We make a homemade hand pump for water. How to make a do-it-yourself water pump? Diy diaphragm pump

Once the documents are on suburban area decorated, newly-made summer residents begin to search for water. It is good if there is water on the site, but if there is none? You can take it from your neighbors, but even for making dinner you will need two buckets. You can no longer apply it to watering the garden. Where, then, can you get life-giving moisture? If you look around, you will surely find a lake or a rivulet somewhere, even a stream will do. All you need is a pump. And it doesn't have to be electrical. A homemade water pump can use solar energy, vacuum, or the natural vibrations of a lake. This is both economical and no dependence on the voltage in the mains.

Many individual areas are not connected to the mains. DIY water pumps can use more than just electricity. They work perfectly on the "free" energy of the sun and wind, use natural water fluctuations and river currents. You can even pump water using a vacuum, and for this you only need a barrel and a fire.

Wave pump: easy to assemble, pumps efficiently

To make a wave pump you need:

- corrugated pipe(harmonic);

- two bushings with valves;

- bracket;

- log.

If a brass pipe was used, then the log must weigh more than sixty kilograms. Although if you use a plastic accordion, you can get by with a lighter one. In the latter case, the weight of the log can be accurately determined only in practice.

The pipe is closed on both sides with bushings with valves. One end is attached to a bracket, the other to a floating log. Natural fluctuations in the water in the river will power the accordion. If the wind speed reaches two meters per second, then the pressure rises to four atmospheres, and about twenty-five thousand liters can be pumped per day.

A home-made wave pump for pumping water will last longer if you fasten the ring stop with a bolt on the lift. So the log in the horizontal plane will only turn slightly. This will eliminate unwanted torque. You can also solder tips into the ends of the pipe, onto which the sleeves are screwed.

The log that will be used in this construction must be soaked three to four times with a mixture of kerosene and natural drying oil in a one-to-one ratio. The ends and cuts must be soaked six times. If the mixture begins to solidify, it must be heated in a water bath.

Oven-pump: to heat - does not heat, but pumps water regularly

The name of the system is misleading to many: the oven-pump does not provide heating of water. The principle of operation is to create a pressure difference. To assemble a pump oven, you need:

- steel two-hundred-liter barrel;

- blowtorch or kerosene stove;

- branch pipe with a tap;

- rubber hose;

- mesh nozzle for the hose;

Experience shows that it takes about an hour to fill a barrel. And this is provided that the diameter of the hose is millimeters, and the water must be raised from a six-meter depth

V lower part the barrels cut into the tap pipe. A hole is drilled in the screw plug, which closes the barrel from above, and a rubber hose is inserted very tightly. Its other end is closed with a mesh nozzle, and then lowered into the reservoir. A blowtorch or kerosene stove is placed under the barrel.

1-2 liters of water is poured into the barrel, and a fire is made under its bottom. The steam displaces air, which enters the reservoir through the hose. Then the fire is extinguished, the barrel cools down. As a result, the pressure inside drops, and water begins to flow from the reservoir.

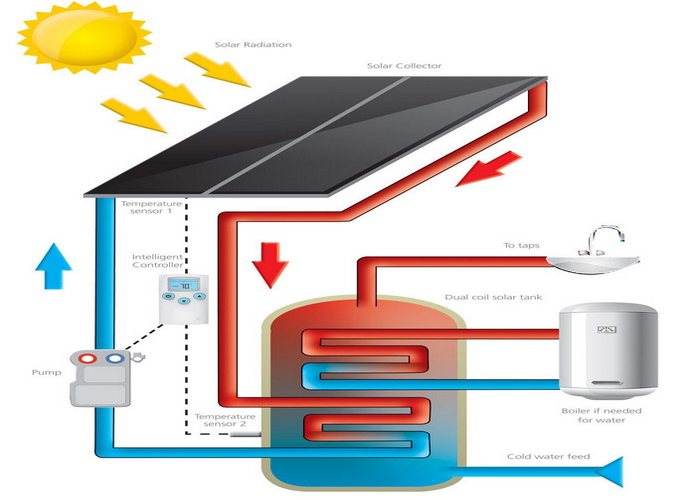

Solar pump: always running

The grate tubes contain propane-butane. It is connected to a rubber bulb dipped in a can. There are two valves in its cover: one allows air to pass inside, and the other releases it under a pressure of about 1 atm. into the air pipe.

