Smokehouse from 200 liter hot smoked barrel. Hot smoking in barrel - homemade structures. Universal device for cold and hot smoked

Smoked people like a huge number of people. Even if someone is not their loyal fan, still invite the company of friends and treat them with something so very nice. The same applies to collectors in a narrow family circle. But buying ready-made foods from the store is very expensive, and there is no complete confidence in their safety for health - rather the opposite. But the simple and fairly effective smokehouse can be made personally from publicly available materials.

Features and advantages

Skolna from the barrel is a very popular thing, while there are a lot of options to perform it. It is not necessary to be limited to one old water capacity, it is often complemented by various accessories. Moreover, even a wooden barrel can be applied as efficiently as steel design. The essence does not change from this: the inward is served smoke, heated to a certain value, under the action of this smoke products and change their properties.

In addition to the availability of source materials (physical and price), it also also also:

- ease of independent work;

- high characteristics of the finished design;

- minimum operating costs.

But there is one weak point that you need to keep in mind - such a smoke can not be put in the room of the country or country house. It must be installed strictly on the street. There is, however, the reason to consider this fact even dignity. After all, it is so nice to gather around the hearth, where meat or fish is preparing, and enjoy a slow conversation in the fresh air.

Views

The many years of experience "Cleells" allowed to create a lot of variants of boching boots. The easiest (in every sense) is even mobile, can be brought by car to the place of picnic or fishing, on the hunting base. As a basis for such products, beer kegs or small-sized wooden barrels are performed. If there is a desire to make a chamber with the grill effect, it must have a framework.

Great variety of stationary products, one of them are intended for hot smoked, others - for cold, and others can carry out both of these functions harmoniously.

It is necessary to provide analogs of devices present in industrial smoking chambers:

- chimney;

- smoke generator;

- hood.

The specificity of hot smoked is that smoke must come from below, overcoming the minimum distance. Technically, this is solved in two different ways. In one of the schemes cut the window so that you can throw the sawdust and ignite them. In the other - they put the smoking chamber over a separate furnace. The flake itself is performed in different ways: it can be a simple gauge in the ground, and a small brand, laid out of bricks.

Another approach is practiced when they create a cold-type smokehouse.Here it is already required to cool the smoke, sometimes it is necessary to even lay the chimney in several meters long. It is performed in the form of trenches, buried to the ground pipes and so on - there are a lot of options. If suddenly there is very little space, you have to install a double chamber with artificial cooling, in which there are two compartments and the wet cloth separating them.

More efficient and practical than all homemade smokehouse, which allows you to combine hot and cold processing modes. A dual horizontal chamber is made from a pair of the same barrels that are binding to smoke trumpets. When using a wet filter, you can organize a half-oscillage smoking; Below is always located the combustion chamber.

Some of the home masters preferred the traditional look at the so-called closet. As a base, a frame of wood is made, key elements - a timing segment of 40x40 mm. Whatever the body is chosen, it is trimmed from three sides by boards, the thickness of which is 25 mm, and the greatest width is 100 mm.

Optimal will be the lining of deciduous wood:

- osinova;

- olkhova;

- lipova.

Only in extreme cases are permissible to use coniferous parts, especially since finding the three listed breeds will be quite simple. Regardless of the specific type of material, you need to achieve maximum tightness of the case. This task is solved through the use of thermal insulation materials, such as a hen rope, placed even in the most minor joints.

The door must match the oven wall dimensionsFor it, a plate of 25x100 mm is applied. The perimeter of the opening should be sealed with sealing food rubber, like that which the refrigerator doors are covered. The roof of the smokehouse make a single or duplex. In the first case, it must be fixed back, such a product is formed from boards, which are 40 - 50 mm longer than at the base. In the second, a rafter system is formed, whose skate can be from 0.55 to 0.65 m; Connection locations always make hermetic.

Stationary street smokehouses are ground and stain in the top of the oil paint. Since the roof will not be heated anyway, the detachment is not worthwhile, much more importantly focus on protecting water. The chimney is always complemented by dampers and shabby mechanisms (only such a solution ensures high efficiency of smokehouse).

Dimensions

The miniature smokehouse is easily made from the old beer keg. It is necessary to bring the tube to the tank at which the smoke will be served, and in the kega itself, the hole is to be cut, where the grille with the products will be placed. It is even easier to put an ordinary barrel from above on the brazier, and do not engage in additional tubes.

A larger option is a vertical camera for smoking with a volume of 200 liters.By choosing such a solution, you will have to equip the base and special furnace at the bottom of the structure. You can load meat, fish or bird both in the vertical and horizontal plane. When using a hydraulic shutter, the recommended dimensions of the smoke are 45x30x25 or 50x30x30 cm. The lid in which the shutter is present, should not be thicker than 0.2 cm.

Stages of creation

Most different step-by-step instructions for manufacturing smokers based on barrels include several basic manipulations that always have to make hands:

- pick up suitable materials;

- make plans and drawings;

- collect design;

- install it and try in action.

And the fact that smoother smokehouse does not reduce demanding to design, nor to the materials used.

Make a stationary smokehouse, broken into the ground, is quite simple: digging the trench in advance connecting two remote parts. The furnace in such a design is represented by the bone in the pit, and the autonomous stove. The working chamber should be shuffled into the ground, the hole in the barley housing is left for smoke. In order for the hot gases and the heat being brought to the longer longer inside, the barrel is barely brick.

In order not to stick it, you can use a flue drive from a street stove.To do this, weld the pipe connecting the smokehouse and the box of the furnace, or a flexible hose and a device that is injected smoke. In the second type, attractive is that the total occupied area is reduced. It is very convenient when the working chamber is equipped with a thermometer that helps withstand prescription prescriptions. Great favor will have a viewing window and means for regulating traction.

IMPORTANT: It is possible to use even barrels in which a lubricating oil or other chemical has previously been. To do this, they are filled with firewood (sins, sawdust), burn, ash thrust into the garbage. The cooty layer appeared first with metal brushes, and then bring the surface to shine using any detergent.

Materials

In the process of working on the creation of smoking, you will need to use:

- barrel iron stainless or wooden (oak);

- or stainless steel keg;

- bricks;

- cement solution;

- slate sheets;

- rod and lattice;

- sheet metal.

The most practical size is 200 liters, and all auxiliary materials to the barrel must comply with the chosen project. In the minimum option, you can use a set of lid or bag tissue, rods for fixing products and filtering rags.

The need to use the welding machine is not always not, but absolutely accurate:

- shovel bayonet;

- grinder machine;

- roulette;

- building level.

Maximum clearly and competently make a smokehouse from an old barrel or even two barrels will help the plan. Typically make simply a schematic mapping of a future design in a longitudinal projection and show internal parts. If smoking camera breaks into the soil, you need to draw lines separating cameras from each other and show the nuances of each compartment. In cases where the device is stationary, it is recommended to show the mutual arrangement of the elements, their size and consolidation methods.

Cold-type smokehouse implies that the furnace goes into the ground approximately 0.5 mThe chimney is output from it in the direction of the working chamber. The input of the chimney is organized or in the side part, or below (if the pedestal is thought out). The total length of the chimney with natural cooling is from 300 cm, and if smoke is cooled forced, the minimum length will be 1 m. If a hot smokehouse is equipped, the smallest allowable gap is 0.3 m, it avoids overheating of products and clogging their soot. The width of the chimney is made at least 0.6 m, it takes into account when the trench is rotated.

Be sure to put the filter barrier and provide for the capture of fat with a metal pallet; The other is periodically cleaned, that is, they must be removable. In addition, free access to the pallet in the process of smoking should be provided. It is advisable to put a barrel not directly to the ground, but on bricks. Many masters recommend to make fireboxes of smaller (compared to the main) barrels or apply welded boxes of steel.

