Video the principle of operation of thermostats. Angle valve RA-N with side connection Nomenclature of headings

Thermostatic expansion valves type RA-G are used mainly in one-pipe systems Oh. All RA-G valves are compatible with all RA series thermostatic sensors.

The RA-G valves are equipped with a gray protective cap. The cap should not be used to shut off the controlled medium. For these purposes, use a special metal handle (code no. 013G3300). The packing pin is made of chrome plated steel and does not require lubrication for the entire life of the valve. The entire gland assembly can be replaced without draining the system. To prevent deposits and corrosion, type RA-G valves should be used in hot water heating systems where the heating medium meets the requirements of the Regulations. technical operation power plants and heating networks Russian Federation... It is recommended not to use a thermal fluid containing mineral oil.

Modern heating devices manufactured by the Danish company Danfoss. RA-G interacts with all RA group thermostatic elements installed in modern heating devices.

general information

The main feature of the device presented in this article is its increased throughput. Its field of application is one-pipe water heating systems of a house with a pump circulation of a heat conductor. The latter must meet the requirements of the "Rules for the technical operation of power plants and heating networks of the Russian Federation."

The buyer should be aware that this device should not be used in systems where the heat conductor contains mineral oil impurities.

An important advantage of the device is its oil seal (product code - 013G0290), which can be easily replaced from the home heating system at any time. The gland pressure pin is made of chrome-plated steel, so that it can be lubricated throughout the entire service life of the device.

Protective caps included gray... The user should remember that they should never be used to shut off the flow of the heat carrier. For this purpose, the device has a special shut-off handle (item code 013G3300).

Video: Radiator Danfoss thermostats RA

Nomenclature of commodity items

Today Danfoss products are profitable to order online. Online prices are much lower than on the market or in specialized stores. To place an order via the Internet, you need to know the product code. Below we provide a table with codes and some technical parameters of the goods presented in this article.

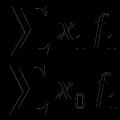

Code numbers and specifications for RA-G angular vertical design

| Device type | Bandwidth | Code number | ||||

|---|---|---|---|---|---|---|

| with thermocouple | without thermoelement | |||||

| RA-G 15 | 0.54 | 1.07 | 1.61 | 2.06 | 4.3 | 013G1676 |

| RA-G 20 | 0.57 | 1.11 | 1.16 | 2.2 | 5.01 | 013G1678 |

| RA-G 25 | 0.59 | 1.27 | 1.77 | 2.41 | 5.5 | 013G1680 |

Code numbers and technical data for RA-G for direct execution

| Device type | Bandwidth | Code number | ||||

|---|---|---|---|---|---|---|

| with thermocouple | without thermoelement | |||||

| RA-G 15 | 0.51 | 0.94 | 1.35 | 1.63 | 2.3 | 013G1675 |

| RA-G 20 | 0.54 | 1.07 | 1.61 | 2.06 | 3.81 | 013G1677 |

| RA-G 25 | 0.57 | 1.16 | 1.71 | 2.27 | 4.58 | 013G1679 |

The maximum differential pressure across the valve, at which it is capable, for models 013G1676, 013G1675, 013G1678, 013G1677 is 0.2 bar. For models 013G1680 and 013G1679 - 0.16 bar.

The maximum temperature of the coolant, for normal operation of the valve, should not exceed 120 ° C.

Application in one-pipe heating system

As a rule, the series of devices presented in this article is intended for installation in one-pipe heating systems of a building. Due to the small temperature difference in the radiator batteries of such systems, the heat transfer control range is insignificant here.

Changing the flow through the radiator does not affect its heat transfer. Reducing the flow through the radiator by up to 30 percent in relation to the design value leads to a decrease in heat transfer by only 10%. Such a decrease will not cause a decrease in the indoor climate, since the heating devices have a margin of heat transfer surface.

Some installation features

When purchasing and installing the RA-G, the buyer should consider several important points:

- In a one-pipe heating system with thermostats, there must be a closing section between the return and supply connections to the battery. Its diameter is recommended to be taken 1 standard size below the diameter of the liners.

