Plywood laser cutting. Laser cutting of plywood products. Why order laser cut plywood

Which is carried out on special laser and milling equipment. Cutting of plywood is very often required when it becomes not very convenient to use large format plywood sheets, or when it is required to perform curly cutting material in large quantities.

Prices for milling plywood

| Plywood thickness, mm | Price for 1 running meter, rub. | ||

| up to 100 m | from 100 to 500 m | more than 500 m |

|

| 3-6 mm | 32 | 27 | 20 |

| 8-12 mm | 35 | 28 | 23 |

| 15-18 mm | 40 | 35 | 30 |

| 20-24 mm | 50 | 45 | 40 |

| 27-30 mm | 63 | 58 | 55 |

Prices for laser cut plywood

| Plywood thickness, mm | Price for 1 running meter, rub. | ||

| up to 100 m | from 100 to 500 m | more than 500 m | |

| 3 mm | 45 | 38 | 30 |

| 4 mm | 53 | 45 | 38 |

| 6 mm | 60 | 53 | 45 |

| 8 mm | 68 | 60 | 53 |

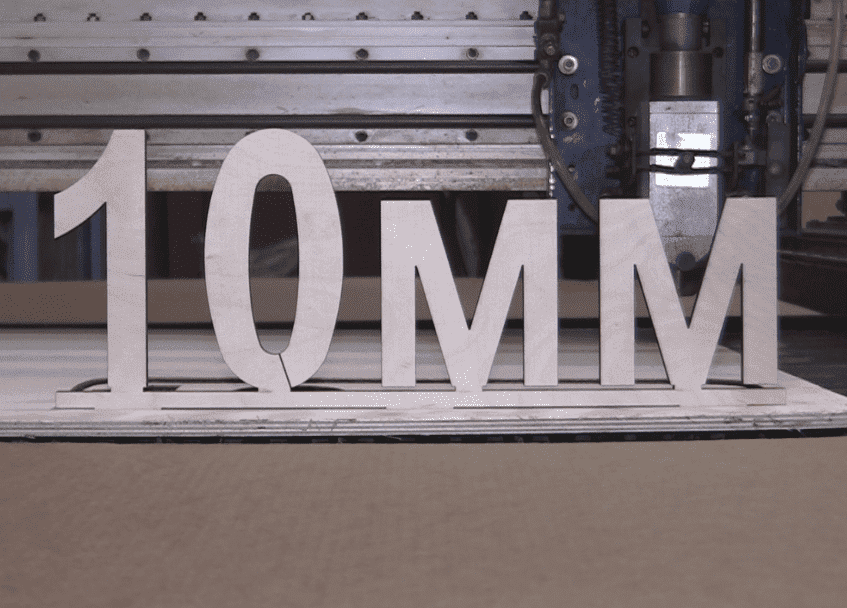

| 10 mm | 75 | 68 | 60 |

| 12 mm | 83 | 75 | 68 |

Plywood is made from veneer sheets, connected to each other with a special glue on a resinous basis, which, when cutting plywood, very bluntly and wears out the cutter knives and other elements of the tools. In this regard, it is very important to use tools made of very strong, hard alloys for cutting plywood. good quality... Only in this case plywood will lend itself well to cutting and processing, and the tool will not wear out and retain its performance longer.

Cutting plywood with a laser

Laser cutting is the most modern and popular method of processing, cutting and decorating plywood. Laser cutting allows for a short period not only to cut plywood into pieces, but also to create high-quality drawings.

Modern laser devices cut any plywood sheets with sufficient quality and make it possible to make various elements without exerting any mechanical effect on them. This cutting method eliminates the formation of chips or pile on the edge of the material being processed. However, very often the result of laser cutting depends on the quality and type of raw materials from which it is made plywood sheet, as well as on the method of its processing and the type of glue that was used in its manufacture.

The cut of the material after laser processing burns, slightly changing its color, which can be both a positive and a negative feature of this type of cutting. The darkened edge of the plywood, formed after cutting, emphasizes the contours of the material, which can be used for decorative purposes.

