We make water heated floors in the house. How to make a water heated floor in the house. There are two main designs of underfloor heating

Today, water heated floors are a very popular option for heating private homes. In addition to high efficiency, this design has many advantages, including the possibility of a radical change in the interior, by getting rid of classic radiators. Despite a lot of advantages, the hydraulic system of heated floors has one significant drawback - the complexity of installation, which increases the estimated cost of water heating in a private house at times.

It is possible to reduce the cost of this heating system (CO) if all the stages of creation are performed on their own. This publication will address issues related to the preparatory work and the creation of a hydraulic heated floor with your own hands.

Foundation preparation

Proper preparation of the surface for laying the floor heating coil provides half the success in the implementation of this CO of a private house.

- If the base is a floor slab, then the preparatory work includes cleaning the surface, leveling with cement-sand or specialized mixtures. If the surface of the base is wooden, then the algorithm of work is as follows: cleaning from dirt and debris, stuffing sheets of plywood or chipboard for leveling. If it is planned to lay the coil on the ground, then the following operations are preliminarily carried out: creating a layer of sand and gravel, tamping with a vibrating plate, leveling. In some cases, it is recommended to create a rough reinforced base.

- The fourth stage of base preparation is reinforcement, which is necessary for fixing the pipeline and fixing the screed. The thickness of the screed for a water-heated floor varies from design and materials. The optimal thickness of the "pie" is from 70 to 130 mm.

Design and components of the system

Consider classical scheme underfloor heating water with connection to an autonomous heat generator. This design consists of:

Consider classical scheme underfloor heating water with connection to an autonomous heat generator. This design consists of:Boiler.

Important! It should be understood that the temperature of the coolant in the central CO varies from 70 to 90°C. In order to avoid circuit failure, direct connection to the central heating pipe is not recommended. Even if the piping material and fittings can withstand high temperatures, consider walking comfortably on floors with temperatures above 60°C!

- Expansion tank of the closed type.

- pressure gauge.

- A pump that circulates the coolant in the circuit. This device may be included in the design of the boiler plant.

- Coil piping.

- Thermal conductivity more than 0.43 W / m 0 С;

- The expansion coefficient is not higher than 0.025 mm/m;

- Working pressure - 10 bar;

- Operating temperature 95°C.

The second step in preparing the base is waterproofing. Heating in the floor in a private house cannot be carried out without an appropriate waterproofing layer. Materials for its creation can be: mastics, bituminous materials, polyethylene film, at least 100 microns thick.

Important! After laying the waterproofing around the entire perimeter of the room, a damper tape is fastened, which compensates for the thermal expansion of the floor during heating.

The third stage is warming. This event is designed to ensure that the heat from the coil does not go deep into the floor.

Tip: If it is planned to organize this CO, only as an additional one, then it is enough to use a substrate under a warm water floor made of foamed polyethylene with a foil coating. If a warm floor is planned above a heated room, then expanded polystyrene sheets, 50 mm thick, are used as a heater. If a water heated floor is created on the ground or over an unheated basement, then the insulation layer should be from 50 to 100 mm.

In addition, for self-creation water heated floor will need: ball valves installed at the inlet of the heat generator; circulation pump (may be included in the design of the boiler unit); pipes and fittings for laying the route and connecting the coil to the collector, the number of which is calculated individually, based on the scheme and design of this CO.

The underfloor heating circuit can be connected from an autonomous heat generator (gas electric or solid fuel). If the house provides for heating from central heating, then if you have permits, you can simply connect a warm floor from heating with your own hands. IN Lately, quite popular sources of thermal energy are a boiler indirect heating or instantaneous water heater.

The underfloor heating circuit can be connected from an autonomous heat generator (gas electric or solid fuel). If the house provides for heating from central heating, then if you have permits, you can simply connect a warm floor from heating with your own hands. IN Lately, quite popular sources of thermal energy are a boiler indirect heating or instantaneous water heater.

The main conditions for the use of a particular heat source are sufficient performance, efficiency and safety. Required power the boiler unit can be calculated according to the algorithm: for heating 10m 2 of a brick private house with double plastic windows, you need 1 kW of heat generator power.

Tip: Not all houses are insulated according to European standards (heat loss is not more than 40W/m2). In addition, much depends on the region of residence. Based on this, for houses in the northern regions and poorly insulated buildings, experts recommend increasing the design capacity of the heating installation by 20-30%.

Pipes

The material for creating a water heated floor, when heating a private house, are: metal-plastic, reinforced polypropylene or cross-linked polyethylene. Recently, the recognition of specialists has earned pipes made of polyethylene, which do not have high values of linear expansion when heated, have good tightness and thermal conductivity. The pipe diameter should be within 16-20 mm. In addition, the pipe for the water floor must have the following characteristics:

The material for creating a water heated floor, when heating a private house, are: metal-plastic, reinforced polypropylene or cross-linked polyethylene. Recently, the recognition of specialists has earned pipes made of polyethylene, which do not have high values of linear expansion when heated, have good tightness and thermal conductivity. The pipe diameter should be within 16-20 mm. In addition, the pipe for the water floor must have the following characteristics:

You can calculate the required amount of pipe according to the table below:

Pump

As already mentioned above, circulation pump, today, most modern heat generators are equipped, and it is necessary to purchase it only if it is not in the equipment.

The main condition for choosing this device is performance. You can choose the right circulation pump according to the table below:

The collector for heating and underfloor heating is a branch pipe with a certain number of outlets. This splitter is designed to connect several heating circuits (including underfloor heating) to the supply and return trunk line autonomous SO. In this design, two such devices are used: one - for the distribution of hot coolant, the second - for collecting chilled water from the kennel. The collector also includes air vents, the necessary valves and taps designed to adjust the performance of this CO.

The collector for heating and underfloor heating is a branch pipe with a certain number of outlets. This splitter is designed to connect several heating circuits (including underfloor heating) to the supply and return trunk line autonomous SO. In this design, two such devices are used: one - for the distribution of hot coolant, the second - for collecting chilled water from the kennel. The collector also includes air vents, the necessary valves and taps designed to adjust the performance of this CO.

When choosing this device it is necessary to determine the number of taps sufficient for all heating circuits. If you are willing to pay for the full automation of the process of underfloor heating as part of CO, then pay attention to models equipped with servo valves and mixers. Do not neglect the collector box, the dimensions of which are selected in accordance with the dimensions of all equipment included in the collector group.

For a clearer understanding of the collector assembly process, we recommend that you familiarize yourself with the video

Underfloor heating is no longer a novelty. This technology is used for underfloor heating in apartments, private houses, offices and various other premises. Their principle of operation is simple - they heat the base under your feet, as well as the air in the room, which allows you to warm up any room well enough. They are usually installed in addition to the main heating system. Installing them is not as difficult as it seems, but this is a rather troublesome business. How to make a warm floor? This process will largely depend on what type of system was chosen for installation.

Now there are three main types of underfloor heating, which differ in the type of coolant, and also have different technology arrangement. However, in general, they are united by one main advantage - the heating element is installed directly into the floor cake, due to which it is heated. At the same time, the air masses in the room also warm up, but the air will be warmer near the floor, but above this limit, at the level of a person’s head, the air remains slightly cool, which allows you to create an optimal microclimate in the room.

On a note! In certain cases, underfloor heating can completely replace the central heating system. But this is not always possible, and you still shouldn’t refuse the main radiators.

Water based heating

In this case, the heat carrier is ordinary heated water, which flows inside pipes laid according to a certain pattern and filled with a concrete screed. The service life of such a system is approximately 20 years. A fairly reliable and safe option, but it is used either in private homes or in new buildings where it is possible to connect such a floor. In old high-rise buildings without permission management company it will not work to connect the water floor, since the installation will involve connecting it to the central heating system, which is not designed for additional loads - it can become very cold in other apartments.

