Heating systems for country and country houses. Boilers, geysers, water heaters - Repair, service, operation. Recommendations for assembly and installation. Junkers - geyser: instruction manual, reviews How to connect a geyser junkers

Why one article at once about the columns of two different brands Junkers and Bosch? At its core, the Junkers WR-11 and Bosch WR-10 speakers are the same speaker. They have slight differences in body and handles. For example, on Junkers columns you can find a tap, which is fixed on a water block and is sold together with the column. This is where the differences generally end. Inside the case is the same stuffing. Both columns are semi-automatic, they have proven themselves well for their simplicity, maintainability, and the price of new products. In Russia, they have been very popular for a long time. Repair of these geysers can be done with your own hands, using my step by step instructions disassembly.

How does this column work? In order to ignite it, you need to set the slider on the front panel to the middle position and press on it. Thus, we forcibly open the electromagnetic gas valve and supply gas to the igniter (wick) of the gas column. In order for the gas to ignite, it is necessary to ignite it with a piezoelectric element, which is located in the lower left corner of the gas column. After the spark has ignited the gas coming out of the wick (igniter), you must continue to hold the slider button pressed for 10 to 40 seconds. At this time, the column thermocouple warms up. Then we release the slider, while the wick should continue to burn without pressing. If this does not happen, then you need to repeat the whole procedure from the beginning. If the igniter does not light up, then most likely the column needs repair or maintenance, cleaning the wick (igniter). After the thermocouple has warmed up, it generates an EMF, which independently holds the electromagnetic gas valve of the column in the open position. The column is ready to go. It remains only to set the gas flow rate you need with the slider and the water flow rate on the water block.

What happens when you turn on the faucet hot water mixer? Further, everything is simple. The membrane of the water block presses on the stem, which in turn opens the mechanical gas valve, and gas is supplied to the main burner of the Bosch (Junkers) column. gas mixture ignites from a burning igniter wick and heats the water that flows through the gas column radiator.

1. Remove the handle from the water block, set the gas regulator slider to the middle position, unscrew the two self-tapping screws from the bottom of the column housing (on Junkers there may just be clip-latches) and remove the housing.

2. We unscrew the two self-tapping screws that fasten the cap of the exhaust device to the column body and two self-tapping screws on the bar attached to the cap, which fixes the radiator (heat exchanger) of the gas column.