To start the pump, it is enough to water the grate in the summer. cold water... Liquefied propane-butane is cooled, and its vapor pressure is reduced. As a result, the rubber bulb is compressed and the can is filled with air. After a few minutes, the sun will dry the grate and reheat it. Liquid vapors will inflate the pear, as a result of which the pressure in the can will increase, and air will begin to escape through the valve into the pipe. Airlock like a piston drives water in front of it to the shower head. This sip of water falls on the grate and cools it down again.

The tubes from which the grid is assembled may contain not only propane-butane. Any other liquid that boils at low temperatures is also suitable.

Such a system works even in winter, however, the cycle “reverses”: frosty air cools the grate, and underground water heats it up.

If the site is located on the shore of a lake or river, then it is not necessary to carry water in buckets to water the garden. You can make a pump from scrap materials. The sun and river flow will do all the work on their own.

A summer cottage and the presence of a well on it is a joy for every nature lover. Especially if the village has electricity and it is possible to pump water for irrigation from the well using a powerful unit.

But what to do if there is no electricity at all or it was temporarily cut off ?! Of course, you can simply carry water to the beds with buckets, but this is tiring, and just for a long time. Especially if the gardens have a large area.

We bring to your attention a solution to the dilemma - assembling a water pump with your own hands. And believe me, such a water machine will work, although a little slower than an electric pump, but still quite productive. Consider several options for do-it-yourself pumps.

Is it worth thinking about the fact that producing your own home pump is not profitable and will not lead to anything. We are ready to prove to you otherwise, referring to several advantages of such work:

- Firstly, the summer resident will always have a device at hand for supplying water from the well upstairs, even if the electricity is cut off.

- Economy is also an important point. family budget... So, electricity tariffs are growing by leaps and bounds, and a powerful pump in working order shakes a lot of kW. Such pump cycles, even for the purpose of watering the beds in a month, can result in a tidy sum for the average family.

Important: you can only assemble a manual one with your own hands. piston pump... All other types of pumps (vane, diaphragm, vane) are more difficult to assemble on their own.

The operation and device of the piston unit for the well

A piston is installed in the flask (body) of the pump, which, under the influence of physical force on the lever, moves up and down. The piston has an inlet and outlet that are closed by valves. At the moment of pressing the lever, the piston descends down the flask and opens the inlet valve. Water fills the working chamber, the pressure rises in it. Due to the differential pressure, the water is pushed out through the outlet valve of the device.

Important: the performance of a piston-type pump is on average 2-3 liters per cycle (pressing the lever). But at the same time it can be increased by increasing the cross-section of the body and the piston in it. Most often, these pumps are used for abyssinian well... But provided that the pump is securely fixed, it can be used with a conventional well.

Stages of work to create a pump

- First you need to prepare the cylinder body. It can be made from a pipe cut of the desired section. It is desirable that the pipe diameter is at least 8 cm. And its length is 1 meter.

Important: the cross-section of the case for a hand pump does not have to be round. It can be either a square or a polygon. The main thing then is to adjust the cross-section of the piston to the shape of the body.

- Now two brackets need to be welded to the pump body so that the future lever is located between them freely. The brackets are attached to the top of the pump.

- The next step is to drill the holes for the inlet and outlet. Accordingly, we make holes in the lower and upper parts of the case.

- The lower part of the housing must be closed with a lid. It can be metal, fixed by welding, or just larch. The latter is in excellent contact with water without decay.

- It is also necessary to close the upper opening of the flask with a lid. This is not necessary, but a cover will increase the efficiency of the pump and prevent water from splashing when it is being lifted.

- In the top cover we make a hole for the stem. It should be in the form of a slit.

Making a piston for the pump

Now you need to make the main working unit of the pump with your own hands - the piston. It needs to be made from the following materials:

- A disc made of metal, the thickness of which should be about 3-4 cm;

- A piece of dense rubber of the same section as the piston (the thickness of the material must be at least 5 cm).

