How to make a do-it-yourself underframe. We add warmth and comfort to the house by making a simple solid wood table with our own hands according to understandable drawings. Step-by-step instructions on how to make a wooden table from a bar with your own hands

There is none home master, who would not want to assemble a wooden table with his own hands, and this desire does not depend on gender and age. It is important to observe many aspects so that the result of the work is really high-quality.

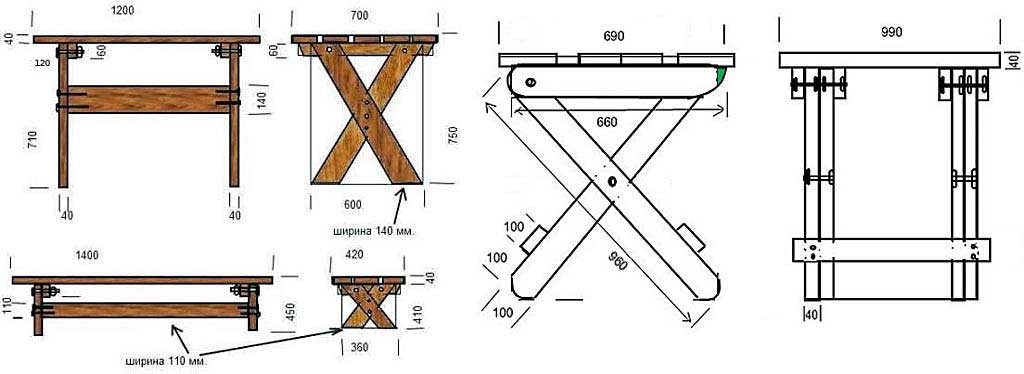

Figure 1. Scheme of a wooden table with legs in the form of crosses.

In the beginning there was a tree

Initially, the type of table is selected, and then the material with which the work will take place. Tables are different (Fig. 1, 2 and 3), and in each case, different materials are used.

Particleboard among all the cheapest and easiest to work with, therefore it enjoys the highest popularity. Thickness usually borders 1.5-3 cm, colors are limited only by imagination, and density depends on preferences. But chipboard also has its drawbacks: low strength indicators, all colors of artificial origin (even if you wish, you cannot stylize it like original wood), as well as harmful chemical emissions from non-laminated places.

The array, in turn, is the least popular due to its high cost. In this case, the work is quick and easy, because the cut just needs to be shaped to get the countertop, after which you can mount it, and the shapes can be from simple to the most intricate.

Figure 2. Scheme of a coffee table.

Edged boards and beams are the main elements that are present in most cases as a supporting structure, but sometimes they are used as the main material, which makes the work much more difficult, but the result is many times more interesting.

It is a table made of a board and a bar that will be considered as an example, since starting with the complex, you can easily learn to do the simple.

Work activity

Tools and materials:

- jigsaw;

- grinder;

- screwdriver;

- roulette;

- timber;

- bar;

- edged board;

- rail;

- steel corners;

- furniture plugs;

- stain and varnish;

- the brush is flat.

Initially, you need to decide on the dimensions of the future table, and only after that start sawing. Let the table have a standard 110 cm height, 90 cm width and 150 cm length, although any of the given data can be changed depending on desire. And then precise definition you can start cutting:

- timber 75 * 75 mm - 4 pcs. 105 cm each;

- bar 45 * 80 mm - 2 pcs. 75 cm and 2 pcs. 135 cm each;

- edged board 50 * 150 mm - 6 pcs. 135 cm and 1 pc. 90 cm;

- wooden lath 10 * 40 mm - 5 pcs. 145 and 2 pcs. 85 cm each.

After the cut is completed, each working element must be carefully sanded with a grinder or sandpaper zero, and collect all the remaining dust with a barely damp sponge. From above, the wood is covered with an antiseptic solution from moisture and insects, and only after complete drying can you continue to work.

Figure 3. Circuit diagram of the round table assembly.

To begin with, a supporting structure is formed from beams and bars. To connect them, you will have to round off the bars at the ends by 2.5 cm, and at the very top of the bar make round holes with a corresponding diameter to a depth of 2.5 cm. a few drops).

The worktop is made much more difficult, because for a start, you need to cut a 90 cm board exactly in half longitudinally. Between the resulting 2 cuts, all the rest are laid alternately. The result is a shaped tabletop, but not yet adhered.

In the front and back boards, 6 wide holes are made to a depth of 2.5-3 cm, and all holes should be located exactly in the center of those boards that are on the other side. After that, with a thin drill, full holes are made to the depth of the screw, and if this is not done, then with very likely it will be possible to split the wood.

For coupling, galvanized screws are used, because they are not susceptible to rust, and this is very important for wood. From the bottom, the rail is screwed onto all joints, and the fixation is carried out in a checkerboard pattern with a step of 20 cm for the longitudinal ones, and in pairs on each board for the transverse ones. Thanks to this, the countertop is no longer scary.

At the very end, it remains only to combine the legs and the tabletop into 1 structure, for which pins and steel furniture corners are used. At the junction on the pins, you will again have to use glue, and then press the table with a load of 20-30 kg for 5-6 hours so that everything is fixed in this position. The corners, in turn, will act as a control fixation.

At the very end, plugs of the color of interest are put on the heads of all visible screws.

Completion and additional aspects

After you managed to assemble the table with your own hands, you need to completely cover it with varnish and stain. What is especially important in this case is the ability to give the appearance of any breed. The varnish dries for 30-36 hours, so after coating you need to leave finished work just for this time. It is often misleading that after 4-5 hours there is no smell anymore, and the fingers completely stop sticking, but at the same time, harmful chemical compounds still continue to be thrown into the environment.

To form large-diameter holes, special drill bits and crowns on drills are used, and they allow not only to form the inner contour, but also to cut the outer one.

Before making a wooden table, you need to allocate 1-2 free days for the whole process, because interruption will be very inopportune. Sometimes mistakes and shortcomings occur during work, but this is within normal limits, so you need to have a stock of all materials in 10-15%.

