What can be made from the electric bissing with your own hands. How to make a logging machine with your own hands? Lobzic machine using thin saws

Lobzic Machine Allows you to quickly and effectively deal with saws. It consists of a working surface, racks, motor and spindle node. Some devices are made on stands. The clamps are often installed in the side of the working surface. It is also worth noting that the models differ in power. The manufacture of a logging machine can only be carried out if the instructions are followed.

Desktop devices: specialist reviews

If you believe feedback, then make a desktop modification is very simple. First of all, the stand is harvested under the working surface. Its width should not exceed 30 cm. Motor is more expedient to pick a single-phase type with a limit voltage of 220 V. The homemade logging machine (bench-top) on average produces a working frequency of 55 Hz.

Professional reviews suggest that the tees is better to use from steel, if desired, you can cut them yourself. The carriage is installed on the spindle node that is attached to the rack. Many models will apply a retainer, which plays the role of stop. To secure the punch, a small screw is applied.

Models on legs

If necessary, you can make this with your own hands. Drawings of modifications include frames different sizes, and spindle nodes are usually used with guides. Many models are made on a wide bed. The legs can be installed from the tubes. There are also machines with plates. After the cutout of the working platform, the spindle node should be done.

If we consider devices with control blocks, then the model will require the controller. Motor It is more expedient to apply a collector type on 220 V. TiSi on the jigsaw machines installed a rotary type. The direction must be welded to the edge of the plate. The pink in this case should be securely fixed. The optimal height of the spindle node is 2.2 cm. At the end of the work, it is important to make installation power cable and connecting equipment.

Reviews about devices with a wide frame

Professionals are able to assemble the logging machine with their own hands. Drawings of devices indicate the presence of broad stops. However, first of all it is necessary to install the bed. If we consider a simple machine, then the fixator for modification can be selected small lengths. Professionals indicate that two racks are enough for the model. To assemble the machine applied welding inverter. The spindle node directly is installed in the central part of the working platform. A hole for the peel can be made of cutter. It is also worth noting that experts do not recommend using two-phase engines.

Compact modifications

Adhering to the instructions, you can collect a compact logging machine with your own hands. Drawings of devices include double racks and narrow frames. Stannes are used with a low profile. Many models have a spindle knot without holder. In this case, the guides are set by small length. For self-assembly Models are recommended primarily to select a quality frame.

Additionally, the retainer is soldered under the work plate. To reduce the level of vibration, you can use the lining. For its fixation, ordinary glue is applied. The filling for modification should be selected with a small thickness. Optimal distance Installation of the central node is 14 cm. In this case, the platform width is on average 17 cm.

Lobsiki for 2 kW

If you wish, you can make this logged machine with your own hands. Drawings for assembling modification is very simple. As a rule, the frames are used with a width of 35 cm. The plate thickness should be about 1.5 mm. The hole under the pedal must be made before installing the central node. If we consider models without stops, the frame is used with a low profile. It is also worth noting that the spindle node is expedient to install on the lining.

To reduce noise, the casing is used. Many models use several stops. In this case, the node is set at height from 10 cm. The pylon is better fixed on the plate. Clamp You can use a screw type. After fixing the central node, the motor is put. To modify this type, a device with a single-phase block is suitable.

Models for 3 kW

For 3 kW, the desktop electrolybiz is pretty simple. Experts recommend using racks with wide stops. Fixators need to be installed only after the central node. Pink for modification can be chosen by 1.2 mm. Some experts hole do after installing the frame. In this case, the supports are soldered around the table.

This is further important to estimate the size of the spindle. Motor is more expedient to use with a protection system and a casing. It is also worth noting that collector devices that work at a frequency of 45 Hz are very popular. They have low energy consumption, and they do not overheat. To fix billets apply holders. The optimal height of the spindle is 15 cm. It is also worth noting that there are models with tuning plates. A flywheel is used to control the rack. To install the control unit, there is a regular controller.