It is not necessary to use a traditional fire way of smoking meat or fish. Simple and easy to use solutions based on electric stalks. The heating element transmits heat to solid. They are smoldering, and hot smoke comes on the products, food is dehydrated.

The advantages of electric smokehouse are:

- offline work;

- the ability to adjust the temperature using the thermostat;

- creating from publicly available components;

- no need for complex culinary knowledge.

In order to enjoy tasty smoked, it is not necessary to buy a professional smoking. It is possible to make it yourself from the remedies, for example, from a regular barrel.

What you need to know about smoking barrel

Barrel is perfect for homemade smokehouse.

Barrel is perfect for homemade smokehouse. For the manufacture of the design, you will need a minimum set of tools and materials that can be found in any farm without any problems.

Which barrel is better to choose

For smoke equipment, a metal barrel is perfect, the volume of which is two hundred liters. At the same time, no role is played by what was kept in it before. The main thing is that the metal was high-quality, which will increase the service life of the finished device.

How to prepare barrel

First, the barrel is burned from the inside to eliminate all the harmful substances that can be in it.

In the event that the barrel was previously stored in the barrel or fuel, it should be carefully witch. After that, the container is burned on the fire. There is no other way to eliminate the unpleasant smell. After that, the barrel is cleaned again, but this time already from the soot and soot appeared. If there is a hydrodynamic mini-sink in the presence, then with its help, the container is thoroughly washed. After these simple actions, the purified barrel can be used to smoke a variety of products.

Production varieties

Make a smoke barrel can be made several different ways. All of them have their advantages and disadvantages with which it is worth familiar with the start of the assembly of smoking equipment. This will make it possible to choose the most acceptable option in each individual case.

In order to make such a smokehouse, the container is horizontally. If she has no top, then the barrel is brewed with sheet iron. After that, you need to act according to the following instructions.

In order to make such a smokehouse, the container is horizontally. If she has no top, then the barrel is brewed with sheet iron. After that, you need to act according to the following instructions.

- The cover is cut into the barrel. The capacitance will open up, so the upper part of the lid should be on the top edge of the tank. The cut cover is then attached to the design using loops. For convenience, the handle is additionally welded. You can also make a valve or a small castle.

- Luke edges need to be fastened with leaf iron, which should be a little extinguished by the edges of the obtained hole. It will not allow the lid to fall inside the device.

- On any side of the apparatus, you need to make a small hole and make chimney using for this pipe or fittings.

- Inside the design, slightly below the lower part of the hatch, it is necessary to weld or attach the guides to which the lattices will be installed during smoking.

- In order to clean the design it was easier, you need to make a pallet in which fat will be gathered. For him, guides inside the device are also predefined.

- Chip can be poured directly to the bottom of the tank.

The design is fully ready. It can be placed on fire, load products and start the smoking process.

This design can be used exclusively for the hot smoked method. For the assembly it is necessary to perform the following steps.

This design can be used exclusively for the hot smoked method. For the assembly it is necessary to perform the following steps.

- The barrel is installed in a vertical position.

- In the bottom of the container, several holes are made so that in the finished device it turns out the imaging function.

- At the bottom of the case, it is necessary to cut a small fragment of the rectangular shape. Through the resulting hatch can be loaded fuel. The carved piece is attached to the side of the loop. Free edges of the design are additionally strengthened with a small iron strip.

- From the bottom of the container, it is necessary to retreat about a third of the all height and make another bottom, which should have a sufficiently thick thickness.

- In the lateral part of the case the chimney is installed. To do this, you need to make a hole and spend the pipe through it.

- At the top of the barrel, it is necessary to make fasteners on which lattices will be located.

- Next is made of metal sheet or wooden circle perforated cover.

Using soldering lamp

Scheme of smoking with a soldering lamp

The device is incredibly simple, and the solder lamas must be used exclusively during the smoking process. In order to get a self-made smokehouse, it is enough to perform the following steps.

- A barrel is prepared. If it is solid, then the top is pre-cut.

- At the top of the capacity you need to privar the rods with which the prepared products for smoking will be suspended.

- In the days of the barrels there is a small hole. Then the coupling is welded, which has internal threads.

- Then it is prepared according to the size of the pipe. One of her end is brewed tightly, and a carving is made on the second.

- The lid is made from the sheet iron for the design. Circle It is advisable to cut a little more than the diameter of the used barrel. Perpendicular to the metal strip must be welded. For more convenient operation, a handle is made.

The cryptine of this type is installed or on bricks, or on a special stand.

Spot products are very easy. They need to be placed inside the design, fuel falls asleep into the pipe. In order to begin to stand out smoke, a soldering lamp is directed to the pipe.

Of two barrels

In this case, one of the barrels will be installed vertically and perform the role of firebox. The second barrel becomes horizontally and is the case of the finished design. For the manufacture of such a smoke, it is worth performing the following steps.

In this case, one of the barrels will be installed vertically and perform the role of firebox. The second barrel becomes horizontally and is the case of the finished design. For the manufacture of such a smoke, it is worth performing the following steps.

- The vertical barrel is cut off the top. Elements that appear up, it is better to leave.

- At the bottom of the horizontal capacity it is necessary to make a hole. Further, both barrels are welded.

- At the bottom of the vertical container, the door is made. For this, the square piece is cut and is hanging with loops. After the valve is ready, the edges are fixed with a thin iron strip.

- In the horizontal barrel, the hatch is made according to the same principle as during the manufacture of horizontal smokehouse.

A distinctive feature of this device is that the filter is additionally installed. It is necessary to install it in the place where the barrels are connected to each other. You can use burlap or the most ordinary wet cloth.

In addition to conventional tools and materials, in this case it will be necessary to use a special heating element, thermostat with temperature adjustment, cable and plug. Electric smokehouse is manufactured according to the following principle.

In addition to conventional tools and materials, in this case it will be necessary to use a special heating element, thermostat with temperature adjustment, cable and plug. Electric smokehouse is manufactured according to the following principle.

- Barrel put vertically. From the bottom of the capacity you need to retreat about 10 cm and make several holes throughout the barrel circumference. The diameter of the holes should be no more than one centimeter.

- Inside the container is attached to the heating element in the central part of the case. Then it is connected to the thermostat. The sensor must be installed slightly below the top edge of the tank. A thermometer is attached next to it.

- For a container, which will be filled with chips, you can use an old cast-iron frying pan or a saucepan.

- In the central part of the case, it is necessary to make fasteners on which the pallet for fat will be.

- Slightly above the mounts are made for lattices.

- A small hole is made in the lid, which places a pipe or fitting for chimney.

So that the finished smokehouse is more mobile, you can additionally attach to the chain body.

For the manufacture of a universal smokehouse, which can be used both for the cold method of smoking, and for hot, it is possible to use an exceptionally metallic barrel. It is necessary to do everything exactly as in the case with a vertical smoking option, but you do not need to add a firebox.

For the manufacture of a universal smokehouse, which can be used both for the cold method of smoking, and for hot, it is possible to use an exceptionally metallic barrel. It is necessary to do everything exactly as in the case with a vertical smoking option, but you do not need to add a firebox.

In the wall of the case, it is necessary to make a small hole, through which you can spend a pipe that goes from the smoke generator. If the universal smokehouse will be installed on a special platform, then the hole for the pipe of the smoke generator can be done at the bottom of the housing.

How to make a smoke barrel

In order to make a smoke barrel, you do not need to have any special knowledge. It is enough to prepare all the necessary tools and materials that may be needed during the work.

Schemes and drawings with dimensions

Scheme Smoke Barrel

In order for the assembly to take less time and at the same time it was easier, you can use special schemes and drawings with dimensions.

You can easily find them on the Internet and choose the most suitable option in each individual case.

Tools and materials

So that there are no stops during the workflow, it is worth pre-prepare everything that may be needed.

- Bulgarian and welding machine;

- Iron sheet;

- Corners from which you can make guides;

- Armature;

- Loops, handles, locks for doors;

- Coupling, pipe and fitting for the device of the chimney;

- Ruler, chalk or special pencil in order to make it easier to make markup;

- Thermometer.

