Desktop machine from an electric bissing. Options for making a desktop logging machine. How to make a logging machine with your own hands

The desktop electrolovik is an indispensable thing for any owner who is accustomed to independently cope with homework. Especially electric jigsaws are good for residents of the private sector, lovers of manual labor and dacha rest. From its pre-edge, ordinary manual jigsaw, desktop electrical model Gone far enough. The desktop electrolovik makes it easier and speed up the pumping procedure, not to mention the quality improvement.

Concept of desktop electroballs

The jacket is a saw that is characterized by reciprocating movements of the saw blade, serving the working body. It has a ski, intended for the direction of the saw blade when moving over the surface, which is processed, and performing movements with a frequency per minute to 3000 oscillations.

This tool was invented in 1946. His creator is Albert Kaufman, who replaced the needle in a sewing machine on the blade. On sale the tool appeared already in 1947. The manual electrolovka has a housing with a flat platform and a handle. The main difference between the electric jigsion from manual lies in its greater functionality and the quality of cutting.

Inside Located electrical engine and a special mechanism that leads the blade. In stationary jigsaws, the handle is absent, and the platform is located on top. In the front of the mechanism there is a guide, in the lower - the retractable web, which moves and moves the cuts.

The tool works as follows: The table for the desktop electroballs is securely fastened with the clips in the slider. Recurrent movements have a frequency of up to 3000 moves and can be adjusted. The reference platform allows the jigsaw to focus on the sawn item, so the work is very accurate.

Purpose of desktop electroballs

Lobzik is an integral affiliation of each workshop and every amateur. His thin leg can be successfully divided by Phaneur, copper, iron, thick boards, brass, steel. Tools happens with a motor, foot or manual drive and differ greater performance. The electric jigscription is simply indispensable for carpenters, workers with wood, furniture designers, drywall, manufacturing complex parts.

Electric jigsaw can perform direct and curvilinear cuts on the workpieces with a complex shape and various sheet materials without disrupting the external contour. Most often, desktop jigsaws are used to cut wood and wooden plates, Figures with a complicated essay of laminate and drywall, plastic blanks, also for cutting sheet metal.

Desktop electric logsik Performs clean cuts complex form and works with small

Details. Due to the persistent and fixed position during operation achieved high accuracy cut. The pedel has a stable course due to the tension system and guides, which are deprived of manual jigsaws. The big size of the table makes it stable, therefore the exactly given direction of sawing is observed.

Types of electroballs

Today, the power tool market presents a wide variety of electric bits, which differ in the nature of the application, technical characteristics, power supply and constructive features. In construction stores you can buy desktop Electrolovik For every taste and wallet.

According to constructive features, it is difficult to carry out a classification, because each manufacturer's company seeks to provide its products that are designed to facilitate and improve the operation of the tool. In this regard, the shape of the handle is a significant parameter.

Two varieties of the handle were established - mushroom and D-shaped. Lobzik with a braceband requires a job with one hand. This increases the possibilities of using the jigsaw, but somewhat negatively affects the quality of the material cut.

Mushroom pens suggest the execution of more neat cuts when holding the jigsaw with two hands, pre-fixing the cutting blank. The choice of jigsaw with a specific shape of the handle depends on the financial capabilities and personal preferences of the buyer. You have to choose that the logsik, with which it will be more convenient.

Household electrolovka are not intended for intensive use, but the low price of the desktop electroballs and the power, which is enough for household needs, make them indispensable in the household.

Professional electroballs are characterized by high wear resistance and the possibility of daily many hours (up to 8 hours) use. The essential power of similar jigsaws allows the processing of materials of large thickness. Extended equipment and improved characteristics are reflected in price.

Among professional Lobzikov Industrial is also distinguished, which are characterized by a greater fitness to complex operations and actuations of the drive - for example, an increased voltage of the power supply. Industrial models are machines that are intended for the woodworking industry.

By type of power there are network and rechargeable electroballs. Network models are powered by a power supply network with standard voltage. If productivity is important for you, it is worth choosing a network power tool.

Rechargeable electroballs provide independence from the availability of outlets and greater mobility during operation. When buying a battery model, it is worth paying attention to the type of battery. Increased performance features Inherent in lithium-ion batteries. Battery capacity is responsible for the duration without recharging.