The disadvantages of this design may be the likelihood of leaks and the risk of flooding of the premises located below, as well as the tendency of some types of pipeline to corrode. Installation, of course, is laborious, but this is one of the most economical floor options. You can install such heating under any finish coating. However, if you want to use the possibilities of a water-heated floor as efficiently as possible, study the features different coatings. Finding the perfect match will help.

Heating with cable

Such floors can be installed in absolutely any room - even in old, even in new apartments, houses, offices, etc. This option has become a real salvation for those who, for some reason, cannot make a water heated floor. The system is quite simple to install and is a special scheme laid electrical cable located inside the screed. It converts electricity into heat.

For the arrangement of heating can be used self-regulating and resistive cables. In the latter case, a two-core is usually used (single-core often become sources of radiation harmful to the body, which is why they are not preferred to be used). Self-regulating wires do not have the disadvantages that resistive wires have. Typically, a cable floor is used if the top coat is made of tiles or linoleum.

IR floor

This is perhaps the most popular floor heating system, as it does not require pouring a new screed, it is easy to install, but it is not inferior in quality to other heating options. It is represented by thin mats with carbon strips connected to each other by wires. Such floors heat up quickly, but also cool down quickly (sometimes this function is needed), they are very thin, allow you to quickly adjust the heating temperature, are economical in terms of energy costs, easy to repair and completely safe for humans. Such a system also works thanks to electricity. There is a drawback - a small static and because of this - the attraction of dust to the base. Read more about infrared underfloor heating, depending on the finish, in separate articles of the portal: under the laminate, and under the tile.

Table. Comparison of characteristics of different systems.

| Characteristic | water floor | electric floor |

|---|---|---|

| Presence of EMP | Not | Possibly, depending on cable type |

| Possibility of arrangement in apartment buildings | Only in new buildings with a separate connection | Yes |

| Quick settings management | Not | Yes |

| Dependence on the heating season | Yes - in apartments and no - in private houses | Not |

| Installation time | Long due to the need to fill the screed | Short |

| Possibility of laying any finishing coating | Yes | Certain types of flooring should not be placed on top of an electric floor |

| Ease of repair | Complicated repair | In the case of IR floors - quick repair |

Prices for electric underfloor heating "Teplolux"

electric underfloor heating thermolux

If you have not yet decided on the type of underfloor heating, read. There we examined in detail the advantages and disadvantages of different materials and compiled a list of recommendations.

We make a warm water floor with our own hands

Let us consider in more detail the process of work in the arrangement of water floor heating. It includes a number of stages - this is the preparation of a rough base, the installation of the system itself, as well as pouring the screed and laying the finish coat. In this case, a budget option for creating a heating system will be considered.

Heated floors are a serious cost item during repairs, so it is important to accurately calculate how much and what materials will be needed. To facilitate your labor costs, we have prepared a guide that tells how to calculate a warm floor - water or electric. Online calculators are included. And in the article "" you will find a complete list of everything that you may need during installation.

Foundation preparation

Consider how to make a subfloor for the arrangement of a water system based on expanded clay.

Step 1. First of all, the old wooden floor is completely dismantled. Boards and logs are removed. Remains of bricks and oversized construction garbage may be left on the ground.

Step 2 A laser level is used to determine the height of the final floor. The main target of the required level is Entrance door. The marking should be 1.5-2 cm below the threshold.

Step 3 Markings are applied to the walls. The first mark indicates the boundary of the screed with the laid heating pipes (the thickness of the screed should not be less than 6 cm thick). The second indicates the thickness of the expanded clay insulation (in this case, the thickness of this layer will be 10 cm).

Step 4 Along the line of the laser level, marks are applied to the walls along the entire perimeter according to the level of the finished floor.

Step 5 Markings are also applied to the walls of two other levels - expanded clay bedding and screed. The reference point in this case is the mark of the finished floor.

Step 6 The rough concrete floor is covered with sand, which is evenly distributed over it. You can focus on the bottom mark.

Step 8

Step 9 The holes in the walls left from the log are sealed with pieces of brick and cement mortar.

Step 10 Waterproofing is laid on a layer of sand. In this case, it is a dense polyethylene film, which is laid with the plant on the walls. For convenience, the film is fixed with adhesive tape.

Step 11 Beacons are being installed. For this, high-density foam block cubes are used, on which metal beacons will then be installed. Cubes are installed on polyethylene at a distance of about 1 m from each other. The height of one cube is 9 cm.

Step 12 Metal beacon profiles 1 cm high are installed on the cubes.

Step 13 At the junctions of the lighthouses, a cube must be installed. For proper docking, the beacons are cut. With proper docking, the beacons overlap each other in the direction of the future movement of the rule.

Step 14 Lighthouses are set by level. Landmark - a line on the wall indicating the height of the screed. To level them, you can use plywood linings.

Step 15 When the beacons are level, they are fixed on the cubes with self-tapping screws.

Step 16 The draft floor should have a slight slope (the difference is up to 5 mm for each meter of the base length). If necessary, the cubes can be pressed into the sand to achieve the desired result. The operation is performed along the entire length of the lighthouses.

Step 17 Additional cubes are installed between the main cubes.

Step 18 Expanded clay is mixed with a small amount cement mixture. This will give you a stronger floor. A bucket of sand, 2 kg of cement and about 3 liters of water are used for a bag of expanded clay.

Step 19 The prepared expanded clay is laid out on the base and leveled. Backfilling is done starting from the far corner of the room. There should be about 1.5 cm of free space left to the top level of the beacons.

Step 20 The expanded clay layer is covered with cement mortar. The solution is leveled with a trowel over the entire surface.

Step 21 The screed is aligned with the rule according to the beacons. Perfect evenness can not be achieved. To make it easy to remove the beacons from the screed, their surface is not smeared.

Step 22 Two days later, when the screed dries, the beacons are removed. To do this, the screws fixing them are unscrewed. Together with the beacons, wooden linings are removed.

Step 23 After that, the resulting cracks are cleaned of debris and sealed with cement mortar.

Pipe laying and connection

After preparation, the installation of the heating system itself begins.

Step 1. In this case, the existing heating system will be kept on the basis gas boiler. The battery is powered by a supply circuit located on the second floor. The water leaving the radiator is sent to the return circuit, which is located in the basement. The warm floor will be connected to the second output of the battery and to the return circuit. Taps will be installed to turn off the radiator and underfloor heating. A circulation pump will be installed at the entrance to the return circuit.

Step 2 The radiator is equipped with the necessary fittings. These are connectors and pipes. To seal the connection, plumbing linen and sealant are used.

Step 3 This is how the finished outputs from the battery will look like. One of them will be used to connect a warm floor.

Step 4 Before further installation of pipes around the perimeter of the room is glued damper tape(we have already talked about her choice). She sits on the walls with glue.

Step 5 Multifoil is laid on the rough screed - a special insulation. Separate strips of material are fixed to each other with adhesive tape.

Step 6 A reinforcing mesh with 10x10 cm cells is laid on top of the foil. Individual pieces are overlapped by 1-2 cells. The grid is connected to each other with a wire.

Step 7 A pipe leading to the return is installed and connected.

Step 8 A water floor pipe with a cross section of 20 mm is mounted to the other outlet from the battery. A piece of protective corrugation can be put on the initial section of the pipe.

Step 9 The pipe is laid on the floor and fixed to the reinforcing mesh with plastic clamps. When laying, it is important to ensure that there are no kinks on the pipe. To form knees, you can use a hair dryer that heats the pipe. The distance in the circuit between adjacent pipes should be about 20 cm in this case.

Step 10 The underfloor heating pipe is laid with a snake.

Step 11 The ends of the return pipe and the underfloor heating are sent to metal pipes leading to the basement. Voids can be sealed with mounting foam.