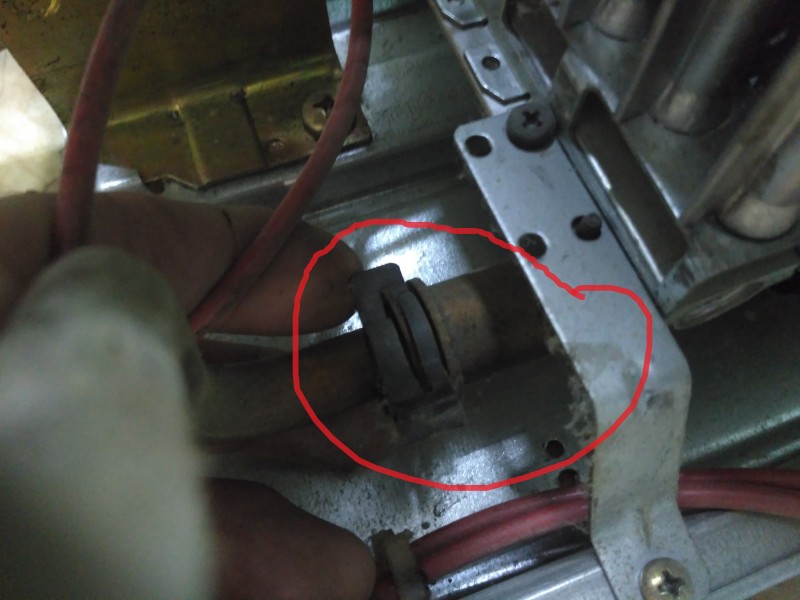

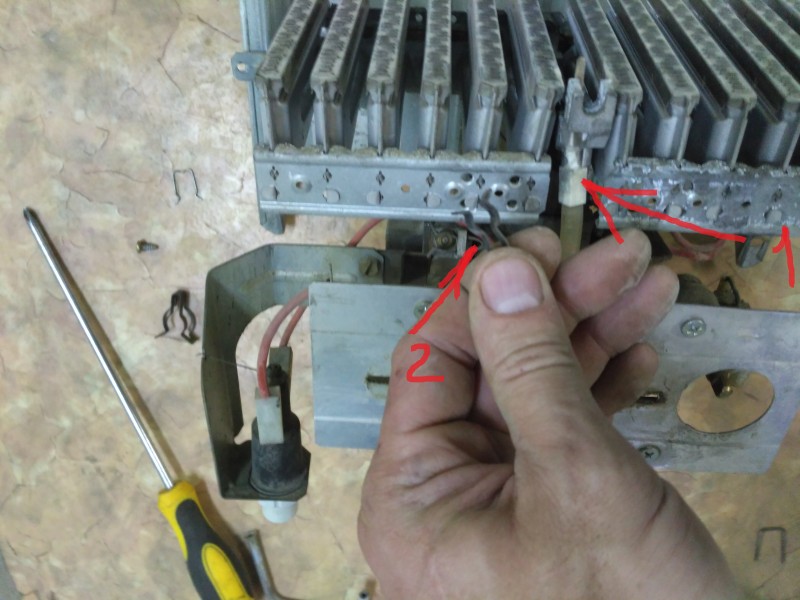

3. Remove the draft sensor 1 (it is located on the right side of the smoke exhaust hood), disconnect the wires from it. We remove the temperature sensor 2 from the heat exchanger by disconnecting the automation wires from it. Here, Junkers and Bosch have slight differences. At Bosch, the wires from the thrust sensor are removed, at Junkers they are soldered. Do not try to remove them - you will only break them.

4. Next, nothing prevents us from disconnecting the gas outlet cap from the heat exchanger (radiator) and the column housing.

5. To remove the heat exchanger, it is necessary to pull out the threaded branch pipe from the left branch pipe of the heat exchanger, having previously removed the latch. You can not remove the threaded pipe, but unscrew the hot water hose from it. From the right branch pipe of the heat exchanger, it is necessary to remove the tube that connects the heat exchanger to the water block of the gas column. It is also attached to the latch, after removing the latter it can be removed. Rubber rings are used as seals in both nozzles. They often leak after disassembly-assembly, because. rubber ages and dries out. You have to take it apart carefully. When assembling, I advise you to change the rubber bands, in any case, lubricate the pipes during assembly.

.jpg)

6. Nothing prevents us from removing the heat exchanger. Although ... Bosch has back wall The housings are stamped with two brackets for the heat exchanger. It is better to bend them up. They are not particularly needed and do not affect anything. After that, we remove the heat exchanger of the geyser up.

7. Disconnect the igniter tube from the burner. From above, it is attached with such a bracket (if it has not been thrown out before you) and in the area of \u200b\u200bthe jet it is attached in a latch. We pry off the tube with a screwdriver in the area of \u200b\u200bthe latch and remove it from the grooves at the top.

8. Behind the igniter tube is a ceramic ignition electrode. It also fastens with a quick-release latch and is easy to remove.

9. In order to remove the burner, we unscrew a pair of self-tapping screws that attach the burner to the gas column body, and a pair of screws that fix the burner in the gas column column. Next, gently press the screwdriver down on the thermocouple so that it comes out of the burner body. You can stagger to remove the burner up from the gas block.

10. To clean the burner, disassemble it into parts. To do this, we need to unscrew 4 screws. We separate the two parts of the burner from the gas train.