- We make holes about 1 cm in diameter over the entire surface of the piston (metal disc). There should be several of them.

- Cover the disc on top with a rubber gasket and connect them.

- A cut must be made through both piston elements in the central part in order to securely fix the rod.

- A rod made of metal or steel can be used as a rod. Its length should be 1-1.5 m. The stem is threaded through the hole formed in the piston and fixed from below with a strong nut.

- We attach the upper end of the stem to the lever after it is pulled out through the upper housing cover.

Making a lever

It remains to make a working pump lever. To do this, take a pipe with a diameter of 3 cm and a length of about 35 cm. One end of the pipe must be flattened with a hammer and a bolt hole made here. In the future, it is through it that the bolt will pass, which will also be located in the two brackets. This is how the lever is attached. The upper end of the stem is also brought to the bolt, securely fixing it. The outer side of the operating lever can be wrapped with electrical tape or put on a piece rubber hose for easy grip.

The inlet valve is mounted from a cut of dense rubber. Its diameter should be slightly smaller than the inlet. In the central part of the valve we form a hole and mount a guide in it. It is thanks to her that the valve will always return to its place after the piston returns to its usual position.

Important: the guide must be longer than the distance from the drain pipe to the lower end of the pump body.

The finished pump is pushed onto a pipe, the length of which should reach the water mirror in the well. It remains to securely fix the pump at the walls of the source in order to freely raise water from it.

Fire pump

One more simple construction pumps for a well. In this case, you need to prepare the following materials:

- Metal barrel with a volume of 150-200 liters;

- Outlet tap;

- Water intake hose;

- Bricks for laying a small stove.

We assemble the structure in this way:

- First, lay out a small brick stove so that a barrel stands on it.

- Now in the side of the tank at the top we make an inlet, and in the side at the bottom - an outlet for the tap.

- We attach a hose to the inlet pipe, the length of which will reach the water mirror in the well, and a tap to the outlet.

Such a pump will work according to the following principle:

- First, pour 3-5 liters of water into the barrel.

- We make a fire in the stove and wait until the water heats up well.

- Putting out the fire in the oven. After that, the heated air will go into the well, and the pressure in the tank will become rarefied. As a result of this phenomenon, water will begin to flow into the tank. As soon as the barrel is full, you can open the tap and take water from the tank through a standard hose attached to it.

Solar pump

And you can make a pump for a well that will work from the sun. To make it yourself, you will need:

- A metal can of any capacity (the larger, the better, but, as a rule, they take a tank of 50 liters;

- Rubber heating pad;

- Metal tube in the form of a lattice filled with propane-butane;

- Two valves - inlet and outlet.

Assemble the structure in this way:

- A rubber heating pad (pear) is mounted in the can, we first tightly connect it to a tube in the form of a lattice;

- The grate is placed on the sunny side of the well, however, like the can;

- We attach a hose to the inlet pipe, and lower its second end into the well;

- We close the outlet with a valve in the form of a faucet.

Such a homemade pump will work under the influence of heating the propane-butane in the tube. He boils at the most low temperatures... As soon as the tube heats up, it must be poured with cold water, after which the substance will cool down. This, in turn, will inflate the pear, and water will begin to flow into the reservoir. At this moment, the tube will heat up again and immediately cool down due to the water passing through the system. The process of continuous pumping of water from the well will be ensured.

So, it became clear that making a pump for a well with your own hands with minimal skill can be very simple.

Almost every gardener or gardener has to deal with the problem of obtaining the water necessary for irrigation. You can, of course, order a professional installation: specialists will install a pump that will perfectly cope with the tasks assigned to it. However, why waste money if you can make a hand water pump with your own hands? There are many varieties of homemade pumps that pump water perfectly and are made with your own hands literally from scrap materials. If you also want to know how to make a pump, check out the instructions below.

Features of making a water pump with your own hands

The main parts that are responsible for the correct operation of the water pump are the valves, especially the lower check valve.

This valve determines the performance of the system and its constant availability. So that half of the water does not run back and forth unnecessarily, and the pump left without work does not drain all the water back into the valves, it is necessary to be made of high-quality material.

