Hydrogen generator with your own hands for heating at home. Using a hydrogen generator for heating. Positive feedback on hydrogen machines

One of the most convenient and practical ways to produce hydrogen, and its further, reasonable use is a hydrogen generator, the so-called hydrogen burner. But the production of hydrogen at home is a rather dangerous occupation because listen to the Council described.

Homemade hydrogen generator:

The basis of the hydrogen burner is a hydrogen generator, which represents a peculiar capacity with water and plates from of stainless steel. Construction I. detailed description hydrogen generator You can do without much effort to find on other sites, because I will not spend printed symbols for it. I want to convey very important subtleties that you will be very useful if you are going to make a hydrogen burner with your own hands.

Figure No. 1 - Structural diagram of hydrogen burner

Figure No. 1 - Structural diagram of hydrogen burner The essence of the hydrogen burner consists in obtaining hydrogen by electrolysis of water. You should understand that in the electrolyzer (water capacity and electrodes) and therefore, it is impossible to pour that it fell, I recommend using distilled water, but I read that for more efficient electrolysis, another caustic soda is added (I do not know the proportions).

My electrolyzer is assembled from stainless plates, rubber gaskets, and two thick plates plexiglass, and externally it looks like this:

Figure 2 - Electrolyzer

Figure 2 - Electrolyzer Electrolyzer It is necessary to fill in water exactly half to comply with safety, follow the level of fluid, since with its decrease, the electrical parameters and the intensity of hydrogen is changed!

But before you spend a bunch of time and materials on the assembly of the electrolyzer, take care of the power supply to it. My electrolyzer, for example, consumes current about 6a, at a voltage of 8V.

Metal plates (electrodes) are connected using thick copper wires soldered to them, and thick copper wires (about 4mm section).

Figure 2 - How to connect wires

Figure 2 - How to connect wires You should also understand that everything should be tightly connected and well breathed, the short circuit of the plates and the spark is unacceptable !!!

Figure No. 4 - insulation plates

Figure No. 4 - insulation plates Actually have a lot of different kind The designs of the electrolyzer is because I do not want to focus your attention on it, although it is the most basic and time-consuming detail for the hydrogen burner, in itself it is not very important (you will be suitable for any of its design).

When working with a hydrogen burner, follows:

If you are going to make a hydrogen burner, then be careful! Hydrogen is very explosive !!! When assembling and working with a hydrogen burner, there are many vital subtleties. Pay attention to my advice - I really did it and I know what I say.

In the homemade hydrogen burner, the pressure of hydrogen must be consistently, and the protection against the inverse explosion, good tightness and insulation!

The fact is that when working with a hydrogen burner, you use a power supply for electrolysis. And while it is turned on, hydrogen stands out about the same intensity (as it can fall, since the water evaporates and the current density varies between the plates of the electrodes), therefore do not proceed to work without familiarcing the burner device.

How to use the hydrogen burner:

First, first of all, always work in the means individual protection (be sure to put the protective shield or glasses on the face), secondly follow the rules fire safety. Thirdly, follow the water level in the electrolyzer, and the flame burning intensity.

It is not necessary to wait for the flame right away, give hydrogen to displace the remains of oxygen (it takes it about ten minutes, depending on the intensity of the selection and volume of vessels with water shutter and the fuse A, B Fig. 1)

Be sure to keep about yourself Capacity with water - it will need you to extinguish the flame burner when you finish the work. For this, you just need to send the tip of the needle with a flame under the water and thereby block oxygen to fire. Always pull the flame first and then turn off the metering of the generator - otherwise the explosion is unnemptom.

Water shutter and fuse:

Pay your attention to Figure No. 1 - there are two tanks there (I designated them a and b), well, a needle from disposable syringe (B), all this is connected by tubes from droppers.

In the first capacity (a) it is necessary to pour water, it is a water shutter. It is necessary in order that the explosion would not get to the electrolyzer (if it ripping, then it will be like a fragmental grenade).

Figure No. 5 - Water Shutter

Figure No. 5 - Water Shutter Please note that there are two connector in the water shutter cover (I have all adapted from the medical dropper), both are sealed in the lid with epoxy glue. One tube is long, according to it, hydrogen from the generator should flow under water, bud, and through the second hole to go through the tube to the fuse (b).