Milling plywood allows you to perform shape cutting or high-quality cutting of material in a straight line. At the same time, the plywood at the cut site does not change its color.

Milling cutting allows you to perform both through cuts of plywood and surface cuts, when the cutter penetrates into the material only to a predetermined depth. The milling unit also allows you to mill technological recesses, grooves and many other different operations.

Milling cutting of plywood involves a mechanical effect on the material, but, despite this, thanks to the use of specialized cutters, this method of cutting plywood makes it possible to almost completely eliminate the formation of chips and pile on the cut of the material.

CNC woodworking milling machines provide accurate, reliable and fast cutting of plywood according to preprogrammed parameters. Using a milling machine, you can not only cut plywood and make it shaped cutting the required configuration and size, but also to carry out the final processing of the edges of the material to remove various roughness, creases and irregularities from them. Also, using milling cutting, you can perform decorative trim in the form of relief engraving or figured cutting, which is often used when decorative design furniture.

Cutting plywood at home can be done by hand or electric jigsaw for cutting sheet materials... This cutting method does not allow achieving sufficient High Quality cut, since after cutting there may be chips at the edges of the plywood, and the cut itself may have irregularities.

The manual way of cutting plywood is the simplest and most affordable way. To cut plywood at home, you can use a regular hand saw. Since plywood is a fairly dense and durable material, cutting it with a hacksaw requires a certain amount of physical effort. The thicker the plywood is, the more difficult it will be to cut. That's why manual way cutting is usually used for relatively thin plywood and for cutting predominantly in a straight path.

except hand saw an electric circular saw can also be used to cut plywood at home. With the help of a saw, you can easily cut plywood of any thickness. However, this method is also mainly suitable for cutting plywood in a straight line. Also, the disadvantage of this method is the formation of a large number of chips on the cut surface of the material.

|

PLYWOOD (FC) VENEER |

|||||

|

Material |

Material thickness in (mm) |

Length of laser cut, r.m. |

|||

|

up to 100 |

up to 500 |

up to 1000 |

over 1000 |

||

|

PLYWOOD FSF, WATERPROOF PLYWOOD, bakelite plywood |

|||||

|

Material |

Material thickness in (mm) |

Length of laser cut, r.m. |

|||

|

over 1000 |

|||||

|

Cost of laser cutting, rub. |

|||||

|

PLYWOOD WATERPROOF, |

|||||

Minimum order 5,000 rubles

The cost of the tie-in is 3.5 rubles.

We carry out laser cutting of large formats from 1650 to 3010 mm

Examples of custom-made laser cutting woodwork

12,000 rubles

23,000 rubles

4,000 rubles

6,000 rubles

32,000 rubles

8,000 rubles

14,000 rubles

39,000 rubles

57,000 rubles

HOW WE ARE WORKING

The client sends the drawing by email

At a scale of 1: 1 in dwg, dxf format, AutoCad 2007 software products with an indication of the material and quantity of parts, then the cost of the order is calculated automatically (a special program is used) and a commercial offer is developed.

Sent drawings in other formats or CorelDraw13 or a scanned drawing of the product increase the processing time and cost of the order.

File Requirements for Laser CuttingThe client leaves his coordinates

(phone number for a call) or arrives at the office at the agreed time for a more accurate discussion of the order.

The company makes a cost calculation

The minimum order amount is 3000 rubles.

The client makes an advance payment of 50%

From the cost of laser processing and brings your material.

The company informs about the readiness of the order,

As a rule, the production time is from 1 to 5 days (depending on the volume);

The client pays the remaining 50%

And takes the order

Order laser cutting of plywood or MDF from the LUMUS LASER company!