Step 12 The sections of the metal mesh rising above the floor level are fixed on the floor base with the help of dowels and metal plates.

Step 13 Further work will be carried out in the basement. A circulation pump is being installed. It connects to the return pipe. Two cranes are also installed in the system. One of them will block the natural circulation. The lower valve completely blocks the entrance to the return pipe.

Step 14 The control unit is assembled and all pipes are connected. In natural circulation mode, water flows through the underfloor heating pipe into the return line with both taps open. If you turn off the top tap, then the water from the warm floor will move through an additional pipe towards the pump - this is the mode of rapid heating of the floor. If the bottom tap is closed when the pump is off, then the warm floor will be completely turned off.

Filling the screed

The final stage of the installation of the water floor is the pouring of the screed and laying the floor covering.

Step 1. To make the screed even, metal beacons are installed. They are located on pieces of concrete.

Step 2 Pieces of concrete are fixed to the base with cement mortar.

Step 3 Beacons are fixed on concrete with self-tapping screws in pre-made holes. All of them must be aligned strictly according to the level.

Advice! It is better to start installing the first beacons from the side of the door. This will allow you to correctly select their height relative to the doorway.

Step 4 A concrete solution is prepared in exact proportions.

Step 5 The concrete is evenly distributed over the prepared floor.

Important! At the time of laying the screed, the floor pipes must be filled with water.

Step 6 The concrete solution is aligned with the beacons using the rule.

Step 7 The screed is dried for 28 days. The floor is covered with a top coat.

Video - Installation of a water floor

Video - Installation of a warm infrared floor

The complexity and the entire process of manufacturing a warm floor will depend on which heating option is chosen. The water floor is perhaps the most best option for arranging base heating in a private house or new building. Those who do not want to mess with the screed can be recommended to use infrared floors.

Warm floors are considered in our understanding to be a more modern heating system than radiator heating. However, this is far from the case - they appeared much earlier. Stubborn historical facts indicate that underfloor heating has been successfully used since ancient rome, in Korea, and in Russia too. True, only stove heating was used at that time, since the system for transporting hydrocarbons through pipes did not yet exist. In the modern world, the most economically successful countries widely use underfloor heating, and this is done not only for reasons of obvious comfort, but also takes into account the fact that such heating saves energy resources, the demand for which is growing every year.

This type of heating is not cheap. Parts and labor are very expensive. That is why any zealous owner may have the idea of making a warm water floor with his own hands. Why not? Moreover, the experience of both successful and unsuccessful implementations has already been accumulated enough to give specific recommendations. The purpose of our article is to give specific advice to those owners who are going to make a warm water floor, but at the same time so that they save their money and in the end get what they wanted - comfortable and economical heating.

Why underfloor heating?

Of course, they are easier to implement, they are easier to manage, but the cost of energy carriers makes its own adjustments - this type of heating is much more expensive to operate than a water heated floor. It will take only 4-5 years and a warm water floor will pay off with interest, but only on condition that it is done correctly and correctly. This is what the authors of the article want to tell our readers. Sweeping aside colorful catalogs with expensive equipment, but based only on the experience of people who were able to implement a warm water floor in their home.

Most heating systems currently use natural gas as a heat source - and this is completely logical, since this type of fuel is cheaper than others. And this trend will continue for at least a few more decades. Therefore, warm floors are best implemented with water, the coolant in which is heated by the energy of natural gas combustion. But for this, a number of conditions must be met.

Water floor heating device

A warm water floor is a complex multicomponent system, each part of which performs its own function. Consider its device in the following figure.

Typical design"pie" of a warm water floor

Typical design"pie" of a warm water floor This kind floor heating called "wet" because "wet" are used in its arrangement construction processes, namely the pouring of a cement-sand screed. There are also so-called dry warm floors, but they are made mainly. Within the framework of this article, we will consider exactly “wet” warm water floors, since they are much better, although their installation is more difficult.

A warm water floor is mounted on a stable and solid base, which can be a concrete slab or soil. A vapor barrier made of a polyethylene film with a thickness of at least 0.1 mm is laid on the base. The next layer of the "pie" is a heater, as it is best to use extruded, which has a very low thermal conductivity, high mechanical strength and reasonable cost. On top of the insulation is equipped cement-sand screed, to which a plasticizer is necessarily added - for the mobility of the mixture, ease of installation and reduction of the water-cement ratio. It is desirable to reinforce the screed with a metal wire mesh with a cell pitch of 50 * 50 mm or 100 * 100 mm. In the same place, inside the screed, pipes of a warm floor pass with a coolant circulating in them. It is recommended to make the screed height above the pipes at least 3 cm, however, practice suggests that 5 cm is better, so the strength will be higher and the heat distribution across the floor will be more uniform.

At the junction of the walls to the screed, as well as at the boundaries of the warm water heating circuits, a damper tape is laid, which compensates for the thermal expansion of the screed when it is heated. The floor covering must be specifically designed to work with underfloor heating. The best way out is ceramic or porcelain stoneware, but some other types of coating - laminate, carpet or can also be used with underfloor heating, but there should be a special icon in their marking.

Such coatings, however, require strict adherence to the thermal regime of the floor, which is achieved by using automation - special mixing units.

Requirements for premises where heating with warm water floors will be implemented

The smartest move in construction is when the underfloor heating pipeline is laid even at the stage of construction of floors. This is very successfully used in Germany, Sweden, Norway, Canada, yes, and in other economically successful countries where energy resources are very expensive and therefore they use floor heating, which is 30-40% more economical than radiator heating. It is quite possible already in the finished room, but it must meet certain requirements. Let's list them.

The most correct underfloor heating pipeline is the one that was laid at the stage of building a house

The most correct underfloor heating pipeline is the one that was laid at the stage of building a house - Given the significant thickness of the warm water floor - from 8 to 20 cm, the height of the ceilings in the room should allow the installation of such a heating system. It is also necessary to take into account the value doorways, which must be at least 210 cm in height.

- The subfloor must be strong enough to support a heavy cement-sand screed.

- The base for the underfloor heating must be clean and level. Irregularities should not exceed 5 mm, since drops greatly affect the flow of the coolant in the pipes, they can lead to airing of the circuits and an increase in hydraulic resistance.

- In the room where a warm water floor is planned, all plastering work, windows are inserted.

- Heat loss in the premises should not be more than 100 W / m 2. If they are larger, then it is worth thinking about warming, and not heating the environment.

How to choose a good pipe for underfloor heating

About the pipes of a warm water floor it is written in sufficient detail on our portal. Obviously, for underfloor heating it is better to choose pipes made of cross-linked polyethylene - PEX or PERT. Among PEX pipes, preference should be given to PE-Xa pipes, as they have a maximum crosslink density of about 85% and therefore have a better “memory effect”, that is, pipes after stretching always tend to return to their original position. This allows the use of axial fittings with a sliding ring, which can be walled in without fear. building construction. In addition, when a pipe is broken, its shape can be restored by heating the problem area with a building hair dryer.

PERT pipes do not have a memory effect, so only push-in fittings are used with them, which must not be walled up. But if all the contours of the warm floor are made with solid pipe sections, then all connections will be only on the collector and it is quite possible to use PERT pipes.

In addition, manufacturers produce pipes of a composite structure, when aluminum foil is placed between two layers of cross-linked polyethylene, which is a reliable oxygen barrier. But the heterogeneity of the material, the difference in the coefficients of thermal expansion of aluminum and polyethylene can provoke pipe delamination. Therefore, it is better to choose PE-Xa or PERT pipes with a polyvinylethylene (EVOH) barrier, which significantly reduces the diffusion of oxygen into the coolant through the pipe wall. This barrier can be located in the outer layer of the pipe, or inside, surrounded by layers of PE-Xa or PERT. Of course, that pipe is better, in which the EVOH layer is located inside.