Figure No. 6 - Fuse

Figure No. 6 - Fuse In the tank with the fuse you can pour as water (for greater reliability) and alcohol (the alcohol pairs increase the flame burning temperature).

The fuse itself is done like this: you need to do in the lid hole with a diameter of 15 mm, and holes for the screws.

Figure No. 7 - what the holes look like in the lid

Figure No. 7 - what the holes look like in the lid You will also need two thick washers (if necessary, it is necessary to expand the inner diameter of the washer using a round file) two tap layers and a foil from chocolate or an ordinary air ball.

Figure No. 8 - Sketch of the Protective Valve

Figure No. 8 - Sketch of the Protective Valve He is going to simply, you need to drill four coaxial holes in the iron washers with a lid and gaskets. First you need to solder bolts to the upper washer, it can be easily done with the help of a powerful soldering iron and active flux.

Figure No. 9 - Washer with cogs

Figure No. 9 - Washer with cogs  Figure 10 - soldered to the puck of screws

Figure 10 - soldered to the puck of screws After you soldered the screws, you need to wear one rubber gasket on the washer and your valve directly. I used a thin elastic band from the bunting balloon (it is much more convenient than to wear a thin foil), although the foil is also suitable quite successfully, at least when I experienced my hydrogen burner for explosion hazard, then the foil was in the valve.

Figure №11 - put on a gasket and protective gum

Figure №11 - put on a gasket and protective gum Then we put on the second gasket and you can insert protection into the holes done in the lid.

Figure No. 12 - Ready Valve

Figure No. 12 - Ready Valve  Figure No. 13 - Protection Elements

Figure No. 13 - Protection Elements The second washer and nuts are needed to be hermetically and firmly fix protection, spinning nuts (look at Figure No. 6).

Understand correctly and take to normal, it is impossible to neglect the safety regulations, especially when you work with explosive gases. And such a simple adaptation can save you from unpleasant surprises. Protection on the principle of "where it is thin - there and breaks", the explosion knocks out a protective film (foil or gum), and the explosive force does not go to the electrolyzer, and also the water shutter is prevented. Believe the word if the electrolyzer explodes, then you will not seem little :) !!!

Figure No. 14 - Explosion

Figure No. 14 - Explosion It should be understood that the emergency situation is necessarily inevitable. The fact is that the flame burns at the outlet of the nozzle, (in which a needle from a one-time syringe sufficiently sufficiently fit) only because the gas pressure is created (the pressure is consistent).

Figure No. 15 - nozzle from the syringe, on the pedestal

Figure No. 15 - nozzle from the syringe, on the pedestal For example, you work your burner and got into the light, believe me! You will not have time to bounce from the burner, the flame will instantly go back on the tube and thunders the blast of the defensive valve (he needs it that he would have rushed and not the electrolyzer) - it is quite normal when the burner is homemade - be alert and careful, stay away from the hydrogen burner and carefully Wear personal protective equipment!

Personally, I am not in a great delight from the hydrogen burner, I tried to make it only because I had a ready-made electrolyzer. Firstly, it is very dangerous, secondly, it is not very effective (I'm talking about my hydrogen burner and not about the burners as a whole) to melt it that I did not succeed. And because you have come to mind the idea to make this type of burner, ask yourself a completely rational question "And it is worth it", since it is worth collecting an electrolyzer from scratch, this is a fairly troublesome case, and you still need a powerful power supply such that would have enough to coordinate hydrogen pressure and The diameter of the outlet nozzle. Therefore, "If only it was," I don't recommend it to you, but only if she really needs you.

From the TV screens, we declare that the amount of oil is rapidly decreasing, and soon gasoline cars will be departed in a distant past. That's just not quite right.

Indeed, the number of extended oil reserves is not very large. Depending on the degree of consumption, they can be enough for a period of 50 to 200 years. But this statisticians still do not take into account the undiluted places of oil production.

In reality, oil on our planet is more than enough. Another question is that the complexity of its prey is constantly increasing, and therefore the price is also growing. In addition, it is impossible to write off environmental factor. Exhaust gases are strongly polluted Wednesday and you need to do something.