In total at full hand the table is made in 1 day, after which it is dried, and you can start using it.

After reading the title of the article, many will have a question: why make a wooden table with your own hands, if you can buy it in a store? There are different ways to answer this question.

For some, this is cost savings, especially if you need an uncomplicated piece of furniture. For others, making a table with your own hands from wood means putting your soul into the original copy and making this piece of furniture unique.

In addition, a self-made table will perfectly fit into the space, because it will have the desired style and size. Moreover, wood is a versatile and affordable material.

Varieties of tables

Structurally, countertops can be divided into several types:

- formed by solid array wood;

- prefabricated;

- glued;

- made in the form of a shield from wooden lamellas.

A solid array, as a rule, is used for the manufacture of expensive premium furniture, and in order to make tables for giving out of wood with your own hands, other technologies are used, both individually and in variations.

Glued countertops with lamellas (boards) look very nice and decorative. different breeds trees. This is achieved due to the different structure and pattern of wood. Such products are practically not subject to deformation, since this process does not affect the wood fibers in products made using adhesive technology.

In shape, country tables, most often, are made rectangular or round on various legs. But some craftsmen manage to make them in the form of a hemp or a log, which looks very decorative.

You can complement the table by making a whole ensemble with chairs or stools made in the same style.

Countertop material

To make a table with your own hands out of wood, use the following materials:

- Edged board or timber. Manufacturing will cost some work and time, but the result will please. In addition, with the help of wood stain, you can change the original appearance of the board beyond recognition.

- Croaker. Suitable for those who want to give the table a rough, rough rustic look, because the edges of this material are not processed, but only the top and bottom are sanded. A solid tabletop can be made from a wide slab.

- Barrel cut. The simplest, but perhaps the most time-consuming option can be the option of making a tabletop from a cut of the trunk. Besides the fact that you need to find a trunk of the required diameter, you also need to make a perfectly flat cut. This is fraught with the formation of a large amount of waste. The cut is not stained, but varnished.

The main requirement is that the table with your own hands made of wood (photos of the products are presented in the article) must be made so that it is strong and durable. These parameters can be provided not only and not so much by wood processing as the right choice suitable type of wood for the job.

It may seem that solid tree species are best suited for these purposes. But ... They have one significant drawback: under the influence of temperature changes and from the action of moisture, countertops from such rocks swell and crumble.

Therefore the right choice for garden countertops or country table there will be elastic wood. It combines two qualities: hardness and the ability to return to its original state, that is, resistance to deformation.

The following tree species combine these properties in the best way:

- larch;

- Linden;

- aspen.

You need to know that before you make a table out of wood with your own hands, the wood must be sanded and treated with antiseptics, and at the end of the work it must be varnished.

Benefits of wood

The most popular type of material used to make a side table is wood. This is due to the following:

- wood is easy to process and has an aesthetic appearance;

- the tree is resistant to natural phenomena and climatic factors;

- due to good shock absorption, chips and scratches rarely form on the wood;

- if necessary, a wood product can be easily restored;

- the material gives room for imagination in terms of processing and painting;

- products can be decorated different ways, giving originality;

- the tree is environmentally friendly and safe for health;

- the price of wood material is affordable for many;

- wood is distinguished by its visual appeal.

Tools for work and dimensions

In order to make a table with your own hands out of wood, you will need:

- thickness gauge;

- saw, jigsaw, hacksaw for wood;

- jointer;

- cutter;

- screwdriver;

- drill;

- grinding device;

- clamps;

- pencil, tape measure, square.

From the materials you need to prepare:

- antiseptic impregnation;

- sandpaper of different grain size;

- wooden boards, beams or slabs;

- varnish, paint and stain;

- joiner's glue.

In order to make a table with your own hands out of wood without any problems, the drawings must be prepared in advance, having thought over the shape and dimensions of the product.

The size of the table largely depends on the size of the room. And the standard height is usually 70 cm. For a family of four, it will be enough to make a square table with a meter side. And if a rectangular tabletop is planned, then the optimal dimensions will be 120x90 cm, which will allow you to receive both hosts and guests.

Making a simple table out of wood

To make a simple table for a gazebo made of wood with your own hands, you will need a bar and boards. The step-by-step process can be described as follows:

- Select the required amount of material. Ideally, for sufficient width, six to seven planks with a thickness of 3 cm will be required. The planks should be treated with a jointer and strictly flat. The presence of knots is encouraged.

- Treat the material with an antiseptic and dry well.

- Lay out the boards, align to the desired length, check the joints. You should get an even rectangle.

- Attach the block to the boards on both sides and cut evenly, forming a perimeter.

- Screw the timber to the boards. To do this, from the underside of the tabletop, in the center of the boards on each side, make a two-thirds recess through the block with a small drill for a bolt with a lock. On the timber, widen the hole slightly to drown the bolt head.

- Trim the corners a little to get a rounded shape.

- On the underside, secure with self-tapping screws, smearing with glue, another board diagonally.

- Sandpaper, first coarse, and then fine sand the surface of the countertop, board and timber from below.

- Cover the table with wood stain and varnish or paint.

Making table legs

At first glance, it may seem that the problem of how to make a table out of wood with your own hands has been solved by making a tabletop. But the appearance of the table largely depends on how the legs or leg of the table are made. After all, this detail should not only match the style of the entire product, but also have certain sizes and shape to ensure stability.

An interesting fact is that the more difficult the table legs are in making, the more likely they will not last long. The main task is to make simple, easy-to-use, low-weight supports under the table with your own hands from wood. Drawings of the legs can be omitted.

For their production, it is necessary to select four identical beams 85 cm long, which will be installed in the corners of the table. Then you need to connect them on each side with boards or beams: two of them will be equal to the width of the tabletop, and two - to the length. After that, the structure is attached to the countertop, glued and left to dry for a day.

Instead of glue, it is better to use furniture corners, which need to be fastened with self-tapping screws. Or apply both options at the same time.