The list of tools and materials can change a little depending on which exactly the smokehouse from the barrel will be manufactured.

Production of the lid.

In the design without a cover it will not be able to smoke food, because smoke will not hold onto the container. You can use a solid metal sheet for a cover or knock it off from small pieces of wood.

How to make chimney

Chimney can go under the ground or above it. Make chimney can be made from a conventional metal pipe. You can also make a trench that is covered with boards or soil. Chimney with a long service life is made of stone or bricks.

Chimney can go under the ground or above it. Make chimney can be made from a conventional metal pipe. You can also make a trench that is covered with boards or soil. Chimney with a long service life is made of stone or bricks.

Choose which variant of the chimney is most suitable, it is necessary to consider the type of smokehouse. It is important to remember that the length of the chimney can reach three meters, and the height is up to 30 cm, the width is no more than half a meter. Due to this length, the smoke will have time to be cooled to the desired temperature, which will allow you to prepare delicious and fragrant smoked.

How to make a furnace

Scoop can be poured directly to the bottom of the design or use for this an old pan, a skillet. You can also apply any other tank made of durable metal.

Preparation of the base of the chamber

At first, the barrel is thoroughly washed out and cleaned from the products that were kept in it earlier. The easiest way to leave the barrel is what it is. It is enough to do inside the fastening, on which the fuel container will be located and for collecting fat, as well as the grids to which the lattices will be placed.

How to make a pallet for grease collection

In any smoke, regardless of whether it is a home-made design or purchased, a tractor must be present in which fat will be collected. Otherwise, it enters fuel, which leads to constant damping. The easiest option is to use the metal capacity of the appropriate size or bent. You can also use a conventional iron disk to which a slight concave form pre-attached. In the middle of the disk you need to additionally make a small hole in which the bolt is fixed. Due to this, the pallet will be more convenient to remove from the finished homemade smokehouse.

In any smoke, regardless of whether it is a home-made design or purchased, a tractor must be present in which fat will be collected. Otherwise, it enters fuel, which leads to constant damping. The easiest option is to use the metal capacity of the appropriate size or bent. You can also use a conventional iron disk to which a slight concave form pre-attached. In the middle of the disk you need to additionally make a small hole in which the bolt is fixed. Due to this, the pallet will be more convenient to remove from the finished homemade smokehouse.

It is possible to install the used containers directly on the fuel, but this method is not considered the best. It is best to spend some more time and make a simple support for the pallet, which should be located slightly above the smooth chip.

It is possible to install the used containers directly on the fuel, but this method is not considered the best. It is best to spend some more time and make a simple support for the pallet, which should be located slightly above the smooth chip.

- Three bricks are laid on the bottom of the design and the container for grease collection is installed on them.

- At an altitude of 15 centimeters from the bottom in the walls, three holes are made in which long bolts are inserted. They must be additionally fixed with nuts. At such bolts and the pallet is installed.

- You can make four holes and stretch your rods from fittings. They will act as a reliable support for the pallet used.

- Directly to the pallet you can fight legs and install it at the bottom of the homemade smokehouse.

The easiest option is the usual sticks or bars, which are located in the upper part of the design.

The easiest option is the usual sticks or bars, which are located in the upper part of the design.

Also in the walls you can make holes in which rods are stretched.

They put a grid or grille. Another option is to make fasteners for the lattice, which assumes the mounting of several hooks around the circumference of the barrel used.

How to cook in smoke barrel

Cook smoked in homemade smokehouse is very easy. It is enough to place the prepared products on the lattices or hooks, close the design and pour the fuel used through the door.

Preparation of smokehouse and product bookmark

In the lower part of the finished design, sawdust or chips. The pallet is further exhibited, in which fat will be flown from products. The products themselves, pre-pickled and prepared, are laid out on the grille or are suspended with hooks.

In the lower part of the finished design, sawdust or chips. The pallet is further exhibited, in which fat will be flown from products. The products themselves, pre-pickled and prepared, are laid out on the grille or are suspended with hooks.

The design is closed with a lid, and the firewood under the barrel is set on fire. When the bottom of the smoke is warm up to the temperature, the chips will begin to gradually smoke. The process of smoking is running, it remains only to wait a bit.

What chip is better to use

Ideal for smoking at home, flowers of fruit trees or alder are suitable. You can not use chip from coniferous trees, because the finished smoked breaths will have a bitter taste and an unpleasant smell.

Ideal for smoking at home, flowers of fruit trees or alder are suitable. You can not use chip from coniferous trees, because the finished smoked breaths will have a bitter taste and an unpleasant smell.

In order for the products to be even more delicious and fragrant, a small amount of juniper can be added to the chip used. Smoke that will come from him, give smoked sophisticated and original taste.

In order for the smoking process to be easier and brought exceptionally positive emotions, it is worth adhere to some simple tips.

- While choosing chips should be traced to be the same size. Otherwise, small sawdust will be burned faster, which will lead to uneven processing of products.

- It is better to smoke those products that contain the minimum amount of moisture. It is also necessary to ensure that the prepared meat or fish is solid enough. Otherwise, ready smoked smokedels will be tasteless.

- It is important to take into account the features of products. For example, large pieces of meat will prepare much longer and additionally needs cuts.

- Pre-training products need to pay a sufficient amount of attention. The better the products of marinade and spices are impregnated, the tastier smoked meat.

- Be sure to use pallets for fat, so that during the process of smoking it is not a drip on the chip, because it will cause constant attenuation.

- No need to pour too much fuel.

- Chip must necessarily be slightly moistened before use so that it does not occur.

If there is no finance to purchase a professional smokehouse of factory making, it can be easily constructed without any problems using the old barrel. It suffices to follow simple instructions and even a person without experience will turn out to make a simple and efficient design for the preparation of delicious homemade smoked.

Many consider smokehouse for giving an indispensable thing. It is difficult to argue with this. And if you are a hunter or fisherman, then such a product is simply invaluable for you. It is always pleasant to whine smoked meat, fish or game, cooked in nature. If you need smoking, then you have two development options. The easiest thing is to go to the store and acquire a smokehouse. But, not everyone can afford it. Therefore, many choose the second option - to make a smokehouse for the cottage yourself. I would like to say that for this you do not need to be a craft master, and the tools and materials necessary for work, quite affordable.

Many have a barrel at the cottage, which is lying out. If you have no such, you can buy it, because it will become our raw material for smoking. It is desirable that the barrel is 200 liters. This will allow smoking a lot of meat. So, if you configured, let's find out how to make a smoke barrel.

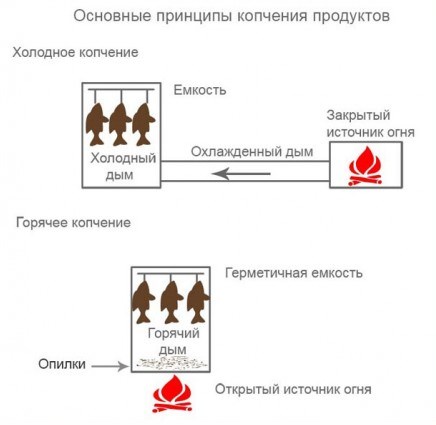

Concept of cold and hot smoked

To begin with, you should understand that there are two types of smoked, which can perform your unit:

- hot smoking;

- cold smoking.

The essence can be clear. In the first case, the method is quite fast, safe and high-quality. The raw material, placed inside, is processed by smoke, the temperature of which on average reaches 70 degrees Celsius (range from 45 to 120 degrees). In such a medium you need to perform smoking since two hours, ending with two days. As a result, you will have a juicy, fragrant and delicious finished product. It can immediately eat. This is the main difference.