Modern science Created many alternative energy sources up to the engine of the nuclear decay in your machines. But most of these technologies are as long as concepts without the possibility of real use. At least so it was until recently.

Every year, machine-building companies produce more and more cars working on alternative sources Nutrition. One of the most effective solutions In this context, the hydrogen engine is from the Toyota brand. It allows you to fully forget about gasoline, making the car with environmentally friendly and cheap transport.

Hydrogen engines

Types of hydrogen engines and their description

Science is continuously developing. Every day new concepts are invented. But only the best of them are embodied. Now there are only two types of hydrogen engines that can be cost-effective and productive.

The first type of hydrogen engine operates on fuel cells. Unfortunately, hydrogen engines of this type still have a high cost. The fact is that the design contains expensive materials like platinum.

The second type includes hydrogen engines internal combustion. The principle of operation of such devices is strongly reminiscent of propane models. That is why they are often reconfigured to work under hydrogen. Unfortunately, the efficiency of such devices is an order of magnitude lower than those function on fuel cells.

On the this moment It is hard to say which of two technologies to create hydrogen engines will win. Each has its pros and cons. In any case, work in this direction does not stop. Therefore, it is possible that by 2030 the car with a hydrogen engine can be bought in any auto show.

Principle of operation

The hydrogen engine is based on the electrolysis principle. This process It occurs in water under the influence of a special catalyst. As a result, hydrogen is allocated. His chemical formula Next - NGO. Gas does not have explosive qualities.

Important! Inside special containers, the gas is mixed with the fuel and air mixture.

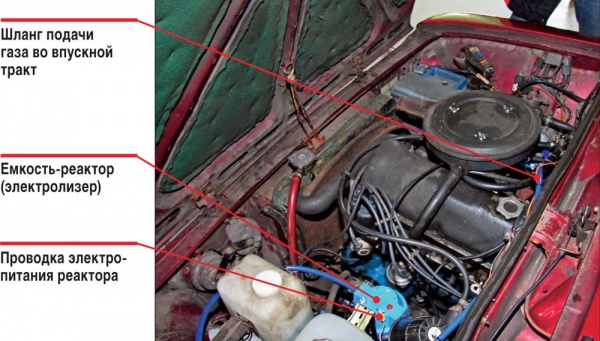

The generator includes an electrolyzer and a tank. The process of gas generation is responsible for the gas generation process. To ensure the best results in injection hydrogen engines, an optimizer is installed. This device is responsible for adjusting the ratio of the fuel and air mixture and the Gas Brown.

Catalyst characteristics

Catalysts used to create the desired reaction in the hydrogen engine can be three species:

- Cylindrical banks. This is the most simple designworking on a fairly primitive management system. The capacity of the hydrogen engine operating with this catalyst does not exceed 0.7 liters of gas per minute. Such systems can be used on hydrogen engine machines with a volume of up to one and a half liters. An increase in the number of cans allows you to exceed this limit.

- Separate cells. It is believed that this type of catalyst is the most efficient. The performance of the system is more than two liters of gas per minute, efficiency - maximum.

- Open plates or dry catalyst. This system is designed for long term Work. Performance fluctuates in the range from one to two liters of gas per minute. Open location provides the most efficient cooling.

The effectiveness of hydrogen engines is growing every year. The hybrid devices functioning on hydrogen and gasoline are beginning to be introduced into operation. In turn, designers do not stop looking for the most efficient catalyst model, providing even greater performance.

Hydrogen engine do it yourself

Generator

To create an effective hydrogen engine for the car with your own hands, you need to start from the generator. The easiest home-made generator is a sealed container with a liquid in which the electrodes are immersed. For such a device, a power source in 12 V.

The fitting is installed on the design lid. It takes a mixture of hydrogen with oxygen. Actually, this is the basis of the generator for a hydrogen engine that connects to the engine.

To create a full-fledged system, you will also need an additional drive and battery. As a case, it is best to use a plumbing filter or you can buy special installation. In the latter, cylindrical electrodes of high performance are applied.

As you can see, allocate the necessary gas for the reaction is not so difficult. It is much more difficult to produce it in the quantity necessary for the hydrogen engine. To improve efficiency, it is necessary to use copper electrodes. In extreme cases, the stainless steel is suitable.