For underfloor heating circuits, there are three main pipe sizes: 16 * 2 mm, 17 * 2 mm and 20 * 2 mm. Most often, 16 * 2 and 20 * 2 mm are used. How to choose exactly the “right” pipe.

- Firstly, the brand in this matter matters and you need to pay attention to it. The most famous manufacturers: Rehau, Tece, KAN, Uponor, Valtec.

- Secondly, pipe marking can “tell” a lot, it should be carefully studied and you should not be shy to ask more questions to the sales assistant.

- Thirdly, the qualification of the sales assistant is very helpful when choosing a pipe. Do not forget to require certificates of conformity, inquire about the availability and price of fittings, mixing units, manifolds and other equipment. It is necessary to find out in which bays the pipe is sold, by how many meters, in order to take this into account in future calculations.

- And finally, if a PE-Xa pipe is chosen, then a small test can be carried out. To do this, a small section of the pipe must be broken, and then warm this place with a building hair dryer. High-quality PE-Xa, and PE-Xb pipes should also restore their original shape. If this does not happen, then whatever is written on the label is simply not a PEX pipe.

Underfloor heating design principles

One of the most important stages in the arrangement of warm water floors is their competent calculation. Of course, it is best to entrust this to specialists, but already enough accumulated experience suggests that this can be done on your own. On the Internet you can find a lot free programs and online calculators. Most well-known manufacturers provide their software for free.

water heated floor

First you need to decide on what temperature the warm floor should be.

- In residential areas where people spend most of their time standing, the floor temperature should be between 21 and 27°C. This temperature is the most comfortable for the feet.

- For working premises - offices, as well as living rooms the temperature must be maintained around 29°C.

- Hallways, lobbies and corridors optimum temperature– 30°C.

- For bathrooms and pools, the floor temperature should be higher - about 31-33°C.

Heating with warm water floors is low-temperature, therefore, the coolant must be supplied at more low temperatures than in radiators. If water can be supplied to the radiators at a temperature of 80-90 ° C, then no more than 60 ° C can be supplied to the warm floor. In thermal engineering, there is such an important concept as temperature drop in the heating circuit . This is nothing but the difference in temperature between the supply pipe and the return pipe. In underfloor heating systems, 55/45°C, 50/40°C, 45/35°C and 40/30°C are considered optimal.

A very important indicator is (loops) of a warm water floor. Ideally, they should all be the same length, then there will be no problem with balancing, but in practice this is unlikely to be achieved, therefore it is accepted:

- For a pipe with a diameter of 16 mm, the maximum length is 70-90 m.

- For a pipe with a diameter of 17 mm - 90-100 m.

- For a pipe with a diameter of 20 mm - 120 m.

Moreover, it is desirable to focus not on the upper boundary, but on the lower one. It is better to divide the room into more loops than to try to achieve circulation with a more powerful pump. Naturally, all loops must be made with pipes of the same diameter.

Laying step (laying) of underfloor heating pipes - another important indicator, which is made from 100 mm to 600 mm, depending on the heat load on the warm floor, the purpose of the room, the length of the circuit and other indicators. It is almost impossible to make a pitch of less than 100 mm with PEX pipes, there is a high probability of simply breaking the pipe. If the underfloor heating is equipped only for comfort or additional heating, then you can minimum step make 150 mm. So, what layout step should be applied?

- In rooms where there are external walls, so-called edge zones where the pipes are laid in increments of 100-150 mm. In this case, the number of rows of pipes in these zones should be 5-6.

- In the centers of the premises, as well as in those where there are no external walls, the laying step is 200-300 mm.

- Bathrooms, baths, paths near the pools are laid with a pipe with a pitch of 150 mm over the entire area.

Ways of laying the contours of the warm floor

The contours of a water-heated floor can be laid in different ways. And each method has its advantages and disadvantages. Let's consider them.

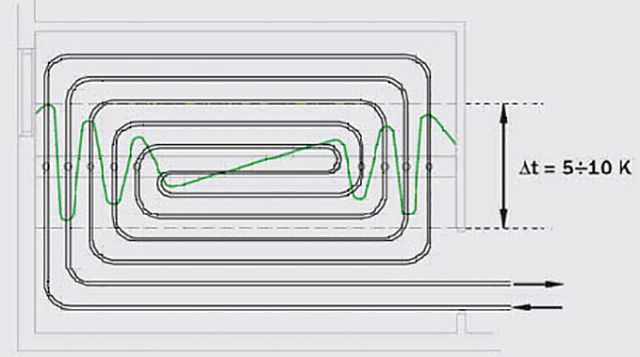

- Laying a pipe for underfloor heating "snake" easier to install, but its significant drawback is that there will be a noticeable temperature difference on the floor at the beginning of the circuit and at the end - up to 5-10 ° C. The coolant, passing from the supply manifold to the return one in the underfloor heating structure, cools down. Therefore, there is such a temperature gradient, well felt by the feet. It is justified to use this laying method in boundary zones, where the floor temperature should decrease from the outer wall to the center of the room.

- Laying a pipe for underfloor heating "snail" more difficult to implement, but with this method, the temperature of the entire floor will be approximately equal, since the supply and return pass inside each other, and the difference is leveled by a massive floor screed when the design requirements of the laying step are met. In 90% of cases, this method is used.

- Combined methods of laying underfloor heating pipes are also used very frequently. For example, the edge zones are laid with a snake, and the main area with a snail. This can help to correctly divide the room into contours, distribute the pipe bay with a minimum of residues and provide the desired mode.

Each method can be used variable paving pitch when in the edge zones it is 100-150 mm, and in the room itself 200-300 mm. Then it is possible to meet the requirements for more than intensive heating edge zones without using other laying methods. Experienced installers often do just that.

The layout of the heating circuit "snail" with a constant step (left) and with a variable bare (right)

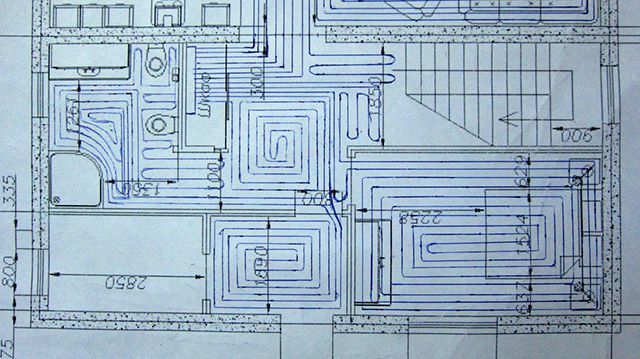

The layout of the heating circuit "snail" with a constant step (left) and with a variable bare (right) To calculate the contours, it is best to use special and very easy-to-learn software. For example, the well-known manufacturer Valtec, which distributes its program for free. There are also simpler programs for calculating the layout of the contours, which calculate the length of the loops, which is very convenient. For example, the program "Snail", which is also distributed free of charge. For those who are not very friendly with a computer, you can do the calculation of the contours on your own, using millimeter paper, on which you can draw a floor plan on a scale and “lay out” the contours on this sheet with a pencil and calculate their length.

When dividing the premises into contours of a water-heated floor, the following requirements must be met:

- The contours should not move from room to room - all rooms should be regulated separately. An exception may be bathrooms if they are located nearby. For example, a bathroom next to a toilet.

- One heating circuit must not heat a room larger than 40 m2. If necessary, the room is divided into several circuits. Maximum length either side of the circuit should not exceed 8 meters.

- Along the perimeter of the room, between rooms, as well as between individual circuits, a special damper tape should be laid, which, after pouring the screed, will compensate for its thermal expansion.