The piston can have a sufficiently large clearance between the walls of the housing and itself. Water will flow between the piston and the walls, but most of it will flow through the valves. If you want everything to fit snugly, make sure that the piston can move freely back and forth.

The pump body can also be made from a piece of some pipe with a diameter of 80 mm. Optimal length section - 60-80 m. The insides of the pipe, if possible, should be turned lathe or remove irregularities with a scraper. But if you can't do that, it's okay. A piston with covers can be made with your own hands from thick plastic, metal, or even wood. Wooden lids are much cheaper, although they last only 1-2 seasons. It is especially convenient to use oak and larch for the manufacture of lids, because they swell with water and provide reliable sealing of the gap between the walls of the housing.

Back to the table of contents

Popular types of homemade pumps

There are several types of homemade pumps that can be made in a very short time. One of the simplest DIY designs is a wave hand-held water pump. To make this type of hand water pump, you will need the following tools and materials:

- Corrugated pipe.

- Valve bushings.

- Log.

- Bracket.

- Die.

- Sander.

- Gas keys.

- Sealing tape.

Such pumps for water have often been made for installation in their areas before. If you used a brass pipe, then the weight of the log should be more than 60 kg. In the case of using a plastic corrugated pipe, you can get by with a lighter log. In the latter case, the weight of the log can only be determined in practice. The pipe on both sides must be closed with bushings with valves. One end attaches to a bracket and the other to a floating log. Due to natural fluctuations of water in the river, the corrugated pipe will be activated. If the wind speed exceeds 2 m / s, then the pressure rises to 4 atm., And about 25,000 liters of water can be pumped in 24 hours.

A hand-made wave pump for water will last much longer if you attach a ring stop to the lift. This can be done with a bolt. This way the log will only rotate slightly in the horizontal plane, which eliminates unwanted torque. Tips can be soldered into the ends of the pipe of such a water pump and bushings can be screwed onto them.

The log used in this construction must be soaked 3-4 times with a mixture of natural drying oil and kerosene in a 1: 1 ratio. The cuts and ends should be soaked 6 times. If the mixture starts to solidify, warm it up in a water bath.

Such a pump will be a great find for gardeners, on whose site there is a natural reservoir. Despite the unsightly appearance and simplicity of execution, such a home-made pump is capable of developing a capacity of up to 20 tons of water per day.

The water pump oven is no less popular. The name of the design is misleading for many, but this design does not provide water heating. To assemble this water pump with your own hands, you will need:

- Steel barrel for 200 liters.

- Primus or blowtorch.

- Rubber hose.

- Branch pipe with a tap.

- Drill.

- Mesh hose nozzle.

The pump oven is perfect for watering your garden. A branch pipe with a tap is cut into the bottom of the barrel. A hole is drilled in the rubber stopper that covers the top of the barrel and the rubber hose is inserted very tightly. The second end of the hose is closed with a mesh nozzle, after which it is lowered into the reservoir. A primus or blowtorch is installed under the barrel.

1-2 liters of water is poured into the barrel, and a fire is made under its bottom. The steam will displace the air that enters the reservoir through the hose. After that, the fire is extinguished, the barrel cools down, as a result of which pressure drops inside and liquid begins to flow from the reservoir.

A do-it-yourself water pump is an excellent solution to the problems associated with watering a garden. For it will not be possible to constantly use imported water. Will arrange the presence of a reservoir, river or stream (the spring is considered ideal option). Everything is decided by installing the pump.

However, at first, you can get by and homemade construction for watering.

Some types of water pumps

Of the countless number of such devices, the following can be distinguished.

American river pumps. Such models do without electricity. They are used by craftsmen, whose sites are located on the banks of turbulent rivers. The device is a narrowed barrel (with a length of 62 cm and a diameter of 52 cm, it weighs about 17 kg), from the narrow end of which the blades are attached. A spiral-shaped hose is wound inside the container in even turns. All kinds of creases and kinks are excluded. A structure that looks simple works reliably enough. Thanks to the flow of water, the barrel rotates, and the liquid is able to rise through the hose to a height of 25 meters;

Homemade wave pumps. They function successfully where the current is not very strong. The device consists of:

- corrugated pipe (accordion type);

- bracket, two bushings with valves;

- logs.