During the reaction, the current must be supplied with different strengths. Therefore, without electronic block, it is not necessary. In addition, the reservoir should always have a certain amount of water so that the reaction takes place under normal conditions. The automatic feeding system in the hydrogen engine solves this problem. Electrolysis intensity provides sufficient number Salt.

Important! If the water is distilled, the electrolysis will not be at all.

To make water for a hydrogen engine, you need to take 10 liters of liquid and add a tablespoon of hydroxide.

Hydrogen engine device

First of all, you need to take care of additional tanks and pipelines. The hydrogen engine needs a water level sensor that is installed in the middle of the lid. This will prevent false response when moving up and down. It is he who will give the command to the automatic feeding system when it takes.

A special role is played by the pressure sensor. It turns on in an indicator of 40 PSI. As soon as the internal pressure reaches an indicator in 45 PSI, the podachka is turned off. When 50 PSI exceeds, the fuse will work.

The fuse of the hydrogen engine should consist of two parts: alarm reset and discontinuous disk valve. The discontinuous disk is activated when the pressure reaches 60 PSI, without applying any harm to the system.

To remove heat you need to use the coldest candle. Do not fit candles with platinum tips. Platinum is an excellent catalyst for the reaction of hydrogen and oxygen.

Important! Pay special attention to creating a hydrogen engine ventilation.

Electrical part

An important role in B. electrical scheme The hydrogen engine plays the timer 555. It performs the role of a pulse generator. Moreover, with it, you can adjust the frequency and width of the pulse.

Important! The timer has three frequency bands. Resistance to resistors within 100 ohms. Connection occurs in parallel.

The hydrogen engine board should have two pulse timers 555. At the same time, the first must have capacitors of greater tank. Exit from foot 3 enters the second generator. He actually includes it.

The third yield of the second timer of the pulse hydrogen generator is connected to resistors by 220 and 820 ohms. The transistor enhances the current to the desired value. For its protection corresponds to the diode 1N4007. This ensures the normal operation of the entire system.

RESULTS

Now the hydrogen engine is no longer the fruit of the fantasy of scientists, but a very real development that can be made independently. Of course, according to the characteristics, such an aggregate will give up the factory model. But savings for the engine will still be noticeable.

Hydrogen engines do not just help reduce gasoline consumption, but are completely safe for ambient. That is why there is already a sales first quarter hydrogen car Brand "Toyota" broke all records in Japan.

Interest in hydrogen generators, HHO and Gas Brown, continues to grow as on yeast, but the most joyful fact is a huge number of people who start or plan to collect hydrogen generators with their own hands. Moreover, it does not matter which generator a man is needed, a hydrogen generator for a car or a hydrogen generator for a boiler or welding, the principle of its action will still be the same. To help practitioners mastering this hard industry, we begin to prepare answers to frequently asked questions on the assembly of hydrogen generators with their own hands.

We offer you the first part of the answers to frequently asked questions on the assembly of hydrogen generator with their own hands. All the answers are given "as is", that is, without any veil, understone and hidden goals, we are pursued.

Part 1. Common Questions

In this issue:

1. Why do you need it? You can go and buy a hydrogen generator in the store, as you need?

2. Does there be ways to build a hydrogen generator that will work with the efficiency above the unit?

5. You publish super-nuclear hydrogen generators from Alexander ( ). He will never share his schemes and developments too?.

7. What need to use water?

8. What is the necessary metal? In various manuals, it is said about the need to use only very rare stamps ....

9. How long does the plates of the electrodes?

10. How to properly prepare plates for electrodes?

11. What are the temperature modes of the electrolyzer and water?

12. Is it possible to complete the car on Gas Brown?

13. What proportions of Brown gas in the fuel are harmless to the OI?

14. How many liters of Brown gas per minute need to work in DVS?

1. Why do you need it? You can go and buy a hydrogen generator in the store, as you need.

While the selection of hydrogen generators in stores is very zudd. The price of them is unreasonably high, the efficiency of their work rarely exceeds 50% and never exceeds even 90%. In order to obtain an effective hydrogen generator, working with the efficiency of more than one, currently there is only one way: to make it yourself.