- The valve diameter should be selected according to the diameter of the connections. Observing points 1 and 2, the buyer will be able to create the flow rate of the heat conductor through the heater only 25-30 percent of the flow rate in the riser.

- In the event that the diameters of the connections and the section are the same, it is recommended to use the Danfoss trademark to ensure the coefficient of coolant flow into the device.

- To reduce the residual heat transfer of the radiator with a fully closed thermostat valve, it is advised to install an RTD-CB return flow throttle on the return connection between the section and the device.

Device design

The RA-G valve consists of the following parts:

- valve disc

- sealing ring

- stuffing box

- pin

- valve seat

- spring

- union nut

- connecting nipple

- frame

The parts that underlie the device are made of stainless materials, which allows the device to perfectly resist corrosion and increases its service life.

The RA-N control valve is designed for use in two-pipe pumping systems for hot water heating.

RA-N is equipped with a built-in device for preliminary (editing) adjustment of its bandwidth within the following range: K = 0.04–0.73 m3 / h - for valves DN = 15 mm;

The RA-N valves can be combined with all thermostatic elements of the RA and RAX series, as well as with the thermoelectric actuator TWA-A.

For identification of RA-N valves, their protective caps are colored red. The protective cap must not be used to shut off the heating medium flow through the heater. To do this, use the handle (code number 013G3300).

Valve bodies made of pure nickel plated brass

Technical characteristics of RA-NCX valves in combination with thermostatic elements of the RA and RAX series comply with European standards EN 215-1 and Russian GOST 30815-2002, and the size connecting thread- HD 1215 standard (BS 6284 1984).

Everything radiator thermostats Danfoss products are manufactured in ISO 9000 (BS 5750) certified factories.

To prevent deposits and corrosion, the RA-NCX thermostat valves should be used in water heating systems where the coolant meets the requirements of the Rules for the Technical Operation of Power Plants and Networks of the Russian Federation. In other cases, Danfoss should be contacted. It is not recommended to use compositions containing petroleum products (mineral oils) for lubricating valve parts.

High-tech body

Quiet operation

Low noise characteristics of the valve are especially important for the consumer. This is why Danfoss valves are equipped with a specially designed flow stabilizer to operate absolutely silently, even with high differential pressures.

Lowest susceptibility to valve sticking

Sticking is the sticking of the valve plug to the seat due to prolonged contact when the valve is closed. For liquid filled bellows, the closing force is extremely high. With Danfoss gas-filled thermostats, there is practically no increase in closing force when the temperature rises, as all gas condensate will then evaporate. This, as well as careful selection of valve plug and seat materials, made of a special alloy of glass and plastic, minimizes the possibility of "sticking".

Valve that won't clog

Danfoss RA valves are optimized to work with gas-filled thermostatic elements and therefore their stroke is increased by 1.5 times: from 0.46 mm (for liquid thermocouples) to 0.74 mm.

Greater stem travel and larger valve area reduce the chance of valve plugging.

Simple maintenance

Danfoss RA valves have a single capacity setting window, with a gradually increasing cross-section.

In valves from other manufacturers, the settings window is a set of round holes of different cross-sections. If dirt clogs such a round hole, disassembly is required to clean the valve. Whereas for a Danfoss valve in such a situation, it is enough to turn the infusion ring - without disassembling the valve and without using any tools.

Easy customization

For settings Danfoss valves RA for the performance of the radiator does not require special tools.

It is enough to lift and turn the setting ring. The adjustment ring positions are marked with numbers from 1 to 7, the fully open position is marked with the letter N. So the adjustment is not only easy to carry out, but also easy to check.

Precision setting

The RA valve setting ring has 14 precise fixed flow positions. Many other manufacturers offer no more than 6 drills / holes and therefore only 6 possible capacities.

Replacing the stuffing box under pressure

If the stuffing box is replaced, there is no need to shut off the valve and drain the system - it can be replaced under pressure.

Thermostatic expansion valves of the RA-G type are used mainly in one-pipe systems. All RA-G valves are compatible with all RA series thermostatic sensors.