Both ends of the roll are equipped with bushings. At one end, it is attached to a rack dug into the bottom of the reservoir. On the other hand, a log is attached to the pipe, which is lowered into the water. Waves shake the "accordion". As a result, it shrinks and propels the next portion of water. If there is a wind of 2 m / s and a pressure of up to 4 atm. then the structure is ready to supply up to 25 thousand liters of water per day. So that the log does not fall apart, it is pre-processed with a ready-made mixture, which includes natural drying oil and kerosene (in equal parts). The barrel is soaked 3-4 times, and the ends (with increased hygroscopicity) - 6 times;

Differential pressure furnace. They are also called "pump ovens". By the principle of operation, it is similar to a samovar. The device is assembled from a steel 200-liter barrel, a branch pipe with a tap and a rubber hose with a mesh pad. The assembly with the crane is installed in the lower sector of the barrel. The top of the latter is closed with a threaded plug. A hose is screwed onto the plug. The other end is lowered into a water tank. The barrel is filled with two liters of liquid and heated with a kerosene stove or blowtorch... A bonfire under the bottom will also do. Hot air escapes through the hose. The fire is extinguished. When the container cools down, the internal pressure drops, and the liquid begins to be drawn inward. The entire cycle will take no more than an hour;

Black grates working in the sun. This is enough for watering the garden. complex construction... First, you need to get a lattice of hollow tubes filled with liquefied propane-butane. A rubber bulb is attached to it, which is inserted into the can. The lid of the container is equipped with two air valves (inlet and outlet). It is more expedient to cover the lattice with black paint, for the latter heats up well under the sun's rays;

Homemade pump functions as follows. On a sunny day, cold water is poured onto the grate. The propane-butane mixture is cooled. As a result, the gas pressure drops. The rubber container is compressed and the can is filled with air. As soon as the grate is dry, the pear swells under the influence of vapors. The released air begins to flow through the valve into the pipe. The air plug here plays the role of a piston that pushes a portion of water outward. According to experts, such a pump does not lose its performance during the winter cold weather. In this case, the cooler is the masses of frosty air. The grate is heated by the extracted groundwater;

Blower made of plastic bottles. The device may seem frivolous, but it performs its function properly. To build such homemade pump will need plastic bottle, the cap of which is equipped with a plastic gasket-membrane, a hose of the appropriate length and a piece of a standard tube with a diameter equal to the neck of the bottle. When the hose is immersed, it fills with water, which is held in place by the valve. If the hose is periodically lowered into the water and then removed from it, the liquid inside will be pushed to the outlet;

Homemade pump in which water is drained through the handle. In this model, the liquid moves upward inside the rod itself, made of PPR pipe, and comes out through the holes in the handle. In this case, the installation of the check valve on the end of the plastic roll is carried out by the "hot" method: when the end of the pipe heats up, a fitting is inserted there, and the uncooled connection from above is reinforced with a worm clamp. The nose part is used for the manufacture of the piston head. The heated segment is placed in a sleeve. Then the edges are trimmed to the desired size;

The finished part is placed on the backdraft valve, where it is fastened with a coupling and a nut. Then the piston is inserted there. The top plug is made. It may be leaking, but the stem must move smoothly in it. At the free end of the pipe, a perpendicular squeegee is fixed, to which the hose is attached.

This pump is quite reliable, but not very comfortable, since it has a movable drain point. Therefore, the operator cannot be far away;

Spiral hydraulic pistons. With this ingenious device, water is supplied over short distances from rivers with the current. It is based on a carousel with blades. Outwardly, the device resembles a water mill, for which driving force is a river stream.

The pump is flexible pipe... It is fixed to the wheel with spiral clamps. The intake part is equipped with a bucket (a fragment of a pipe of a larger diameter).

The main unit here is the pipe reducer. This is a former part of the factory equipment or part of the sewage pumps. Through it, water enters the pipeline. The unit is located on a wheel axle, solidly fixed on a fixed base. The water rises to a height equal to the size of the pipe itself (directly from the fence).