2. Does there be ways to build a hydrogen generator that will work with the efficiency above the unit?

Of course exist! And built on completely different principles The work and efficiency of which exceeds the unit not on the share of interest, which can be written off on measurement errors, but exceeds one by times!

3. I studied well at school and university, and therefore I do not believe that there are generators of hydrogen working with the efficiency more units, how can I be convinced of this?

For a start, we offer to look at the universal ferris of hydrogen generators with spent. You can also use our, for calculating the efficiency of hydrogen generators and the high-speed thermal power.

4. Are there currently well-described and repeated schemes for assembling superior hydrogen generators?

No, there is no! The absolute majority laid on the Internet schemes for the assembly of super-efficient hydrogen generators are non-working. Therefore, it will not be possible to find a scheme, collect the generator on it and rejoice. Before you have to experiment much.

5. You are publishing super-sided hydrogen generators from Alexander (). He will never share his schemes and developments too?

Alexander very actively helps on the forum practices, answering their questions. It just has concrete and clear goals for bringing its developments to a logical completion, and it needs funds. Because Alexander does not plan to respond to a certain range of issues to a certain range of issues, mainly electronic circuit Electriculizer control.

6. Where and what can I read or see, and also where to ask questions?

7. What kind of water should be used?

Almost any, from plumbing to distilled. The best efficiency is achieved with the use of sodium hydroxide solution in distilled water in proportions one tablespoon for ten liters of water.

8. What is the necessary metal? In various manuals, it is said about the need to use only very rare stamps ...

This is one of the delusions! Suitable any stainless steel! The best results are achieved with steel, which is not attracted permanent magnet (It is not a ferromagnet), since it does not stick anything at the process of work, but this moment is not appropriate. The main thing is that the steel is stainless and, accordingly, so that it does not oxidize in water.

9. How long does the plates of the electrodes?

During the operation, the plate is not destroyed, so you do not need to change them.

10. How to properly prepare plates for electrodes?

All plates must be thoroughly rinsed before assembly, first in the soap solution, then alcohol or vodka. Then it is necessary to "drive" the electrolyzer a certain time, periodically replacing the water to clean, and so for several days until it is distinguished by all dirt and iron.

Subsequently, water will remain clean. Than cleaner waterThe smaller the heating of the installation.

11. What are the temperature modes of the electrolyzer and water?

With a propheted electrolyzer, the plates and water should not be heated.

It is also extremely desirable electrolyzer and plates do not overheat above 80 degrees.

If the temperature on unclean water raises higher than 65 degrees, then dirt and metal with minerals are climbing to the plates and you will not delete them already and you cannot clear the plates from them! They will have to be deleted only with abrasive processing, with the help of sandpaper, etc.

12. Is it possible to complete the car on Gas Brown?

Yes, theoretically possible. Almost any DVC works on Gaza Brown completely calmly and steadily without any alterations. However, it is necessary to remember that the product of the combustion of Gaza Brown is water, which, without adopting appropriate measures, will accumulate in the engine crankcase, turning the oil into the emulsion, which will result in rapid wear of parts that will contact it during operation. Therefore, for the long-term work of DVS on Gaza Brown, it is necessary to choose special additives and solve the problem with the removal of water from the oil.

13. What proportions of Brown gas in the fuel are harmless to the OI?

In the case of gasoline engines, up to 90% of fuel can be replaced with Brown gas, leaving only 10 percent of gasoline. In the case of diesel fuel, the amount of brown gas in the fuel should not exceed 75-80%. In compliance with the above proportions, the use of Gaza Brown will not apply in the economy of no visible damage, and its power apparently increases.

.

14. How many liters of Brown gas per minute need to work in DVS?

First of all, it all depends on the volume of the engine, the injection engine or carburetor, what year of the service of the car ... if you simply take as the basis for the example of the Zhiguli "Kopeika", then it is enough 17-18 liters per minute idling and 20-24 liters on the work move. This is the calculation of the fact that 90% of fuel is replaced with Brown gas. The weight of such an installation will be about 55-60 kilograms, taking into account the flooded water.

As we have already written above, it is only the first part of the questions. As they arrive, we will publish new articles with answers to the questions received.