If we talk about cold smoking, then such a process is much longer. There are already ready-made saline small slices of product, which are processed there for 4 days (minimum of 2, it all depends on the result). As for large pieces, they can be inside even a week. The average smoking temperature at the same time reaches 40 degrees. What is the essence of this method? Moisture from meat or other product is removed gradually saturated with the raw material with smoked taste and aroma. The dish will be moderated dried and with a particle of fat.

Note! This kind of smoked is good because the source product can be stored for a long time.

As you understood, the smoked smoking smoked smoking, and the smoking smokehouse differs only in the work temperature, and, accordingly, the final product. Let's find out what kind of hot smoked smoking smoked smoking. In addition, you can make an aggregate of two barrels to increase the amount of raw materials that can be processed. So you can make a smoke smoked smoking with your own hands and hot. But what it will be, decide for yourself.

Preparation of tools and materials to create a smokehouse

The first thing that our work begins is the workpiece of all necessary for work. As mentioned first, all the tools are simple and everyone will be able to work with them. Yes, and the material on the arrangement will leave a little. Here is the list of all Arsenal:

This is enough for you to have a wonderful smoking of cold or hot smoking from the barrel. It remains only to consider the design instructions. We will look at two variants of shocks from the barrels: made without a welding machine and with its use. After all, not everyone can use them or do not even possess them. This will help you implement everything.

Make a smokehouse from a barrel without a welding machine

This method has a huge advantage, because only a limited number of people can and know how to use the welding machine. This is not a Bulgarian, here are needed professional skills. It is this option that most users choose. So, let's start working on creating a smoke barrel.

First of all, you need to prepare a barrel to work. What does it mean? Its surface needs stripping. This will help you a grinding machine or a special nozzle on the grinder. Carefully treat the surface of the barca so that there are no traces of rye and paint on it.

Important! Do not neglect security rules. During operation, small particles will be formed, which are harmful to eyes and respiratory tract. Therefore, you need to work in the respirator and glasses.

Look at the photo. It is such a design that we will construct with you. You do not need to do the drawings, as the photo will help you navigate.

Here, a metal design is used as a stand. It can be corners. You decide. Now the whole instruction on creating a bochki boch will be filed step by step:

That's all, now do Copeous as you like. This design costs cheaply, and its creation will require a maximum half of the day. Everything is pretty quickly, easy and cheap. And no welding was used. The photo shows how everything looks in the finished form.

Note! You can make a barrel of smithal and in a vertical position. The essence of the work is exactly the same, only here is the type of design.

Skolna from the barrel do it yourself, option number 2

If you are a welder, or know how to use the welding machine, you can simplify life and do everything much faster. You only need to choose clean and outside and inside the barrel. If chemicals were kept before it was stored, it is better not to use it. In this embodiment, we consider the vertical location of the smokehouse. This is how the smokehouse from the barrel and the process of smoking in it will look.

Manufacturing instructions:

Look at the photo where the smoking process is schematically depicted and the smokehouse itself, made by hand.

Socker version number 3 - Cold smoking

If you are interested in the Cold Smoking Scheme, then the design can also be made with your own hands. This is a universal smoke apparatus, which is done without built-in furnace. Its feature is that the barrel can be used for both smoked method and for the other.

You need a barrel who has a durable bottom. It needs to make small holes (holes). The firebox is constructed as a separate design. It can be made of metal or brick. Make the top of the furnace.

A smokehouse will be made on the furnace from above, and the products that are inside will be processed according to the hot smoked method.

Now you need to make a firebox for cold smoking, making the chimney and the hole for the pipe input from the bottom. In fact, the insides of the barrel are made according to the same principle, only here without a collection of waste and combustion products. Chilled smoke will penetrate the barley through the pipe and perform its work. Look at the photo as it can be realized.

Conclusion

Now you know how you can make a smokehouse in your dacha from the barrel. You could make sure that the way is simple and quite realizable. You only need to prepare everything you need and allocate several hours to work. But in the near future you will be able to enjoy a delicious sluggish fish, sausage or other meat. This taste will help you forget about all the writings you did. The design will accurately leave you indifferent. And to help you with the task, we have prepared a video.

Read in the article

Smoking process in smoking barrel

The convenience of smoking the lamp, is that it does not need a constant punching of pressure in manual, if it does not hurt it (and we are thinking about it, for this we drove the hole), and no nozzle will be drunk, it will "buzz" about 3 hours, until all gasoline is spent.

The process of smoking in time can occupy from 40 minutes to several hoursit depends on the ambient temperature, naturally that we will save on the street, so in the winter the process can delay, because the temperature in the smoke itself remains too low, the perfect temperature in my opinion, it's when palm suffers but not long (hand put on a barrel ). If the temperature is not sufficient, then you can get a rubber chicken. You can affect the temperature, you can cover the smoke with a blanket with a blanket, but so that it would not be caught up, for this bricks under the smokehouse should stand around the perimeter, this will also retain heat under the barrel itself, with such conditions as I described smoking the wings 1-2 hours, fish About an hour.

By the way, you can smoke fish with meat, and not afraid of smelling. Only the fish lies on the bottom lattice.

Smoking result:

Mackerel

Chicken wings

For the last, I will share the recipe for smoking the wings that I really like, I only do this:

- We fall asleep in the washed wings are as follows:

- salt, sugar, pepper, citric acid in proportion 1: 1: 1: 0.5

- Mix, wait for 1-2 hours, Impham.

(Visited 758 Times, 1 Visits Today)

Popular on this blog

- Connecting DRL with the help of a Chinese controller (14 174)

- The phone is charged for a long time (14 088)

- Automation for gates from China and its connection (9 572)

- Drive for roll backdrop do it yourself (7 100)

- Duck for snow to Niva with his own hands (6 876)

- Refracting Router from China Clone Hame-A15 (5 772)

- How to check the power supply or battery using a multimeter (5 338)

- Replacing the Volkswagen Polo stove thermal stitch. ... (4 939)

- How to strengthen the Internet in the country (4 801)

- (3 648)

Universal smokehouse

The universal smoked smoked smoke is made only from a metal barrel. In it, everything is done as in the case of a vertical option for smoking from one barrel, but without firebox. Additionally, a hole is made in the wall, through which it will be possible to start the pipe from the smoke generator. The hole can be made and below, if you plan to install the smokehouse on the prepared platform, but it will be necessary to come up with a way, thanks to which it will be possible to close the hole closely during hot smoking. Another example of the design of such a smokehouse can be viewed on the video:

When there is no welding machine

Not every person has a welding machine, but a homemade smoke can easily be done without it. After the barrel is well cleaned and washed, its surface should be well cleaned. The next step will be its firing. To do this, it is enough to put firewood in the barrel and dilute there a fire, when the firewood burns, you can move to the markup.

Cleaning barrel

Cleaning barrel

Important! Use the means of protection so that dust and metal particles do not get into the eyes, nose and mouth. . On the side of the barrel there is a markup for the hatch, then you need to use the grinder to cut off a small part or even half of the barrel, everything will depend on your drawing and how to use smoking.

On the sides, you can attach metal strips that will fix the lid

On the side of the barrel there is a markup for the hatch, then you need to use the grinder to cut off a small part or even half of the barrel, everything will depend on your drawing and how to use smoking.

On the sides, you can attach metal strips that will fix the lid.

The next step is to create a barrel support, they are attached using special clamps, for this you should make small rivets.

The hatch should be a handle, so to use smoking will be much simpler. You can use old door handles or from furniture, but most importantly - so that they can be convenient to use.

Inside, it is necessary to make supports and guides for the lattice, first selects the most suitable position, and then holes are drilled on the side. After that, supports are inserted.

If you decide to handle the barrel of paint inside and outside, it should be resistant to high temperatures.

Smokelift using a welding machine

Again, there will be a high-quality smoke from 200 liter barrel if it was well aware and burned fire. With the help of the grinder, the upper part of the barrel is cut, it can be used as a pallet for the smoking chamber.

