Mechanical tools for wood carving. What tools are needed for wood carving. The main types of tools

From time immemorial, wood has been a priority building material, raw material for the manufacture of household utensils and decor. The emergence of new products in this area does not prevent the tree from maintaining high popularity and being in demand. One of the important qualities of this natural material is its easy processing. This allows not only experienced craftsmen, but also amateurs, creative people to create unique decorative elements, building structures. Special tools for woodworking are indispensable helpers in such operations.

The main types of tools

Specialists in the field know very well what devices and mechanisms can be useful in various works with wood. It is quite difficult for a beginner to understand the huge assortment. In order to create your own universal arsenal that allows you to perform any operations, you need to get acquainted with the classification of tools, their types and features.

These products include professional and household, universal and specific products. In the category of tools for woodworking, you can choose:

- mechanical hand products;

- electrical devices;

- machine tool equipment.

Most owners who prefer to independently engage in repairs and construction have simple hand tools. The use of various electrical devices, networked and mobile, simplifies the process, allows you to conveniently and efficiently perform complex operations.

Electric woodworking tools greatly simplify the process

Wood processing machines are installed not only in specialized enterprises. In the model range of equipment, there are also household options that have compact dimensions and are easy to operate.

Hand tools for the DIY master

In the line of mechanical tools for wood, there are many universal devices that are used in a variety of works. They should be in stock for every craftsman. The presence of this tool makes it possible to perform a lot of chores around the house, on the site. A practical owner should have:

- saw a hacksaw;

- axe;

- chisel;

- a hammer;

- plane;

- brace.

Hand tools for wood

These are the main assistants of the carpenter, without whom it is impossible to do in construction and repair. A hacksaw is a tool that consists of a plastic or wooden handle and a metal blade with teeth. Saws are produced in a large assortment, differ in size, size of teeth. The tool is intended for dividing a whole part into elements, eliminating excess. In performing small operations, a special jigsaw with a thin blade is used. Cleavers and axes are used for splitting, chopping, cutting.

Thin blade jigsaw for small operations

A metal chisel, consisting of a working part and a handle, is useful in chamfering, forming recesses, etc. In working with this tool, a special hammer is used, which is called a mallet. A plane will help to make the surface even, to give the board ideal geometry. If you need to use it regularly, you should purchase a power tool for woodworking. There are several varieties of devices of this type: tongue-and-groove, jointer, etc. In the formation of holes in wooden materials, a brace is used that works with various types of drills.

The plane will help to flatten the surface.

In the work, the master will also need special materials for processing, which make it possible to create a perfectly flat, smooth surface. In such operations, sandpaper is used. You need to stock up on material with various sizes of abrasives in order to carry out roughing and finishing work.

Sandpaper for finishing works

Electric tool in working with wood

Qualified specialists and many home craftsmen prefer to acquire electrical equipment that allows them to quickly and efficiently perform various types of work. This woodworking tool is offered in a wide range. The most demanded devices are electrical:

- planers;

- drills;

- chain saws, circular saws;

- screwdrivers;

- grinders, etc.

The electric planer greatly simplifies the process of giving the ideal performance to a wooden surface. Using a drill, holes of the required size are created. You can use this device in the installation of fasteners, mixing solutions.

The electric planer greatly simplifies the process

Electric grinders are very popular among professionals and amateurs. The production uses tape models designed for large volumes of work. In everyday life, in repairs, vibration, planetary tools are used for grinding wood.

A chain or circular saw is an indispensable piece of equipment for a craftsman who has to carry out large-scale woodwork. Modern multifunctional models perform a variety of operations.

A circular saw for wood is an indispensable tool

A home craftsman, a specialist who is engaged in the manufacture of complex structures, will need a milling device. Mechanical, power tools for wood processing allows you to create curly elements, stairs and frames for windows, furniture.

Not only hand jigsaws are used in the creation of small elements, in work that requires special precision. An electric woodcarving tool is also available.