How to make a device for 5 kW

Preparing several stops and you can make a logging machine with your own hands. Professionals indicate that 5 kW models are well suited for longitudinal cutting. Before starting work, all required tool. It will take a saw as well welding machine and cutter. Frame for the logging machine is more expedient to collect from steel plates with a thickness of 1.3 mm. For the motor you need to immediately foresee. Stannes in devices are installed high profile.

At this stage, you can immediately cut the hole under the pipe. The plug assembly must be mounted on the top of the plate. Additionally, it is worth noting that a big holder will be required for the peel. If we consider simple model, Racks can be installed on the sides of the frame. Tisi used turning type. At the top of the frame, there is a rack. A small casing is selected for the motor. On average, the width of the frame should be 35 cm. If we consider professional models, they use regulated clamps.

Two pin cells modifications

How to make a logging machine with your own hands? The model with two pinoles is collected only on a wide frame. First of all, the plates are cut under the face. If we consider the desktop modification, then the control unit is more expedient to install in the upper part of the device. The optimal frame width is 45 cm. At the same time, the spindle node is installed behind the stops.

For racks should be provided in many models used transmission blocks. In this case, the motors are only a collective type with a frequency of 30 Hz. The pedel is installed standard in the holder. The optimal height of the spindle node in the models is 35 cm. Pinoli for adjusting the beds are used with flywheels.

Models for three pinoles

On the basis of a single-phase motor, it is easy to make this with your own hands. Tools should be harvested in advance. Many models are equipped with frames for four stops. They have a big length and high profile. It is also worth noting that spindle nodes are selected from at the beginning of work it is very important to calculate the length of the frame. If we consider conventional spindle nodes, then the rack is harvested with a small length.

The central support must withstand heavy loads. A welding inverter is used to install the plates. The motor will require a casing, which will significantly reduce the noise level of the device. Saw for modifications of this type is suitable for 1.2 mm. With a power of 3 kW, the device for three pin will produce a frequency of 55 Hz. For fixing the flywheels you need brackets.

Desktop logging machine will be useful to each wizard, discharged thin details. However, it is not always possible to have the opportunity and make sense to acquire a full-fledged machine. In this case, take the case and make it with your own hands!

Lobzic machine device - what lies inside?

Lobzic machines belong more to the tools special than to the devices that are needed as experienced MasterAnd a lover hovering in the garage. Their appointment comes down to a special task, namely the discharge of complex curvilinear contours from sheet materials. A special "chip" of such machines can be attributed and the execution of cut without disrupting the integrity of the external contour. Most often, drinking occurs on wooden and derived materials (plywood, chipboard, fiberboard), although modern machines equipped with appropriate sawmills are capable of working with other materials, such as plastic or plasterboard.

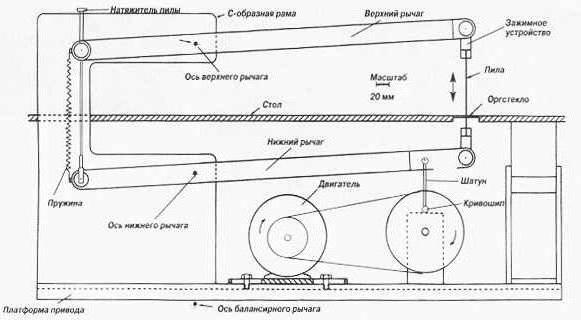

Such equipment has been applied in the music industry (manufacturing musical instruments) And, of course, in the furniture. Buy such aggregates and lovers to make their own workshop. The device of the traditional logging machine, designed by all the rules, is as follows: working surfaceTo which the saw was removed, hides with the drive (electric motor) and the crank-connecting rod design. The tension mechanism can be both bottom and top of the machine.

To handle the item, it must be put on the desktop. Many models have the ability to turn it at different angles to perform inclined cut. Stops and guides on the surface as well rotary mechanism May be marked, which greatly simplifies and speeds up work. It is from the length of the desktop and the length of the cut is the majority of models are limited to 30-40 cm. The power of the electric motor is important, but still far from the most fundamental factor, since the machine has a huge reserve for unclaimed power. For example, for a home workshop or even small production Enough "engine" is only 150 W.