Building a water pump yourself

There are situations when the purchase of a store model is impossible. Then you can build this device with your own hands.

To assemble the structure, you should stock up on:

- brake chamber;

- metal balls;

- copper tubes;

- epoxy glue;

- car camera.

Assembly guide

First, the old brake chamber is taken. It should be unmounted. All wells are plugged, except for one (it will become a hole for the stem). WITH back side holes are made for valves.

At the next stage, you will need a small length of copper or brass tube (with strong walls). Then you need to find a suitable size metal ball. Its diameter must be larger than the inner diameter. A hole with a slightly larger diameter than the ball itself is drilled in the tube (up to half its length).

Then the ball itself is placed in it, which is fixed on top with a soldered piece of wire. This assembly is the intake valve. The lower pressure will lift the ball, opening the opening, while the upper pressure will close it.

The outlet assembly is assembled in the same way. Here the ball and the soldered wire are separated by a spring. The latter is compressed under pressure from above, opening the valve. After that, the valves are inserted into the wells and fixed with epoxy glue.

After that, you should take the car chamber and cut out a membrane circle from it, corresponding to the diameter of the brake chamber. A hole is cut in the center of the part, to which a washer is added on both sides. Insert the threaded pin / stem here and tighten with the nuts.

The disc is mounted to the bottom of the brake chamber with glue. Finally, the top and bottom segments of the camera are connected. The stock is passed inside. The hand pump is ready. To make it convenient to use, it is recommended to equip it with a handle.

If there is a small body of water nearby, then a similar water pump Is a find that makes life easier for any gardener or gardener. The unit, simple in design, is capable of providing a head within 4 atm. moving about 100 tons of water during the day.

Providing water to a rural backyard in the absence of electricity can hand pump for water from the well. Power supply problems often arise in the provinces. In this case, and the hand pump will be the only way to water cattle and plants. A silent apparatus will help out if the aquifer is located no deeper than 30 meters.

Varieties of hand water pumps

Whatever the design of the hand pump for water, it will work if the hydraulic regulation and bypass system is verified. The valve systems are used to create pressure with the use of human muscle strength.

Whatever the design of the hand pump for water, it will work if the hydraulic regulation and bypass system is verified. The valve systems are used to create pressure with the use of human muscle strength.

All manual pumping devices are subdivided by device:

- piston;

- rod;

- membrane;

- vane.

Of these, only sucker rod hand pumps are suitable for a well with a depth of 20 m.

Piston pumps are used to lift water from a depth of no more than 10 m. The ground part can be done simply and with delights. But it is a pipe string and a lever.

The working part is a piston moving in the liner. Their mating parts are ground in. The movement of the handle to the piston is transmitted through the rod. There must be a non-return valve on the suction pipe, since the system works under the head. At the end of the piston there are valves that open to bypass water under pressure.

Determining phases of the piston group:

- The system is under the bay, the chambers are filled, the check valve does not allow the water column to fall.

- The lever is pushed down, the piston moves up and displaces the water above it into the chute. Under the piston, water flows into the discharged area from below.

- When the piston moves down, the check valve closes, and the holes on the piston open, allowing water to flow upward. The cycle is over.

The system returns to its original position. The amount of water supplied depends on the volume of the chamber, that is, on the section of the pipe and the linear movement of the piston.

A sucker rod hand pump for water from a well differs little from a piston pump in its principle of operation. The difference is that the worker piston group located in the casing, under the bay. Place the knot in the water, at least 1 m from the surface, as deeper as possible. The system is in the water, there is a check valve on the bottom of the steam pipe. With each stroke of the piston, it pushes a column of water above it. Thus, the liquid can be taken from a layer 30 m deep.

All hand pumps, regardless of the design and depth of the well, have an approximate capacity of 40 liters per minute. The amount depends on the effort expended, and in humans, muscle strength is approximately the same.

A prerequisite sucker rod pump operation is a casing section of 100 mm or more. The structure will not fit in a narrow barrel. The long arm provides a long piston stroke, but water comes in intermittently, from each stroke. The determining factor for such a system is a long leverage that facilitates muscular work.