Making a round table

To make a round table with your own hands out of wood, you will need:

- square timber with a side of 10 cm and a length of 75 cm - 4 pcs;

- boards 10x2 cm, length 75 cm - 2 pcs;

- boards 25x4 cm, length 200 cm - 4 pcs;

- boards 10x2 mm 80 cm long - 2 pcs;

- boards 10x2 cm long 160 cm - 2 pcs.

Step-by-step manufacturing guide:

- Put long 4 boards next to each other, tightly fitting together.

- Draw a circle using jigs or shapes.

- Cut the boards along the drawn lines with a jigsaw.

- From boards 160 cm long, assemble a shield in the form of a circle.

- Form a rectangular frame from the rest of the boards and fix the shield with galvanized screws.

- Attach the legs from the timber to the frame.

- Test the structure for stability and strength.

- Then carefully disassemble.

- Next, process the wood with a grinding device with coarse sandpaper.

- Then sand with medium to zero grit sandpaper to perfect smoothness.

- Treat the wood of all parts with wood stain and varnish in the direction of the wood grain.

- Assemble a do-it-yourself table made of wood, a photo of a round table is presented above.

Decorating the finished product and caring for it

In order to get a country table that is unique in style, it must be decorated. The material for this can be cuts of thin trunks laid out on the table top. Decoration can be and carved elements on the table top and legs, which will add visual lightness to the product.

For a change, you can play with the color of boards that have been treated differently with wood stain or painted with paint.

In order for a table made of wood with your own hands to serve as long as possible, you must follow simple rules:

- Do not leave the product in the open sun or rain.

- Clean the worktop surface weekly and rub with polish.

- To preserve the varnish for the winter, bring the table indoors.

Who said that a table is a simple piece of furniture? In fact, creating a table is an exciting experience, especially with your own hands from natural wood. Today, in the review of our editorial office, we will tell you how to make a table out of wood with your own hands, what knowledge you need to have in order for your structure to serve long years flawlessly.

Ideas for making a wooden table with your own hands: photos, recommendations, drawings and step-by-step instructions

Before getting to work, it is important to decide on the following points:

- Dimensions and operating conditions. The functionality and additional measures that need to be taken will depend on this.

- Find (draw) a plan diagram.

- The choice of material and accessories.

For a novice master, it is better to choose simpler sketches. Here are some sketches that you might find useful.

Related article:

Photo examples, drawings, diagrams, materials; features of making furniture for the garden, nursery, baths, gazebos, advice and recommendations of the masters - read in our publication.

Wooden table for a summer residence and at home: choice of material

Best to use natural wood... For an experienced craftsman, even old boards are suitable. A few strokes with a plane and now - the raw materials are ready for work. The prepared wood must be dried.

Tools needed to create a do-it-yourself wooden table

For manufacturing, for example, you need a minimum set of hand tools: a hacksaw, a hammer, a miter box, a screwdriver, nails, screws, a tape measure or ruler, a square and a pencil.

Related article:

: what it is, advantages and disadvantages; step by step production coffee table, armchairs, sofa, benches, shelves; decor features with a photo - read the publication.

DIY wood table: drawings, photos and step-by-step instructions

For work, you can use both solid boards and. Conduct an audit old furniture it is possible that you will find materials that you can use.

Making a round wooden table

Let's look at the process of making a simple round table from planks for a summer residence. We need ordinary boards and slats for securing the structure.

Important! Before starting work, the boards must be processed with a plane and sandpaper.

| Illustration | Description of action |

| We lay out the processed boards in the sequence in which we will knock down the table. In our case, they have grooves and we will connect them according to the thorn-groove system. |

| We connect the boards with the help and squeeze with clamps. The clamps can be removed after 24 hours. |

| With the help of the bars, we build up the countertop. Further, on the received shield, find the center and, using a compass or auxiliary means (a nail, twine and pencil), draw a circle with a diameter of 1000 mm. |

| Next, with the help, we cut out a circle along the outlined contour. |

| We grind the work surface. |

| We will make the legs from 4 × 4 cm blocks. We process them with a grinder. |

| We fix the legs on the corners. |

| Here we have such a simple table for a summer residence. |

Related article:

: photos of the stages of work, the advantages and disadvantages of such beds, their varieties, as well as a step-by-step master class on the manufacture of such structures, how to choose the right mattress for pallet beds - in our publication.

How to make a wooden kitchen table

A very simple and stylish table can be obtained by literally spending one evening at.

By the way, this model is very popular, if you want the same in your kitchen, you can make it yourself.

And here is another option for making a simple kitchen table with your own hands -

Photo gallery of various options for do-it-yourself wooden tables

For example, we suggest studying several options for wooden tables for different premises in our photo gallery.

1 of 8

This piece of furniture is one of the most versatile in use. The table can be a dining room, utility table, installed in a living room, on a veranda, on the territory, in a workshop, and so on. In a word, it is impossible to do without it. But the purchased products do not suit many in a number of parameters - sizes, design features, form or for any other reason.

Considering that the tree is relatively easy to cut, polish, make a table out of it according to your own drawing, it is not a problem for a good owner with your own hands. And it will come out much cheaper. Plus - the satisfaction of such work.

Premises

Ideally, this is an extension, a shed, an empty garage, although a small covered area will do. Working with wood in the open air means completely dependent on the vagaries of the weather. If there are suitable for the manufacture of furniture " square meters", Then you should worry about high-quality ventilation... Natural is sometimes not enough (besides, it depends on the change in wind direction and pressure), and an exhaust hood is installed.

Arguments that if you use protective equipment, you can work in an enclosed space, do not stand up to scrutiny. Wood dust will immediately settle on everything, including on the sample with which some action is performed. Neither an accurate cut along the line, nor a high-quality surface treatment of wood (not to mention impregnation and topcoat paint and varnish) cannot be obtained.