Advantages of desktop electrolovikov

Desktop Electric Lobzik is stationary design, therefore, this cutting type The tool has many advantages. Modern models C. wooden materials 40-50 millimeters thick. A narrow saw, which performs vertical progressive movements, acts as a working body. Due to the peculiarities of the notches of the teeth and mechanics of movements of the saw, the material is cut by the way up.

Desktop Eletkrol Compact allows you to drink complex decorative details, produce longitudinal, straight, inclined and transverse propuls. A wide countertop allows you to process large details and make cuts inside wide blanks. Reliable fastening Protects the housing from extra oscillations and allows you to have a good material, so the motor can work without overload.

The advantages of desktop electroballs can be called good accuracy and clarity of cutting, high safety and ease of operation, the wide possibilities of setting up from the material and the required part of the cut blanks.

If you need to cut the items little size, manual Electrolzik It will not be very convenient. He is pretty heavy, so it will have to keep one hand and direct the workpiece. And the desktop logs is deprived of this shortage. Perhaps inconvenience are too large size and difficulty working with large details.

The desktop electrolovik is a kind of mini-machine for cutting blanks. If you acquire an electrolybiz in the store, most likely there will be possible to select the power and adjustment of the frequency of the pink. However, you can make the simplest homemade desktop electrolybiz, and very quickly. It will take a manual electrolybiz, several screws, a piece of plywood small sizes And just an hour of work.

Production of desktop electroballs

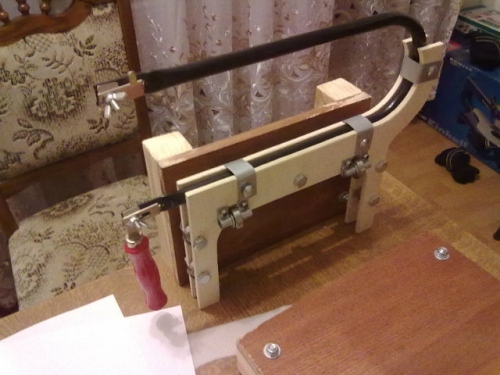

Carefully made electrolovka little to give up to the factory-made, and in some respects even surpasses it. Collect such an electrobzik is not difficult if there is essential materials. Next, we describe simple schema Such manipulations.

The design of the electrolybiz includes the following components: handle, switch button, insulating washer, power cord, frame, heating thread, screw clip and earring. First you need to make a frame. You will need a duralumin tube with an outer diameter to twelve millimeters.

You can also use for the base textolite with a thickness of at least ten millimeters or a thick phanener. But keep in mind, the easier it will be the frame, the more convenient the electrolybiz will be used. Be sure to pride the channel so that the power cord can be laid in the future. The best form of the frame is the one, one side of which is rejected by 45 degrees.

Next you need to make an earring. It is performed from a copper sheet of one millimeter thick. After that, it is attached to the screws to the frame, where it connects with the handle. Thus, the screw, the bars nut and the earring will form a clamp, in which you can fix the heating thread. The thickness of the duraluminum sheet should be up to 0.8 millimeters. It is necessary to make the clamping cheeks, between which the switch button is located.

After that, you need to cut into the plywood of the gap, through which the fend can pass. It can be done using a drill. To do this, drill holes along the markup line, and the transitions are smoothed. Instead of plywood, you can use plastic, metal, plexiglas and others. Next, you place and drill fasteners on the plywood and the support plate of the jigsaw.

Then it is necessary to fix the jigsaw screws on the plywood base so that the pilper can pass through the slot. You attach the design to the table using a clamp so that the pilper is pointing upwards. You can also consolidate the platform in any available way.

The pilot for the electrolybiz remains usual, but the possibilities for good drinking are expanding due to the release of the hands.

You can use nichrome spiral from any household heating device (iron for example) as a heating thread. It is necessary with the tension to fasten between the ends of the frames of the frame. To heat the thread, it is necessary to submit a tension of about 14 V. To control the mode of operation, you can use the row.

The current is determined by the thickness and length of the nichrome thread. With the help of the row, it is possible to establish the optimal current strength (no more than 3-5 A), which will affect the temperature to which the thread is heated. Before starting work, it is necessary to determine the strength of the current. But keep in mind when too high power The cutting material can be seized with a flame, and with insufficient - it will not take. Made with your own hands the desktop electrolybiz will allow cutting figures with complicated contours from of various types Materials.