A prerequisite sucker rod pump operation is a casing section of 100 mm or more. The structure will not fit in a narrow barrel. The long arm provides a long piston stroke, but water comes in intermittently, from each stroke. The determining factor for such a system is a long leverage that facilitates muscular work.

The vane-type hand wheel is controlled by a wheel connected to the blades. The working chamber consists of 3 compartments. Two of them are connected to the suction inlet. There, through a system of valves, water enters the chamber under vacuum and is pumped out into the system from the compartment with overpressure... The water entering the upper compartment is poured out evenly. An equilibrium state is achieved by adjusting the valves.

A diaphragm hand pump for a well is a chamber divided in half by an elastic membrane. The movable partition is connected by a rod to the handle. The upper chamber is air, it does not participate in the transfer of water. In the lower section, one branch pipe is connected through the valve to the suction, the other is the discharge one. When the membrane is pushed down in water chamber the pressure rises and the valve opens. During the raising of the stem, the diaphragm rises, the working liquid chamber under pressure through the check valve starts the liquid. The action takes place in 2 cycles. The membrane pump can supply water from a depth of 6 m.

A diaphragm hand pump for a well is a chamber divided in half by an elastic membrane. The movable partition is connected by a rod to the handle. The upper chamber is air, it does not participate in the transfer of water. In the lower section, one branch pipe is connected through the valve to the suction, the other is the discharge one. When the membrane is pushed down in water chamber the pressure rises and the valve opens. During the raising of the stem, the diaphragm rises, the working liquid chamber under pressure through the check valve starts the liquid. The action takes place in 2 cycles. The membrane pump can supply water from a depth of 6 m.

Hand pumps are inexpensive and easy to manufacture. You can buy a product with a decent decoration, or you can make it yourself.

DIY piston pump

When making a hand pump for a well with your own hands, you must accurately follow the sequence of operations. It is important to have a sufficient water layer in the receiving chamber at a level higher than 10 m from the surface. A piston chamber equipped with:

When making a hand pump for a well with your own hands, you must accurately follow the sequence of operations. It is important to have a sufficient water layer in the receiving chamber at a level higher than 10 m from the surface. A piston chamber equipped with:

- inlet and outlet pipes with valves;

- a crank that transmits force to the piston;

- check valve on the suction line;

- water lifting hose.

The working chamber can be made from a pipe on a lathe, use a hydraulic cylinder body or a diesel chamber, inner diameter should be more than 80 mm, the length of the blank is 600-800 mm. The main condition is that the inner surface must be smooth, processed. The tube can be rectangular, but the piston follows the internal shape.

The suburban pump can be in a plastic case, but for year-round residence only metal versions of speakers are suitable.

To get a sealed chamber, it is necessary to close the ends of the cylinder with plugs made of metal, plastic, wood. The top of the cover is drilled to fit the stem. At the bottom, a valve is installed, carefully fastened in place. The outlet pipe is welded on the side.

To get a sealed chamber, it is necessary to close the ends of the cylinder with plugs made of metal, plastic, wood. The top of the cover is drilled to fit the stem. At the bottom, a valve is installed, carefully fastened in place. The outlet pipe is welded on the side.

The manufactured piston must have rubber seals and move inside the housing without force. The material can be anything, even a wooden chock. The piston is connected with a threaded rod and a stopper.

The check valve determines the performance of the future pump. The tightness of the fit in the nest determines whether the water will be held in the hose. A diaphragm or ball valve is used. It is better to buy this part.

Better to install assembled structure into the pit, bringing the control and the rod out. In order for the lever to return to its original position on its own, a spring must be installed.

You can make a pump or sucker rod pump. Accuracy and use of working drawings will create an efficient mechanism.

Homemade hand pump for water - video

Invisible calories: why alcohol gains weight Calorie content of alcoholic beverages in 100 g

Invisible calories: why alcohol gains weight Calorie content of alcoholic beverages in 100 g Olives: useful properties

Olives: useful properties How many calories in buckwheat Kcal of buckwheat porridge on water

How many calories in buckwheat Kcal of buckwheat porridge on water