Crop-connecting mechanism - wherever more important detail, In this case, in this case, it is from it that the quality of the drive of the drive in a progressive-return movement directed in the vertical plane is depends on the vertical plane.

Standard feeding machines are considered to be apparatuses with an amplitude of motion in the region of 3-5 cm at a frequency of oscillations up to 1000 per minute. In many models there is a change of high-speed regime for different materials. The lyobzic pink itself is usually made up to 35 cm long and able to cut the material to 10 cm thick. The width of the sawmakes can fluctuate in a fairly wide range - from very thin two-millimeter to more rough ten-millimeters, with a thickness of from 0.6 mm to 1.25 mm.

Even the thick and wide sawing will be easy to break if it is not enough to ensure a sufficient tension of the saws along the entire length. This uses spring and screw springs. Quite often such machines are equipped air pumpwhich cleans through blowing cut from sawdust, as well as a drilling unit. The last device is especially useful, because in this case the master does not need to be distracted by connection electric drill And drill holes - everything happens on the working plane of the machine. Of course, for convenience will have to pay!

How to make a logging machine with your own hands from the manual electroball?

On the network you will find many different designs Homemade machines, but most of them are reduced to repugrnation in this device. Applying the smell and watching the video, you will be completely easy to make a homemade logging machine from this tool. You need to refine an electrolovka only a bit. In fact, it performs the role of the drive of the machine and the crank-connecting mechanism, the rest must be infidant and implement.

Of course, manufacturers are trying to please consumers and in this area, offering their platform options for fast and convenient alterations, however, in fact, only you can make the apparatus corresponding to your needs.. So, the first thing you need to make a support table, for which most often use sheet metal. It needs to make a relaxed oblong hole for the saws and holes for fasteners (screws with secret head), And attach the jigscription from the bottom of the support table.

This design remains only to strengthen wooden table. You may not be limited to this and install guide rails. The convenience of such an apparatus is that in addition to performing the functions not completely inherent in it, you can always disconnect the drive and a slight movement of the hand turn it again into the manual electrolybiz! If this tool is constantly required to work, it makes sense specifically for the machine - it will be cheaper than spending on the real machine.

Advantages and disadvantages - we continue to modify!

But such an unit inherits not only the advantages of the instrument, but also its disadvantages, in particular, too broad for filigree works, which significantly limits the curvature of lines. If there is a need for this, there is a way out. So far, our machine is different from the classic logging unit in the absence of springs that would provide sufficient tension of the sawmill. But to build a simple rocker, which on the one hand will be under the tension of the springs, and on the other is fixed on the sawing, quite easily.

There is another option - to clamp a sawtur between two guide rollers, but the first option is still reliable. Do not forget to turn off the pendulum running on the electrolovka before start using the homemade machine. There is another design - if your tool is quite powerful, then it can only serve as driven in the design of two rockers, between which the sawo is stretched. The movement is transmitted by means fixed on the lower rocker.

Machine from the sewing machine - give the second life with old tools!

If you inherit the grandmother or mom got a foot or manual sewing machine, consider yourself the owner of a great logging machine! Of course, for this you need to "put a little" above the machine. First, remove the device for the nitcutting, which is usually located at the bottom of the device. There is nothing difficult in this, it is enough to unscrew two bolts. Then we knocked the pin and remove the drive shaft leading to the mechanism of the nitcipette.

Revealing top panel, protecting mechanisms, it is necessary to expand the slot in which the needle walked. Focus on the needs and width of the file that you will apply in work. Pilking for a logging machine of this kind also need to modify slightly, namely it is cut under maximum length The needles that could be used on this typewriter. Streeting the upper teeth and sharpening low part On the edge, you will only stay insert a file in a needle holder and experience your machine in action!