The door and outlet for the chimney is cut from below. Ideally, the size of such a door is 20 * 30 cm, the cut part is fixed on the daughter with the help of loops, it turns out the door for firewood.

Conditionally divide the barrel into 3 parts, the iron sheet is attached to one of them, its thickness should be 40-50 mm.

Cut out the opening for chimney, the pipe is attached to the barrel. The higher the pipe - the better. The thrust will increase, and this contributes to the excessive selection of fat in the preparing product.

At the bottom of the barrels are set legs, it should not just stand on the ground. When creating airspace, burning inside happens much better.

We weld legs

The furnace can be located both in a barrel and any other place. In this case, the furnace is constructed from bricks, and the barrel will be above the furnace, the smoking space will be increased.

The lid of the barrel can be used as a pallet for grease collection. For its installation, fittings are welded at an altitude of 20 cm from the bottom of the smokehouse.

At the top to make the base for the lattice, for this it uses fittings in the form of loops. The width between the grids is 15-20 cm. The grille itself can be made of wire.

For the cover, a perforated tree or a jute bag is suitable.

Questions on fuel

So that smoking in the barrel AHC brought positive and amazing results and delicious dishes, and not a handful of coal, make serious attention to the type of fuel used and temperature. . Competently built apparatus, thanks to the tightness of the working capacity, allows you to achieve the necessary temperature modes

A competently built apparatus, thanks to the tightness of the working capacity, allows to achieve the necessary temperature modes.

As it was already noticed, fuel here should smooth, and not ignite. Here will help raw materials from wood. It is a bit wetting before use. If it is with a large moisture content, the food simply welds.

Only due to the reasonable amount of moisture dishes get the right taste.

Fuel is raw materials from suitable wood. If you wish to get dishes with good quality and taste, you should not apply raw materials from coniferous rocks. From it, the resins are distinguished during smoked. They impregnate the product and spoil his taste and smell.

The best options are the materials from fruit trees. Apple, cherry, pear sawdust are often used.

You can apply oak, lime and outer raw materials. You can combine types of raw materials to achieve an exquisite taste of dishes.

Smoke is the key component. His tightness and thrust hold it in the barrel.

Sawdust in the focal zone is added gradually, approximately 100 grams. There they must be distributed evenly.

Alas required to eliminate. If the filter is arranged in the device, it is necessary to replace it every 4-5 hours.

After each application, the device is thoroughly clean and dried. In another situation, fat and soot negatively affect the taste properties of the product.

Coals are periodically removed from the hearth. They only prevent the smoke movement.

Smokehouse on the basis of a tree barrel, even well-treated with protective preparations, still needs enhanced control. It must be on a metal sheet.

Views

The many years of experience "Cleells" allowed to create a lot of variants of boching boots. The easiest (in every sense) is even mobile, can be brought by car to the place of picnic or fishing, on the hunting base. As a basis for such products, beer kegs or small-sized wooden barrels are performed. If there is a desire to make a chamber with the grill effect, it must have a framework.

Great variety of stationary products, one of them are intended for hot smoked, others - for cold, and others can carry out both of these functions harmoniously.

It is necessary to provide analogs of devices present in industrial smoking chambers:

- chimney;

- smoke generator;

- hood.

The specificity of hot smoked is that smoke must come from below, overcoming the minimum distance. Technically, this is solved in two different ways. In one of the schemes cut the window so that you can throw the sawdust and ignite them. In the other - they put the smoking chamber over a separate furnace. The flake itself is performed in different ways: it can be a simple gauge in the ground, and a small brand, laid out of bricks.

Another approach is practiced when they create a cold-type smokehouse.Here it is already required to cool the smoke, sometimes it is necessary to even lay the chimney in several meters long. It is performed in the form of trenches, buried to the ground pipes and so on - there are a lot of options. If suddenly there is very little space, you have to install a double chamber with artificial cooling, in which there are two compartments and the wet cloth separating them.

More efficient and practical than all homemade smokehouse, which allows you to combine hot and cold processing modes. A dual horizontal chamber is made from a pair of the same barrels that are binding to smoke trumpets. When using a wet filter, you can organize a half-oscillage smoking; Below is always located the combustion chamber.

Some of the home masters preferred the traditional look at the so-called closet. As a base, a frame of wood is made, key elements - a timing segment of 40x40 mm. Whatever the body is chosen, it is trimmed from three sides by boards, the thickness of which is 25 mm, and the greatest width is 100 mm.

Optimal will be the lining of deciduous wood:

- osinova;

- olkhova;

- lipova.

Only in extreme cases are permissible to use coniferous parts, especially since finding the three listed breeds will be quite simple. Regardless of the specific type of material, you need to achieve maximum tightness of the case. This task is solved through the use of thermal insulation materials, such as a hen rope, placed even in the most minor joints.

The door must match the oven wall dimensionsFor it, a plate of 25x100 mm is applied. The perimeter of the opening should be sealed with sealing food rubber, like that which the refrigerator doors are covered. The roof of the smokehouse make a single or duplex. In the first case, it must be fixed back, such a product is formed from boards, which are 40 - 50 mm longer than at the base. In the second, a rafter system is formed, whose skate can be from 0.55 to 0.65 m; Connection locations always make hermetic.

Stationary street smokehouses are ground and stain in the top of the oil paint. Since the roof will not be heated anyway, the detachment is not worthwhile, much more importantly focus on protecting water. The chimney is always complemented by dampers and shabby mechanisms (only such a solution ensures high efficiency of smokehouse).

Option 1. Manufacture of smokehouse without the use of a welding machine

The advantage of the method is that you do not need a welding machine. The initial stage of the work is stripping the surface of the barrel.

Council. Use protective equipment so that dust particles do not get into the eyes and respiratory tract.

- On the sides it is necessary to attach stripes that will fix the lid and do not let her fall inside. Metal ribbons are suitable from another barrel or specially purchased planks.

- The procedure is performed twice, on both sides of the structure.

- Then the handle is attached to the hatch. You can use old copies removed from the refrigerator, a closet or other furniture. You must drill holes and lock the knob to the screws.

- The point is left for small - the installation of the coupons. It will take the installation of supports and guides for the lattice. Select the appropriate position for fasteners and drill the opening on the side. Insert the supports.

- It is possible to handle the surface of the barrel as follows: light the fire inside and give it to embello the paint, go through the brush and remove the remains of Gary. Then degrease the surface and cover the paint, resistant to high temperatures.

We make marking on the side of the barrel and with the help of the grinder cut off part. It will be a hatch of future smokehouse. How to cut a barrel, this is the case of everyone. You can cut a small rectangular hatch or cut the barrel in half. It all depends on the option and drawing of your chosen.

Mounting hatch and fixing stripes for him

The next step is to fasten the hinges for the hatch. Use the same technology as for supporting the hatch, i.e., attach a loop with rivets. First try manipulations on one side, and then repeat from the other.

Mounting loops for Luke Smoke

Make chimney. You can use any pipes or fittings as a material for this detail. The main thing is that they are well attached with the help of bolts, since this method of manufacturing smokehouse does not provide for the use of welding.

Chimney is made of a suitable diameter pipe

The robe holder can be collected from metal corners and copp through bolts.

Finished smokehouse made without welding machine

Smoking smoked smoking

The homemade crypton for the preparation of products for hot smoke is made very simple, but everything cooked on it has an amazing aroma and even more unsurpassed taste. Photo smoked with your own hands made, as a rule, do not differ in variety

This is not surprising - no matter what size you decide to make an aggregate (from a bucket or from a whole barrel), the principle of its work will remain unchanged, as the design itself.

So, to make a smokehouse yourself (as in the photo) you need eat a small jam, diameter with a bottom of barrels, marshrette stone or brick foundation. Instead of the broken bottom of the barrel put a piece of the grille, and at the top of the smoke it is necessary to make small holes or hooks so that the products are more convenient to hang. The chips are laid under the grille located on the bottom.