Choosing the type of insulation for underfloor heating and its thickness

Insulation for a warm water floor is mandatory, because no one would like to spend their money on heating the earth, the atmosphere or unnecessary building structures, but the floor is exactly the right one, which should take the lion's share of the heat from the heating circuit. For this, a heater is used. What types should be used? Among all their diversity, the authors of the article recommend that you should pay attention to only two of them.

- Extruded polystyrene foam (EPS). This material has low thermal conductivity, high mechanical strength. EPPS is not afraid of moisture, it practically does not absorb it. Its price is quite affordable. This insulation is produced in the form of plates of standard sizes 500 * 1000 mm or 600 * 1250 mm and a thickness of 20, 30, 50. 80 or 100 mm. For good joining of the plates on the side surfaces there are special grooves.

- Profile heat-insulating from expanded polystyrene of high density. On their surface there are special round or rectangular bosses, between which it is very convenient to lay the pipe without additional fixation. The pipe fastening pitch is usually 50 mm. This is very convenient during installation, but at a price they are much higher than XPS boards, especially from famous brands. They are produced with a thickness of 1 to 3 cm and dimensions of 500 * 1000 mm or 60 * 1200 mm - it depends on the manufacturer.

XPS boards can have an additional foil layer with additional markings. Marking the plates is, of course, useful, but the presence of foil only increases the cost of the insulation, and there will be no sense in it for two reasons.

- The reflectivity declared by the manufacturers will not work in an opaque medium, such as a screed.

- Cement slurry is a strong alkaline environment, which perfectly "eats" an insignificant (several tens of microns) layer of aluminum even before it hardens. We must realize that foil plates are a marketing ploy and nothing more.

The authors of the article recommend using XPS boards for insulation. Savings compared to profile mats will be obvious. The difference in cost is enough for fasteners, and there is still a lot of money left. Let's remember folk wisdom that money saved is akin to earned money.

What thickness should be the insulation in the design of the warm water floor cake? There are special and complex calculations, but you can do without them. If you learn a few simple rules.

- If warm floors will be made on the ground, then the thickness of the insulation must be at least 100 mm. It is best to make two layers of 50 mm and lay them in mutually perpendicular directions.

- If warm floors are planned in rooms above ground floor, then the thickness of the insulation is at least 50 mm.

- If warm floors are planned above rooms heated from below, then the thickness of the insulation is at least 30 mm.

Additionally, it is necessary to provide for the fastening of XPS boards to the base material, since when pouring the screed, they will tend to float. Dish-shaped dowels are ideal for this. They need to fasten all the plates at the joints and in the center.

To fasten the pipe to the EPS, special harpoon-brackets are used, which securely fix the pipe. They are fastened at intervals of 30-50 cm, and in the places where the PEX pipe turns, the pitch should be 10 cm. It is usually calculated that 500 pieces of harpoon-staples are required for a 200-meter pipe bay. When purchasing them, you do not have to chase the brand, as it will cost several times more. There are very high-quality and inexpensive staples of Russian manufacturers.

The choice of the collector-mixing node of the warm floor

Water floor collector - essential element, which receives the coolant from the main, distributes it along the circuits, regulates the flow and temperature, balances the loops of the circuits, and helps to remove air. Not a single warm water floor can do without it.

It is better to entrust the choice of a collector, and more correctly, a collector-mixing unit, to specialists who will select the necessary components. In principle, it can be assembled independently, but this is a topic for a separate article. Let's just list which elements should be included in order not to make a mistake in choosing.

- Firstly, these are the collectors themselves, which can be equipped with various fittings. They must be equipped with adjusting (balancing) valves with or without flow meters, which are located on the supply manifold, and on the return manifold there may be thermostatic valves or just shut-off valves.

- Secondly, any collector for removing air from the system must be equipped with an automatic air vent.

- Thirdly, both the supply and return manifolds must have drain valves to drain the coolant from the manifold and remove air when the system is filled.

- Fourthly, fittings must be used to connect the pipe to the manifold, which are selected individually in each case.

- Fifthly, special brackets are used to fasten the collectors and ensure the required center distance.

- Sixthly, if the boiler room is not equipped with a separate riser for underfloor heating, then a mixing unit, including a pump, a thermostatic valve, a bypass, should be responsible for the preparation of the coolant. The design of this node has many implementations, so this issue will be discussed in a separate article.

- And, finally, the entire manifold-mixing unit should be located in a manifold cabinet, which is installed either in a niche or openly.

The collector-mixing unit is located in such a place that all the lengths of the lines from it to the underfloor heating loops are approximately equal and the main pipes are in close proximity. The collector cabinet is often hidden in a niche, then it can be placed not only in change houses and boiler rooms, but in dressing rooms, corridors and even living rooms.

Video: What calculations are needed before installing a warm floor

Do-it-yourself installation of a water-heated floor

After calculations and the purchase of all the necessary components, you can gradually implement a warm water floor. First, it is necessary to outline the places where manifold cabinets will be placed, hollow out, if necessary, niches, and also make passages through building structures. All grooving and drilling work must be completed before the next step.

Insulation installation

Before this stage, it is necessary to prepare the premises for this - take out everything unnecessary, remove all construction debris, sweep and vacuum the floors. The room must be absolutely clean. When installing the plates, wear flat-soled shoes, as heels can damage the surface. We list the sequence of actions during the installation of insulation.

- First of all, the level of the clean floor is beaten off on the walls with the help of laser or water. All the irregularities of the base are measured using a long rule and a level.

- If the irregularities exceed 10 mm, then they can be completely leveled with clean and dry sand, which should subsequently be leveled.

- If a warm floor is made on the ground or above the basement, then it spreads waterproofing film with an overlap of adjacent strips of at least 10 cm and with entry to the wall. The joints are sealed with adhesive tape. As a waterproofing, a polyethylene film of 150-200 microns is quite suitable.

- Starting from the far corner of the room, the process of laying XPS boards begins. They are laid close to the walls with the marked surface up.

- XPS boards must be tightly joined to each other using the grooves that are on their side surfaces. When laying each slab, it must fit snugly against the base and be in a horizontal plane, which is checked building level. If necessary, sand is poured under the slab.

- If obstacles in the form of protrusions, columns and other elements are encountered along the laying path, then after preliminary marking, the slab is cut with a construction knife along a metal ruler. In this case, the EPS must be placed on some kind of unstable base so that the knife does not become dull, for example, a piece of plywood or OSB.

- When laying the next row, it should be borne in mind that the joints of the plates should not coincide, but go apart, like brickwork. In order, if a part of at least 1/3 of its length remains with the remaining XPS slab in the row, then laying the next row should begin with it.

- If it is planned to lay the second layer of XPS, then it should be carried out in a mutually perpendicular direction with the first layer.

- After laying the thermal insulation, use a perforator with a long drill and a hammer to fix the dish-shaped dowels at each joint - at each joint and in the center of each XPS board. The joints between the EPPS are sealed with construction tape.

- If cavities or gaps remain after the installation of the insulation, then they can be clogged with EPS scraps and blown out with mounting foam, but this can be done later, after the pipes have been installed.

After that, we can say that the installation of insulation is completed. Although XPS boards are dense enough to support the weight of an adult, you still need to take precautions when moving on them. It is best to use wide boards or pieces of plywood or OSB.

Installation of a pipe of a warm water floor

The most responsible has arrived difficult moment- Installation of underfloor heating pipes. At this stage, you need to be especially careful and accurate, and here you can’t do without an assistant. It is also desirable to have a special device for unwinding the pipe, since it is strictly forbidden to remove the pipe from the coil with rings, since then there will be very strong stresses in it, which will complicate or make installation impossible. The main rule is that the coil must be twisted, and not removed from the fixed coil. In principle, this can be done manually, but with a device it is much easier.