Although materials made from wood fiber are always different affordable price, the issues of economical consumption always remain relevant. Conventional mechanical processing methods wood materials accompanied by a huge amount of waste, the mass of which can even exceed the volume of the finished product. The use of a progressive instrument, which is a laser beam, made it possible to solve this problem. In addition, the focused light output provides a degree of precision that is not available mechanical methods processing. Laser cutting of plywood, due to the peculiarities of the technique itself, offers an extremely high speed of operations. In fact, all operations within a specific workpiece are performed within one sheet setup and require minimal operator intervention after starting the NC machining program.

At professional approach to the organization of work, even despite the rather high cost of operating the equipment, the implementation of structures and samples of the most complex shapes remains much more convenient and financially affordable for our clients. The price for laser cutting of plywood, as well as for other materials, is formed mainly by the thickness of the workpiece and the total length of the contours of the parts. With a professional approach to template design, selection of the type and nature of the impact, it is possible to successfully avoid any additional costs.

We carefully track modern materials and we determine the possibilities and features of their processing, therefore, in our company, the most professional and rational approach is always carried out. The price for laser cutting of MDF remains affordable for both small and large orders, so cooperation with us is extremely profitable and convenient.

Videos about our work

- Principle of operation

- Possibilities

- Manufacturers and service

The industry is responsive and offers many options for functional processing and cutting equipment different materials: wood, metals. Moreover, the devices often combine many necessary and not-so-important functions that save space by combining several machines into one. Modern woodworking shops are now almost always equipped with a laser cutting machine for plywood and wood.

Principle of operation

The main working tool of the apparatus is a laser, a beam of light high power... When directed at a wood product, the contact area heats up strongly and the fibers of the material simply burn out. Thus, a non-contact laser thread occurs. Have different models beam power may fluctuate. The field of application of the device depends on this parameter:

- Low power laser machines are used for woodworking;

- More intense radiation is used to cut more solid materials- metals, natural and artificial stones.

The advantages of this processing method:

- The edges are perfectly smooth, do not require additional processing;

- Products of any size and shape can be processed;

- The devices are simple in manual and automatic control;

- Precise work down to small details and strokes.

The disadvantage of laser cutting and wood engraving is that the processing sites remain scorched, dark brown and black. For natural material the natural shade is not critical, often manufacturers do not process the ends because of their finished appearance, combined with the main background. Another nuance is not in favor of the equipment - its high cost, although it depends on the configuration, functionality, size and power of the machine.

Possibilities

What can be done using a laser machine:

Depending on the filling of the equipment, the functions are present in different quantities, which, accordingly, is reflected in the cost.

Which machine to choose: exploring the varieties

Laser cutting machines are divided according to several principles.

By functional load:

- Laser engraving machine emits a weak beam of light, which is enough for engraving and burning. By increasing the wavelength, the unit can cut a plywood sheet.

- A laser-milling machine for cutting plywood with an increased power of a light beam is able to cut wood, create grooves on products. Often with its help, you can apply engraving by simply adjusting the laser for this function.

By type of control:

- Wood machine manual control the cheapest and most understandable to work with. With its help, unique products are created.

- CNC noticeably increases the cost of equipment, but also improves the quality of production of absolutely precise patterns and shapes. It is enough to set the program and the machine will do everything by itself. For the most part, such installations include both methods of control.

By power and size:

- The laser engraving desktop device with low power up to 80 W is compact, it can be placed in small workshop or at home. The installation is suitable for creating small souvenir products, the machine can engrave and cut thin plywood.

- Professional machine laser engraving and cutting produces a power of 80-195 watts. It has increased dimensions and is used in the woodworking and furniture industries for serial production and cutting out precise parts. The cost of such a device starts from 150 thousand rubles.

- An industrial wood laser cutting machine can cut, sharpen, engrave and much more. It has an impressive size and is used in large workshops for woodworking.

Manufacturers pack equipment with different functions that affect installation costs and replace use additional tools facilitating the processing:

- Chiller is a device for cooling the laser tube. It is necessary for prolonged operation of the machine to normalize the temperature of the working parts of the equipment. Works on the principle of a secondary enclosure with circulating water connected to a pump. If the machine is not equipped with such a device, it is bought separately. Cost from 30 thousand rubles.