Actually, the disassembly of the column is completed. For maintenance (cleaning), this is quite enough. A gas block usually doesn't break if no one has climbed it. There is nothing to do there. This factory product. If necessary, another water block can be removed and disassembled to replace the diaphragm or stuffing box cover.

We carefully wipe the disassembled elements, wash them from dust, soot and other deposits.

Special attention to the heat exchanger. I wash it both outside and inside with chemistry or solution citric acid. She, by the way, eats away scale and rust from the inside. If the water is from a well, with increased hardness, then this simply needs to be done at every maintenance, because it overgrows from the inside so that the compressor then does not blow through. Scale and soot impair heat transfer, increase gas consumption, and can lead to heat exchanger failure. Burnt-out heat exchangers on these columns are rare, but clogged with soot are very common. Both the Bosch column and the Junkers at the same time begin to heat the water poorly. Usually all these "jambs" come up at the beginning of winter, when the water begins to flow through the pipes colder than in summer.

Dust accumulates in the burner, which enters the apparatus with air, and combustion products fall onto the gaps from above. In this column, the burner cannot be cleaned without disassembly, so drive all those who offer you to clean the column with a vacuum cleaner, these are freeloaders!

Thoroughly clean the thermocouple from carbon deposits and soot. I have not seen burnt thermocouples on these columns. It is better to wipe the insulator of the piezo ignition electrode from soot and dirt with alcohol so that it does not flash onto the body. Thoroughly blow out the igniter tube from dust. Most often, due to this dirt in the tube, the wick becomes weak, smokes, heats the thermocouple poorly, and the column may go out and not ignite. Clearing the tubing usually resolves the problem and the column wick lights up. Ideally, the pilot flame should be blue color and beat on the thermocouple horizontally. If the wick flame is yellow and with a large “tongue” goes up, the igniter clearly needs to be cleaned.

Now about the malfunctions of the columns Junkers (Junkers), Bosch (Bosh)

- As I wrote above, the column is assembled on rubber O-rings. In old columns, they become stiff, and the seals begin to leak. Well, if the master has them. Often you meet with different collective farm options from windings to sealants.

- The membrane of the water block, unlike the membranes of Chinese columns, works for a very long time. I met a torn membrane once. The price of the original membrane is about 1800 rubles, the Chinese analogue costs around 400 rubles. Who will find it. There is no sense in the original, because the prices are cosmic.

- The water block of the geyser assembly costs around 4500-5000 rubles. The price is high. for sale repair kits seals. You can sort out the water block yourself. Often a flow regulator flows at the block. It is treated by replacing the sealing ring.

- Rarely, but there is a leak in the stem seal of the water block. Alas, the seal cannot be replaced separately. Changes with the water block cover. The price of a cover with a stem is 2700 rubles. Very expensive!

- On Junkers (Junkers), the thrust sensor and the overheat sensor are often tormented. Sometimes they are so tormented that I change the entire set of thermocouples and sensors. If it was not part of the plans to change the automation, then the temperature sensor can be painlessly short-circuited (it is not available at all on many imported gas water heaters). I do not advise shorting the thrust sensor, a thing that is clearly necessary and has saved more than one life. It stops the gas supply to the column if the draft is lost in the chimney. It can be shorted out for a while so as not to sit without hot water, and only in order to quickly find a replacement for it.

If you decide to buy such a column, then read the reviews on the useful Otzovik website. There, each described his column and put marks. My review is old enough. http://otzovik.com/review_1713020.html

Now I would give a solid four to this column. I recommend buying. Usually everything is treated without spare parts. From the "minuses" of the column I will note big price for parts. Thankfully they don't break often.

If anyone is interested, I post the instructions here on geysers Bosch and Junkers

Bosch gas water heater manual /upload/file/quickdir/201104111631310.therm 4000 o type p.pdf

Instructions for the Junkers gas column /upload/file/quickdir/gazovaya_kolonka_bosch_junkers_wr10_13_15p_1.pdf

In short, I have everything. Climb into the column yourself, or call me, it's up to you.