An electric jigsaw will do jobs that require extreme precision

The advantages of electrical devices include the efficiency of operations, the absence of the need to spend a lot of effort. For stationary work, it is advisable to purchase models that operate on the network. Battery powered mobile devices allow you to perform operations anywhere.

Additional accessories

In addition to the main tool, additional devices are used in working with wood. The home master will come in handy:

- working workbench with a vice;

- pliers and pliers;

- clamps;

- rulers and tape measure;

- carpentry pencils;

- corner and protractor;

- plumb line.

Workbench guarantees ease of use

The presence of a workbench guarantees ease of use. This design is used to perform a large number of operations. It is equipped with drawers, they store various little things, which should always be at hand at the master. Using pliers, pliers, you can easily remove hardware, quickly dismantle. Clamps of different configurations are useful for fixing elements.

You can competently choose the necessary tool for wood in a large assortment without spending extra money. Experienced craftsmen give several recommendations:

- When choosing a hand tool, special attention must be paid to the quality and reliability of the working part. In working with him, you have to use effort. Durable, perfectly sharpened products will allow you to spend less time and effort.

- Any tool should be comfortable. Handles, configurations, dimensions of equipment, devices are selected taking into account personal characteristics. Comfortable models will eliminate inconvenience, fatigue, and ensure safety.

- Home craftsmen who rarely use tools for wood processing, if necessary, should give preference to manual types. This will significantly save the cost of purchasing equipment. If such work is performed regularly, it is better to purchase electrical counterparts.

For regular work, purchase an electric woodworking tool

You don't have to have all kinds of tools in your arsenal. You can limit yourself to several types of universal devices, if woodworking is not a professional activity, a favorite hobby.

Wood carving assistants

At all times, the skill of wood carving was highly valued. Refined figured elements adorn the facades of houses, furniture items, and household utensils. The advent of CNC machines that perform this operation at a high level did not make hand carving less popular. She remains one of the most popular hobbies for creative people. Special tools for wood cutting allow everyone to master this skill.

Wood carving remains one of the most popular activities for creative people.

There are several types of this art. The flat carving technique is used to create silhouettes with shallow contours. In the embossed mode, the decor protrudes above the recessed background. For geometric patterns, a line deepening technique is used. In the execution of openwork carving, gaps are cut out. With this art, you can create volumetric images in 3D.

The carving specialist uses a wide variety of tools. They are selected depending on the type of work. In the arsenal of the master there are universal products that are used in many operations with wood. These include hacksaws, chisels, milling cutters. There is also a specific tool:

- knives;

- engravers;

- incisors.

Wood tools are selected depending on the type of work

Carving knives

Knives help the master to create skillful carving. There are many types of this hand tool. The most popular options include:

- tatyanka;

- Bogorodsky;

- jamb.

Wood knives for skillful carving

The tatyanka knife has a long handle. The beveled blade during work is 2 centimeters from the hand of the master, which allows you to create small elements. Bogorodsk knives are available in several models, they can be used for rough and fine carving. The handle of this tool has a semicircular contour, the blades are partially sharpened, similar to a penknife. The jamb is identical in structure to a professional shoe tool. Its blade is beveled at an angle of 45 °, sharpening is one-sided.

Bogorodsk knives for fine carving

In the process of work, the tool for cutting wood becomes dull, regular sharpening is required. The master should have on hand special tools to maintain the necessary sharpness of the blade. To do this, use:

- bars with surfaces of various grain sizes;

- fabric skins of several numbers;

- leather belts and special grinding paste.

Wood cutting tool needs regular sharpening

Chisels in wood carving

An important working tool is a chisel. These devices also have several types. Craftsmen use devices:

- straight,

- reverse,

- corner,

- curved,

- cranberries.

Chisels differ in profile shapes, create a groove of the desired configuration. The tool uses a mallet. The sharp working part allows you to do without the power load. There are electric chisels in the modern assortment that can be operated from the mains or from the battery.