Products worth hanging out only after the chips go thick smoke and all the container will warm up. At the same time, do not ignore and the temperature regime - for this you need to follow the fire (the chips should be smoldering, highlighting the smoke, not to burn). From above, smoking should be covered with a sacking or iron sheet.

Observing these conditions, it is possible to quietly prepare your most nice smoked delicacies from simple everyday products as soon as possible and with minimal costs.

Features of hot smoked

In the "hot" smoke, made with your own hands, cook very nice, and so that homemade smoked smokers are treated, required do not forget about some nuances:

- the composition of "fuel" for smokehouse is heterogeneous - it consists of 60% of firewood, and 40% from chips;

- the chips should not be overly small (since it will quickly burn) and not large (very badly tweets), and medium size;

- in the staff should not be open fire;

- the temperature near the lattice should be about 50 degrees for meat products and approximately 120 degrees for fish.

Materials

In the process of working on the creation of smoking, you will need to use:

- barrel iron stainless or wooden (oak);

- or stainless steel keg;

- bricks;

- cement solution;

- slate sheets;

- rod and lattice;

- sheet metal.

The most practical size is 200 liters, and all auxiliary materials to the barrel must comply with the chosen project. In the minimum option, you can use a set of lid or bag tissue, rods for fixing products and filtering rags.

The need to use the welding machine is not always not, but absolutely accurate:

- shovel bayonet;

- grinder machine;

- roulette;

- building level.

Maximum clearly and competently make a smokehouse from an old barrel or even two barrels will help the plan. Typically make simply a schematic mapping of a future design in a longitudinal projection and show internal parts. If smoking camera breaks into the soil, you need to draw lines separating cameras from each other and show the nuances of each compartment. In cases where the device is stationary, it is recommended to show the mutual arrangement of the elements, their size and consolidation methods.

Cold-type smokehouse implies that the furnace goes into the ground approximately 0.5 mThe chimney is output from it in the direction of the working chamber. The input of the chimney is organized or in the side part, or below (if the pedestal is thought out). The total length of the chimney with natural cooling is from 300 cm, and if smoke is cooled forced, the minimum length will be 1 m. If a hot smokehouse is equipped, the smallest allowable gap is 0.3 m, it avoids overheating of products and clogging their soot. The width of the chimney is made at least 0.6 m, it takes into account when the trench is rotated.

Be sure to put the filter barrier and provide for the capture of fat with a metal pallet; The other is periodically cleaned, that is, they must be removable. In addition, free access to the pallet in the process of smoking should be provided. It is advisable to put a barrel not directly to the ground, but on bricks. Many masters recommend to make fireboxes of smaller (compared to the main) barrels or apply welded boxes of steel.

It is not necessary to use a traditional fire way of smoking meat or fish. Simple and easy to use solutions based on electric stalks. The heating element transmits heat to solid. They are smoldering, and hot smoke comes on the products, food is dehydrated.

The advantages of electric smokehouse are:

- offline work;

- the ability to adjust the temperature using the thermostat;

- creating from publicly available components;

- no need for complex culinary knowledge.

Most homemade electric bootylene works in barrels with a capacity of 200 liters. It is recommended to supplement them with a thermostat that changes the temperature from 20 to 90 degrees. Instead of the traditional lattice for sawdust can be used by an old pan. To make it easier to move the camera for smoking, you can screw the wheels from the furniture to the housing.

With electrical tiles you need to remove the cover and delete all the details., With the exception of the tan, which, together with two wires, attached with screws at the bottom of the barrels in the center. The thermostat is fixed slightly above the furnace, connect it with the heating element sequentially according to the scheme. The fastening of the thermal sensor should be made in the place where products will put. The optimal cross section of the wires is 2.5-3 mm.

The thermometer in a similar system should be purely mechanical. As a pallet for fat, baking molds are sometimes used, the diameter of which is 0.5 m. It can be a special pallet shot from the oven ancient gas stoves. Better than usual show themselves in the practice of smoking with a hydraulic shutter.

Skolna from two barrels

Skolna from two barrels

Skolna from two barrels

When creating a smokehouse with a barrel with your own hands, you can use even two barrels, and from them to make one smokehouse. Smoke will be distributed in it better. So that she pleases all the delicious dishes that will be prepared rather quickly, it is necessary to try to make it well. The first thing is created a drawing.

Two barrels depending on the desired size of the smoke tank, are put on each other, they should not have the bottom, and the filter is laid between them. You can make the filter from burlap or conventional wet fabric, every 2-3 hours it will have to be changed. In the bottom barrel there will be a firebox, wood and sawdust are laid. The top is the prepared product. To further increase the amount of products prepared at a time, you can make two tiers, for example, install two lattices, or raise hooks in two tiers.

Thanks to the use of the filter, the temperature is controlled much better, moreover, products are protected from soot.

Speakers are evenly added to the focus, the sawdusts so that the process of their degeneration does not stop. Keep track of the temperature and condition of the filter if there are many ash on it, it should be replaced, pre-delivered products from the top chamber.

Smoking requires constant attention, only in this case you can achieve a stunning result! Products will be perfectly prepared and not overpowered.

Important! Do not forget about the pallet for grease collection. .

How to choose sawdust?

Chip for smoked

Chip for smoked

If you decide to smoke in a barrel, then besides the fact that it must be correctly executed, you must use the corresponding sawdust (or chip).

Best breeds:

- alder;

- birch.

Fruit trees are also very valued:

- apple tree;

- cherry;

- plum;

- apricot.

It is not allowed to use sawdust from pine tree trees, besides the fact that they excrete oil during burning, they give me dishes even severe bitterness. For piquancy dishes, you can add a bit of juniper to the main layout, it is folded at the bottom of the tank for smoking.

Remember that sawdust must be smoldering, not to burn. To do this, you can pre-moisten them. A small amount of moisture will not allow to cut the dish, it will get a very pleasant taste. But the sawdust should not be wet, otherwise they will simply won't smooth.

Do not be lazy to add sawdust in the furnace with small portions, enough 100 grams at a time, they must be distributed as uniform as possible.

It is also necessary to care for the smokehouse, only so she will delight you with delicacies. After each use, it is well washed and dried. If there are particles of fat and oil after the previous smoking, then future dishes will deteriorate.

Conclusion

Preparation for smoking in barrel

Preparation for smoking in barrel

If you are the owner of a private house or cottage, then the smokehouse from the barrel will be perfect for you to prepare delicious and homemade dishes, which can be called delicacies with confidence. It is not difficult to make a smokehouse with your own hands, the most important thing is to properly prepare for the process. As a rule, it will take no more than 2 hours. After that you can enjoy homemade smoked sausage, meat, dried fish. After you try to taste our cooking dishes, you will immediately forget about all the difficulties that could face during work.

SD homemade with their own hands on any vital case

- the main

- Add your homemade!

- Vegethers

- Machines and tools

- Selfieckers

- Furnaces and mangaly

- Mini tractor

- Country homemade.

- Mototechnics

- S / x homemade

- FURNITURE

- Children's homemade

- Cars

- Retro cars and equipment

- Arbor

- Buggy.

- Crawler all-terraines

- Quadrocycles

- Snowmobiles

- Smokehouse

- Boats and Plalling

- FURNITURE

- BLACKSMITH CRAFT

- Mini tractor

- Mototechnics

- From benzopil

- Male recipes

- Weapons

- HOUSE HEATING

- Furnace-Rocket

- S / x homemade

- Self-timers of survivalors

- Apparators

- Building

- SCHEMES

- Tanks

Recent Entries

- Win-350 first Soviet quad bike

- Moped Riga-22 Restoration

- Mokik Delta RMZ 2. 124

- Motorcycle Casting to 750

- Restoration of motorcycle Sunrise 1968

Archives

- November 2018.

- October 2018.

- September 2018.