Rules for using desktop electrolovka

When working S. desktop Lobzik It is necessary to adhere to some rules:

- During cutting, do not press much tool, otherwise the needle will break at the worst, you will spoil the work.

- From time to time replace saws. Old saw can spoil and destroy the surface of the material.

- If you work with organic glass and colored alloys, the plane of the product must be mixed with water. Such an operation will speed up the process and extend the service life of the saw.

- If you cut the surface with a thickness of less than one millimeter, put a sheet of wood or plywher under the treated material.

- Before speaking, it is necessary to secure the material. Long cuts are better not to do from hand, the line may turn out to be a curve.

- For cutting different materials Appropriate canvases are needed, with a special step and length.

- Turns to the tool, turning only the back of the tool.

- When cutting a laminate, a tape is pasted on the cut line, which removes the material from chips.

- If there is a need for curvilinear cuts, install the jigsaw pendulum at a minimum.

If you have not yet fully understood how to make a desktop elet collectrol bzya, see the video about this procedure. This tool allows you to drink complex parts from wood and other material, producing longitudinal, inclined, straight and transverse propuls. With the help of an electric bike, you can process large parts, wide blanks and minor products, which is not excess at home.

Lobzic Machine - A special device that is intended to perform work on sawing wood, its derivatives, as well as other materials (for example: plastic, plasterboard sheets, foam and so on) on curvilinear contours and direct lines.

Depending on the power of the electrical drive, it is possible to divide into two types:

- with power up to 150 W;

- power over 150 W.

Machines with a capacity of up to 150 W are mainly used at home, for work on the manufacture of various crafts from medium and low density materials and thickness.

Drive machines Over 150W, mainly used in industrial environments, when working with solid wood and other materials. Such leafs are allowed to produce work with a thickness of the material reaching 10 centimeters.

For home and semi-professional use, in order to save money, you can make a homemade logging machine. At the same time, it will take the presence of initial knowledge in the locksmith and electrical business as well as a small amount of manual instrument.

Making a homemade logging machine

In order to make a logging machine with their own hands, you will need:

- eight wooden planks for making frame;

- tolstoy plywood sheet for table top;

- some metal corners, welding machine;

- electric jigsaw;

- accessories for fasteners, drill.

1) The design of the machine is starting with a frame. For the frame will be required wooden bars Square cross section 50 * 50 mm. For reference racks, four vehicles are used long 250mm.

For longitudinal connecting beams are 380mm long bars. Face connecting beams have a length of 250mm. All the bars are connected to each other with the help of conventional wood screws.

2) We make a countertop. For the table, we take Paneur, in this situation it is necessary to be guided by the principle: the thicker, the better. Normal can be considered a sheet of plywood in 10mm thick. The sheet is cut into the dimensions of the frame so that the edges and the angles appear for the edge of centimeters on 5.

After that, on the plywood board it should be noted the places of attachment of the legs and the jigsaw itself. Holes drill on the markup in such a way that the self-tapping screw came in the center of the leg.

In the label markup should be transferred the attachment points and drill holes. Also, the hole is cut into the spray canvas. Countertop using self-tapping screws to frame.

3) The next step is to install the jigsaw under the worktop. To do this, turns over the entire design of the rack on the tabletop cover.

Electric jigsaw is installed on the markup and is screwed to the tabletop bolts. At this stage, you must not forget that the canvas must already be installed and occupy the position provided for it with a reserve by the hole.

At this stage you need a welding machine for the manufacture of a locking structure. It will take four corners. Lower plank 50 * 50mm with two bolt holes. It is fastened to the corner of a long 200mm. Next, a 230mm corner (selected for each case individually, depending on the distance from the edge of the table top to the canvas).

The descent to the canvas is performed from angle of 150mm long, which is attached to the jigsaw wheel. Such a design perceives all the vibration from the canvas and prevents breakdowns. The whole design is attached to the tabletop with two bolts. They should not weaken from vibration.

The work on the manufacture of a logging machine is completed, the machine is ready for full operation.

Video: Lobzic Machine with your own hands.

What to do when you need a jigsik, but there is no need to buy it? You can make a jigsaw with your own hands. There are many ways to manufacture or repair such a tool. Consider the simplest and affordable of them.

Hand Lobzik - Just, Quick and Available

How to make a jigsaw quickly from affordable and inexpensive materials? Here is the easiest way.