Electric jigsaw - tool that for last years firmly took a place in the arsenal of almost every owner. And if I have not yet taken - it means that this article will be by the way, because to choose a good table or manual Lobzikwhich would meet all the goals set, a rather difficult task.

Manual Lobzik on the tree - the first drinking lessons

What is a manual jigsik on a tree, all the boys will learn at school in labor lessons. This is one of those tools that can be trusted even a child without fear of his safety. The simplest structure from the U-shaped frame with fixers at the edges is actually intended for the finest work in the art of drinking - electric logsik Although accelerates work at times, but not always able to cut the thin curl you need. Therefore, in any workshop, the manual junk will always occupy its honorable place, besides, it is not difficult to make such a jigsaw.

In drinking hand tool There is one feature - for the convenience and speed of work, a miniature saw blade should be stretched like a string, eliminating possible sagging. With a superior blade and work it will be uncomfortable, and the blade at the first encumbrance is most likely breaking. The direction of the teeth is strictly against the movement of the canvas down. The thinner the blade you have chosen, the thinner and iron will be a thread.

What to choose a logby - the main characteristics

Before going to the market, find out for yourself what the main characteristics of the tool should pay attention to the choice of jigsaw. The engine power is definitely this parameter should be taken into account in the first place. It depends on the minimum and maximum thickness of the sawn material and the speed of cutting. The quality of the engine depends on the engine capacity. For household tools, quite normal power from 280 to 550 W.

The pendulum movement is a function that is not in all electrical lobby, but its presence is necessary for serious tasks. If in the usual mode, the logs is moving the file only up and down, then the jigsik with the inclusive pendulum movement deflects the cloth from the cut back at the bottom and gives the canvas towards the sawing on the top. Due to this, it is better cleaned from the chips, the sawdill is reduced and the wear of the peel is reduced, and the sawing by an electrolybiz becomes easier task.

The amplitude of the oscillation is regulated during the cut of different materials, for example, for soft rocks and plastics, the maximum mode is selected, whereas with a greater thickness of the wood, the cut of soft metals and the amplitude chipboard decreases.

This function turns off at all when we are talking About working with metal sheets or sawed steel. The number of moves is defined with what to select a jigsive, pay attention to this factor. The single-speed electrolovka can work properly only during woodworking, when cutting metal, the instrument engine can fail. Therefore, for greater functionality, it is recommended to buy devices with as best adjustment as possible and the most wide range. The wider the last characteristic, the universality becomes the tool.

In some jigsaws, the number of moves is regulated by the recorded switch, which sets the speed predetermined by the manufacturer. But the logs are considered more professional, in which the speed is adjusted by the power of pressing the start button.located on the handle under the index finger. However, even in such models there is the possibility of working at fixed speeds. The maximum power of the tool includes when working with wood, the average number is selected to work with soft metals, for example aluminum, and and ceramics involves the minimum number of strokes.

In this case, the load on the engine goes exactly on low speeds, Therefore, working with metals, let's get tool from time to time either in the off position or on the maximum number of moves. However, listen to the instrument, the sound of the electrolovka and the ease of cutting - the best advisers.

Fastening the sawmill canvas - be sure to pay attention to this characteristic. After all, in the future it depends on it, how easy you can pick up the toolpillers. Often the mechanism for fastening the pylon provides for the possibility of fixing the canvas in the planting socket by clamping hexagon bolt and a notch under a screwdriver or a quick-inspection mechanism. If the tool can work with the saws that have a cross on the tail, it means you can safely buy it. Crusades are the most common type that you will find in any store.

Lobzik selection - Pleasant additions

In addition to the main characteristics, it will not hurt to pay attention to the secondary additions that are able to do the work with this tool much more comfortable. The blower and dust systems are not uncommon among this kind of tool. Air flow from the working engine, directed in the desired side, perfectly copes with the removal of sawdust from the cut line. If there is and the ability to connect a bag for dustproof, the workflow will become much more comfortable.

