The grinder does not work interskol 125 900. Do-it-yourself repair of the grinder interskol. The main electrical malfunctions of the Interskol grinder

Angle grinders (grinders) from INTERSKOL have a reputation as a reliable tool. However, over time, they also wear parts and may need to be replaced. Repair of INTERSKOL angle grinders is not too complicated, so in some cases it can be done by yourself. However, for correct repair you need to know the procedure for disassembling the INTERSKOL angle grinders USHM-125/700, USHM-125/750, USHM-125/900, USHM-125 / 1100E and USHM-125 / 1400EL, have necessary tool and familiarize yourself with the device diagram.

We remind you that disassembling the case outside the service center automatically voids the warranty. Therefore, if the warranty period has not yet expired, it is better to contact the service center.

Typical grinder design (angle grinder) 125 mm

INTERSKOL company is a Russian manufacturer of various power tools. The company's products are popular in our country due to affordable prices, good ergonomics, ease of use and ease of maintenance.

The company produces several series of angle grinders, differing in the diameter of the tooling. The series for 125 mm circles is the most popular (65-70% of sales of all angle grinders). The grinders of this series have different engine power - from 700 to 1400 W. At the same time, structurally, these models differ from each other insignificantly.

All models for 125 mm wheels are characterized by the following design features:

- The spindle is mounted on 2 rolling bearings;

- The body and the handle are made as a single whole, or rather, the rear part of the body and serves as a handle (except for the model UShM-125 / 1400EL).

These features define certain requirements to the procedure for disassembling INTERSKOL angle grinders for 125 mm tooling, which will be discussed a little later.

What tool is needed to disassemble a 125 mm grinder?

Before you start repairing an angle grinder, it is worth making sure that you have everything you need. It is better not to start repairing without preparing the tools according to the list:

- A set of flat and Phillips screwdrivers;

- Open-end wrench set;

- Vice;

- A hammer.

It is also worth making sure that you have on hand a liquid for washing off grease, disposable wipes or rags, and grease for lubricating parts.

Repairs must be carried out in a prepared place where there is sufficient lighting. You should not start repairs without a clear understanding of the nature of the malfunction and the mechanism of your own actions. It will be helpful to find an assembly diagram and keep it in front of your eyes. If there is no such scheme, it makes sense to photograph in detail each stage of disassembly, so that in the future, during assembly, you can see how this or that part is installed.

It is also worth remembering that any disassembly of the case outside the service center will automatically void the warranty. Therefore, if the warranty period has not yet expired, it is better to contact the service center.

How to disassemble an INTERSKOL 125 mm grinder?

You need to start disassembling the INTERSKOL angle grinder by removing the back cover of the grinder body. Unscrew the screws holding the cover. Removing it, you can get to the electric brushes, which are placed in special brush holders.

- Remove the brushes and inspect them. If their length is less than 5 mm, it means that they have worn out during the operation and it is time to replace them with new ones.

- The motor block housing can now be removed.

- Next, you need to unscrew the nut in the gearbox housing and remove the rotor.

- Now you can disconnect the armature and the gearbox.

- To remove the bearings from the anchor, it is better to use special universal pullers.

Assembly is carried out in reverse order. But before that, you need to lubricate all the mechanical parts of the machine again. Most experts recommend domestic lubricants, since imported lubricants do not exceed their quality, but are much more expensive.

For the gearbox, it is worth choosing lubricants that adhere well to the surface. This characteristic can be assessed by the value of adhesion.

How to repair a grinder gearbox?

Most gearbox faults are audible. Noise, atypical noises, vibrations and beating of the instrument in the hand, excessive heat - these are the signs of a malfunction of this part.

To repair the gearboxes of angle grinders, you need to know the procedure for disassembling this unit. For 125 angle grinders, it is as follows:

- We unscrew the four screws, remove the spring washer and the gear cover.

- Next, you need to separate the spindle from the cover. It is better to use a press for this, but you can knock out the spindle with a hammer.