I hope the article was of some use to you.

If you have taken care of the arrangement of your country house and installed a geyser - you have left last step on the way to a warm and comfortable life. And this step is setting up and properly turning on the column. To make the gas water heater work, you have to do a few simple steps. First make sure that the gas supply valve that supplies gas to the column is open. Then open the valve responsible for supplying water to the tank of the water heater. Switching on or ignition can be carried out in only three ways, which depend on design features columns.

Most old way ignition, provided by the manufacturers of geysers - manual. This method is already going down in history and is not used by manufacturers today. In the very first columns, the wick was set on fire with ordinary matches. To start such a column, first open the valve that shuts off the water supply, then open the valve that supplies gas to the wick. Light the wick and open the main gas supply valve. The main disadvantage of such columns was the absence of any protective mechanisms, for example, in the event of a sudden drop in water pressure in the column system, the ignition wick will still burn, and the column will continue to waste fuel. This ignition system is extremely simple, but it will require certain skills from you. It is highly undesirable to use such speakers at home. More modern system- piezo ignition. To ignite such a column, simply press the button responsible for setting fire to the wick located in the combustion chamber - the piezoelectric element will provide a spark that will ignite the wick. These speakers include Junkers WR 10-2 PВ, Bosch WR 10-2 P miniMAXX-2, Nevalux 5111 and others. They use the principle of converting mechanical action into a spark, the power of which is enough to set fire to the ignition wick. To ignite the main burner, open the main gas valve. If the regulator is returned to its original position or the water supply is cut off, the wick will still burn further. Like hand-ignited burners, these designs are considered too "gluttonous" due to excessive gas consumption. Thanks to the abundance of choice, today you can purchase a gas column of absolutely any modification. In order to increase sales and simplify the process of using the burner, some manufacturers, for example, Rihters, Ariston, Neva, have significantly improved the operation of their complexes. It was developed and then put into production completely automatic system burner ignition: both the pilot wick and the central burner are ignited automatically without human intervention. For this, a special turbine was installed, driven by a strong pressure of water. After starting the turbine, all the main functions that were previously performed manually are done in offline. The disadvantage of such systems is one - in many residential buildings, water is supplied at low pressure, which is not enough for the full functioning of the turbine. Activating such speakers and adjusting the water heating temperature can often be done using a conventional remote control.

Modern gas boilers absolutely safe, unlike their early predecessors. Most of the key processes associated with their proper operation are simplified and do not require the user to additional training. But despite this, do not forget that any gas apparatus is a source of potential danger.

The geyser is today considered one of the most popular tools for obtaining hot water. Such units are the most economical in their field. With the help of the device, it is possible to serve several water points at the same time, satisfying completely family needs. It is guided by the recommendations below that you should choose a specific model that will have the necessary characteristics.

If you are interested in the manufacturer of this company, you can purchase it at any store of the relevant goods at an affordable cost. However, you must follow the rules that will ensure safe operation equipment. Replacing the device is not a panacea for the troubles that arise during the operation of the device - Junkers say this is rarely the cause of dissatisfaction that arises from the quality of the device. If you want to get such a column that will serve for a long period of time, then you should be guided by the operating rules.

Maintenance, as well as installation of the device, should be carried out by professionals; do not trust these manipulations to people who do not have enough specialized knowledge. It is important to clean the heat exchanger and igniter from time to time, which acts as a fundamental factor in the correct and stable operation of the unit.

If you are interested in the manufacturer Junkers, the gas water heater from this supplier will surely please you with its quality characteristics. However, in order not to speed up the completion of the operation of the device, you should not experiment with very high heating temperatures of the coolant, as this can accelerate the process of deposits that form in the heat exchanger. If the system has sufficiently hard water, then it is recommended to supplement it with Antinakipin, which will extend the life of the column.