- August 2018.

- July 2018.

- June 2018.

- May 2018.

- April 2018.

- March 2018.

- February 2018.

- January 2018.

- December 2017.

- November 2017.

- October 2017.

- September 2017.

- August 2017.

- July 2017.

- June 2017.

- May 2017.

- April 2017.

- March 2017.

- February 2017.

- January 2017.

- December 2016.

- November 2016.

Recent topics

Mushroom Ginochka

Tags

- # Banya

- # Vice

- ALTERNATIVE ENERGY

- Car

- Buggy

- Werethod

- Caterpillars for all-terrain vehicles

- Crawler all-terrain

- Out of 200 liter barrel #

- From chainsaws

- INSTRUMENTS

- Quad bike

- COMPRESSOR

- SMOKEHOUSE

- FORGE

- Cold smoked smoked smoking

- BAND-SAW#

- FURNITURE

- MINI TRACTOR

- MOPED

- Hiking oven.

- Furnaces and mangaly

- Rocket-rocket

- Snowmobile

- MACHINE

- FUEL

- Tractor from Motoblok.

- DRAWING

- avtoModelki

- gAZ 66.

- children's homemade

- drift-Tryk

- quadchal

- hot smoked smoked smoking

- mototechnics

- motorcycle

- loader-excavator

- tractor

- tricycle

- low pressure tires

Rubric

- Cars (20)

- Alternative Energy (5)

- Apparatuses (13)

- Buggy (13)

- Bath and sauna (4)

- Arbors (3)

- Westers (92)

- Bicycles (3)

- Crawler all-terrain vehicles (3)

- Country homemade. (21)

- Wooden Homemade (7)

- Children's homemade (14)

- Drift Track (1)

- Homemade Ideas (3)

- From chainsaw (6)

- From Berestov (1)

- From the canister (1)

- Cap and Suvel (2)

- Quad bikes (14)

- Computer homemade (1)

- Design workshop (6)

- Smokehouse (16)

- Costa (1)

- Blacksmithing (12)

- Aluminum casting (3)

- Boats and Plalling Means (1)

- Furniture (17)

- Metal detectors (1)

- Metallurgy (9)

- Mini tractor (34)

- Mopeds (3)

- Mototechnics (32)

- Motorcycles (16)

- Men's recipes (3)

- Outline (1)

- Science and Technology (3)

- Weapon (1)

- Garage Heating (1)

- Heating at home (7)

- Furnaces and Mangaly (43)

- Furnace-rocket (8)

- Loaders (1)

- Fixtures (9)

- Retro cars and machinery (9)

- Fishing (5)

- S / x Homemade (17)

- SelfDinks (42)

- Survival Selfokers (12)

- Scooters (2)

- Plumbing (3)

- Lamps (1)

- Snowmobiles (7)

- Machines and tools (77)

- Building materials (7)

- Construction (12)

- Tanks (4)

- Fuel (6)

- Tractor (3)

- Drawings (6)

- Excavator (3)

- Electrician and electronics (8)

Forums

Of two barrels

You can build a large smokehouse of two barrels.

You can build a large smokehouse of two barrels.

Such a design will help significantly reduce cooking time, and accommodates more products.

So, they connect two barrels, one put vertically, the second horizontally on it. Between the barrels, as in the previous version, must establish filters.

For this, a moistened fabric or burlap is suitable. All recommendations are applied for this method as for smoking from one barrel.

The lower barrel will act as a chamber for the furnace, which is filled with sawdust and chips. The top barrel will serve as a wardrobe for products.

Council from practice: The barrel on liters 200 is well suitable for smokers from one barrel, and when the filter is located inside, there will be the same effect as of two barrels.

How to do without welding

The barrel must be carefully prepared. Since the old capacity is most often used, it must be cleaned, remove rust and paint. You can use solvents, but it is easiest to do this with a torch or fire from a soldering lamp. Pamping barrel from all sides with a flame, it is thoroughly cleaned with a metal brush and washed with water.

Council. While cleaning the capacity you need to protect your eyes and respiratory tract from dust particles using a mask or respirator.

Stages of manufacturing smoking:

- on the sides are attached with ripples metal stripes or strips, which will not give the door to fall inside;

- screws fasten the handle to the door (you can take the old one about furniture, refrigerator);

- cut a hole for the chimney;

on the side of the barrels cut through the hatch (door) with the help of a grinder;

Sleeping Luc

with the same ripples attach loops;

fresh loop

attach the chimney pipe using fitting and bolts;

fixing chimney pipe

- perform the mounting support for the lattice;

- rama holder made of metal corner is bolted.

Council. The finished smoke can be treated outside the degreasing solution and covered with fire-resistant paint.

Making a smokehouse with a welding machine

Prepared barrel as carefully as at the first time. Then come as follows:

- with the help of the grinder cut off the top of the barrel (this cover will be pallet);

- cutting the door of the furnace (20 by 30 cm) and the yield for the chimney;

- fasten a perforated bottom of durable iron (it will be confused)

- make a hole for the chimney corresponding to the feeding diameter;

- strengthen chimney;

- the smokehouse is installed on the legs (made of metal corner or brick).

the flue door is suspended on the loop (need drill and screws);

fastening the door

Design can be simplified. The furnace is out of the barrel outside, into the recess in the ground, covered with bricks. The bottom of the smokehouse in this case will be the barrel itself. The smoke camera will increase. In the rear of the furnace you need to leave a place for chimney.

The barrel cover is ideal for a pallet, which is installed on a cross-shaped backup from iron fittings. Fat will be gathered for this pallet when smoked. From above, barrel is covered with a perforated lid or burlap.

Each master in the process of manufacturing a smokehouse will arise their ideas, how to improve the design. The main thing is to make a safe and comfortable smokehouse, which will serve not one season.

Creating a smokehouse from a barrel

1 way

In this way, a trench of a depth of 40 cm is first digging. At the same depth, the location is noted. The trench in length should be at least a meter, but not more than 2 m. The bottom of the barrel is cut manually. The barrel itself bursts approximately the same depth as the trench. Bricks need to be laid around it so as to eliminate air and heat loss. The joints also should not pass the air. Everything should be hermetically. Next, bricks will be needed for the layout of the trench, followed by a covering with a metal sheet.

Skolna from a barrel with a trench

Skolna from a barrel with a trench

The trench is replaced by the tube of the required length, if such is prepared in advance.

In the top of the barrels are done by holes for metal rods. The interval between them should ensure safe accommodation on the rods of a large piece of meat. They are attached with self-tapping screws or welded. On the rod, then hooks for products are performed. You can start smoking.

On the video you can see homemade smoking in action:

2 way

Dig a place to smoke cold smoking with your hands out of the barrels optional. In this way you will need to make an exaltation. The bottom of the barrel is not cut. Stand for it is made of bricks or metal. To do this, cook together pieces of metal to form a frame for "table". A metal pipe is used as a chimney, which is hermetically combined with a hearth and barrel.

The focus is made of metal container, which is swapped into the ground for a short distance, for stability. A small barrel is suitable. You can make a seifama. The focus door should not skip smoke. Mesh is made from the rod. They can also be placed on each other, but at a distance of at least 15 cm so that smoking products are not connected. Rods are welded or fixed using self-tapping screws.

There are many ways of the device of smokehouse, some of them are laid out on the network. Depending on the source materials and ingenuity, you can come up with something.

We make smoking personnel personnel

The main material for the construction of smokehouse with their own hands is a metal barrel, the dimensions of which have such parameters: 70 cm - diameter, 130 cm - height. It may also be a tank for watering with a capacity of 200 liters, which has rusted bottom.

After the desired capacity of 200 liters is found, it is cut into two halves of the grinding machine. The incision of the 200-liter barrel is made horizontally. Then the upper part, the height of which should be about 1m, will serve as a smoking chamber, and that from the bottom - furnace.