One cannot but take into account the fact that many preparations used for processing wood contain toxic components. For example, varnishes, paints, impregnations, if they are not natural, then harmful fumes are guaranteed.

Tools

Their set depends on the extent to which it is planned to "refine" simple design from wood, what shape to give it and a number of other nuances. If the master does not claim the grace of a wooden table, does not aim to achieve its originality, then the usual carpentry set will be enough.

For more "delicate" work in the process of making a table of unusual shapes, external design you will need special tools.

El / jigsaw. It will not be possible to make an inclined vertical cut with an ordinary saw, keeping the angle exactly. The canvas will "play", and therefore the quality of work will be extremely low. The electric jigsaw is universal in application, and it also gives high precision cutting wood or cutouts in it.

Many of the listed fixtures can be rented if making furniture is not a hobby, but a necessity.

Impregnating and other compositions

Rotting protection:

- Dealing with engine oil is an effective and free tool. But not for dining tables.

- Linseed oil. A natural and effective product that penetrates deeply into the structure of the tree and protects it from mold and mildew. The downside is the high cost. But if the table is intended for eating - a great option. The drug has no color, therefore, after processing lumber, it does not leave any traces in the form of darkening, stains, streaks, in contrast to working off.

- Water-polymer emulsion. It is characterized by long-term action and health safety.

- Acrylic varnishes. They practically ousted their predecessors of the "NC" category, as they are harmless and in many respects better compositions which are diluted with solvents.

- PVA, bone glue and a number of others. More information on joinery -.

For decorating a tree:

- Colorless varnishes are used not only to protect materials from moisture. With their help, you can save the texture of the wood, shade it.

- Stains.

- Varnishes with a coloring effect (tinting).

- Paints (but only for wood!).

- Putties.

Using colorless varnish and pigments, you can make a coloring composition, and of any shade. It is enough only to correctly determine the proportion of the components. This is easy to do by experimenting with mixing and applying a sample to the rejected board. This will help you find an acceptable tone. It is more than advisable, since it is not always possible to buy exactly what you need on the market.

Fasteners

All advice on assembling a wooden table with nails (argumentation - simple, fast and cheap) is better to ignore. The reasons are as follows:

- A nail easily pricks dry wood (and this is what is taken; more on that below).

- It is rather difficult to correctly direct its leg (strictly vertically). In some cases, it is even more difficult to redo your mistake.

- The tree, even the most protected from rot, succumbs to it over time. The maintainability of a table knocked down by nails is extremely low. Practice shows that it is rarely possible to remove such fasteners without damaging adjacent structural parts. As a result, instead of the planned replacement of one element, 2 - 3 will have to be changed.

- When assembling a wooden table, if glue alone is not enough, only self-tapping screws should be used.

- Sometimes its individual parts (at the joints) require reinforcement. Strengthening the strength with a hardware with a thicker and longer leg is impractical. The reason is the same - the likelihood of splitting the tree. For these purposes, metal strips, staples, corners are used.

Features of the choice of wood

Someone is guided by the cost of lumber, another is important the resistance of the tree to decay, for the third - its texture. What can you recommend for a novice furniture maker? Do not use for a table, unless it is intended to be installed somewhere in a utility room or garage, the same type of wood. This is exactly what many novice "craftsmen" do, picking up the same type of boards and bars from what is left of construction or repairs and gathering dust in the barn.

When making a wooden table for living quarters, verandas, and so on, you need to take into account the properties of individual species. Naturally, if you don't have enough experience in assembling furniture, you should pay attention to cheaper wood. The first table in life (chair, stool) is just a kind of training in making, gaining experience.

Table top. Here, strength and minimum moisture absorption are in the first place. It is on this part of the table that something is constantly spilled. Optimal choice- pine, larch, oak (although the latter is more expensive). Thickness - at least 3 cm.If the dimensions of the countertops are small, then wood-based panel products (, OSV and the like) can be used. But only with lamination to prevent swelling of the material when liquid hits the table surface. For example, laminated chipboard.

Low-grade sawn timber is not used in the furniture industry. This is not economically feasible, as pre-treatment of the wood increases the production cycle. But in the manufacture of something, wood of lower grades, substandard - just right. The same pallets left over after using stacks of foam blocks or bricks.

And not only because it's free or relatively cheap. With a competent approach, many disadvantages of such wood can be turned into advantages. For example, after coating with a colorless varnish, the tabletop takes on a unique original look.

The main thing is that the boards do not have obvious defects in the form of rot, cracks, knots falling out and wormholes.

If pine is chosen for the countertop (this also applies to many others conifers), then you need to pay attention to the location of the annual rings. These arcs are called humps. The cuts of the boards show how they are oriented, and this is taken into account in the process of laying them in a row. Samples obtained by the tangential sawing method are arranged alternately (the top is down, the next one is up); radial cutting - the same (arcs in one direction). The nuance is insignificant, but it is precisely the observance of this recommendation that eliminates the risk of warping and splitting of the boards.

For furniture, if you think about its durability, you should take only dry lumber. During wood shrinkage, it will deform; this is a natural process, and its consequences in the form of twisting, warping, bending are inevitable. Such a table will quickly become warped, and you will have to repair it. And here you need to decide - to purchase high drying wood or to rid it of moisture on your own. The first option is simpler, but such a tree is more expensive. The second is cheaper, but there are a number of purely technical difficulties.

- Firstly, it is necessary to ensure a stable temperature regime at the place of storage of blanks. Changes in its value will lead to uneven moisture evaporation, which will negatively affect the strength of the tree.

- Secondly, there must be good ventilation.

- Thirdly, and, perhaps, this is the most unpleasant moment - you will have to wait, up to about six months, depending on the initial moisture content of the tree. But this is not a guarantee that the result will be expected; even in this case it takes practice.

This once again confirms the idea that when starting to make furniture out of wood for the first time, one should focus on the simplest table for household needs made of cheap lumber, without claims to its sophistication and originality of the design. For example, for a barn, garage and the like.