If there are markings on the upper side of the XPS boards, then this is just great, then pipe laying will be greatly simplified. And if not, then you should not “be led” to purchase a thin foil insulation made of polyethylene foam with applied markings. There will be no sense from him. You can also mark up yourself. To do this, marks are made on the upper side of the plates with a marker at the distance of the required contour step, and then lines are beaten off with a paint thread - this way you can make markings in a short time. After that, you can draw the paths of the contours of the warm floor.

screed for underfloor heating

In the intended place, a collector cabinet is attached and a collector is mounted in it, while without a pumping and mixing group, it will be needed later. At the entrance to the collector, at the exit from it, as well as at the entrance to, each pipe must be protected by a special corrugation. However, corrugation from eminent manufacturers costs mind-boggling money, so it is quite acceptable to replace it with thermal insulation of the appropriate diameter. Pipes must also be protected when passing from room to room and from circuit to circuit.

The installation of the underfloor heating pipe should be started from the areas most remote from the collectors, and all transit pipes should be insulated with polyethylene foam, which will ensure maximum energy conservation to the destination point and will not “lose” heat along the way. Further, the pipe “emerges” from the EPS boards, already “naked” bypasses its entire heating circuit and “dives” back and already in thermal insulation follows to the collector. The transit pipes themselves are placed inside the XPS slabs; for this, passage routes are pre-cut into them with a knife.

If the thermal insulation consists of two layers of XPS boards, then the first layer is laid first, then all communications are laid, including the transit pipes of the underfloor heating, and then the second layer is adjusted and cut on the spot.

In addition, pipes to radiators, as well as hot and cold water supply lines, can go in the area of \u200b\u200bthe warm floor. If there are several pipes, then they can be fixed in a bundle either with dish-shaped dowels, or with a perforated metal strip and dowels. In any case, they should not protrude beyond the upper surface of the XPS boards, so that the contour of the warm floor can be easily laid from above. All cavities are blown out with mounting foam, which, after hardening, is cut flush from the surface of the insulation boards.

Along the perimeter of the room where there will be warm floors, a damper tape is glued to the walls, which is designed to compensate for the thermal expansion of the screed. Tape comes with or without adhesive. When acquiring it, you do not have to chase the brand and overpay several times more. Now a worthy damper tape is being produced in every sense Russian production. If there is no tape at all, then this is also not a problem - it can be replaced by foam plastic 1 or 2 cm thick, glued to the wall with liquid nails or mounting foam.

The damper tape must also be installed between rooms and different circuits. For this, a special tape with a T-shaped profile is produced. And in this case, it can be replaced by thin foam glued with mounting foam or glue.

Pipe installation is done as follows:

- 10-15 m of pipe is unwound from the coil, thermal insulation and a corresponding fitting are put on its end for connection to the collector.

- The pipe is connected to the supply of the corresponding outlet of the collector.

- A pipe is laid along the previously marked routes and fastened with harpoon-brackets in straight sections after 30-40 cm, and on turns after 10-15 cm. The pipe should be bent carefully, without creases.

- When laying, do not try to fasten the pipe immediately, but you should first lay it out approximately along the tracks for 5-10 m, and only then fasten it with brackets. The pipe should lie on the insulation without tension, there should be no effort that tries to pull the staples out of the EPS.

- If for some reason the bracket flew out of its place, then it is mounted in another, at a distance of at least 5 cm.

- After bypassing the entire circuit of the warm floor, the return pipe returns to its supply pipe and follows it next to the collector. If necessary, thermal insulation is put on it.

- Upon arrival at the collector, the pipe is connected to it with an appropriate fitting.

- Near the corresponding loop of the warm floor on the wall, as well as on paper, the length of the contour is necessarily recorded. This data is necessary for further balancing.

All contours are laid in the same way. At first it will be difficult, but then, after one laid “snail”, everything will already be clear and the work will go without problems. When moving along already laid contours, it is necessary to lay boards, plywood or OSB under the legs or knees.

Walking in shoes through pipes is not recommended. It is better to organize such "paths"

Walking in shoes through pipes is not recommended. It is better to organize such "paths" Video: Laying a floor heating pipe

Reinforcing mesh installation

Disputes about the appropriateness of reinforcing mesh are ongoing. Someone says that it is needed, others say the opposite. There are many examples of successful implementation of underfloor heating without reinforcing mesh and, at the same time, there are examples of unsuccessful implementation of underfloor heating with reinforcement. The authors of the article argue that reinforcement will never be superfluous, but only correctly performed.

The Internet is replete with examples when a metal mesh is laid and fixed on the insulation, and only then to it with the help of plastic ties the underfloor heating pipe is attached. It seems to be convenient, but this is not reinforcement, but simply putting an absolutely useless mesh under the screed, on which money was spent. Reinforcement is when the mesh is inside the screed, and not under it. That is why the authors recommend placing the grid on top of the pipe.

For reinforcing the screed, a metal mesh made of wire with a diameter of 3 mm with a cell size of 100 * 100 mm is suitable - this is quite enough. It is not recommended to use reinforcement meshes due to the fact that the reinforcement has a corrugated surface and during installation can damage the smooth surface of the pipe. Yes, and you should not spend extra money on excessive strength of the screed, because it is assumed that the warm floor is already mounted on a fairly solid foundation. The mesh is laid with an overlap on one cell and is connected either with a knitting wire or plastic clamps. Sharp protruding ends must be bitten off so that they do not damage the pipe. Additionally, the mesh is attached to the pipe in several places with plastic clamps.

Instead of a metal mesh, a plastic mesh may well be used, which will perfectly reinforce the screed and save it from cracking. It is more convenient to lay a plastic mesh, as it comes in rolls. Application plastic mesh virtually eliminates damage to pipes, and its cost is significantly lower.

After laying the mesh, the question of protecting the pipes again arises, because, moving in shoes along a metal mesh, you can easily damage both it and the pipe. Therefore, it is again recommended to move only on boards, plywood or OSB. But there is still a very competent solution that will avoid damage to the pipes when pouring the screed.

being prepared cement mortar- the same as it will be when laying the screed (1 part of M400 cement and 3 parts of sand) and in the process of laying “blogs” are made from the mortar, which protrude slightly beyond the surface of the grid - 2 cm is enough. These "blobs" are made at such intervals (30-50 cm), which will allow you to put boards or plywood on them in the future and move completely safely. Another plus of this approach is the fixation of the mesh, because when walking on it, it tends to bend, and this can damage the welds.

"Foots" from the solution will fix the grid and help you move safely

"Foots" from the solution will fix the grid and help you move safely Filling in contours. Hydraulic tests

This operation should definitely be carried out even before the screed is poured, since with a hidden malfunction it is easier to fix it immediately than after the floors are filled. To do this, a hose is connected to the drain pipe on the collector and discharged into the sewer, since a lot of water will be spilled through the heating circuits. It is best if the hose is transparent - it will be easy to track the exit of air bubbles.

To the inlet of the supply manifold, which must be equipped with a shut-off ball valve, is connected tap water through a hose or pipe. If the quality of tap water is low, then it is worth filling the system through a mechanical filter. A pressure test pump is connected to any other output connected to the underfloor heating circuits. This may be a free outlet of the supply manifold, a return outlet from the manifold and other places - it all depends on the specific implementation of the collector unit. In the end, a tee can be screwed into the ball shut-off valve of the supply manifold and both filling the system and pressure testing can be done through it. After testing, the tee can be removed and the manifold connected to the supply line.

Filling the system is done as follows:

- On the collector, all the contours of the warm floor are blocked, except for one. Automatic air vents must be open.

- Water is supplied and its purity and air outlet are controlled through the drain hose. Process grease and chips may remain on the inner surface of the pipes during production, which must be washed off with running water.

- After all the air has escaped and the water flows absolutely clean, the drain valve is closed, and then the already washed and filled circuit is closed.

- All these operations are done with all contours.