The RA-G valves are equipped with a gray protective cap. The cap should not be used to shut off the medium to be controlled. For these purposes, use a special metal handle (code no. 013G3300). The packing pin is made of chrome plated steel and does not require lubrication for the entire life of the valve. The entire gland assembly can be replaced without draining the system. To prevent deposits and corrosion, RA-G valves should be used in hot water heating systems where the coolant meets the requirements of the Rules for the Technical Operation of Power Plants and Heating Networks of the Russian Federation. It is recommended not to use a thermal fluid containing mineral oil.

At the end of the last century the lineup radiator valves famous brand Danfoss has received an RTD-G version adapted to Russian one-pipe heating systems. The result of generalization is the most good options its application was a new modification of the RA-G thermostat valve, which the company now offers for use all over the world.

An example of a permanent renewal of valves of this series was the appearance on the market since May 2011 of an updated set of thermal control equipment in a blister pack. It consists of a RA2940 thermal head with a built-in gas-filled temperature sensor and a direct thermostatic valve RA-G20.

Thermostat valves RA-G: basic technical and operational characteristics.

The entire RA-G range of thermostatic expansion valves has a nickel-plated body and internal thread... Manufacturers offer models in straight and angular design with a nominal diameter of 15 to 25 mm. The RA-G series valves are designed for one-pipe pump heating systems with top / bottom filling. They can also be used in two-pipe gravity heating systems. They can be combined with any RA thermocouples.The RA-G thermostat valves are characterized by increased flow capacity. Regulation range temperature regime ranges from 0 ° C to 26 ° C. It is possible to completely shut off the coolant supply.

They are distinguished by their high strength, which at a maximum temperature of 120 ° C allows them to withstand an operating pressure of 16 bar. And this means that even with unstable operation of heat supply systems, it is guaranteed that an emergency situation cannot be created.

The RA-G valves can be identified by their gray caps, which perform only a protective function and are not intended to restrict the movement of the coolant.

The device of the RA-G thermostat valves.

The latest valve designs for the RA-G thermostat consist of the following components:1.Nickel plated body

2. oil seal

3.O-ring

4. cymbals

5.saddle

6.Chrome steel push pin

7.Return spring

8.stock

9.cap nut

10.Connecting nipple

Features of the choice of the RA-G thermostat valve and its connection

When choosing a thermostatic valve of this series for one-pipe heating systems, you should pay attention to the presence of a closing section between the supply and return connections to the radiator. In this case, the diameter of the RA-G valve is selected according to the diameter of the inlet, and the diameter of this section is one size smaller than the diameter of the inlet.In conditions of the same diameter of the connections and the closing section, it is advisable to use a bypass choke of the RTD-BR type. And with a fully closed valve, to reduce the residual heat transfer from the radiator, it is recommended to install an RTD-CB return flow throttle on the return line between it and the closing section. The implementation of these recommendations will ensure that the difference between the flow rate of the coolant through the radiator and in the riser is at least 30%.

The connection to the pipelines is carried out through the coupling fitting, and to heating devices- using threaded shanks with union nut.

What are the advantages of the RA-G thermostat valves?

The recognized advantage is that they are the only valves with such high flow rates. This was achieved by increasing the diameter of the seat, profiling the inner surface, which has an effect on increasing the coefficient of leakage into the radiator, as well as reducing the risk of valve clogging.The indisputable advantage of RA-G valves is the use of modern high-quality technologies for the manufacture of all control components, as well as the use of special materials eliminating the threat of mechanical wear, damage by corrosion

Along with this, they have unique operational capabilities of replacing the crane-axle box, saddle, cone of the structure in place without stopping the operation of the heating system.

All this makes the RA-G thermostat valves the leaders in providing the most high level energy efficiency among analogs existing on the world market of heat engineering.

Who and how makes money on import substitution and innovations in agriculture R

Who and how makes money on import substitution and innovations in agriculture R What is the industrial production index, its role and calculation

What is the industrial production index, its role and calculation Calculation of the design population of the city Term in metallurgy

Calculation of the design population of the city Term in metallurgy