Carved patterns on the windows. Wooden architecture in drawing lessons in elementary grades. Master class with a photo. How to make window trims - choice of material

The facade is the face of the house, and the windows, the most significant objects, are its eyes. So they demand an appropriate attitude towards themselves. Close attention is paid to the decoration of windows with platbands even with a slight use of house carving elements, because it is the platbands that give the building a special look, completeness and attractiveness. Thus, if we are talking about houses in the private sector, then, of course, window frames are indispensable.

The purpose of the window casing

The word "platband" is found in the description of houses in Russia, which dates back to the 15-18 centuries. Today little is said about platbands, but they still remain an integral element of the window from the side of the facade and the entire building, regardless of what material the house is built from and what kind of finish it has. An exception may be multi-storey buildings made of concrete or brick, the windows of which are recessed from the outside into the wall, as well as houses with glazing replacing the windows.

In essence, the platbands are a frame made of boards, 30 - 40 millimeters thick, which frame the window. However, window frames are not just a decorative element of design: they are necessary to close the gap between the window frame and the wall, so that heat does not escape outside, and precipitation and dust do not enter the house, as well as to reduce the level of noise coming from the street. If necessary, the platbands act as a frame for shutters.

If we classify window platbands by shape, then figured, flat and rounded platbands, as well as platbands with a convex surface, are distinguished. The most inexpensive and easy-to-install flat trims. Platbands that have a convex surface are made using special equipment, so the price of platbands for windows of this type is higher. And the most expensive ones are carved platbands.

According to the method of installation, two groups of platbands are distinguished: telescopic, which have special projections that fit into the grooves on the box, and overhead platbands. When choosing the profile of the casing, it is imperative to take into account the slope, which is in the upper part of the casing and allows snow and rain at the top not to accumulate, but to flow down. The most popular at present are carved platbands in shape, and plastic in terms of material.

Material for window frames

Facade design requires more than just an aesthetic profile from a casing. The frame for the window must be resistant to changes in outdoor temperature. If we talk about the climatic conditions of the middle zone of our country, then the facade elements can heat up to plus 50 degrees in summer, and cool to minus 35 degrees in winter. The total difference between the temperatures to which these elements on the facade are exposed reaches 85 degrees. Therefore, the material from which the platbands are made must withstand such temperature fluctuations, as well as snow, wind and rain.

Remember that the material should not crack or crumble. In this case, MDF and plywood become unpromising for the manufacture of facade elements. We all know that derived materials from wood, after being installed on the facade, absorb water, crack when moisture freezes inside, dry out, then paint will peel off, and after a few years such platbands have to be changed.

Therefore, MDF platbands are used mainly inside a house or apartment. The material is characterized by ease of processing and relative cheapness. In addition, such a product can be made in a short time. Well, if you decide to use such platbands for the facade, they need to be regularly treated with varnishes and adhesives to protect against moisture and preserve color.

The upper part of the window casing is decorated with a "kokoshnik", where it has long been customary to depict the Sun. The upper part, if necessary, can be extended by connecting the component parts with spikes. The lower one is called "towels", it must have a drainage bevel for the water drain. The bottom bar should be 10 millimeters thicker than the top bar. The drawing of the lower part stylistically should coincide with the image on the "kokoshnik".

To prevent cracking of the thread over time, it is better to place the elements along the wood fibers, this is true, first of all, for conifers. Thin ends and fishnet folds are usually short-lived. The simplest cut is a round hole that is drilled with a drill.

Therefore, it is preferable to choose patterns that contain many round holes. Most often, the pattern for a carved window casing is a one-piece ornament that includes repeating details. Each such repeating element consists of several round and semicircular holes, as well as complex cutouts.

Stretch the selected ornament along its entire length. To do this, draw a picture on paper in a 1: 1 ratio, you can also print it on a printer. Mark the areas where the cuts are to be made with a separate color. Stick the drawing on a piece of wood. With the help of a drill, round holes are drilled, giving them the required diameter. Wherever jigsaw work is needed, drill small holes better.

Manufacturing of carved platbands

Naturally, all windows of a residential building should be decorated with the same platbands. Sizes, shapes and patterns must match. Platbands on the windows of a wooden house are made in the form of a solid frame, consisting of several well-connected parts. When processing, special care is not required, but reliable protection from atmospheric agents is needed. To do this, treat the wood with different impregnations and paint with a compound intended for outdoor use.

If the window will open outward, the platband should be placed 30 millimeters above its sashes. When making platbands, keep in mind that they should not interfere with windows opening at an angle of at least 90 degrees. The rest of the parameters will depend on the size of the windows themselves.

It is recommended to make platbands as follows. It is necessary to plan dry boards that are up to 30 millimeters thick and 75-150 millimeters wide, from all sides. Window frames should be 25-50 millimeters wider than the box. On the reverse side of the casing, you need to choose a groove or gap, which has a depth of no more than 2 millimeters, which should not reach the edges by about 10-15 millimeters. In this case, the platbands will adhere more tightly to the walls and boxes.