List of tools and materials:

- plywood sheet (10 mm);

- plywood sheet (4 mm);

- steel sheet (2 mm);

- bolts and nuts;

- drill;

- chisel;

- grinding paper;

- file.

The base of the manual jigsaw is a bracket, it should be prepared from plywood sheet (10 mm). Next it is recommended to make thickening for a tool handle from more thin plywood (4 mm). These thickening should be pasted on the handle on both sides, which will ensure further more convenient. The bracket and the handle are well treated with grinding paper and a file. From the steel plate must be cut off with chisel, and then clean the clamping sponges with a file. After that, in sponges, drill a drill of the slits, and then cut with a sharp chisel of notches inside the clamping sponges. In the left clamping sponge, modify the slot for the bolt, for this you need to make a thread. Sponges attach to the bracket, then screw the bolts into the left clamp, securing them with nuts.

Back to the category

Desktop Lobzik: Two manufacturing options

The desktop can be made both new and with the help of refinement or repair of remedies.

Manufacture of new table mechanical jigsika will require the presence of such tools and materials:

- pipe Dulely;

- plastic base;

- clamps;

- screws;

- copper sheet;

- drill.

First you need to prepare a framework, it is better to use a duralum pipe for this purpose. When making a frame, it is necessary to provide a passage to which the cord will be laid, providing power supply. Copper sheet should be taken to make a P-shaped frame, which will be subsequently needed to attach to the carcass itself. In place of a frame connection with a knob jigsaw frame to fasten with screws. In a plastic basis, drill with a drill hole for a sawdill, as well as slits for fasteners. On the prepared plastic, fasten the jigsaw so that the feck passed through the hole. Using clamps, attach the finished tool to a flat surface, for example, to the table.

Manual device made based on sewing machine, this is perfect optionif the repair of the sewing machine is not as important as the manufacture of such a tool. List of tools and materials:

- sewing machine (you can use both foot and manual model);

- pink;

- feet;

- drill.

Having twisted the bolts at the bottom of the sewing machine, you should remove the entire system of working with the thread. Next, knock out the metal fastener and remove the actuator's actuator actuator. The panel closing the details of the sewing machine is easy to remove, if you unscrew another 2 bolts. Gently remove the needle. The slot for the needle requires a small repair - it should be expanded so that the Pillet can be placed in it. To do this, it is better to cut the hole with the help of the leg, focusing on the size of the peking itself. After that, it is necessary to adjust its size to the highest possible size of the needle, cutting the upper part of the saw. After stepping up the upper teeth using a file, and the lower part on the tip can be started up to the next step. Prepared Pilling must be put in place former needle - in the needle holder. After that, you should turn the wheel and check:

- so that the saw did not come into contact with the panel and with the presser foot;

- so that in the upper position of the plywood passed freely under the saw;

- so that the material takes place smoothly.

Such a junction is suitable in order to work with materials from plywood, balz wood and plastic, and if you use an electric machine, it turns out the jigsaw electric.

Cut small parts of wood are performed by the jigsaw. The device has small sizes and usually has an electric drive. Factory models differ in their characteristics and in terms of cost. With small volumes of wood processing, it makes sense to make a logging machine on its own, from the subwoofers. For this you need a few factory parts.

Lobzik in factory execution is a reliable device whose work guarantees the manufacturer. Manual models are distinguished by low cost. Stationary devices are expensive, but ensure proper comfort when processing wood. The set of components in the device is more the same for everyone.

The design consists of the following details:

Detail for processing is false on the desktop. The value of the processed part depends on its size. Some models have rotary tableThat makes it easier to work with the detail - the visibility improves. The presence of graduation facilitates material marking.

Medium characteristics of factory machines:

Specializable models may have radical characteristics. There are specification of small sizes, for processing small parts. As well as Large Sizes, also manufactures industry for retail sale. But such options will be distinguished by high cost.

Specializable models may have radical characteristics. There are specification of small sizes, for processing small parts. As well as Large Sizes, also manufactures industry for retail sale. But such options will be distinguished by high cost.

In the middle class there is a high competition for the consumer, so the devices will be cheaper. Characteristics are also sharpened under typical tasks joiner. Pulling out of them you need to make the drawings of the logging machine with their own hands. Complex components for it are purchased in the store.

Specialists classify jigsaws by type of construction. Features of the execution of the mechanism determine the possibilities of processing wooden products.

The classification leads depending on the design of the logs.