And now a gift for students of universities, who were too fascinated by the search free energy And completely forgot about learning. There is a place where you will be helped, and if desired, even do

Hello mozgosobertors! In today's project, an electric generator converting ordinary water in fuel will be created from scratch.

Step 1: What is a hydrogen-oxygen generator

The hydrogen-oxygen generator, similar to this, uses electricity from a car battery to split water to gaseous hydrogen and oxygen. (Electricity + 2H20 -\u003e 2H2 + O2). As a result, it turns out fuel, much more powerful than gasoline, and as a result of emissions, only water is released!

This is a fully pure type of fuel, like the energy of the sun, wind or water, electricity is used only for the formation of gas.

In the video shown step-by-step creation This generator.

Note: Number electrical Energyrequired for gas formation exceeds the energy that can eventually be obtained from the generator. This is not an energy generator, but a simple energy converter.

Step 2: Preparation of metallic blanks for the plates of the generator

To fulfill this project, we will need stainless steel parts and plastic pipe fittings. You can purchase them at the nearest store of household goods.

I used stainless steel caliber 20 (0.8 mm) and using a hydraulic perforator struck the required holes in the upper and lower parts of the plates. As a result, we obtained 12 plates with a size of 7.6 x 15, 2 cm, 4 plates 3.8 x 15.2 cm, and 3 connecting strips 2.54 cm, 4 - 1.27 cm and 3 - 0.62 cm. The tape-grinding machine is used to smooth off the edges around the holes.

Step 3: Increase the plane of contact plates

Next I used emery paper With grain 100 for squeaking plates diagonally. On both sides of the plate you can see the symbol "X". This increases the area of \u200b\u200bcontact with the plate and promotes education more Gas.

Step 4: Configuring Plates Collected

The plates are connected in such a way that 2 internal plates are connected to one electrical output, and 2 the upper plates are connected to another output. Plastic rods, plastic washers and stainless steel nuts help make reliable electrical connections.

The generator plates are collected in next order - Plate, plastic washers, plate, stainless steel lock nut and so far all 8 plates are connected.

Step-by-step video Instructions for assembling the generator plate is shown.

After collecting the plates, it is necessary to establish a plastic plug of 10.1 cm, which is attached at the top with several stainless steel screws.

Step 5: Production of the generator body

The housing consists of two plastic adapters of 10.1 cm, with an inverted plug of 10.1 cm at the bottom. The base of the housing is a acrylic or plastic pipe with a diameter of 10.1 cm, the plates of the generator and the lid are screwed into the upper part.

The water mixer is made in the same manner of acrylic pipe with a diameter of 5 cm. It must be attached to the side of the device.

Step 6: Making clamps for the mixer

Clips can be made from the remains of an acrylic or plastic pipe, and it is subsequently glued in the side part of the housing.

For the manufacture of the clips, I cut off the pipe with a diameter of 5 cm of a blank of 1.9 cm and cut off the upper part of 0.8 cm in size for the capture forming. Next, the obtained workpiece I attached to the acrylic rod and attached to the lateral side of the generator.

Step 7: Setting the current valve

In the top knee there is a transparent tube and a one-way turning valve. Make sure the valve is booming gas, and it does not return back to the device.

Step 8: Preparation of electrolyte

To prepare the electrolyte, distilled water and 2-4 spoons of KOH (potassium hydroxide) are used. Salt or baking soda Also suitable, but over time they can cause pollution and corrosion of plates.

I stirred potassium hydroxide flakes in water, then used a filter for supplying a solution into the generator body (after thorough cleaning).

Note: Potassium hydroxide is a caustic agent and therefore can cause skin burns. Avoid direct contact!

Step 9: Final Strokes

I tested the device using a 12 V voltage battery and cable jumpers. The formed gas is assembled in a small bottle of water, and is set on fireplate.

At a voltage of 12 volts, we obtain 1.5 liters of gas per minute. If you consistently connect 2 batteries, then at a voltage of 24 volts we have 5 liters of gas at the output per minute. This is enough to fill the capacity of 4 gallon (15 liters) for 38 seconds!

Note: With a larger voltage in the system there is a larger current, which leads to significant heating. In this case, there is a danger of melting the plastic hull due to the effects of high temperature.

Step 10: How much power under the hood of our generator?