Chisels differ in profile shapes

The choice of tools must be guided by the purpose:

- jigsaws and chisels are used in the manufacture of sculptures;

- wooden posts, balusters are decorated with a hacksaw, milling cutter;

- an engraver and cutters will help to make ornaments on platbands, planks, furniture.

Engravers in carving

A popular carving tool is the engraver. It is an excellent replacement for the traditional cutter, it performs complex operations faster and better. There are several types of such devices. The work can be used:

- manual engraver with a set of working attachments;

- flexible shaft;

- laser apparatus.

Manual engraver performs complex operations with high quality

Hand engravers can be installed on a screwdriver or drill, a sharpening machine. Such a complete set is a convenient electric tool for making ornaments, openwork, curly or applied carving.

The flexible shafts are equipped with chucks for fixing on a standard drill. The working tool can be a drill, cutter, bur. It is advisable to have a sharpening machine available, which will allow you to regularly edit the equipment, ensure the sharpness of the working blades.

All novice carvers ask: "What tools do I need first of all?" First we need a small number of tools. Instead of buying a complete set of cutting accessories, purchase tools as needed. Usually, when buying a set, you do not save a penny, but there are always things that you almost never need. Get the best quality tools you can afford; Good, sharp, high-carbon steel tools will last you long and save you money.

Knives

You will need a good knife - one that is comfortable to work with. There are three types of knives - folding blade (pocket knife), fixed blade and interchangeable blade. I prefer to use fixed blade knives because they are the safest. Knives also differ in blade shape and steel type.

I recommend a 55 to 60 RC high carbon steel blade - it will last longer than a stainless or mild steel blade. For finishing and shaping, I use a blade that is 4mm thick and 3.8 to 5.1cm long. A knife with a narrower, shorter blade is better for detailing. Some carvers prefer knives with a replaceable blade, because in this case, instead of sharpening the knife, simply changing the blade is enough. Another advantage is that. that the handle of such a knife can be used with small chisels.

Chisels

Chisels come in different widths and curvatures. Curvature is indicated by a number. The steeper the curvature, the larger the figure. So, chisel number 3 is almost flat, and number 11 is U-shaped. Of course, a 10 or 11 chisel cuts deeper and removes more wood than a 3 chisel. On the other hand, a 3 chisel is handy for finishing. The corner chisel with number 12, which has a V-shape, is characterized by a wide range - from 24 to 90 degrees, but the most common chisels with an angle from 60 to 70 degrees.

When choosing a chisel, pay attention to the handle so that the tool does not roll to the floor when you place it on the table. Otherwise, you will have to constantly repair the blade.

When choosing a chisel, also keep in mind the size and type of thread you want to make. For manual work, palm-sized chisels are more suitable, and even less tools are needed for small parts. Sculptural and embossed carvings involve the use of standard heavy-handled chisels.

Saws

Carvers use saws of various types depending on the task, but the bow saw ("snake") is most often used.

It includes a replaceable high carbon steel blade mounted on a steel frame with a handle. A bow saw can be used to draw narrow, curved lines, although a fair amount of patience is required to prevent the blade from breaking or warping. The saw is also used to remove excess wood.

Special tools

The staple is used to remove bark and to quickly, roughly remove excess wood, such as when working on furniture. The spoon knife has a double-edged circular blade, ideal for making spoons, cups or masks.

Abrasives

Files and rasps remove excess wood quickly and smoothly. They differ in the nature of the surface, which can be rough, medium or relatively smooth. Always use flat, semicircular or round tools with a handle. Riffler files and rasps have two-ended teeth and a variety of shapes. They are used to penetrate hard-to-reach places and remove small chips. Tools with a rough surface are used for cleaning small areas.

The flexible sanding belt is convenient when working on curved surfaces. Grinding cylinders as part of a hand drill or press are indispensable for finishing. Polishing tools differ in surface texture and material nature, meeting a wide variety of requirements. Use sandpaper only after finishing work, otherwise the abrasive particles will get stuck in the wood and your tools will quickly become dull.