Variants and schemes of wooden tables

It should be noted right away that any work related to the design and self-assembly- a creative process. In this case, stereotypes do not exist, so you can only take the model you like as a basis, and everything else - linear parameters, shape, manufacturing specifics - depends on the purpose of the product and your own imagination. Here are just a few examples of what wood tables can be. For example, for summer cottages, small utility rooms it is worth choosing designs whose geometry can be easily changed - folding, camping, hanging, garden, level, and so on.

Tables that are supposed to be used for eating, playing, as magazine tables for installation in living rooms intended purpose, are made stationary, that is, unchanged dimensions. These assemblies are more "solid", since all mating parts are rigidly fixed; no swivel joints.

Features of the assembly of wooden tables

If a person undertakes to make something, it means that he knows how to use the tool, read the drawings and work with lumber. It is not necessary to teach such a home craftsman the basics of carpentry. But a number of nuances in the manufacture of a wooden table will be worth noting. These notes will only help in the process.

Let's start with the types of connections. There are quite a few of them, but for a table that is assembled with your own hands, the following are quite enough.

On dowels

In this case, the fastening of the parts is done by landing on the adhesive (Fig. 1 - 3).

The nuance is that for the manufacture of "cylinders", which are inserted into pre-drilled "channels", a tree of a denser structure is taken than the elements of the table. This is what ensures the strength of the joints. Before installing them, chamfers are removed from the edges of the dowels and holes.

These round sticks are commercially available in any furniture showroom in several standard sizes. Grinding them, even having a carpentry machine, is a waste of time. It is not recommended to purchase plastic dowels for the table; they are used for dismountable connections. For example, frame furniture (walls, multi-level shelving, etc.).

It is not worth using nails to fix the table elements (Fig. 4). Metal and wood differ in the degree of thermal expansion. Such a connection will not last long - the "shuttle" will begin, especially if the table is intended for installation on the territory or in an unheated room.

On kings

It is advisable to make such connections if the table has to be disassembled either periodically, or without this it cannot be transferred through the doorway. Although not all drawers involve dismantling the structure. The most commonly used options are shown in the figures.

Bolted

Such connections are mainly used for garden furniture or furniture installed in outbuildings; for household tables. An example is shown in the figure.

The nuance of working with fasteners

So that the self-tapping screw can be easily screwed in and "go" into the right direction, preliminarily at the point of its installation with a drill, with a diameter slightly smaller than the leg of the fastener, a hole is made. The main thing is to maintain the coincidence of the center lines, that is, to avoid skewing. In this case, you can do without a screwdriver to "land" the self-tapping screw.

Features of wood processing

Everyone knows that a plane is used first, an abrasive with a coarse grain, and then a fine one. But sometimes it turns out that the last stage, grinding, has to be done many times. Much depends on the type of wood and the degree of its drying. After applying the first layer of varnish, the villi can "stand up". Nothing wrong with that. Wait until the workpiece dries and repeat abrading it. The work is painstaking and takes time. But it is precisely by this technique that you can bring the "problem" wood to the ideal "smoothness".

To eliminate the risk of injury to a person, all edges and corners of the table should be slightly rounded.

Features of exterior decoration

- Small defects in the form of cracks, chips are eliminated with a putty compound.

- After sanding is complete, remove all wood dust. In this case, the usual household vacuum cleaner with the corresponding attachment. After such cleaning, it is recommended to wipe the entire table with a slightly damp cloth, let it dry and repeat the cleaning of the remaining dust. After that, you can safely start applying stain or varnish - there will be no "pellets" on the wood.

- You can add originality to the table not only with the help of curly cutouts, the unusual shape of the table top or legs, the combination of the texture of different breeds, and so on. One of the good options is art painting.

And finally. The work of self-making something from wood (the same table) is just First stage mastering the skill of the "constructor-assembler". Having worked out technologies, methods on wood, having acquired the necessary skills, it is enough just to switch to other materials - metal, plastic, glass. So the benefits of a wooden table made from even the simplest drawing (besides the pleasure of work and the saved money) are obvious - not wasted time.

Best remembered for poorly designed dinner table... One that is too low or too high, under which there is not enough free legroom, where there is not enough space. To help you design a table that will only be remembered for its good looks, we provide some basic standards here.

HEIGHT OF THE TABLE. Distance from the floor to the top surface of the cover. Usually it is 68–76 cm.

SPACE ABOVE FEET... The distance from the floor to the bottom edge of the drawer side is vertical legroom. The minimum distance is 60 cm.

Knee space... The distance from the edge of the table to the leg is the space for the knees when the chair is moved up to the table. The minimum distance is from 36 to 40 cm, the optimum is 36–46 cm.

SPACE ABOVE THIGH... The distance from the seat to the lower edge of the drawer side is the vertical space for the hips when a person sits on a given chair pulled up to the table. Minimum 15 cm.

SPACE FOR ELOCKS... Side space on the table for everyone. The minimum is 60 cm, but 75 cm is much better.

DEPTH FOR HANDS... Front desk space for everyone seated. Less than 30 cm will be small, and more than 45 cm is too much.

CHAIR SPACE... The distance from the edge of the table top to the wall is sufficient to move the chair away from the table. The architects say that you need a minimum of 90 cm, and 110 cm would be the best option.

Side table

When you hear the word "table", don't you think about flat panel on four legs? Aren't you thinking about a table like the one drawn here? Yes, this design is the most primordial of the original. In the simplest version, a table - of a typical design - consists of only three types of parts: legs, drawers and a lid (table top). The legs and side girdle form a solid yet open supporting structure. Structurally, many tables are side-belt tables, although we rarely call them that. Much more often they are called according to their functional purpose or their location: dining, kitchen, bedside, writing table. As you leaf through the book, you will come across the original designs of different tables, and many of them will return to this "basic" table. Such a table is usually found in a kitchen or dining room. Its massiveness gives the impression of being robust. Although the legs are quite massive, the chiseled profile visually reduces their massiveness. Plus, the generous dimensions of the legs make them ideal for strong joinery connections. Despite the simplicity of the design of the table with a side belt, many variations are possible. The table can be round, square, oval, rectangular. Its legs can be square, chiseled, tapered, or carved. Even tsars can influence the look of the table.