This system is not intended for use on vehicle, but simply demonstrates the process of electrolysis of water and gas formation.

See the video where the experiments on the gas fence are shown, as well as some useful characteristics Generator.

For the heating of a private house use different methods. They differ in each other by the method of heat transfer and the type of energy used. When using water heating, several types of boilers are distinguished depending on the type of fuel:

Hydrogen generator for the heating of a private house

- Solid fuel - solid fuel used for operation, which he highlights heat during combustion.

- Electric - in such boilers heat is obtained by converting electricity.

- Gas - heat is highlighted during gas combustion.

If we consider gas boilersthen they mainly work on natural gas, although there are models and under liquefied gas, and B. lately We begin to apply hydrogen as fuel produced from water in special devices - hydrogen generators.

Principle of operation

From the school year of physics, it is known that water when exposed to it electric current decomposes into two components: hydrogen and oxygen. Based on this phenomenon, a so-called hydrogen generator is built. This device is an aggregate in which an electrochemical reaction takes place to obtain hydrogen and oxygen from water. The water electrolysis process is shown in the figure below.

Water electrolysis process

Water electrolysis process At the outlet of the generator, no hydrogen and oxygen is formed in its pure form, and the so-called Brown gas, by the name of the scientist who first received it. It is also called "rattling gas", as it is certain conditions Explosive. Moreover, when combustion of this gas, it is possible to get almost four times more energy than it was spent on its production.

Such an installation for hydrogen production is shown in the figure below.

Industrial installation for hydrogen production

Industrial installation for hydrogen production Pros and cons

Of the advantages of this type of heating, the following can be distinguished:

- This is an environmentally friendly type of heating, since water in the form of a pair is formed during the combustion of hydrogen in the oxygen medium, and there are no more emissions of any harmful substances into the atmosphere.

- You can connect the generator without special alterations existing system Water heating of a private house.

- The installation works silently, so does not require some special place.

Disadvantages:

- At hydrogen big temperature The combustion, which in the oxygen medium can reach 3200 ° C, so the usual boiler may fail very quickly. IN modern devices Scientists have achieved the result of gas combustion at a temperature of 300 ° C, so the problem can be considered practically solved.

- When working with Gas Brown, you need to be very careful because it is explosive. This is solved by using various safety valves And automation.

- Requires the use of distilled water or water with alkali.

- Great cost of equipment. To solve this problem, many are trying to assemble the installation to produce hydrogen with their own hands.

Hydrogen generator with their own hands

The self-made device is schematically a container with water where electrodes are placed to convert water into hydrogen and oxygen.

In order to make such a device with your own hands, you will need:

- Stainless metal sheet 0.5-0.7mm thick. Stainless steel brand 12x18n10t.

- Plates of plexiglas.

- Rubber tubes for water supply and gas removal.

- Sheet benzomal-resistant rubber thick 3 mm.

- Voltage source - Latr with a diode bridge for receipt direct current. It should provide a current of 5-8 amps.

First cut the stainless plates on the rectangles of 200 × 200mm. Corners on the plates need to be cut to pull the entire structure with bolts. In each plate we drill a hole with a diameter of 5mm, at a distance of 3 cm from the bottom of the plates, for water circulation. Also, the wire is supplied to each plate to connect to a power source.

Before assembling rubber make rings with external diameter 200mm and inland - 190mm. You still need to prepare two plates of plexiglass with a thickness of 2 cm and sizes of 200 × 200mm, while you need to pre-make the holes in them in four sides under the M8 tightening bolts.

The assembly is starting like this: first they put the first plate, then the rubber ring, the sealant-missing on both sides, then the next plate and so to the last plate. After that, it is necessary to pull the entire design from both sides using the M8 studs and the plates of the plexiglass. Holes are drilled in the plates: in one - at the bottom for the supply of fluid, in the other - at the top for the gas removal. The fitting is inserted there. Medical polychlorvinyl tubes are dressed for these fittings. As a result, the design should turn out, as in the figure below.

Hydrogen generator with their own hands

Hydrogen generator with their own hands In order to exclude gas from entering the gas generator, on the way from the generator to the burner it is necessary to make a water shutter, and even better two shutters.