Feedback on the main benefits

Quite often today, consumers are interested in Junkers products. The geyser from this company is no exception. Such popularity of such devices is due to several factors. Among them, one can single out ease of operation, safety of work, efficiency, acceptable dimensions of equipment, as well as a very aesthetic appearance. The degree of its "voracity" is the main criterion for the efficiency of the device. The owners of such columns, who previously operated alternative heaters, emphasize that the devices described in the article are cheaper compared to electric heaters or models that run on other types of fuel. This is due to the fact that natural gas, which is used to heat water, is much cheaper compared to other energy sources. If you use such modern equipment, the savings can be even more impressive.

Feedback on the main functional characteristics

When visiting a store, quite often modern consumers are interested in Junkers brand products. The geyser of this company is an excellent example of this. You should read the opinions of users before visiting the store to purchase the device.

It is important to note that the column may have different types ignition. It is extremely rare to find a device on sale that is characterized by manual ignition, so it makes no sense to focus on its features. According to users, models that provide for piezo ignition are more convenient. In this case, a special button located on the panel is used. The required water temperature will be set by the regulator, which is located on top.

If you are interested in Junkers, the geyser, the instructions for use of which are described in the article, will keep burning constantly, which is true after turning on.

Reviews of models with electric ignition

As buyers emphasize, speakers that are equipped with electric ignition are the most reliable option. The spark is created by a battery or a turbine. This allows us to assert that gas will be spent even more economically. The only thing that consumers advise future owners of such speakers to pay attention to is the higher cost. However, you should be sure that the operation of such a model of equipment seems more convenient.

The Junkers company existed until 1932. From that moment on, the company was bought out by Bosch Gruppe, which, however, did not affect the name of the water heaters produced by the division of the main office.

The Junkers company existed until 1932. From that moment on, the company was bought out by Bosch Gruppe, which, however, did not affect the name of the water heaters produced by the division of the main office.

Flow-through geysers Junkers (Junkers) are available in several modifications that differ in the principle of ignition, as well as the type of combustion chamber. Flow-through boilers operating using an ignition burner are popular among domestic consumers. Average term service column Junkers exceeds 15 years.

Junkers speaker device

The Junkers brand is synonymous with quality and reliability throughout the world. Speakers are distinguished by a well-thought-out internal arrangement and design. Domestic consumers are offered water heaters of the following type:- semi-automatic The company began producing speakers back in 1968. During operation, an ignition burner is used. Ignition is carried out using a piezoelectric element. The main burner is switched on when the DHW tap is opened.

- Automatic - run on batteries or a hydrogenerator. The series includes simple Junkers geysers with open cam combustion, and multifunctional models with modulated power. The performance of the burner device varies depending on the water pressure.

In the internal structure of Junkers gas flow columns, only quality materials. All water heaters undergo mandatory testing and are subject to certification.

More information about technical specifications Junkers columns can be found in the following table:

Specifications | Junkers column model |

|||||

Power and water flow |

||||||

Max. nominal thermal power Pn (kW) | ||||||

Min. rated heat output Pmin (kW) | ||||||

Thermal power (adjustment range) (kW) | ||||||

Permissible gas supply pressure |

||||||

Natural gas H G20 (mbar) | ||||||

LPG (butane/propane) G30/G31 (mbar) | ||||||

Gas consumption |

||||||

Natural gas H G20 (m³/h) | ||||||

LPG (butane/propane) G30/G31 (kg/h) | ||||||

Number of nozzles | ||||||

Hot water |

||||||

Max. admissible pressure pw (bar) | ||||||

Water volume switch in extreme right position |

||||||

Temperature rise (°C) | ||||||

Flow range (l/min) | ||||||

Min. working pressure pwmin (bar) | ||||||

Water volume switch in extreme left position |

||||||

Temperature rise (°C) | ||||||

Flow range (l/min) | ||||||

Flue gas characteristics |

||||||

Required thrust (mbar) | ||||||

Flue gas mass flow (g/s) | ||||||

Temperature (°C) | ||||||

The marking of the water heater contains detailed information regarding the principle of operation and internal device. To understand the abbreviations will help the table with the decoding of the symbols:

- W - Geyser

- R - Power regulator

- 10 - Max. water consumption (l/min)

- –2 - Version 2

- P - Piezoelectric ignition

- B- Electronic system battery operated ignition (1.5 V)

- G - Electronic ignition system from a hydro generator

- 23 - Work designation number on natural gas H

- 31 - LPG designation number

- S.... - Country code

Installation of a Junkers flow boiler

The operating instructions provide detailed plan water heater connections. In particular, the following is stipulated:

Gas pressure adjustment table |

||||

| Natural gas H | Butane / Propane |

||

Injector identification number | for resetting to 20 mbar | |||

for resetting to 20 mbar | ||||

for resetting to 20 mbar | ||||

Connection pressure (mbar) | ||||

Max. nozzle pressure (mbar) | ||||

Min. nozzle pressure (mbar) | ||||

After connection instantaneous water heater in the passport a mark is put on commissioning. From this moment on, the Junkers column is put on warranty service.

How to light a Junkers gas flow column

The vast majority water heaters Junkers, offered to domestic buyers, operate in a semi-automatic mode. Ignition of a semi-automatic gas boiler is carried out as follows:- on the front panel of the water heater there is a valve that opens the gas supply;

- the button is clamped and the wick is set on fire with the help of a piezoelectric element;

- the gas valve is left clamped for another 20-30 seconds;

- now the button is released, the flame on the burner should continue to burn.

How to clean the Junkers column with your own hands

Any repair work gas-consuming equipment must be carried out by a specialist with an appropriate work permit. Cleaning the pilot burner and the heat exchanger is a job that must not be done by yourself. Service is carried out at your own risk.To clean the Junkers column at home, you will need to do the following:

- turn off the gas and water supply;

- remove the cover;

- disconnect the smoke inlet and water unit;

- pull out the heat exchanger.

Do-it-yourself repair of Junkers geysers leads to the manufacturer's refusal to provide warranty service for the equipment.

Junkers columns - malfunctions and methods for their elimination

German water heaters rarely fail. With regular maintenance, the likelihood of breakdowns is completely reduced to zero. The main malfunctions of the column are the attenuation of the wick and main burner, the failure of the membrane, the water unit. The described breakdowns are associated with poor quality of water and gas.A description of breakdowns and troubleshooting methods for Junkers geysers is given in the table:

Malfunction | elimination |

|

| Pilot burner blocked. | Clear. * |

| The gas supply is insufficient. |

|

The water temperature is too low. | Check the position of the power regulator and set to a higher power. |

|

The burner switches off while the appliance is in operation. |

|

|

Reduced water flow. |

|

|

* can only be done by a service and repair technician |

||

Geysers are installed in many apartments and private houses. They allow you to forget about problems with shutdowns and repair of water supply. On the other hand, they also have flaws and are prone to breakage. How to repair Junkers speakers with your own hands? In the article, we have analyzed the main methods.

Typical malfunctions of the Junkers geyser

The Junkers heater is more often subject to malfunctions that relate to ignition systems. Users complain that over time the wick or burner goes out, the device does not ignite, it does not heat the water well.

To determine the cause of the breakdown, you need to inspect the parts, check their performance. We will provide examples of common Junkers problems and how to fix them.

The equipment does not turn on, does not light up

Why it happens? The reasons may be hidden in external factors:

- Wrong water connection. Check the condition of pipes and connections. Open the instructions - make sure that the liner is done correctly, the water enters the system normally. Otherwise, the pressure in the line will be weak and will not allow the gas valve to be opened.

- no traction. The latest models are equipped with protective sensors. The principle of operation of the thrust sensor is to detect its presence. If there is no draft, the sensor sends a signal to the module - the column turns off. The main reason is a clogged chimney. Combustion products are not discharged normally, the burner goes out. Perhaps the room is poorly ventilated. It is necessary to clean the chimney or install a ventilation valve.