- Then we knock out the key and remove the bevel gear.

- We remove the driven gears and, having examined them for defects, replace the damaged ones.

We assemble in the reverse order.

Disassembly and repair of the INTERSKOL 125 mm angle grinder is not a very difficult matter if you start it with sufficient knowledge and the necessary tools.

IN household and in industrial production often there is a need to cut and grind metal, stone or other products from solid materials... Very effective for these purposes is such a power tool as the grinder "Interskol" UShM-125 / 1100E.

What is this tool?

Angle grinder "Interskol" UShM-125 / 1100E is electronic device... In everyday life, it is often called a grinder and is used to work with iron, stone, concrete and other materials. "Interskol" UShM-125 / 1100E - angular using nozzles with a diameter of 125 mm, with a power of 1100 watts. It is a product of the Russian company Interskol. Working with a grinder is not limited to cutting only. This electrical device you can also grind and polish the surfaces of products if necessary. Wide application versatility is possible due to design features and technical capabilities LBM.

Bulgarian "Interskol" UShM-125 / 1100E. Design features

Grinding and polishing work on concrete surfaces is often accompanied by abundant dust emissions, which is very undesirable for a power tool. The settling dust negatively affects the service life of any angle grinder. The grinder "Interskol" UShM-125 / 1100E is assembled in such a way that the dust generated during polishing / grinding does not penetrate into the mechanism. This is made possible by guiding the armature impeller, which sends air currents through the front of the gearbox.

In these corner gears, the gears are pressed onto the spindle shaft. The entire mechanism of the USHM-125 / 1100E grinder is assembled in one case, in the back of which there is a convenient handle. This grinder is a very handy and powerful machine designed for professional use. The two-handed design (main handle + additional handle included) provides comfort and convenience when using this power tool.

What is the grinder equipped with?

"Interskol" UShM-125 / 1100E has an electronic system that allows, if necessary, to adjust the speed (from ten thousand per minute to three). The owner of this power tool can reduce them to required level without worrying that the power of the grinder will also decrease. This quality, which is possessed by the "Interskol" grinding machine UShM-125 / 1100E, is especially appreciated by professional tilers. By lowering the speed, glazed tiles and other delicate surfaces can be easily processed.

except electronic system, angle grinder "Interskol" UShM-125 / 1100E contains a special board for smooth start, which greatly facilitates the operation of the grinder. The smooth start of the system is especially useful when working with heavy grinding discs and diamond attachments for stone surfaces.

How is the reliable retention of angle grinders ensured?

Comfort during operation is provided by special handles - holders. Each angle grinder is equipped with them. "Interskol" UShM-125 / 1100E has one more handle, an additional one. Despite the fact that this electric device is compact in size, allowing it to be held with one hand, an additional handle is included in the kit and is indispensable for work related to cutting metal.

Technical Indicators

- The power consumed by the power tool is 1100 watts.

- Voltage - 220 V / 50 Hz. Power is supplied from the electrical network.

- The frequency of revolutions is from 3,000 to 10,000 per minute.

- Weight is 2.2 kg.

- The power tool is designed for a circle with a diameter of 125 mm.

- The main handle is three-position.

- Smooth start.

- There is a function for adjusting the frequency of rotation.

- There is a fixed spindle.

When selling Interskol, UShM-125 / 1100E is completed with:

- additional handle;

- a set of gaskets;

- a special key for installing discs and attachments.

Dignity

The grinder "Interskol" UShM-125 / 1100E is considered one of the most reliable and durable Russian-made products. Consumer reviews testify to the good work and high reliability of this electric tool.