Electric tools

When you start making your own blanks, you will need a band saw. A huge selection of blades allows you to easily make the most difficult cuts, far surpassing anything that can be done with a bow saw. An openwork saw will help cut the inside surface, but not every wood can handle it. Belt and disc sanders are good for both finishing and removing bark. Many carvers use rotary tools with a wide range of heads to cut parts such as nibs. There are hand-held grinders and small high-speed cutters. There are also at least four types of reciprocating electric chisels that allow arthritis sufferers and people with "tennis elbow" to enjoy carving.

Strengthening devices

If you are holding the workpiece in a vise, choose a tool that does not leave marks on the workpiece (or insert some material between the workpiece and the vise). I often use a 6mm wood grouse and wing nut to attach the workpiece to the workbench. If you are a beginner, you can wear a steel wire glove to protect your hand.

I have an old friend, also a carver, who puts on a heavy leather apron when working towards the chest. When finishing or painting the product, you can use an awl or a dye stick.

SUPPORT

To better hold the workpiece when you cut wood with a snake saw, I recommend using a support - a regular board that supports the wood while cutting. Simply attach it to a workbench or table and hold the saw upright in the V-piece as you cut the workpiece.

MAKE-UP VISE

If you are planning to do embossed carving, I suggest you also make a simple bench vise. One clamp holds the vice at the bottom in a stationary position, while the angle formed by the other two at the top prevents your work or workpiece from slipping out of your hands during operation. Attach a bench vise to the work surface.

Additional accessories

Electric burnout tools can be used to paint, texture, and sign work. When doing this, you will need a dust mask and a vacuum cleaner. You also need the artist's tools and various brushes if you want to paint or varnish the item. To transfer the pattern to the workpiece, I advise you to use tracing paper or copying. A good light source and a magnifying device are needed when doing fine work on parts.

Instrument care

You should periodically inspect your tools, wipe them with an oiled cloth to prevent them from rusting. Store instruments in individual compartments or wrapped in cloth to protect them and reduce the time spent sharpening.

SHARPENING TOOLS

Keep your tools sharp at all times and pause to sharpen from time to time. All the carvers I know have developed their own editing system; everyone has found their own procedure, which is convenient for him personally. Some use whetstones with oil, others with water, and still others use electrical devices.

The first step is to sharpen the blade using a fine-grained abrasive such as diamond chips or sandpaper. First, one side is processed until burrs appear on the metal, then the other. At the next stage of dressing, the surface irregularities that appeared at the beginning are eliminated. In conclusion, a special compound should be used to grind the blade to a mirror finish, reducing friction between the blade and the wood.

How to tell if the blade is sharp enough? Take a piece of unnecessary wood and run the knife across the grain. If there is an even mark, then the blade is sharp. If the fibers stick out in different directions and the track is rough, then you need to sharpen the blade more.

TOOLS REQUIRED

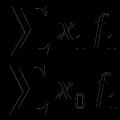

Cutting tools

Knife (preferably with a fixed blade)

Four straight chisels (palm-sized enough)

No. 3 sloping chisel 1/2 width (1.3 cm)

No. 7 semi-circular chisel 1/2 (1.3 cm) wide No. 11 steep chisel 1/4 (6 mm) wide

No. 12 chisel corner 1/4 wide (6 mm)

Drawing supplies and patterning tools

Copier (MFP)

Bow saw ("snake")

Support (see above)

Drawing accessories

Pencil

Copy paper

Wood carving is challenging and exciting. It allows you to create unique crafts, decorate your home, make gifts to friends and acquaintances.

Also, carving will be a constant source of positive emotions, and for some it will even bring income. For children, this hobby will be a great way to spend their free time and develop artistic thinking.

Most often, wood carving tools are made. This happens for three reasons:

- Firstly, it is rare to find a good cutter on sale.

- Secondly, many cannot afford it, especially adolescents and children who are fond of carving. Most often, incisors are sold in sets, have a high price and half of them are unlikely to ever be needed.