Design options

For example, a round table with the same chiseled legs as base table looks completely different. This excellent look gives it a square side belt when round lid... Despite the elegant Queen Anne-style cabriole legs of the table, the massive drawers make it a work table. The cutaway drawers at the third table create significant visual and practical differences by making the table appear lighter and taller and creating more hip room.

Country style table

This table is called by various names - country-style table, retro-style table, bar table - and by many different names. Furniture researchers usually describe it as a simple, low, oblong table on a massive underframe with chiseled legs and prongs. This characterizes it quite accurately: a table with a drawer belt and prongs. Legs, especially as strong as in the picture, significantly increase the durability and rigidity of the structure. With intensive daily use, the strips can extend the life of the table for years. The terms "country" and "bar" are definitely associated with the 17th and 18th centuries, when such tables were widely used in hotels, taverns and bars in the countryside and towns. The surviving examples of such tables do indeed have massive punctures - albeit badly worn out by many legs. The table shown here is equipped with one mid-leg instead of two longitudinal ones to make it more comfortable to sit at the table. However, many early tables had perimeter pro-legs. The design is straightforward. The trestles and projections cut with spikes into the legs with reinforcement with wedges, pins, etc. The table cover is a wide panel “in the tip”.

This table is called by various names - country-style table, retro-style table, bar table - and by many different names. Furniture researchers usually describe it as a simple, low, oblong table on a massive underframe with chiseled legs and prongs. This characterizes it quite accurately: a table with a drawer belt and prongs. Legs, especially as strong as in the picture, significantly increase the durability and rigidity of the structure. With intensive daily use, the strips can extend the life of the table for years. The terms "country" and "bar" are definitely associated with the 17th and 18th centuries, when such tables were widely used in hotels, taverns and bars in the countryside and towns. The surviving examples of such tables do indeed have massive punctures - albeit badly worn out by many legs. The table shown here is equipped with one mid-leg instead of two longitudinal ones to make it more comfortable to sit at the table. However, many early tables had perimeter pro-legs. The design is straightforward. The trestles and projections cut with spikes into the legs with reinforcement with wedges, pins, etc. The table cover is a wide panel “in the tip”.

Design options

The easiest way to change the design of a table is to change the legs. Our "original" table has round legs - turned - and the shape of the turning can be changed endlessly. Just remember that you need a flat, rectangular surface for the drawer-to-leg connections. At the country-style table, you can also change the prongs - both in appearance,

and by their configuration, as shown in the figure below.

Side table with drawer and drawer

The name "table with a side-belt" refers rather not to style, but to construction. This type of table is the base for kitchen, library, desks etc. Even for a workbench. A drawer or two enhances the functionality of the table because the tools that are used to use it can be stored in those drawers. In some cases a small drawer is sufficient, in others the largest possible drawer is required. There are only a couple of ways to incorporate such a drawer. The simplest approach is to simply cut a box opening in the tsar. For a relatively small box and a fairly massive drawer side, it is quite suitable. If the opening turns out to be so large that it creates a risk of destruction of the board, then it is better to replace the tsar with box bars. The bars can be rotated 90 ° to match the width of the leg. Spike connections provide rigidity. The design with two - supra-drawer and under-drawer - bars is preferable, since the upper block will prevent the legs from moving inward.

The name "table with a side-belt" refers rather not to style, but to construction. This type of table is the base for kitchen, library, desks etc. Even for a workbench. A drawer or two enhances the functionality of the table because the tools that are used to use it can be stored in those drawers. In some cases a small drawer is sufficient, in others the largest possible drawer is required. There are only a couple of ways to incorporate such a drawer. The simplest approach is to simply cut a box opening in the tsar. For a relatively small box and a fairly massive drawer side, it is quite suitable. If the opening turns out to be so large that it creates a risk of destruction of the board, then it is better to replace the tsar with box bars. The bars can be rotated 90 ° to match the width of the leg. Spike connections provide rigidity. The design with two - supra-drawer and under-drawer - bars is preferable, since the upper block will prevent the legs from moving inward.

Design options

Installing a drawer in round table quite possible. But if the tsarovy belt has a square or rectangular shape, then you must be prepared that access to the inside of the box will be limited. If the tsarovy belt is rounded, then the front panel of the drawer should be made in such a way (for example, a layered-bent or block-glued structure) so that its shape matches the shape of the tsarga.

An alternative to a table with a leg in each corner is a table with one central support. Its tabletop is attached to a center post, set on low, diverging legs. Here, the drawers are not structurally required, but some single-support tables have them. At first glance, a table without legs and drawers gives unlimited legroom. However, while it does have a lot of knee and hip room, its "creeping" legs usually get in the way of the seated feet. This is the price of stability: the projection of the tabletop should not exceed the support area by more than 15 cm. A little more - and you risk toppling the table, leaning on the edge. Strength is critical to this design. center pillar and its connection to the base or legs. The table shown here has an oval table top and - in accordance with the major and minor axis of the oval - two pairs of legs different lengths... The legs are connected to the racks tapering downwards, and the racks with the table top brackets are connected with double spikes in the lugs. These intermediate assemblies, in turn, are glued onto a square core rail to form an upwardly flared center support.

A table on a support appeared in the 18th century as small table magazine type with a three-legged base. To make a dining table, carpenters combined two single-support tables or put an oblong tabletop on two three-legged supports. Modern models range from the simplest utilitarian to multi-rack. The structural advantage of multi-post supports is their increased tilt resistance. Although the footprint may be noticeably less than the projection of the table top, a large table with this type of foot can be reasonably stable due to the weight of the foot.