Among users strengths this grinder is:

- the ability to easily turn the gearbox 90 degrees in case of an inconvenient or unusual location of the release key;

- high power;

- the presence of a speed controller. According to consumer reviews, the ability to reduce the rotational speed makes this grinder indispensable for such work as cleaning welded seams, removing rust or old paint with metal structures through various grinding wheels and nozzles;

- equipment with a long cord greatly facilitates carrying and makes it possible to work with a grinder at long distances from the outlet and in other rooms;

- small dimensions and weight make it possible to use "Interskol" UShM-125 / 1100E for working with small products, since for this purpose heavier grinders are very inconvenient;

- the presence of a quick-release protective casing, for the installation of which no tools are required;

- the presence of a power unit that maintains low revs;

- acceptable cost of production;

- the presence of a smooth descent;

- the presence of the main handle, which can be used in three positions;

- complete with an additional handle.

A combination of power, size, weight and additional functions- positive qualities that distinguish the angle grinder "Interskol" UShM-125 / 1100E. Feedback from users confirms the well-deserved popularity of the tool both among craftsmen who professionally use this angle grinder in production, and among amateurs, lovers of tinkering at home.

Disadvantages of UShM-125 / 1100E

According to numerous consumers, weaknesses this grinder are:

- Possibility of breakdown Mostly this occurs as a result of voltage surges from 220 to 260 V. In this operating mode, the regulator quickly breaks down.

- High cost of spare parts.

- Poor ventilation and lack of armoring on the windings. The lack of ventilation, according to user reviews, leads to the fact that the engine located inside the grinder burns out after several weeks of work. This is due, in the opinion of the owners of the tool, to the fact that the plastic casing weakly protects the engine from dust.

Long service life of UShM-125 / 1100E is possible on condition of high-quality lubrication and timely replacement of its carbon brushes and bearings.

Fix

Any power tool breaks down sooner or later. Interskol UShM-125 / 1100E is no exception. You can repair this unit yourself.

All breakdowns of grinders are divided into mechanical and electrical.

For a successful and quick elimination problems will be required:

- instructions containing a detailed algorithm for disassembling and assembling the structure "Interskol" UShM-125 / 1100E;

- product diagram;

- open-end wrenches, hammer, vice, press. These tools are used to eliminate mechanical faults;

- tester IK-2 for detecting short-circuited loops (used for electrical breakdowns of grinders);

- grease, flushing fluid, wipes (auxiliary materials).

Before starting work, ensure quality lighting workplace.

Guided by step by step instructions and visual diagram, you can successfully repair the instrument yourself.

Stator breakage. Malfunction symptoms

The most common stator breakdown is considered to be burning. Mostly it occurs as a result of a fire in the power tool. Before proceeding with the repair of the grinder, it is necessary to inspect the structure and determine the nature of the malfunction. When the stator is burnt out, the grinder rotor begins to spin uncontrollably.

How to fix it?

First, you need to disassemble the angle grinder and remove the faulty stator from the case. You can also check its performance without removing it from the case.

But such a procedure is only possible in a specialized workshop. At home, for such a check, you can use a special device for monitoring short-circuited loops IK-2. It is designed to detect openings or short circuits in the stator windings, which does not need to be removed from the housing for this. The burnt stator needs to be rewound or replaced.

How to rewind the stator?

If it is not possible to purchase a new stator, then the old one can be repaired by carrying out repair measures, which consist in covering the stator with a new winding.

Sequencing:

- from one edge you need to cut the old winding;

- count the turns and determine in which direction the winding was made;

- measure the diameter of the wire;

- calculate the percentage of filling the core slots;

- after removing the damaged winding, it is necessary to check the insulation and clean the grooves, wind the required number of turns;

- put an insulating wire on the ends of the windings;

- solder the ends of the windings.

When implementing the stator winding, it is important to use alternating current, impregnate new windings. After impregnation, traces of impregnation are necessarily cleaned, both inside the stator and outside, on its housing. During operation, it is necessary from time to time to check whether the rotor runs freely inside the stator.

Rotor breakage

There are several reasons for malfunctions:

- wear of carbon brushes;

- power outages and short circuits;

- wear of the lamellae of the armature collector;

- destruction or seizure of the rotor bearings.