- Finally, the third reason is that experienced carvers prefer to make a tool “for themselves”.

DIY woodcarving tools (drawings) can be divided into three types - knives, chisels and shtiheli.

A knife is a tool that works with a straight or curved cutting edge.

Cutting of wood takes place under a force directed mainly across the axis.

A carving chisel is a tool that directs force along an axis, similar to the principle of a conventional carpentry chisel.

Shtikhel is a tool that is a kind of chisel. First, it cuts into the wood, and then there is a "tearing" of a small layer of wood with the skillful movement of the carver. All kinds of klukarzy belong to shtikhels - a special instrument popular in the Transcarpathian woodcarving.

Starting Simple - Geometric Thread Cutter

Geometric thread is the simplest type of thread.

It will be the best choice if you just want to try your hand at carving.

Despite the apparent simplicity, it allows you to create drawings with a "three-dimensional" effect.

It is also a national art craft in Russia, Karelia and Finland.

Geometric threads do not require a lot of hand "hardness" like chisel threads. It consists of simple elements - pegs and triangles.

It is easier to make a tool for carving wood with your own hands than for any other. Objectively, this is the only tool that can be made at home without the use of forging.

A cutter for a geometric thread is a knife. Outwardly, it looks a bit like a slant-blade leather boot knife, but that's where the similarities end. The main difference is the blade width and the cutting angle of the knife.

The width of the cutter for a geometric thread should be about 2 cm, however, this will depend on the size of the chips that you intend to cut.

The angle of the "bevel" of the cutter should be quite steep, almost straight - from 80 to 70 degrees. It is undesirable to work with a too “sharp” nose - the cutter during such work will close the drawing and you will not see what you are doing. In addition, too large angles will constantly break the tip of the incisor with awkward movements.

Blade material

The best option is to make the cutter forged from a bar.

The part of the blade protruding from the handle should be forged from the circular section into a flat knife.

It will cover the drawing less when.

Unfortunately, most carvers do not have access to the forge and do not have the forging skill.

For them, it will be optimal to make a tool for carving wood with their own hands from an old blade of a hacksaw for metal.

The blade is made of R6M5 steel, sometimes - of carbon steel. It has a width of 25 ... 50 mm and a thickness of 2 to 5 mm. If possible, take a blade with a width of 25 and a thickness of 3 mm, it is optimal for the cutter.

How to cut the blade to the right size and angle? After all, it is hardened! You don't need to cut anything. Clamp the canvas tightly in a vice under the desired one.

Then, with a hammer blow, simply break off the blade as needed - in the overwhelming majority of cases, the break will occur along the line of clamping the vise jaws.

Then straighten the cut line on an electric sharpener and pre-sharpen the cutter. Fixation of the blade in the handle is carried out with the help of teeth that used to cut metal. It is best to do this by drilling holes and hammering rivets, but due to the hardness of the material, it will be extremely inconvenient to drill.

Perhaps you will find another, more suitable one. The main thing is that it must be made of high quality steel. Some make incisors by sharpening from files or from surgical instruments, from the blades of knives to strip wire insulation. Excellent cutters are obtained from broken disc cutters for metal from P18 steel. All of these methods are good.

About homemade wood tools - in the video:

Read also:

-

Do-it-yourself folding table for wall fasteners: ...

Do-it-yourself folding table for wall fasteners: ... -

Electric miter box: use as ...

Electric miter box: use as ... -

Unusual DIY crafts from improvised ...

Unusual DIY crafts from improvised ...

Artistic wood carving is a very ancient art form that is still popular today. The fact is that with the help of a small one, you can create a real masterpiece with your own hands.

Thread advantages

Before you start choosing knives or mastering certain methods of making crafts, you need to know about the merits of this craft. So, among the advantages of thread are the following:

High quality finished products, which are in great demand;

Very good decorative qualities of the finished product, which can decorate even the most inconspicuous interior;

You can do carving yourself, while you do not have to graduate from some kind of educational institution;

The work does not require the purchase of any complex equipment, moreover, the wood carving tool can be made independently.