The ability to make an inclined cutter is another feature, very useful in any business. Some tools provide for work only in fixed positions, however, an electrolovka with a smooth adjustment of the tilt of the tool relative to the "sole" is much more preferable.

Well, if we remembered the so-called "sole", that is, the platform, which is a guide in the instrument, completed the review and this detail. The convenience of work depends on its quality. Most preferred cast "soles" - compared to stamped analogs, they provide greater accuracy. Make sure that the model you buy has necessarily attended the possibility of installing an anti-slip liner - a small part, which makes it easier for the procedure for cutting fragile materials.

Not unnecessary complete additions, for example, a protective screen and guides for drunk round figures. Professional instrument Must be supplied parallel stops And the storage case for the tool and carry all components.

Lobzik Table - buy or make?

Professional type tools are characterized by a long work time without interruption. The household are provided for use on occasion to occasion, so they are easier, and less powerful. Accordingly, the price will be much lower.

Professional belongs and a jigsaw electric bench-top, which has many advantages over a manual electrolybiz. His main dignity is the ability to work with thin sawdues, and therefore drinking thinner patterns and complex decorative details. The convenience of work provides a wide countertop on which you can easily process large parts and make rugs in wide blanks. Due to reliable fastening, the body is protected from unnecessary oscillations, which in turn protects the motor from overloads.

When working with a desktop instrument, you can pay all the attention to the material, tightly take it with both hands, which is impossible when working with a hand tool. However, if necessary, you can leave the position, making a homemade stationary logsik, constructing it from a manual type of tool, several screws and a piece durable plywood.

Plywood will serve as a table top in which, with the help of the same jigsaw, it is necessary to make a cut under the saw, and drill a few holes for fasteners. It is possible that you will have to drill the same holes in the "sole" tool. Fix the tool under the plywood, and the whole design is brappy on the edge of the table - our desktop electrolybiz is ready!

The article will first of all be useful to those people who often work with a tree as a hobby without earning this money. The author is presented pretty budget project desktop Electrolovkawhich can be collected in one day when minimum costs on materials.

To create the machine, you will need such materials:

- a working manual electrolybiz;

- plywood;

- self-tapping screws and bolts with nuts;

- guide furniture boxes;

- two bearings;

- tightening spring;

- Paint spray;

- Self-adhesive paper.

Standard materials and tools available in each workshop.

Step 1. Case.

The first step will be the creation of a housing for a manual electrolybiz from plywood. Here you must think in advance where the holes for the switch and the speed control will be located.

Must get up something like this:

Step 2. Countertop.

As the basis of the countertop it is better to take a thick piece of chipboard with good coatingSince the machined workpiece will be thrown on it during the operation of the machine.

A pink hole is drilled in the chipboard. The electrolovik himself will be attached to the back side of the table top.

Also from the furniture guides is made of an adjustment of the boom:

This is how it looks assembly:

And the tabletop is attached to the case:

Step 3. Arrow.

The arrow itself will be made of two furniture guides. They twisted with each other bolts to enhance stiffness.

Arrow supports are made of chipboard. Before their painting and installation, the point of fastening the boom to the support is washed. Before that, they need to be installed in their place:

After that, in the support, drill holes under planting Bearings.

Step 4. Painting.

Prepared supports color from the canister.

While they dry, the machine itself is glued with self-keeper.

Step 5. Assembly.

Bearings are inserted into the supports, and they are screwed into their place.

The mounting axis will be made of two bolts screwed into guides as shown in the photo. The diameter of the bolts is selected in accordance with the diameter of the inner coating of the bearing.

Bolts are reliably tightened, after which two halves are screwed to each other.

It is clearly shown as an arrow will be fixed in supports:

The arrow is installed in its place and fixed with nuts.

Next, you must install a tightening spring. It is necessary in order to return the arrow to its original position after the jigscription pulls it down. Thus, reciprocal movements of the peel will be performed. It must be adjusted so that it is not softer (it will make it difficult to work the machine) and through the chur hard (this can lead to the overheating of the jigsaw engine).