Types of devices:

- With lower caliper.

- Two-portable.

- On the suspension.

- With a degree scale and emphasis.

- Universal.

Models with lower caliper received maximum distribution. The bed of the desktop factory device has 2 halves - lower and upper. The model of the peel and purification from chips is placed on the top of the bed.

Models with lower caliper received maximum distribution. The bed of the desktop factory device has 2 halves - lower and upper. The model of the peel and purification from chips is placed on the top of the bed.

The lower bed contains the controller, the motor, the main transmission, the power button and shutdown. Such a machine allows you to work with any materials and any size.

The presence of two calipers in the jigsaw is beneficial to the fact that the upper half of the bed has an additional rail. Such a junction is ideal for cutting small details. The thickness of the processed parts on both models should not exceed 8 cm. The desktop of such machines, as a rule, has the ability to adjust the height and angle of inclination.

Devices on the suspension do not have a fixed bed, but differ in their mobility. The material being processed is installed motionless, and the wizard moves the working module. Since the latter is attached to the ceiling, the thickness of the material is not limited. The tool move manually, regardless of the bed. This allows you to make patterns of complex shape.

The presence of the range of degrees and stops is suitable for the masters that make processing according to the drawings. Marking allows you to prevent error when working. There are universal models of machine tools on the market, which allows you to make several operations. Such a machine allows you to perform drilling, cutting, polishing and grinding. The cost of such devices will be significantly higher, but it is more comfortable to work with them. These are industrial instances.

Designs and drawings presented in the network options for homemade jigsaw differ. The wines of the entire fantasy of the authors and the desire to make a device that will stand out against the rest of the rest. Only the concept in most cases is the same - as a basis is taken by a manual electrolybiz and recharge it.

Designs and drawings presented in the network options for homemade jigsaw differ. The wines of the entire fantasy of the authors and the desire to make a device that will stand out against the rest of the rest. Only the concept in most cases is the same - as a basis is taken by a manual electrolybiz and recharge it.

Homemade wood processing lovers are often looking for information how to make a jigsaw with their own hands without possessing special skills. You can take advantage of the finished manual jigsaw as the basis. The mechanism does not require careful refinement. Factory manual device - This is the drive. And here crank mechanism We have to develop yourself. Manufacturers try to offer a platform consumer for quick alterations, but personal needs can be satisfied only with their own product.

Assembly order:

- Produce a support table. The metal is taken as a material and make a hole in it. The form is oblong, 3-4 times wider with a saw blade. Holes for fasteners make nearby.

- At the bottom of the support table, the factory device is fixed. Holes for fasteners are made next to the opening for the sawing canvas. As fasteners use screws with secret head. It is necessary in order to provide a perfectly smooth plane of the table. In other cases, the processed products will be clinging for the guilt hats, which will cause inconvenience in work.

- Construction is fixed on a wooden table.

The advantage of creating a machine from an electric bissing with their own hands is that the factory tool can be disconnected at any time. When needed - in the hands of the usual manual Lobzik. Therefore, it is better to acquire manual option tool that can be used on homemade machine - so cheaper. Stationary devices It is expensive.

Comfortable work S. wooden products You can provide the installation of guide rails on the homemade support table. Additionally, the table is marked, which facilitates the measurement of the distance on the details during processing.

Lobzik manual type as the main device for the machine has drawbacks. The main problem lies in the beer - it is too wide in manual models. Because of this, the thin work on the tree it is difficult to perform - the curvature of the lines is limited.

Previous design is simple and does not have additional detailswho facilitate work with the tree. The direction of modernization is the ability to replace the peel to thin.

Options for improving the design:

- Build a rocker. The design will be stretched by springs, on the one hand. The second side of the rocker is fixed on the leg.

- Fix the pylon between two rollers. They serve as the guards of a thin sawdill.

- Use a stationary factory device as a drive system of two rockers. Between the latter stretch the pylon. The movement is transmitted from the factory device to the lower rocker of the peel.

Design when buying or independent manufacture It is necessary to choose based on personal preferences and desires to pick up in the technique. The use of guide rollers is less popular option - the reliability of it is lame.

Design when buying or independent manufacture It is necessary to choose based on personal preferences and desires to pick up in the technique. The use of guide rollers is less popular option - the reliability of it is lame.

Modernization by installing rumors. It is better that at the same time the factory device served only by the drive for the jigsaw. To do this, turn off pendulum in the instrument.