What tools do you need for the job?

All devices can be divided into several types: cutting and auxiliary. The first type includes the following:

1. Various knives:

- cutter - used to design a "rosette" or other element that assumes the presence of bends;

- spoon - the device is used to cut out dishes that have a hole-sphere inside (bowls, spoons);

- Jamb - This woodcarving tool is sharpened so that it has an angle of 30-80 degrees. It is most often used for drawing geometric ornaments.

2. Chisels:

- semicircular and sloping - irreplaceable devices for contour and geometric carving;

- straight line - it is necessary so that you can clean the workpiece, as well as cut through the outline of the main pattern;

- jamb - this chisel is used for geometric carving;

- corner - used to select narrow lines; this chisel is necessary for everyone;

- Caesaric - used for cutting narrow elements on a relief surface;

- cranberry - most often this woodcarving tool is used to decorate embossed and flat-embossed products.

In addition, you will need other tools. For example, for the initial processing of a workpiece, you need to purchase sandpaper, scrapers and scrapes, rasps, metal wire brushes, and engravings. You will also need drills and a drill, as well as tools for cutting out a particular pattern.

And you also need stencils and pencils, with which you can transfer the selected drawing onto a wooden blank.

equipment requirements

All wood carving tools should be of the highest quality. That is, buy those products that are made of durable high quality steel. Naturally, here it is necessary to give preference to well-known and conscientious manufacturers.

In addition, knives for wood carving, as well as chisels, must be correctly and well sharpened. Otherwise, you just crumble the workpiece. Of course, all safety rules should be followed during work.

If you do not have the opportunity to purchase tools, then you can make them yourself. For example, knives can be made in as little as a day. Naturally, you need to work hard for this. In doing so, do not forget to take into account the types of tools, their size and purpose. Poor quality thin steel will not provide the required quality. Such a tool will quickly dull and break.

Features of the choice of material

In addition to the device for work, you will need a base on which you will cut the pattern. Wood for this purpose is different: soft, hard and very hard. The first type includes linden, aspen and alder. These materials are great for your first steps in art carving. The fact is that it is very easy to work with them and you do not need to apply a lot of force to hollow out one or another element. That is, such blanks are usually given to beginners.

Hardwoods - pear, birch, oak, maple, beech - are used by experienced craftsmen who have good skills. The rest of the breeds are rarely used. At first, linden blanks are enough for you.

In addition to the hardness of the rock, the shade of its surface is of great importance. Naturally, after completing the work, you will open the product with colorless varnish. However, there is nothing better than the original shade. It will highlight all the natural beauty of your masterpiece.

The main types of thread

In order to make a craft, you need to master some types of work:

- markup;

- sawing;

- cutting;

- drilling;

- planing;

- pruning;

- chiselling;

- cycling;

- grinding.

In addition, there are several types of the thread itself:

- Through. This type involves cutting holes at specified locations.

- Embossed. In this case, the main elements are at different levels in relation to the background.

- Sculptural. This type of carving is quite complex and is only used by experienced craftsmen. The fact is that this work is very delicate and requires compliance with all the necessary proportions.

- Flat maceous. It is from this type that beginners begin to accumulate their experience. All that is needed is to apply a pattern to the workpiece and hollow it out. In this case, all elements are on the same level with the background.

Features of using special equipment

In addition to these tools, you may also need a machine. Wood carving in this case is performed without your direct participation. All that is needed is to set the program and install the required ornament. Then the machine will do everything on its own.

There are different types of devices that can do this kind of work. They vary in size and function. However, the main requirement for such equipment is the availability of cutters. All that is required of you is control, which is carried out using the control panel. The rest of the process is automated.

At all times, woodcarving was considered a very profitable and beautiful art. There are different tools for it, and their range is very extensive. By purchasing such a set, you can hone your skills in order to one day make your loved ones an original and very beautiful gift. Good luck!