- After flushing, removing air and filling all circuits, the water supply valve is closed.

If leaks are detected even at the filling stage, they are eliminated immediately after the pressure is released. As a result, you should get a system of warm water floors filled with a clean coolant and airless.

To test the system, you will need a special tool - a pressure test pump, which can be rented or invited by an experienced craftsman who has such a device. Let us describe the sequence of actions during crimping.

- All contours of a heat-insulated floor connected to a collector open completely.

- Pure water is poured into the capacity of the pressure test pump, the pump supply valve is opened.

- The pump builds up pressure in the system twice as much as the working one - 6 atmospheres, it is controlled by the pump pressure gauge and on the manifold (if it has a pressure gauge).

- After raising the pressure, a visual inspection of all pipes and connections is carried out, which, in principle, should only be on the collector. The pressure is also controlled by a manometer.

- After 30 minutes, the pressure is again raised to 6 bar and all pipes and connections are again inspected. Then, after 30 minutes, these steps are repeated. If leaks are found, they are immediately eliminated after the pressure is released.

- If no leaks are detected, then the pressure is again raised to 6 bar and the system is left for a day.

- If after a day the pressure in the system dropped by no more than 1.5 bar and no leaks were detected, then the underfloor heating system can be considered properly installed and sealed.

When the pressure in the system rises, the pipe, according to all the laws of physics, will try to straighten up, therefore, it is possible to “shoot” some brackets in those places where they were “greedy” with them. Therefore, the "blobs" from the solution will greatly help to keep the pipe in place. In the future, when the screed is poured, the pipe will be securely fixed, but during pressure tests, a poorly fixed pipe can bring unpleasant surprises.

Video: Filling the system with coolant

Video: Crimping underfloor heating system

Installation of beacons

The underfloor heating screed must be poured through pipes under operating pressure. Considering that in most closed systems heating, the operating pressure should be in the range of 1-3 bar, you can take an average value and leave a pressure of 2 bar in the circuits.

As beacons, it is best to use guide plasterboard profiles PN 28 * 27 / UD 28 * 27. They have sufficient rigidity and a smooth top surface, which is very useful when leveling the screed.

Lighthouses should be installed at the level of the finished floor minus the thickness of the finishing floor covering. To fix them, very often they simply use mortar pads, on which a guide profile is laid, and then it is sunk in level. But this approach has a disadvantage in that if the beacon fell below the required level, it has to be taken out, put in a fresh solution and set up again.

It is best if the beacons from the guide profile will have a rigid support under them and dowels for concrete and a screw of the appropriate length can serve as it. It is preferable to use special screws for concrete - dowels, which do not require the installation of a dowel, which means that the drilling diameter will be smaller. If you need to drill a hole with a diameter of 10-12 mm for the dowel, then 6 mm is enough for the dowel. The upper surface of the screw head should be at the level of the surface of the future screed.

Screws for concrete - pins

Screws for concrete - pins Beacons should be located at a distance of no more than 30 cm from the walls. Between lighthouses should not be long distance, since the solution tends to settle and a hole may form on the already finished screed. Optimal - 1.5 m, then use to level the screed building rule 2 m. When installing beacons, do the following:

- From the walls to the left and right of the entrance, two lines are drawn at a distance of 30 cm - this will be the position of the extreme lighthouses.

- The distance between these two lines is divided into equal parts so that it does not exceed 150 cm. It is desirable that one of the strips falls directly at the entrance to the room. If necessary, the strip attributable to the input can be smaller.

- Position lines for future lighthouses are drawn on the floor. Marks are made on them for the location of the dowels in increments of 40-50 cm.

- Holes are drilled to a predetermined depth with a perforator with a drill corresponding to the dowel.

To set the dowel caps in the same plane, it is best to use a laser level. If it is not in the arsenal of the home master, then it does not matter, now this one is very useful tool can be rented, especially since it is only needed for one day.

Laser level - indispensable assistant when marking and installing beacons

Laser level - indispensable assistant when marking and installing beacons The position of the beacons is marked on the wall. To do this, the thickness of the finishing floor covering is subtracted from the level of the clean floor previously drawn on the wall. The laser level is set at this mark, and then, screwing or unscrewing the dowels, their caps are set at the same level. If you use the usual building level for this operation, it will take much longer, and the error will be higher.

Further, guide profiles are laid on the caps of the dowels, the correct installation is checked by the building level. To fix the beacons in their places, use a cement mortar of the same formulation as for floor screed (1 part cement + 3 parts sand).

The beacons are removed from the caps of the dowels, and then slides are made from the prepared solution slightly higher than the height of the screed. It is enough to make them after 1 meter, since the lighthouse will already be securely fixed on the caps of the dowels. Further, the profile is laid and pressed into the solution, and its excess from above is immediately removed with a spatula. In conclusion, the level checks the correct installation of all beacons.

At the same time, you can check the correct installation of all damper tapes separating rooms and circuits and, if necessary, strengthen their position with mortar.

water heated floor

Video: Installation of beacons for underfloor heating screed

Underfloor heating screed

Increased requirements are imposed on the screed of a warm water floor, because in addition to the mechanical loads it carries, it also experiences temperature deformations. And usually a cement-sand mortar will not work here, the concrete mixture must be modified with a plasticizer and fiber.

The plasticizer is designed to reduce the water-cement ratio, increase the mobility of the mixture and increase its drying strength. Mobility when laying a warm floor screed is extremely important, since the mortar must tightly “grasp” the pipes and easily release air bubbles out. Without the use of plasticizer the only way to increase the mobility of the mixture is to add water to it. But then only part of the water will react with the cement, and the rest will evaporate for a long time, which will increase the setting and solidification time and reduce the strength of the screed. The water/cement ratio should be just enough to allow the screed to set. Usually, 0.45-0.55 kg of water is needed for 1 kg of cement.

The plasticizer is available in liquid and dry form. It must be used exactly as the manufacturer recommends, and nothing else. Any "substitutes" in the form of liquid soap, washing powder, PVA glue are unacceptable.

The fiber is designed for dispersed reinforcement concrete mix, which allows you to significantly reduce or virtually eliminate the formation of cracks, increase strength and abrasion resistance, increase bending and compressive strength. This is achieved by the fact that the microfibers of the fiber are distributed and fasten the screed throughout the volume of the concrete mixture.

Fiber is metal, polypropylene and basalt. For underfloor heating screed, it is recommended to use polypropylene or basalt fiber. Add it according to the manufacturer's recommendations, but it is recommended to use at least 500 grams polypropylene fiber per 1 m 3 of the finished solution. To obtain a mixture with the best properties, add 800 or more grams per 1 m 3.

On sale you can find ready-made mixtures for pouring underfloor heating screeds from well-known and not very manufacturers. The composition of these mixtures already includes a plasticizer, and fiber, and other components. With undeniable ease of use and high quality, the cost of a finished screed will be significantly higher than a self-prepared solution.

Before pouring the screed, it is necessary to remove all unnecessary objects from the floor, if necessary, vacuum the surfaces. It is also necessary to prepare all the tools and utensils for mixing and transporting the solution. All work on pouring the underfloor heating screed in the room should be done at a time, so it is advisable to have two assistants: one prepares the solution, the second wears it, and the main performer lays and levels the screed. All windows in the room must be closed, the screed must be limited from exposure to drafts and direct sunlight.

Self-preparation of a mortar for a warm floor screed should be carried out only in a mechanized way - the quality of the solution should be high. As auxiliary mechanisms, a concrete mixer or construction mixer. No attachments for a drill or a hammer drill will work here, no matter what various “true” sources say.