The heir of the property of grandparents often goes out the old sewing machine. It has already served his destiny for sewing clothes, because now produce more accurate equipment. For the lass in the farm, you can not spend money on its purchase. He is made with their own hands from the sewing machine.

Procedure:

Now the jigsaw for curly dipping on plywood is ready. With a manual drive will work more difficult, because the legs will be tired. An additional minus will serve vibration from the power impact on the tool. The electric drive transmitted to the jigsik, partially solves the problems of vibrations.

Dear logs can be replaced with design own manufacture. It will not give way to their qualities and functionality, if it is responsible to approach the assembly process. It is important to qualitatively perform mechanisms from plywood, which serve as a support table. It is desirable that the table be able to rotate. For the CO version sewing machine It will be impossible to do it. If desired, the table applies markup to make it easier to measure the details during the work.

The logging machine is a device on which transverse, longitudinal and angular cuts of blanks, and also produced figure peeping decorative elements. It is used in carpentry workshops and on woodworking production.

Some models can be equipped with air pumpwhich blows the place of sawing, so that you can conduct permanent control over the performance of operations and markup.

The principle of operation of the feeding machines is as follows: the workpiece is fixed on the desktop, then the cutter performs reciprocating movements. There are some models where the table can be tilted, drop or climb for different parts Pilking canvas.

Dignity

The logging machine easily cuts thick wood, and with the excellent quality of the treated surface. Such a device allows you to stay with both hands free to control the feeding of the workpiece. Thanks to this, you can perform work accurately and, if necessary, cut out quite steep bends. The Lobzic Machine has acquired its popularity and due to safety in operation.

Thickness of processed billets

As a rule, even relatively small logging machines can cut 50 mm wood, and more powerful models are able to cope with a thickness of two times more.

Table Lobzika

Regardless of which material is made of a desktop (from pressed or cast metal), it must, first of all, be smooth, tough and flat. Almost all the jigsaws can be tilted to perform oblique propilov, and some models rise and descend so that it is possible to use various parts of its web.

Electric motor

A small asynchronous 100-cotton driving machine drive electric motor can develop the speed of the web of about 1600 moves per minute. There are models, some can be installed different values Speed.

Pilking Length

Despite the fact that the desktop logs is capable of drinking enough thick blanks, the course of the canvas (vertical movement) is rather short. As a result, if drinking a lot of fine materials, then the peel is just a small part located above the table. For more rational use of the length of the canvas, you can periodically lay the paneur or chipboard.

Fencing web

On the jigsaw machine, as a rule, a very simple fence consisting usually out of 1-2 rods from wire or plastic transparent screen. It is intended to prevent the contact of the fingers with the saw. When sawing, thick wood is often used by the jig without fence. Some models are offered a fence only as an additional equipment.

Clamping device

Sometimes the machines are equipped with a presser device. It is used to prevent the vibration of a sheet fine material so that the workpiece movement is not lifted from the table. Automatically spring-loaded strap when feeding it rises the workpiece.

Removal of sawdust

To one of the quality indicators of desktop logging machines, the presence of a pipe cleaning tube from sawdust, which is installed behind the canvas. Under the pressure according to it, air flowing sawdust lying on the markup is supplied.

Lobsikovka Machine "Zub"

This model is an excellent solution for creativity. The equipment is intended for sawing blanks from wood and plastic under a slash and direct angle, under the tilt and radius. Used, as a rule, on small industries. The desktop can be tilted at an angle of 0-45 degrees, thanks to which it is possible to perform a sawing at an angle. For more accurate execution of the work in the logging machine, the side stop with the transporter is included.

Lobzic Machine Jet.

This high-performance model is designed to dry out contours along various trajectories, both internal and external, including curvilinear, in the wood of any hardness. Cutting vertical blade performs high-speed cut. The blade speed can be adjusted within 400-1600 rpm.

Machine power - 90 W. The model is equipped with a sufficiently convenient desktop 410x254 mm with the possibility of adjusting the angle of inclination by 0-45 degrees to perform a more complex sawing.

Why you can not give icons

Why you can not give icons Is it possible to give icons as a gift: Signs, the opinion of the Church

Is it possible to give icons as a gift: Signs, the opinion of the Church A year ago left her husband, and now I do not know what to do

A year ago left her husband, and now I do not know what to do