Experience is required to eliminate a rotor malfunction. Best Buy new instrument or have your angle grinder repaired at a specialized service center. If the work is done on your own, then it is very important to have required material and follow the procedure:

- the nut and the key are unscrewed, fixing the driving bevel gear of the rotor (11);

- the gear is removed from the rotor shaft (8);

- the rotor is dismantled from the gearbox housing (19);

- using a special puller or improvised means (vise, steel strips, hammer), the bearings are removed from it (9).

What other breakdowns are there?

One of the most common electrical breakdowns are:

1. Breakage of carbon brushes. You can also cope with this problem on your own. Procedure:

- the construction of the grinder "Interskol" UShM-125 / 1100E is arranged in such a way that the carbon brushes are located in special brush holders. You can get to them after removing the back cover in the stator housing;

- unscrew the screws with which the brush holder is attached;

- determine the level of wear of the carbon brushes. This can be done after measuring their remaining length. If the brush is in working order, then its length should be at least 0.5 cm.

2. Broken power cable. This malfunction mainly occurs at the points of entry of the wire into the tool and into the plug. Twisting in these cases will not solve the problem. A defective electrical cable must be replaced.

The final stage

After carrying out all the necessary repairs, the corner Sander going back in the same sequence as it was sorted out. But before the assembly itself, it is necessary to lubricate all the mechanical components of the grinder.

For this purpose, experts recommend lubricants domestic production... On the shelves of stores selling household electrical appliances, you can find greases from foreign manufacturers, but they are much more expensive, although in quality they are not better than domestic ones. Among huge choice of lubricants, you should choose those products that have high adhesion rates (they are recommended for gearboxes of all angle grinders). Such lubricants adhere better to the surface.

Interskol angle grinders (grinders) are very reliable and durable. They are distinguished by good performance and high reliability. But, improper use of the tool, untimely replacement of carbon brushes, grease and bearings leads to premature failure.

Repair of the Interskol grinder can be done independently.

To do this, you need to know the device of the Interskol grinder, the assembly scheme, the procedure for performing technological operations when disassembling and assembling the LBM. To correctly repair the Interskol LBM, it is enough to study the proposed scheme and instructions.

Interskol angle grinders recent times are becoming more and more popular not only among professionals, but also among those who like to craft with their own hands.

Design features of the tool

Firm Interskol is the Russian leader in the development, production and sale of various power tools, recognized by world manufacturers. Interskol products are distinguished by ergonomics, simplicity and ease of maintenance, environmental friendliness, and increased power.

Interskol grinders are classified by disc diameter: 115,125,150,180,230.

Among lovers of DIY crafts, Interskol grinders of two classes are especially popular: with a disc diameter of 125 mm and 230 mm.

In the presented classes, several models are produced, differing in power.

In the 125 mm class, 4 (four) Interskol models are produced: UShM 125/900, UShM 125/1000, UShM 125 / 1100E, UShM 125 / 1400EL.

In the 230 mm class, 10 (ten) Interskol models are produced, differing from each other in terms of power. Interskol 230 class grinders are produced with a power exceeding 2000 watts.

The Interskol UShM 230/2300 marking is deciphered: an angle grinder with a maximum circle diameter of 230 mm, a power of 2300 W.

In Interskol grinders 125, the driven gears are attached to the spindle by means of a keyed connection.

The grinders Interskol UShM 125 are assembled in one body, which serves as a handle.

Bulgarians Interskol UShM 230 have a convenient rear handle on the back of the body. These are powerful professional machines with a two-handed design. In this class of angle grinders, driven gears are pressed onto the spindle shaft.

In the proposed repair instructions, we will consider schemes of two classes of Interskol grinders: UShM 125, UShM 230.

Necessary tool for repairing grinder Interskol

Repair of Interskol LBM cannot be performed without a simple one, the right tool... A set of screwdrivers, open-end wrenches, a vice, a hammer, a press will help you to repair the mechanical part of the Interskol grinder. You will need a tester to repair electrical circuits. It is good if you have the opportunity to use an IK-2 type device for winding. Of auxiliary materials, you will need grease, napkins, and flushing fluid.