The basis of the solution is Portland cement grade not lower than M400, which must be dry and with a storage time of no more than 6 months after the date of issue. The sand must also be dry, washed and sieved. river sand does not fit - it has too regular shape. For a screed, the ratio of cement to sand should be 1:3 by weight, but in practice, few people weigh sand and cement, but a universal measurement method is taken - a bucket. Given that the density of building sand is in the range of 1.3-1.8 t / m 3, and cement during transportation is 1.5-1.6 t / m 3, then you can not be afraid to measure cement and sand in buckets, since the quality mixture will be perfectly acceptable.

The water in the composition of the solution should be approximately one third of the mass of cement, that is, for 1 bag of 50 kg of cement, approximately 15 liters of water are needed. However, the use of a plasticizer reduces the water-cement ratio, therefore, when preparing a solution with water, you need to be very careful - it is better to underfill a little and then add than to overfill.

The technology for preparing the solution with a mixer and a concrete mixer is slightly different. With a mixer, it is necessary to stir dry cement, sand and fluffed polypropylene or basalt fiber at low speeds and then gradually add water with a plasticizer dissolved in it. In gravity-type concrete mixers, which are the vast majority, it is difficult to mix dry cement and sand (dry cement sticks to wet blades and drum), so first pour some water with a plasticizer into it, and then gradually add cement first, then sand, then another portion of cement and the rest of the water. Fiber is added gradually. One part with water, the other with sand. At the same time, the fiber cannot be thrown into the concrete mixer drum in a lump, but it must be divided into portions and fluffed before laying.

The preparation time of the mortar in a concrete mixer is usually 3-4 minutes, and with a mixer a little more - 5-7 minutes. The readiness of the solution is determined by a uniform color and consistency. If you take a lump of solution in your hands and squeeze it, then no water should be released from it, but at the same time the solution should be plastic. If you place the solution in a slide on the floor, then it should not spread much, but only settle a little under its own weight. If you make cuts in it with a spatula, they should not blur, but should keep their shape.

The laying of the screed starts from the far corners of the room and is carried out in stripes along the lighthouses. Only after the completion of one strip, the next one is laid and leveled, the process should end at the entrance to the room. In the process of leveling, it is not necessary to immediately try to perfectly level the surface of the screed along the beacons. The main thing is that there are no dips in the screed, and small influxes and traces of the rule are easily corrected later.

After 1-2 days (depending on external conditions), when it is already possible to walk on the screed, it is necessary to clean its surface. First, it is cut with a construction knife and the damper tape protruding from the screed is removed, and then the construction rule is taken and pressed with a sharp end to the plane of the lighthouses. In the direction away from oneself, with short but energetic movements, cleaning is carried out until the beacons are completely exposed. Then the resulting debris is removed, the screed is moistened from the sprayer and covered with plastic wrap.

The next day, the beacons are carefully removed, you can also unscrew the dowels, and the resulting grooves are rubbed with a solution or tile adhesive. The screed is moistened and covered again, it is recommended to do this daily for the first 10 days after pouring.

Balancing the contours of the warm floor. Commissioning

After the full maturation of the screed, and this is at least 28 days, you can begin to balance the contours of the warm floor. And in this process, flow meters on the manifold will be very helpful. That is why it is necessary to purchase a manifold with balancing valves and flow meters.

The fact is that the underfloor heating loops have different length, respectively, they have different hydraulic resistance. Obviously, the "lion's share" of the coolant will always follow the path of least resistance - that is, along the shortest circuit, while others will get much less. At the same time, in the longest circuit, the circulation will be so sluggish that there can be no talk of any heat removal. In a well-designed underfloor heating project, the flow rate in each circuit and the position of the control valves are always indicated, but if the underfloor heating is done on its own, then a simplified but effective technique will do.

- If the pumping and mixing unit is not yet connected, then it is being installed. The underfloor heating collector is connected to the supply and return lines.

- All contours of the warm floor open completely, collectors open at the inlet Ball Valves supply and return. Automatic air vent valves must be open.

- The circulation is turned on. The maximum temperature is set on the head of the mixing unit, but the boiler does not turn on yet, the coolant must circulate at room temperature.

- The pressure in the entire heating system is brought to the working one (1-3 bar).

- All contours of the warm floor are closed, except for the longest one. The position of the flow meter on this circuit is noted and recorded.

- The second longest circuit is fully opened. If the flow in it is greater, then the balancing valve is twisted until the flow is equal to the longest one.

- Further, all circuits are sequentially opened in descending order of their length, the flow is regulated by balancing valves.

- As a result, the flow rate in all circuits should be the same. If this is not the case, then you can correct the adjustment on the contours without touching the longest loop.

All of the above operations are performed correctly and the flow meters show that circulation in the circuits occurs, then you can start testing the warm floor with a heated coolant. It is necessary to start from low temperatures - from 25 ° C, and then gradually increase the temperature by 5 ° C every day, until the coolant is supplied to the circuits with its operating temperature. What is the sequence of actions at this stage.

- A temperature of 25 ° C is set on the thermostatic valve of the mixing unit, the circulation pump is turned on at the first speed and in this mode the system is allowed to work for a day. At the same time, the circulation through the flow meters is controlled and corrected.

- After a day, the temperature rises to 30°C, and the system of warm floors is left again for a day. The flow and temperature of the supply and return are controlled.

- The next day, the temperature rises by another 5°C, up to 35°C. This is already much closer to the operating mode of the underfloor heating, so it is already worth adjusting the temperature difference between the supply and return collectors. If it is in the range of 5-10°C, then this is normal, and if more, then the speed of the circulation pump should be increased by one step.

- The maximum temperature to which you can raise the temperature in the floor heating supply manifold is 50 ° C, but it is better not to do this, but check it in operating modes - 45 ° C or 40 ° C. Similarly, the temperature difference between the supply and return is checked. The pump must run at the lowest possible speed so that the temperature difference is up to 10°C.

The correctness of the adjustment of the warm floor cannot be assessed immediately, since such a heating system is very inertial. It takes a few hours to feel the change temperature regime. Therefore, everyone who made their own underfloor heating should arm themselves with patience and gradually bring the system to a mode that would provide the desired floor temperature, taking into account the coating. To do this, you will need to “play around” with the settings of the balancing valves, thermal heads (if the collector is equipped with them) and the speed of the circulation pump. The main thing is that the do-it-yourself water-heated floor system works.

Find out how by studying the instructions with a photo in a special article on our portal.

Conclusion

Stubborn statistics suggests that the system of warm water floors, in addition to the obvious comfort, also gives significant savings energy carriers. The same statistics indicate that the number of successful independent implementations of such heating is growing every year. All technologies have already been worked out, the market is flooded with any components, for every taste, color and budget. The necessary information is always in open sources, you can always ask experts for advice. The team of authors hopes that this article has dispelled the initial fear and made it clear to readers that it is quite possible to make a water heated floor with your own hands.

Video: How to calculate and make a do-it-yourself water-heated floor

The use of underfloor heating to create more comfortable conditions began in ancient Greece. In the modern world with the development of technology, everything is much simpler. The warm adjusted floor in the apartment is applied in any climatic conditions. Depending on the drop in temperature outside the window, this is a full-fledged or additional heating system.

The cheapest and most cost-effective is the water-heated floor in the house. The heat carrier is water heated by the boiler, and when living in an apartment - central heating.

Do-it-yourself warm water floor has good and bad sides. Before you make a warm floor in a private house, you need to consider all of them.

What are the advantages of water heating:

- Such a system provides comfortable thermal conditions. Heat rises from bottom to top. It warms up the entire room. This is especially true in private homes with high ceilings.

- When the feet are warm, the drop in ambient temperature is imperceptible to people in the room.

- Since the warm floor from heating is a low-temperature heater, it does not dry the air.

- As a heater, water is used at a temperature much lower than the radiators need. The use of such a system for heating in a private house is well combined with condensing boilers or heat pumps.

- It is possible to disconnect part of the circuits from the system.