- A blowing system for the torch and engraver is needed to reduce the temperature of the cut and burnout area in order to avoid excessive carbonization of the seam. In addition, dust and debris are constantly blown away from the workplace, which increases the comfort of work and the quality of production.

The choice of a laser machine is determined by the needs for its power and functionality. For large-scale production it is impractical to purchase a small tabletop unit, as well as to install a professional or industrial unit at home.

There are universal installations that can work with metal, wood, PVC and perform different operations: engraving, cutting, milling. The cost of such installations is high and it is advisable to purchase them only for large-scale production.

We present a table with three popular models of machines of different configurations and capacities:

As you can see, an increase in laser power for a machine tool affects the cost of equipment and its functionality. Manufacturers offer modifications of similar units with a different set of functions, the price and quality of products may differ significantly from those presented.

Manufacturers and service

Engraving machines for laser cutting wood and processing products are offered by manufacturers different countries: Russia, Japan, European countries. This is not to say that they differ significantly from each other, but representatives have their own characteristics.

A prominent representative of Russian developers is NPF "Lasers and Equipment", Zelenograd. The company manufactures machines different functionality, the products are distinguished by their relatively affordable cost.

The Japanese brands Koike and Mazak produce equipment that is easy to operate both manually and automatically.

European brands Trumpf, ESAB, Bystronic provide the most versatile equipment with a long service life. Installations are designed for processing wood, metals, acrylic and other materials, both specialized and universal.

Reliable manufacturers give a guarantee for their products. High-quality devices serve without interruption for years, the laser device is rarely adjusted if necessary.

✅ Before you buy a plywood laser cutting machine, learn how to choose and use it correctly. This will help you to accurately determine the characteristics of this equipment and understand what its price should be. Only useful information, VIDEO REVIEWS, life hacks and advice from experienced specialists in laser cutting of plywood.

Before you buy a plywood laser cutting machine, learn how to choose and use it correctly. This will help you to accurately determine the characteristics of this equipment and understand what its price should be. Only useful information, life hacks and advice from experienced specialists in plywood laser cutting.

How to choose a laser cutting machine for plywood

It is very easy for an experienced specialist to choose a laser cutting machine for plywood. After all, he has a lot of experience, knowledge, and most importantly, practice. But what should a beginner do, where to start looking for his CNC laser equipment for cutting and nesting plywood? How to buy what you really need at the right price, including additional options? As experienced specialists, we talk about everything in order. First and foremost, you need to know what area of plywood sheets you will cut. For a large one we choose a laser machine with a large working field, for a smaller one - with a small one (such as mini, desktop). The price of a plywood laser cutting machine depends on its size. On the other hand, if you have the ability to cut large-format plywood sheets into small pieces, for example, with a milling cutter or circular, then you can immediately pay attention to medium- or even small-format laser cutting machines. This, for example, is done in the production of small elements and parts made of plywood. These machines are suitable for the home. However, in this case, you will need to take care of the ventilation system. In addition to the area, you need to know what thickness of plywood you will be cutting. At the same time, remember that if you cut out thick plywood on a CNC laser machine, then the edges of the cut will remain charred. Yes, there is one life hack that will help you solve this problem, but more about it below. On the other hand, some end products with black edges are attractive. When you need a clean end, it is better to use other machines for cutting thick plywood, including milling machines, and use laser equipment for engraving. The thickness of the plywood that you will cut affects the power of the CO2 laser emitter and, as a result, the cost of the plywood laser cutting machine. To select it, you can focus on this data:- Plywood up to 6 mm - 50 W

- Plywood up to 8 mm - 60 W

- Plywood up to 10 mm - 80 W

To apply images with a laser on plywood (engraving), you can stop at a 50 W laser tube. But, as they say, the economy must be economical, therefore, if the task is to produce more products per unit of time and establish profitable production, then it is better to buy a CNC laser machine for cutting plywood with a more powerful emitter.