The set of the carver is very diverse, while the higher his professionalism, the more difficult the work, the more tools the master uses (the range can number several hundred units).

So, the wood carver's set consists of the following basic tools.

1. Jamb knife... They perform geometric and contour carving, cut out ornaments.

Jamb knives with different sharpening blades:

The sharpening angle can vary from 30 to 80 ° and is determined by both the labor intensity of the work and its complexity.

A knife with a bevel angle of 60–80 ° is intended for cutting large straight ornaments; knives with a smaller bevel angle are suitable for smaller work or making curved patterns.

2. Cutter knife... The tool can have different shapes depending on the type of thread. In geometric carving, they are made with rosettes, "lights", various curvilinear elements; in the outline - all sorts of rounding and bends.

Cutting knives.

A knife cutter is used in the slotted and laid on thread.

3. Straight chisel which they clean the background, cut through the outline of the ornament, remove the chamfer. The width of the chisels is different - from 5 to 30 mm.

Straight chisels.

4. Chisel-joint... It looks like a straight line, but its blade is cut at an angle of 45–70 °. The blade width ranges from 5 to 30 mm. The tool is used in geometric carving.

Chisels-joints.

5. Sloping and semicircular chisels. This is the main tool with which you can perform staple cuts, semicircular holes in geometric and contour threads.

Sloping chisels.

Semicircular chisels.

Semicircular chisels can have blades with high and medium sides; in sloping chisels, they are practically absent. The blade of such chisels can have a width of 530 mm.

6. Chisels-corners, which are used in almost all types of threads, since they are very convenient for choosing narrow grooves. The blade width is 530 mm and the blade angle is 45–70 °.

Chisels-corners.

7) Cranberry chisels... This is a kind of tool, the short blade of which resembles a bent leg or a hook. Cluckars are indispensable in flat-relief and relief carving, in the processing of an in-depth background and bulges in deepened areas, in wood sampling. The profile of the chisels is different, the width of the blades is 550 mm.

Klukarzy: a - corner; b - semicircular; c - with a straight blade; d - with a wedge blade; d - with a left-side wedge blade; e - with a right-hand wedge blade.

8... Tseraziki chisels... The blades of these chisels are different in shape, but they are always curved in their lower part.

Ceraziki: a - simple; b - cerasic cranberry.

9. Spoon knives, the very name of which indicates the purpose of this tool - the manufacture of spoons, buckets, etc. The unusual shape of the blades, which can be double-edged, semicircular or circular, helps to easily cope with the selection of wood.

Spoon knives: a - semicircular; b - semicircular detachable; c - circular; d - annular, equipped with an additional handle.

10. Staples and scraped... They are used for removing bark, removing depressions, etc. Since the tool involves working with both hands, the workpiece is processed very quickly.

Staples.

Staples.

11. Coins. This is a kind of tool in the form of metal rods of different diameters, one of the ends of which has notches of geometric shapes and profiles. With its help, you can not only trim and compact a rough background, but also give the texture of a smooth surface, fill a picture.

Coins.

12. Scrapers and cycle... The tool differs in its profile, thanks to which you can choose fillets, glazing beads, remove the pile from a surface that has a curvature.

Scrapers of various profiles.

Cycles.

13. Rasps... This tool is used to clean the thread, for which the notches are intended, which are shaped like teeth of different sizes. Rasps are flat, straight, semicircular, etc.

Rasps: a - flat; b - triangular; в - square; r - rhombic; d - semicircular; e - round; w - curly.

14. Steel wire brush, with the help of which the wood texture on the product is revealed. A flat brush can be worked by hand, a round one is put on a power tool.

Wire brushes: a - flat; b - round

Who and how makes money on import substitution and innovations in agriculture R

Who and how makes money on import substitution and innovations in agriculture R What is the industrial production index, its role and calculation

What is the industrial production index, its role and calculation Calculation of the design population of the city Term in metallurgy

Calculation of the design population of the city Term in metallurgy