Put wide board on the goats - and you will get a table. This is the ancestor of the trestle table, which is perhaps the very first type of table. Since ancient times, its shape has been greatly improved, but it remains an easy-to-manufacture collapsible table. Its elementary form is a panel or plywood sheet on free-standing trestles. And when the trestles cease to be free-standing, then such an assembly becomes a table, because they must be connected to each other, to the tabletop, or both. In the table shown here, each half-wine goat consists of a fairly wide rack, cut into a leg at the bottom and a table top bracket at the top. The wider the goats, the better table resists swinging from side to side. A long massive prod is cut into the racks. The table top is fixed to the trestle with screws, and the structure becomes one whole. Although there is plenty of legroom under the tabletop, you shouldn't forget about the slip so that you don't bump your shins while sitting at the table. Also, the ends of the table top should protrude 35–45 cm beyond the trestle to provide sufficient space for those sitting there. Many gantry tables are collapsible. Common ways of attaching collapsible table parts are shown on the next page.

Design options

Thinking about the shape of the racks and legs of the goat is the easiest way to change the look of this table. Several examples are shown here. The original goats were similar to saw goats, and the X-shape was quite popular in medieval Europe. The Penilvan Germans and other Germanic settlers brought this uniform to America, and it can still often be found at picnic tables. Today, the most common is the H-shape. Shakers (sectarian shakers), who made many trestle tables, usually used graceful "high rise" legs

The familiar dining table can be expanded with an additional lid board. Then an ordinary table for a family can be enlarged to receive guests. At first glance, it may not be noticeable that this is a standard table with a side belt, cut into two parts and re-connected using special runners. Runners can be bought ready-made or made together with the table. Each cloth on the table top should be at least 60 cm - the optimal place for one person sitting.

Design options

The design of the sliding table can be varied, as usual, by changing the legs and drawers. The shape of the drawers and countertops practically does not affect general design... If it comes about the table with tsars, then with sliding option work as usual. As the extension limits increase, an additional leg may be required to support the middle section. And don't forget the importance of small details - for example, attaching the drawers to the table top.

Sliding table on one leg

A table on one support is the basic form of a table, which has some advantages over a table with a side belt. If you need a folding table, do not forget to consider this shape as well. With such a table it is quite possible to make a sliding, folding, and hinged lid, which will expand it. The most common option is a sliding cover with an insert section. As shown on the next page, the cover is split in two and the halves are connected by special sliding rails. Thus, these two cover sheets can be pushed apart and an additional board can be inserted between them. What to do with support is a key question for the master. For the table to be stable, the size of the cover and the area of the support must be close. In the example shown, the support is vertically divided into two parts, each of which is fastened to a corresponding cover sheet. When the cover is pushed apart, the support is also separated.

Design options

The basic form has a support that divides when the table is extended. This is not the only option. If a relatively small, say, 30-40 cm, expansion is acceptable, then sliding table can be done on a non-split support. Another option is to make a table on two legs. The table with support for each sliding half can be extended by 90–120 cm.

When choosing one of the types folding tables one of the most interesting designs is a system with pull-out sections. It is easy to manufacture and use. There is nothing unusual about the basic structure of a table. The only difference from the usual underframe made of tsars and legs is the presence of slots in the end tsars. The difference lies on top of the side bars and legs. Instead of attaching the countertop to the side girdle, its side sections, attached to long tapering runners, fit onto the side leg assembly. The runners correspond to the slots in the side bars. The existing center board, dividing the side sections, is fixed with screws on the side bars. The table top fits on top of the center board and side sections, but is not secured firmly. When unfolding the table, the side section simply slides out from under the cover. The skids are equipped with stops that do not allow the section to be extended too far. When extended, the lid will tilt slightly at first, but when fully unfolded it will be flush with the side section. Since the pull-out sections are part of the structure, you do not have to go looking for them in closets and closets when you need to lay out the table before guests arrive. You just slide out a section or two - even if the table is already set.

Design options

The system with pull-out sections can be combined with all types of table supports, provided the drawers are available. Thus, a trestle table or a two-support table (as in the figure on the right), equipped with drawers, can have pull-out sections to increase the number of seats. However, the system is not well suited for countertops with non-linear shapes. When folded, the side section is retracted under the lid and its edges remain (or should remain) visible. If the shape is different from the lid, then the table will probably look rather strange when folded. For example, a semicircular side section underneath a square or rectangular lid will create a gap between the lid and drawers.

Two-base table with pull-out

sections

A table with a sliding folding top (table top) is relatively rare. Despite its low prevalence, this is an excellent system. The table has one additional section - a duplicate of the "main" cover, this section is connected to the cover by means of hinges and when folded lies on the main section (cover). To unfold the table, the "double" tabletop is moved to its extreme position (up to half of the underframe), and then the additional section is folded back on the underframe. The upper edges of the drawers should be covered with felt or felt to facilitate the sliding of the lid. It is not difficult to make a sliding mechanism. Each runner has a ridge that fits into a groove in its guide. The disadvantage is that during the period high humidity ridges can jam in the grooves. The basic version is usually configured as a side table. In the unfolded state, the edges of the tabletop are quite far from the underframe, which creates sufficient space under the table for sitting. The Y-shape of the legs will provide ample legroom for those seated at the ends of the table.

Design options

When folded, this table looks like a somewhat odd dining table. To limit the overhang of the countertop above the baseboard (to ensure stability), the size of the base unit should be close to the size of the folded countertop. Therefore, a foldable table top should be used on a type of table that would not look odd if the top overhang is too small. Good options such uses include side tables (as basic), side tables (shown here), and other tables and tables special purpose... When folded, these tables can be placed close to the wall. Folding lids are commonly found in traditional card tables, but without a sliding mechanism. However, the sliding mechanism will work here as well.