VIDEO. Comparison of laser cutting machines for plywood

Professional industrial and semi-professional models.

VIDEO. Budget plywood laser cutting machines

Small format models.And now we will tell you about the plywood itself for laser cutting, how best to cut it and the nuances of processing.

The ideal grade of plywood for laser cutting is 1/1 or 1/2. When choosing plywood, pay attention to its type. So, marking Ш1 indicates that this is plywood, sanded on one side, and Ш2 - from 2 sides. For cutting with a laser machine, the so-called indoor plywood or FC is suitable (the abbreviation stands for "plywood + urea-formaldehyde glue"). It is better not to take moisture-resistant plywood or FSF for a laser. It is very difficult to cut with a laser. So, this plywood with a thickness of 4 millimeters is cut using the same parameters as ordinary FC plywood with a thickness of 12 millimeters. In other cases, it just burns. And, as they say, do you need it? Such plywood is easier to process with a milling machine. In addition, there is bakilit plywood for the manufacture of, for example, spacers. It is cut with either a router, waterjet, or diamond cutting equipment. At the same time, ideally, it is better to use waterjet, because the same milling cutter burns cutters when processing bakilit plywood (we read - we spend a lot of money on consumables), and all because it is impregnated and covered with a special reinforcing chemical composition, in some cases with epoxy resins. There are also special grades of lightweight aviation plywood. This is just space for the laser. Its plus is that it cuts very well, and at the same time is very durable, because it is intended for aeromodelling. In short, she is perfect. Such plywood is produced with a thickness of 2 millimeters. The better the plywood, the easier it will be for you to process it. Choose plywood with as few knots as possible. They interfere with normal cutting. Plywood for laser cutting must be ordered from specialized companies. In ordinary hardware stores and hypermarkets, plywood is sold that is not suitable for laser processing.

How best to cut plywood on a laser machine

When laser cutting plywood to avoid yellow bloom along the edge of the cut, it is necessary to use a more powerful compressor, with an air supply to the nozzle of 1.5-2 atmospheres. If you need a cut without "shooting" on the other side, then the plywood from the working table must be raised by at least 1 cm. Then the beam scatters when shooting from the table and no traces remain on the material. Perfectly flat plywood does not exist, each sheet leads, twists. To avoid defocusing the laser beam when cutting uneven plywood, either use a long focus lens or press the plywood against the table. You can press it with neodymium magnets, which adhere perfectly to the honeycomb table, or fix a sheet of plywood with corners that you can make yourself. The easiest way to align a sheet of plywood on a table, avoiding shots on the back side, is to place neodymium magnets on the table, place a sheet of plywood on top of them and secure this sheet on top with more neodymium magnets. Then the sheet is located at the required distance from the honeycomb table and is fixed on top by other magnets. When cutting plywood intensively, clean the ventilation mesh more often, because there is much more combustion products and soot from plywood glue than from plexiglass. As a result, the hood clogs up faster. For the same reason, when cutting plywood with a laser, you need to clean your lenses and mirrors more often.

Life hack for cutting thick plywood with a laser

If you want to laser cut plywood thicker than the power of the CO2 tube allows, then you can do it in 2 passes. But, there is one big BUT. When cutting from the first pass, you will have to cut without forced air supply, otherwise the laser machine will not finish cutting and will simply light the plywood, with oxygen, as you know, everything burns better. But already on the second run, you turn on the oxygen supply. And this is BUT: remember, in the absence of air supply to the nozzle, the lens of your laser machine will very quickly get smoked and burst.

Where to Buy a Laser Cutting Machine for Plywood

Our company sells a large number of laser machines for cutting and cutting plywood with different characteristics... In addition to standard serial laser equipment, we can launch into production a laser machine according to your specifications and make it at an affordable price. Do you have any questions? Ask our technical specialists.

- Helpful tips for laser cutting and engraving

- Secrets and life hacks

- Laser Equipment Reviews

- Laser Cutting Models

- Actual promotions and discounts

- Working field size - 1550 x 2050 mm

- Minimum order value - from 7000 p. excluding the cost of the material.