To perform a high-quality repair of an angle grinder of the Interskol family, it is necessary to prepare workplace, pick up correct lighting... On the floor, in a dark room, high-quality repairs are impossible.

To repair the Interskol grinder quickly and correctly, you need a diagram of the grinder that you are going to repair.

Malfunctions in grinders are divided into mechanical and electrical.

The main electrical malfunctions of the Interskol grinder

As a rule, the most common cause of a grinder's failure is an electrical malfunction. The main percentage of failure of grinders for the electrical part is the failure of carbon brushes.

Repair of control circuits of the grinder Interskol

Control circuits for grinders different models slightly different from each other. It all depends on the power of the tool, the availability of innovative developments. Some grinders have a built-in electronic unit that regulates the smoothness of the start.

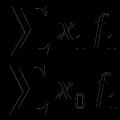

Wiring diagram of control circuits of the grinder Interskol LBM 125

In the grinders Interskol UShM 125 electrobrushes pos. 55 are mounted in special brush holders pos. 44, which can only be reached by removing the back cover pos. 51 of the stator housing pos. 42.

After removing the cover, it is necessary to unscrew the screws pos. 50 holding the brush holder body.

The wear of the brushes is determined by their remaining length. The length of working carbon brushes cannot be less than 5 mm.

Power is supplied through the cable pos. 53. In the places where the cable enters the grinder and into the plug pos. 53, the cable may break off. The malfunction is eliminated by replacing the entire power cord or part that is out of order. No twists are allowed.

The power cable supplies voltage to the switch, pos. 41, inserted into the housing, pos. 47. To operate the switch button there is a lever pos. 46. While doing Maintenance Blow out the engaging lever with silicone grease.

Wiring diagram of control circuits of the grinder Interskol LBM 230

Power is supplied through the cord, pos. 50, to the switch pos. 46, to which the electronic unit pos. 40 is connected, carbon brushes, pos. 38, inserted into the brush holders, pos. 37. The electrical part of the grinder also includes a stator pos. 32 and a rotor pos. 27.

Replacing carbon brushes on Interskol grinders 230 does not require removing the back cover. It is enough to unscrew the cap of the brush holder pos. 36 and pull out the brush holder with a carbon brush. But you can replace the switch, electronic unit, capacitor pos. 42 only by disassembling back handle pos44.45. To do this, unscrew the four screws 4 × 16 pos. 44.

How to repair the rotor of the Interskol grinder

Failure of the rotor occurs for the following reasons:

- Carbon brushes have worked or are out of order;

- Short circuit or breakage of the windings;

- The lamellas of the anchor collector worked:

- Broken or seized rotor bearings.

Rotor repair requires special knowledge, instruments and equipment. It is preferable to buy a new rotor or send it to a specialized service center for repair. But remember, it costs money. For those who are especially gifted, we recommend it.

Use a puller to remove the bearings from the armature. But you can use improvised means. For example, a vice, strips of metal, a hammer, a soft metal guide.

Dismantling of bearings from the armature LBM 125

There are two bearings on the rotor, pos. 31: rear, near the manifold, pos. 32.

Bearing size 608Z.

And on the side of the impeller there is a bearing pos. 28, standard size 6000-2 RS. Russian analog 180100 .

The bearings are removed after dismantling the rotor from the gearbox housing. To pull the rotor out of the gearbox, it is necessary to remove the bevel drive gear pos. 26, which is sitting on the rotor shaft.

To do this, unscrew the M8 × 3.5 nut pos. 25, dismantle the drive gear Z = 12. It is fixed with a key, pos. 30. The bearings are removed with a puller.