A table with a folding board (or boards) is practically a "generic" name for all tables in which the sections of the table top are connected by hinges. It is a common species and has been found throughout American history. In any furniture style, from the style of William and Mary to the modern, you will find a drop-board table with drop-boards being part of the structure. When not in use, they can be lowered to an upright position, saving space in the room. There are many ways to keep the folding sections in the raised position. In the example shown here, slide-out holders are used — you lift the board and slide the support arms out from under it (much like a drawer). Some other support systems see table with swivel frame legs, with swivel legs for a book table and several card tables. The main thing to think about for this type of table is the width of the drop boards, which can be optimally supported by the extendable or swivel / articulated arms. Make drop boards relatively narrow — say no wider than 38 cm. For wider sections — see options with swivel frame supports or swivel legs. A long flip board like the example shown here will require more than one bracket. interesting name which applies to a relatively long utility table with hinged lids. This name, which can be translated as "Passion," creates in consciousness a picture of a large table spread out ", filled with food for hungry seasonal agricultural workers during the harvest season. Regardless of what we call it now, the people who sat at such a table in 1840 or 1880 probably called it a drop-board table or a folding table.

Design options

While the base dining table is fairly long and relatively narrow, with a rectangular top with sharp corners, the drop-board table can be of almost any size, proportion, and shape. The table top (table top) can have folding boards of a rounded or slightly rounded shape. A short or square base can be fitted with a round, square or oval countertop. You can round the corners of the flap sections or make their outer edges curved.

Book table - Russian name tables with swivel frame supports, which are pivotally attached to the drawer-leg-projectile assembly. The support post is connected to the pivot post by the upper and lower crossbar. The entire support can be rotated so that the raised folding section (board) can be placed on it. The pivot bearing was the predecessor to the pivot foot. It has many structural elements that reflect the state of the art of carpentry in the 16th century when it first appeared. But like any well-made frame, it is structurally rigid and provides an excellent support for the folding board. Although the first such tables usually had two frame supports (one for each folding board), tables with one folding board and one swivel support were often found, and it happened, and vice versa, there were several leviaths with 12 swivel supports. When folded, the tables were generally very narrow and saved a lot of space. A large table with two pivot legs on each dropboard could be made so that the legs pivot towards each other or away from each other. If they turn towards each other, then when the folding boards are lowered, the support posts of the frames will be located next to the main legs, visually making them more massive. When pivoted away from each other, the support legs will sit side by side, giving the impression of a table with six legs. The first tables were usually made in the Baroque style, with a complex chiseled profile of the legs. However, the example shown is completely modern in style.

Design options

A significant advantage of a book table is the ability to support very large additional sections. A secure support under the drop board makes the table very stable, even with one section raised. Thus, it is difficult to make a very narrow table with wide drop-boards. When folded, the table takes up very little space. Unfolded - has a huge table top

This table can rightfully be called a table with folding boards, but the swivel leg makes it stand out from others like it. The swivel leg is a descendant of the frame swivel support (see page 158). If the swivel support is attached to the table frame, which consists of a side bar, legs and a prodrug, then the swivel leg is attached only to the side bar. The result is a lightweight appearance. Size rather than pivot foot assembly is characteristic of this table. The diameter of the tabletop is only 107 cm and will be quite comfortable for four people. The swivel leg is used in card tables with small folding tabletops. During the Queen Anne period, a smaller version of the table shown here was called the "breakfast table" and was used for both actual breakfast and games and teas. Larger tables are likely to need additional pivot feet for improved support for the folding boards. The pivot joint - actually a wooden hinge - makes the pivot foot realizable. A sleeker option than shown here makes the connection look like a metal hinge.

Design options

The design of a swivel table leg with folding boards appeared in the first half of the 18th century. Although we chose the “basic” table in the style of Queen Anne, the swivel leg was used in the tables different styles... The foot profile will usually be a style indicator. Chippendale-style swivel tables often have convertibles, but always with a claw-ball finish. Square shaped legs are also used in Chippendale tables. During the federal

Heppleight tables were made with tapering legs, as shown here, and Sheraton tables were made with chiseled, often embossed, legs.

Unfolded folding boards transform

rectangular table to square

The advantage of a frame pivot table over a pivot leg table is the stability provided by the additional legs. When the folding boards are raised, additional legs support them. An extendable leg table also has this advantage over a pivot table, but has one advantage over a frame pivot table: Like a pivot table, this table has an additional leg for each flap. But only a narrow crossbar connects the leg to the table. These crossbeams are placed in a cage of two guides installed between the longitudinal side bars, and are extended through the cutouts in the side bars. The leg is attached to the rungs. Raise the flip board, extend the leg, and lower the board onto it. You have a leg under the drop-board and still have four legs under the stationary table top. This structure can hold very wide drop-boards.

Design options

Here are two very different tables with extendable legs, each with excellent stability thanks to the extra leg (or legs) when unfolded. When the card table is folded up against the wall, the extra leg is unobtrusive. By expanding the game table and pulling out the additional leg, you will receive a support at each corner of the tabletop. Ideally. The extendable legs are also a great addition to a long drop-down table. If you make two retractable legs for each board, then the table will not lose stability when someone leans too much on it.

The armchair table owes its birth to medieval practicality. In the Middle Ages, dwellings were small and draughty. Any furniture was expensive, everything was done hand tools... And if a piece of furniture could serve more than one function, well, so much the better. The table-chair is clearly versatile. With the lid down, this is a table. With the lid up - the seat. And as with most universal things, its functionality is far from perfect. With the development of the furniture industry, the table-chair became more perfect in design and graceful in appearance. The item shown here has legs and armrests attached to the sides of the seat with dowel-to-socket connections. The pronounced shoe-shaped end of the leg makes the chair more stable and the armrests more comfortable. The chair even has a drawer under the seat - more sophisticated storage than a box with a lid. The table top is secured with a dovetail inset.

HTC One X: specifications, reviews, prices, description of NTS X

HTC One X: specifications, reviews, prices, description of NTS X Review of HTC One X - a peppy old man One X

Review of HTC One X - a peppy old man One X Samsung GT-B2710 Xcover - Special Purpose Phone

Samsung GT-B2710 Xcover - Special Purpose Phone