- Cutting material - Customer or own

- File format - * cdr (CorelDraw); * .dxf, * .dwg (AutoCAD)

| Material thickness, mm | up to 300 m | 301 -500 m | 501 - 1000 m | 1001 - 3000 m | 3001 - 10.000 m | more than 10.000 m |

| 3 | 70 | 25.5 | 20 | 15.5 | 13 | negotiable |

| 4 | 84 | 31 | 24 | 20 | 17 | negotiable |

| 6 | 98 | 48 | 36.5 | 29.5 | 24 | negotiable |

| 8 | 126 | 63 | 48 | 39.5 | 34 | negotiable |

| 10 | 140 | 78.5 | 60.5 | 49 | 42 | negotiable |

| 12 | 168 | 94 | 74.5 | 59 | 50.4 | negotiable |

| 15 | 196 | 118 | 91 | 74.5 | 66 | negotiable |

| 18 | 224 | 154 | 106.5 | 91 | 81.5 | negotiable |

| 20 | 280 | 168 | 120.5 | 100.5 | 90 | negotiable |

Better than laser cutting can only be hand carving on wood, but a hand-carved product will cost much more than one obtained after processing with a laser beam. Moreover, the production time of products using a laser will be much shorter compared to the long and painstaking process of cutting by hand.

Laser cutting is considered one of the most effective ways impact on absolutely any materials. High speed the impact and maximum precision of all cut lines has attracted many customers. Products obtained by processing on a milling machine are not comparable in quality to those created using laser cutting.

Laser cutting of plywood, the price and timing of which can only please, for many is a solution to the urgent problem of the urgency of implementation. When a project is on fire, the only the right decision there will be an appeal to the laser system.

Professionalism comes first

It is known that a laser is capable of acting on any surface, but each material has its own subtleties. Only a professional equipment adjuster will be able to select the optimal impact force and set the required beam operating modes. There are frequent cases of damage to the source material due to the fault of an unskilled employee, therefore, to create products using laser cutting, you need to contact a trusted company, which uses good recommendations on the service market.

Nuances of the process

Laser cutting of plywood, in terms of efficiency, repeats cutting and, however, has a number of significant features and subtleties, as well as in business.

The most capricious material for this type of processing is plywood, but also carvings made of wood look very elegant and beautiful. The fact is that different varieties wood requires different power of the laser beam and, in addition, knots that are much denser than the main layer are often found in the plywood array, they can provoke the so-called "undercut". Only an experienced specialist will be able to take into account all the nuances and minimize the risk of damage to expensive material.

Fire may occur when cutting plywood with laser work surface or carbonization of the cut edge, which means its darkening. To avoid this, it is necessary to constantly monitor the intensity of the cooling air supply. Here, one cannot do with one automated process - you need the constant presence of an intelligent adjuster.

All of the above difficulties determine the fact that laser cutting of plywood is the most difficult method of material processing.

Application of plywood products

The area of application of cut plywood products is very large, because wooden objects have at all times been famous for their natural beauty. Often carved wood products are used for interior decoration premises and landscape decoration of personal plots. A variety of panels, furniture elements, floor and wall decorations - wherever the design eye was directed, you can see plywood decor. Also, carved wood products are used as souvenirs: various stands, diplomas, frames, and so on.

Advantages over other methods of exposure:

- clarity and evenness of the cut, which will not need to be sanded after processing;

- high cutting speed compared to other methods of exposure;

- the ability to obtain a wide variety of shapes and lines, the thickness of the resulting elements will be the minimum;

- laser cutting of plywood, the price of which will delight any customer, will allow you to create a product of any complexity, and its cost will not change from this.

Why do women dream of pregnancy

Why do women dream of pregnancy Artificial hormone testosterone cypionate

Artificial hormone testosterone cypionate Is a portfolio required or voluntary?

Is a portfolio required or voluntary?