How to fasten it shown in the photo:

Then, from a thin strip of metal (1 mm), it is necessary to make fastenings of the peel to arrive. They need to rotate freely on the axis, because when working the arrow changes the angle of inclination to the jigsaw, and if they are static, it can lead to a breakdown of the peel.

That's how the fasteners should look:

Arrow supports are additionally enhanced by a long bolt, it can be seen in the photo:

Step 6. Electronic part.

Since access to handle electrolovka It is limited, it is necessary to derive controls to the outer part of the case.

To adjust the frequency of rotation of the electric motor, the author was used by the phase power regulator. Here is its electrical scheme:

That's what it looks like:

When installing the board to sewage, it is necessary to screw the radiator if it does not do it overheat and fail.

Lobzik disassembled and power control is connected to electrical circuit.

You also need to set the power button.

I did not want to put my dear Makitov's jigsaw on a constantly on the table, so I decided to buy another one to create a table. I was very successful turned up in the store "Our House" Lobzik Caliber LEM-610E In just 862r. Included: Tree Pink, Side Pop, Adapter for Vacuum Cleaner, Spare Brushes for Engine.

Next to the showcase was a socket and I looked at it at work. It is quite decently made, it is convenient, there is an adjustment of revolutions with a wheel, the inclusion is fixed with the button. The pilch holder goes clearly without the backlash.

It is very successful that I was able to twist it in my hands before you buy, from the site of all-cutters.ru I would not venture him to order, not knowing what he was. (Although the reviews about him are written good) By the way, it costs it more expensive and still payment of delivery ... So I successfully bought it in our house. :)

Despite the dignity, he has a number of shortcomings to which he saw with a more attentive review:

1) The pink does not climb into the pilch holder. Apparently this is an instance marriage, but I did not spend my time on exchange. Each pylon has to be tolded. (Although in the second jigsik I can not use them after the crawling - it's not trouble, they are relatively inexpensive)

2) And this drawback is visible even in the picture. The canvas tilted strongly forward. (This also managed to fix, with a lining to the back of the sole of tin strips, achieving 90 o.

3) The wheel adjustment wheel spins hard not very clearly and with jammed. At the minimum value of the speed, the instrument can not start at all (however, the same garbage with the launch and other "Calibrovsky" drills is unpleasant, but not much spoils life)

As always, everything is in the spirit of minimalism. It did not do a separate switch. It is quite conveniently turned on with a regular button and fixed.

To do this, I bought a bracket in the clock (this is an element of fasteners from some system iron structures)

By the way, I love the foamarket. Any cogs, wrenches, self-tapping screws, fasteners. Every time something design, go there in thought and gain yourself necessary details.

Excessive cut and crawled.

Back view. Now the distance between the bearings has a fixed clearance under a pink 1.2mm. I have a plan for the future: make the clearance adjustment.

For thin materials, you can lower below.

As an experiment painted an asterisk and tried to cut it exactly

For a saw 130mm -Maximum possible thickness obtained 5cm. It turns out to be very long peels, recently in the market I saw a pylon 300mm

Sloved slice of 1.5mm from bar 40x40mm Bro

What I did. Now it is possible to cut long blanks with a width of 11.5 cm. Old G-shaped design Also remained and if you need a great strength of the holder, it will be possible to put it again, although the new design remains sufficiently strong and reliable.

I also came to mind the idea of \u200b\u200bthe old stupid millet to make a knife, yelling her teeth and pointed.

They can figure out the material like a sealer. The slice is smooth. Much better than a stationery knife. On the photo - the rug from the mouse.

Well, perhaps, everything. The table turned out reliable and convenient. Now I have a tool on which I can produce more subtle works than on a circular.

How to return the love of her husband to his wife - Tips of the psychologist

How to return the love of her husband to his wife - Tips of the psychologist Why you can not give icons

Why you can not give icons