings";

- SNiP 2.01.01-82 "Construction climatology and geophysics";

- SNiP 23-01-99 "Construction climatology";

- SNIP 21-01-97 " Fire safety buildings and structures ";

- Snip P-3-79 "Construction Heat Engineering" 1988

It will also take into account such parameters such as flammability, ignition, smoke and toxicity. It is from these parameters that the use of wall panels in the greatest extent interior decoration premises. There are 4 levels for them, and the higher the indicator, the worse. Ideally, the markings on the label should look like this:

- flammability g1;

- flammability B1;

- smoke formation D1;

- toxicity T1.

In conclusion, I would like to note that when choosing wall panels, you should also pay attention to their appearance in or without packing. The surface of the products should be without defects and damage, edges - whole without chipping, cracks or irregularities. If the panels are multi-layered, then protective covering must be solid, without running, deep scratches or damage. The color of the entire batch should be in the tone. If the parties are different, then the extinguishing in color should be minimal. Castle connections must be integer and perfectly approach to a friend in shape. Compliance with these simple rules will allow without any particular problems to choose the desired wall panels of good quality.

How to return the love of her husband to his wife - Tips of the psychologist

How to return the love of her husband to his wife - Tips of the psychologist Why you can not give icons

Why you can not give icons