Dismantling of bearings from the armature LBM 230

To remove the bearings from the armature pos. 27, it is necessary to pull the rotor out of the gear housing, pos. 19. Unscrew the M8 nut, pos. 20, remove the lock washer, pos. 21, dismantle the drive gear, pos. 22. Pull the rotor out of the gearbox housing by gently shaking it. The bearing will remain in the gear housing. It is closed by a bearing cap, pos. 25, which is attached to the gear case with three screws M5 × 8, pos. 26. A bearing of standard size 6201-2RS is installed in the gearbox housing. Russian analog 180201 .

From the side of the collector, the bearing pos. 28 is removed using a puller. Bearing size 608RT. Russian analog 180608 .

Repair of the stator grinder Interskol

Repair of the stator of any Interskol grinder is carried out after determining the nature of the malfunction. Most often, the stator burns out. This is due to overheating of the instrument. An involuntary uncontrolled unwinding of the grinder's rotor indicates a malfunction of the stator.

For you need to pull it out of the case. The operation of the stator can be checked without removing it from the housing. But this can only be done in specialized workshops. Or if you have a short-circuited loop control device IK-2. It is possible to determine an open or short circuit in the stator windings without dismantling the stator. The burned-out stator is removed, rewound, or a new one is installed instead.

The burned-out stator can be rewound by yourself.

The rewind algorithm is as follows:

- Cut the damaged winding in any way from one edge;

- Count the number of turns of the winding, determine the direction of its winding, the percentage of filling the groove of the stator core, measure the diameter of the wire;

- After removing the burned-out winding, clean the grooves of the core, check the insulation;

- With the prepared wire, wind the required number of turns of the stator windings into the prepared grooves;

- Solder the ends of the windings, after putting an insulating wire on them;

- You clean the traces of impregnation inside and outside on the stator housing;

- Check the free movement of the rotor inside the stator.

DIY Interskol grinder stator repair video

Video: grinder repair burned out stator

Mechanical malfunctions of the Interskol grinder

From mechanical malfunctions of the Bulgarians Interskol weak point the reducer remains. The gears used in the gearbox wear out over time, the teeth are destroyed, and backlash appears in the joints.

Repair of the gearbox of the grinder Interskol LBM 125

In order to repair the gearbox of the Interskol grinder, it is necessary to establish the nature of the malfunction. Most mechanical gearbox failures are detected visually or by ear. Large runout of the spindle shaft, jamming or turning of the gears of the gearbox are determined by a simple inspection of the condition of the spindle shaft. And the increased noise during the operation of the gearbox, uncharacteristic sounds, overheating can be determined by ear or by touching the body with a hand.

To disassemble the gearbox, unscrew (4) four screws M4 × 14, pos. 11, remove the spring washers DU-1000ER, pos. 12, pull out the gearbox cover, pos. 13. The mounted spindle, pos. 10, will remain in it. The spindle is mounted in the bearing, pos. 14. Bearing size 6201-2RZ. Russian analogue 180201.

Use a press to press the spindle out of the bearing housing. But you can gently knock out with a hammer. The main thing is not to damage the cover of the gearbox housing.

The bevel gear wheel pos. 16 is held on the keyed connection and is fixed with a retaining ring pos. 17. A ball with a diameter of 3 mm is used as a key in the Interskol UShM 125/900 grinder. If you remove the retaining ring, then it is not difficult to remove the gearwheel. In other models of grinders Interskol UHM 125 uses a key.

Remove the gears and inspect for teeth licking, crushing or biting, or play in the keyed connection.

Repair of the gearbox of the grinder Interskol LBM 230

To disassemble the gearbox LBM 230, it is necessary to remove the cover pos. 6 by unscrewing 4 (four) screws. The spindle, pos. 8, is held in the bearing, pos. 9, pressed into the cover body, pos. 6. Bearing size 6203zz. Russian analogue 180203.

The gear wheel pos. 11 is pressed onto the spindle with an interference fit. To remove it, you need a press. Craftsmen manage to remove with a hammer, preheating the gear.

Remove the gears and inspect them for licking teeth, their destruction.