To check the draft, bring a burning match to the control window. The flame deviated - there is thrust, it burns evenly - no.

- A similar situation occurs when chimney outlet blocked. Look, maybe some object or a satellite dish on the roof is preventing the output of combustion products.

- Overheat. Scale deposits reduce the efficiency of heat transfer, which can cause the column to overheat. Then the sensor is triggered, and it turns off. Once a year, it is recommended to clean the heat exchanger from scale, as well as install cleaning filters. read the previous article.

- Sensitive Relay. It can be observed that the burner ignites, then the igniter goes out. Try lowering the room temperature by opening the windows, or replace the relay.

- . Electronic ignition equipment receives a spark from batteries. If the batteries are dead, you need to install new ones.

- Insufficient water pressure. Experts recommend choosing a column in accordance with the parameters of your system. If the appliance is too powerful and requires high pressure, you will have to install a pump or put a new one.

- An abundance of dust. If you have not dusted the parts, the flame in the burner may mow and not warm up the thermocouple. Cleaning is carried out with a brush or vacuum cleaner.

The wick goes out. Internal problems

What to do if the equipment stops working? Understand the causes of the problem.

- Faulty rubber membrane. Why is she needed? When you open the mixer, pressure builds up in the line, which acts on the membrane. Bending, she pushes the stem, and he opens the gas valve. If the membrane is damaged, stretched, the system malfunctions. Replace element. Read more about the repair in the article " ».

- Clogged mesh filter. It is located at the entrance to the water node. Clogged with small debris, pieces of scale, rust. Remove and rinse the part under running water, you can use a brush.

- Burner blockage in gas boiler . During combustion, soot and soot are deposited on the walls. If they are not removed in time, they clog the burner holes. Clean up.

- Microswitch failure. In the normal state, when ignited, a click is heard - the switch is activated. If you do not hear sounds, then check and change the element.

- Water valve not working. It is necessary to clean the parts from rust, lubricate.

- Wiring violation. Inspect the entire wiring loop, replace damaged parts.

- Contacts broken. Tightening and cleaning of contact groups is carried out.

Other causes of such problems:

- The gas supply valve is closed.

- The piezo ignition does not work, or little time pressing it (you need to hold it for 10-20 seconds).

- Mixing of flows when a cold faucet is opened more than a hot one. The pressure decreases and the wick goes out.

- The gas sensor has failed. Need a replacement.

What are the factors that cause equipment failure?

- Poor ventilation. There is not enough oxygen to keep the flame burning. Check ventilation for obstruction. If you have plastic windows, the installation of a valve for ventilation will help.

- Mixing streams.

- Late maintenance of equipment.

- When connected, long hoses are involved, which reduces pressure.

When to Call the Master

If you notice such problems, it is better to contact the service. But before that, you must make sure that it breaks:

- The sensor of draft, overheating, flame is constantly triggered.

- The column is clogged.

Often the pipe that is responsible for the gas supply is clogged. How to clean it:

- Remove the temperature control knob.

- Remove the cover of the device.

- There are clips on top of the pipe. Unfasten them.

- Take out the pipe, clean it, wash it under the tap.

- Dry and install the part in place.

- Test the technology. While holding the power control, press the piezo ignition button. Hold for 10 seconds.

If all else fails, it is better to contact the master to replace the sensors. Many reasons for the attenuation of the Junkers heater can be eliminated with your own hands. If you connect the device correctly, monitor its cleanliness and serviceability, such problems will not arise.

Actions of the lender if the debt is not returned

Actions of the lender if the debt is not returned Why did Lera Kudryavtseva and Sergey Lazarev break up?

Why did Lera Kudryavtseva and Sergey Lazarev break up? IQ test result: what do the scores mean?

IQ test result: what do the scores mean?