The design of the shutter is a water container into which the tube is lowered from the generator side, and that tube, which goes to the burner, above the water level. The hydrogen generator circuit with shutters is shutdown in the figure below.

Scheme of hydrogen generator with water shutters

Scheme of hydrogen generator with water shutters In the electrolyzer - a hermetic tank with water with lowered electrodes, gas begins to highlight the voltage. On the tube 1 it is fed to 1 shutter. The design of the water shutter is arranged in such a way as can be seen from the figure that the gas can only move in the direction from the electrolyzer to the burner, and not vice versa. This interferes with different density of water that needs to be overcome on the way back. Next, on the tube 2, the gas moves to 2 shutter, which is designed for greater reliability of the system: if suddenly, for some reason, the first shutter does not work. After that, the gas is supplied to the burner using a tube 3. Water shutters are a very important part of the device, since they prevent the gas movement in the opposite direction.

When gas hits, an explosion of the device may occur back into the electrolyzer. Therefore, in no case cannot operate the device without water shutters!

Exploitation

After assembly, you can start testing the instrument. To do this, at the end of the tube, the burner is installed from the medical needle and begin to pour water. You need to add KOH or NaOH to the water. Water should be distilled or thala in extreme. For the operation of the device, a 10% concentration of alkaline mortar is sufficient. When pouring water should not be any sublishes. Best of all before the fill to blow the design with air, pressure up to 1ATM. If the hydrogen generator can withstand this pressure, then water can be poured, if not, you need to eliminate leaks.

After that, the Latr with a diode bridge is connected to the electrodes according to the scheme. The chain establishes an ammeter and a voltmeter to control the work. Start with minimal voltage and then constantly increase, watching the gas division.

Pre-work better open air Outside home. Since installation is explosive, all work should be carried out with extreme caution.

When testing, observed the operation of the device. If there is a small burner flame, then there may be a low gasmind in the generator, or a gas leak occurs somewhere. If the solution climbed, dirty, it needs to be replaced. It is also necessary to ensure that the device does not overheat, and the water did not boil. To do this, regulate the voltage at the current source. And one more - the plates during heating are slightly deformed and can adhere to one to one. To exclude it, you need to make gaskets from rubber. Wheels can also be observed - to eliminate it you need to reduce the water level.

Generator in the heating system

After the tests carried out, you can connect the installation to gas boiler at home. To do this, the boiler needs to remake a little, namely, make a joyaker with a hole of a smaller diameter than the factory designed for natural gas. The generator was depicted in the figure below.

Hydrogen generator assembled

Hydrogen generator assembled Water must be flooded with the water heating system. The flame burner can melt the boiler if there is no water.

After that, they regulate the water supply to the device and begin to eliminate the plugs in the home heating system. Then, with the help of water supply and supply voltage adjusts the operation of the boiler.

When operating the installation during the heating season, the final test is carried out, during which several questions are solved:

- Litus gas for heating at home. If it is not enough, you can make the installation of greater productivity with your own hands.

- As far as the boiler works on hydrogen, that is, how much the boiler will last.

- The cost of such heating is to make it possible to make a magazine in which to calculate the costs of heating and temperature in the house and on the street during the boiler operation. Based on this data, then we can conclude how profitable to dump the house with hydrogen.

Based on these data, it is possible to prepare more thoroughly to the next heating season. During operation, you can see what needs to be improved, can some part of the device need to remake. Perhaps the boiler itself needs in alteration and modernization, so that he does not have a quick failure. Also, if in the future it is planned to use the device, maybe it makes sense to purchase a distiller for water?

Video about the generator

How to make a hydrogen generator with your own hands without electricity, you can learn from this video.

The main question that interests many are is so expensive or cheaply or cheap? This can be found if you keep statistics during the heating season. Moreover, it is necessary to take all costs, such as the cost of distilled water, the cost of alkali, electricity costs, on the repair of the boiler and on the manufacture of the installation. Based on this, it is possible to make a decision, suitable such a type of heating for the house or not.

In contact with

Why you can not give icons

Why you can not give icons Is it possible to give icons as a gift: Signs, the opinion of the Church

Is it possible to give icons as a gift: Signs, the opinion of the Church A year ago left her husband, and now I do not know what to do

A year ago left her husband, and now I do not know what to do