Top - Camera Smokehouse, Lower - Fire

In order for the smoke quickly cooled, the chimney should be as long as possible. The smallest length of the chimney from the furnace to the camera with smoking products should be 2-2.5 m. It can even be pipes used in the construction of fences, whose length is 2.5 meters. However, if the diameter of the pipe is less than 10 cm, it is better to put two parallel pipes. Some masters recommend making their hands a chimney from 5 to 7 meters long.

Of course, the smoke camera made with their own hands must be located above the furnace. Therefore, for the installation of smoking, it is recommended to search for a suitable relief on the site. The furnace is best located on the plot, covered with rubble, in a place where she will not be confused under their feet. Smoking pipes should be buried. The camera for smoking is also installed on the rubble layer, and also, like smoking, falls asleep the earth. In the heating part on top of one side, a hole for smoking pipes cut through, and outside the other hand make a slot in the form of a rectangle for laying fuel materials.

Homemade firebox is not forgotten. The fact is that when it is arranged, it is necessary to take care of the drainage and tightness of the chamber from above. It will keep the fire from the bay of rainwater during a sudden shower. If everything is done correctly, as a result you do not have to pull water from the firebox and produce drying.

First, they make a hole under the furnace with a block of 30cm from all sides. Under the bottom, in which several holes make a lombing, grinding rubbank. Only after that the firebox can be installed. The lumens between it and the smoking in the entrances close the usual clay. It is desirable to make a clay fish around the firebox for cold smoking and moisturize it. At the edges of the central part of the furnace put a corner with a shelf 40mm.

Dig up the fifth on the furnace on each side we leave the gaps of the emptiness around the furnace fill the clayClose the furnace from above the pre-carved galvanized sheet of the desired dimensions. The grille is placed on top of it, which should be welded from metal rods. A similar lattice can be searched among scrap metal, and not engage in its manufacture specifically.

Flake cover with flat sheet. The grill is put on top

The lattice fall asleep with sand, and the profile sheet is placed on top. It is falling asleep with rubble at the site level.

Access to the furnace can be postned from bricks. It is possible to simplify work when erecting access to the furnace, grabbing bricks by conventional electrodes that need to be bandaged from both sides. Then it is not necessary to make a cement mixture for styling, and bricks will be held by electrode hooks quite firmly.

The air passage in the flue chamber is regulated by the usual galvanized leaf flap.

Thus, constructed without any cash investments. Make it and put into operation can almost everyone.

How to make from one barrel

Use such a way of smoking indoors is categorically prohibited, it is better to install anchitka at the cottage outdoors.

Use such a way of smoking indoors is categorically prohibited, it is better to install anchitka at the cottage outdoors.

After determining with the location, create a drawing taking into account sizes and scale.

What tools are needed:

- metal or wooden barrel (more practical to take a metal barrel);

- shovel;

- bricks;

- metal sheets;

- bars for hanging products (depth);

- fabric for covering the filter;

- construction silicone (for the sealing of the barrel).

The manufacturing process is reduced to the following steps:

Profession of a specialist: The prerequisite is the tightness of the barrel, therefore the beginning and end of the chimney are wrapped up with the simplest cloth or seal by purchased silicone.

The cooking process starts with the ignition of sawdust at the bottom of the hearth. Then laid out already trained products (fish, meat, poultry).

What you need in order to build a smoking

Meat and fish cooked in homemade smokehouse, especially delicious, and it is worth it to be patient and make a simple homemade smoking hot smoking from the barrel.

Device of smoking barrel

Materials that will be needed for its device

- metal barrack with a capacity of 200 liters in which hazardous chemicals were not stored;

- armature (5-6 mm);

- steel rods for the grid;

- segments of a metal corner for a support device;

- metallic pipe segment 1 meter with a diameter of 10 cm for chimney;

- to clean the barrels, the soldering lamp will be needed, rags.

The main tool will be "Bulgarian" with a disk for cutting metal, electric drill, roulette, bolts. If smoking is decided using welding, you will need welding equipment.

Execution options

The number of projects available to implement is huge. You can select small portable products made from keg or wooden barrel. More overalls are grilled smokehouse on the frame. Stationary models are suitable for both hot and cold smoking and can differ significantly to their configuration. How to make a smoked smoked smoked smoked smoky and what design to choose for it - consider further.

Video: smoking barrel with her hands

Methods of smoked

To begin with, we will understand how different types of structures are different for the hot and cold method of processing products. If we consider smoke for a hot way, smoke enters the camera from under Niza, without passing an additional way. As a result, it is possible to maintain high air temperature. Products are smoked for everything for 2-3 hours.

To arrange a bokeh model of such a plan, you need to make a firebox on the bottom of the camera or under it. In the first case, it will be necessary to cut through the window to possibly throw the sawdust and ignition. In the second, it is enough to put a design over a separate furnace.

Important: The furnace can have a type of deepening in soil or laid out of a stationary miniature mangala brick. .

The principle of hot smoked method in the barrel

If a cold smoked smoked smoked smoked smoking is planned, you need to take care of the possibility of cooling smoke. Often, the chimney is equipped for this purpose, a few meters long. It comes out of the location of the furnace and is supplied directly to the camera itself. It can be an earthen trench, a pipe that comes from the stove, etc. With a lack of space for the installation of such equipment, you can apply forced cooling in a double chamber. To do this, the wet rag is suitable as a partition between compartments.

Constructive features for cold smoking

Tip: It is more profitable to build such a smokehouse, which can be used for hot, and for the cold method.

Models of structures

Consider the most common variants of the product design. You can select the following models:

- Mini-smoke Kega. For it, the used beer keg is suitable. The tube is added to it through which the smoke will come, and also cut the hole to install the lattice with products. An easier option is to install a barrel on the brazier.

- Vertical smokehouse from 200 liter barrel. Such a model is characterized by a large volume. For it, it is necessary to equip the base for installation and firebox, which will be located directly under the barrel.

It consists of two identical barrels interconnected by the pipes for which the smoke will climb. If you install a wet filter, the upper chamber is perfect for half-spurs. The main role of the lower section is the furnace.

- Double horizontal camera. It consists of two identical barrels interconnected by the pipes for which the smoke will climb. If you install a wet filter, the upper chamber is perfect for half-spurs. The main role of the lower section is the furnace.

Using two barrels

- Double welded model. Here, the connection of two barrels is made not parallel to each other, and at right angles. The design may have a L-shaped or T-shaped view. Below the heat is diverted and sawdust, and from above - products are placed.

- Stationary smokehouse with gluten in the ground. It is necessary to make a trench in advance, which will serve as a connecting channel between two departments. The furnace can be performed on the principle of a fire in the covered pit or separately equipped stove. The main chamber also deepens to the ground, where the trench is supplied to it. Smoke enters through a small hole in the barrel wall. To prevent the leakage of smoke and heat all the plots are recommended to put the brick.

- Cold-type mobile smokehouse. If there is no possibility or desire to boil the barrel, it can be equipped with a separate submission from the remote stove. A metal pipe connecting it with a furnace box is welded to the main chamber. You can also use a flexible hose and a smoke supercharger, which reduces the area occupied by the design.

Supplement of the main design with auxiliary elements

Trial launch

When ready to use, you can proceed to the first experiments. For cold smoking, you can take a scenery and a little pink salmon for a variety.

Clean the fish in the usual way: we choose the insides, cut off, wash the heads after the carcass and wet the dry towel. Separately prepare a dry salting. For this, there are 2-3 tablespoons of salt on each carcass, which add 1.5 teaspoons of sugar and a little ground black pepper. It is impossible to save on the salt, because in 24 hours the fish does not absorb it more than necessary. Upon its taste, you can use your favorite spices for dry peel, but it should be noted that cold smoking mackerel has a strong pleasant fragrance.

Other types of fish, in particular, pink salmon or keta are prepared for smoke in the same ways. The time of the dry question, if the rig is large, increase.