Repair of the grinder Interskol LBM 230

Video: Unscheduled grinder repair

Assembling the grinder Interskol

The assembly of the Interskol grinder is no different from the assembly of other brands of grinders. Serviceable parts and assemblies freed from old grease are allowed to be assembled. The assembly consists of several stages.

How to assemble a reducer grinder Interskol

To assemble the reducer assembly, you must assemble the spindle by putting bearings and bevel gears on it.

On the spindle pos. 10 put on the cover of the gear housing pos. 13, bearing pos. 14, bearing caps pos. 15, bevel gear wheel pos. 16. The gear is fixed on the spindle with a key connection. In LBM 125, a ball with a diameter of 3 mm is used as a key. To fix it on the spindle, the gear is fixed with a retaining ring, pos. 17. The assembled spindle is inserted into the needle bearing, pos. 18. And the needle bearing is pressed into the gear housing, pos. 21.

The assembly of the gearbox LBM 230 begins with the assembly of the spindle assembly, pos. 8, onto which the bearing, pos. 9, and the circlip, pos. 10, are fitted. Gear wheel pos. 11 is pressed onto the spindle. The spindle is inserted into the roller bearing, pos. 12. Standard size of the bearing NK1210.

To facilitate the process of pressing the driven gear, pos. 11, onto the spindle, pos. 8, heat the gear and cool the spindle.

How to assemble a grinder Interskol

The assembly algorithm for the Interskol grinder is as follows:

- The stator is inserted into the housing;

- The stator is covered with a plastic protection;

- A rotor is inserted into the stator with a protected rubber sleeve on the collector bearing;

- The second end of the rotor is inserted into the gearbox housing;

- The drive gear is mounted on the rotor and fixed with a nut with a right-hand thread;

- The gearbox housing is fixed to the stator housing with four screws;

- The smoothness of the rotor rotation is checked;

- A cover with a driven gear is put on the gearbox housing;

- 4 (four) screws for fixing the gearbox cover are tightened;

- The smoothness of the turning of the tool spindle is checked;

- Carbon brushes are installed;

- The back cover is put on or the handle is assembled;

- A test run of the tool is carried out, the smoothness of work is checked.

According to the given algorithm, all grinders of the Interskol family are assembled without exception.

Several features when disassembling and assembling the Interskol grinder:

- For high-quality removal of old grease from the gearbox housing, it is better to warm up the latter with a professional hairdryer to the liquid state of the grease and then remove it;

- In some models of Interskol grinders, the drive gear is fixed on the shaft with two nuts, one of which is a lock wrench S = 12;

- Carefully unscrew or tighten the fixing nut of the rotor driven gear in the grinders Interskol UHM 115;

- Put lubricant in the gearbox housing, which is less than half of its volume;

- When disassembling, carefully inspect the condition of the collector lamellas; there should be no traces of burning and worn-out tracks on it.

A few words about the lubrication of the Interskol grinder

Before assembling the mechanical units of the Interskol grinder, in mandatory, lubricate the parts with the recommended. On the Russian market lubricants are widely represented by lubricants of foreign and Russian manufacturers... Today you can buy high-quality lubricants from a domestic manufacturer. They are in no way inferior in quality to foreign counterparts, but they are several times cheaper.

A special grease has been developed for the grinder gearboxes with high adhesion. Adhesion is the property of a substance to adhere to a lubricated surface.

Video: Interskol UShM-150 grinder repair

Video: Bulgarian Interskol 180mm Pair replacement

Video: Angle grinder Interskol UShM-125/900 \ Bulgarian Interskol operating experience \ review

Video: Interskol 125/900 disassembly and diagnostics

Who and how makes money on import substitution and innovations in agriculture R

Who and how makes money on import substitution and innovations in agriculture R What is the industrial production index, its role and calculation

What is the industrial production index, its role and calculation Calculation of the design population of the city Term in metallurgy

Calculation of the design population of the city Term in metallurgy