When working with an electric tool, it is not worth "helping" him, that is, it is not recommended to make great efforts in the hope that things will go faster. Excessive pressure on the file causes it to overheat and creates a risk of breakage. If the wood is difficult to cut, it may be due to a dull edge. In this case, the file must be replaced. Use a wide blade to create long, straight cuts. If you have to work with plastic or metal, you should stock up on machine oil or at least water so that you have something to lubricate the file.

Connection of platband parts

In the process of manufacturing a window casing, the parts are connected using a single deaf or through thorn. It is preferable to use a dull spike, in this situation it is not necessary to close the junction of the parts with a decorative element. There is no need to buy a special machine for making thorns, you can do it manually using an electric drill, chisel and hacksaw.

To get a socket for the thorns, drill several holes that have a depth that exceeds the length of the thorn itself by a couple of millimeters, and then remove the baffles. The holes must be made with wood drills, and the partitions must be removed with a metal drill. You can work on the edges with a sharp knife or chisel. According to the scheme of the casing on the window, the spike should fit into the socket tightly, but without much effort.

The spikes are fixed with pins, which are made of dry hard wood (birch or larch). It is not advisable to use glue to connect the parts of the window trim for several reasons, one of which is a significant temperature drop in the air, exposure to chemicals and moisture that are contained in the atmosphere. No glue can withstand such a "load". In addition, lateral loads do not affect the frame of the casing, which is rigidly fixed to the window block.

Window platband decoration

From the front side of the window platbands, you need to select moulders of a certain size and shape. Having cut out the corresponding workpiece, it is necessary to cut it into pieces. In order for the platband to completely cover the unevenness of the wall, slats must be nailed on both sides, the thickness of which is equal to the width of the slot.

It is recommended to complete the manufacture of platbands on windows with your own hands by processing the cut out elements. It is customary to process the edges with sandpaper for grinding. Platbands are painted or varnished. Individual elements must be attached to the base with glue or nails. To highlight certain patterns, you can contrast them in contrast to the rest of the color.

Carved platbands are in themselves a decorative element, however, in addition to carving, you can decorate them with painting. But remember, it should be combined with carved patterns, emphasize them. Wood firing is also used: beautiful tanning looks very impressive. This can be done by using a gas burner or blowtorch.

On the other hand, the decor on the casing should match the overall design of the facade of the house, in harmony with other finishing elements. Window frames made of wood can be complemented by shutters that are decorated in a similar way.

Installation of platbands on windows

Platbands are put in place without glue, on nails. They use nails that are 75 millimeters long, drive in approximately 400-500 millimeters from each other, sinking the caps into the wood. It is customary to fix window platbands close to the front side of the window box, or retreating from it 5-20 millimeters, depending on where the sashes open.

At window openings, the platbands should adjoin closely to the window sill board. This will allow you to put bedside tables - thick pieces of boards that are smoothly planed, without kalevos. The bedside table is necessary to protect the bottom of the platbands from rapid wear.

After installing the platband, the wood must be treated with a special compound, which protects the material from sunlight and moisture. In addition, you need to cover them with paint or varnish for external use. Renew such a coating periodically, then the platbands will serve for a long time, and the facade will look original!

On multi-storey buildings, you can rarely see wooden platbands, but in private construction this is the most common element. A modern private house can be made original and stylish by installing homemade carved frames on the windows. In the old days, unique patterned platbands were installed on each house, which were not only decorations, but also served as amulets. Today in Russia there is a tendency to revive traditions, and many owners prefer to put a beautiful wooden cashing instead of "boring" metal-plastic frames. In this article, we will tell you in detail how to make a carved platband with your own hands.

Modern platbands are made not only from wood, but also from metal, plywood, PVC and laminated MDF. Plywood and MDF products are not intended for outdoor use, since they are not able to withstand temperature extremes, humidity and exposure to ultraviolet radiation.

Useful: the correct name for the external elements of the window trim is cashing, and the casing is called the inner framing.

What are the functions of cashing:

- decorative - window openings acquire a complete and aesthetic appearance. Correctly selected form of platband is capable of visually stretching a low building or expanding a narrow one;

- with the help of a well-chosen pattern or ornament on the platband, you can express individual preferences, traditional features of a family or region;

- platbands help to unite all buildings on the territory into a single architectural style;

- cashing performs a protective function, preventing moisture, litter and dust from getting into the gap between the wall and the window;

- due to the additional wooden frame of the window, heat loss is reduced at the points of junction of the window frames with the walls;

- sound insulation increases;

- often wooden platbands are the only acceptable way to decorate a window, especially when it comes to a wooden house or frame.

The platbands have no drawbacks as such, but there are a number of features that you need to know in order to install them correctly and extend their service life. So, wooden carved platbands will sooner or later deteriorate from the influence of the external environment - after all, wood does not last forever and eventually collapses from moisture, frost and sunlight. But at the same time, treatment with anti-corrosion compounds will extend the "life" of beautiful homemade structures.

It is very important to choose the right type of wood for the manufacture of platbands, as well as to process all areas with high quality. It is necessary to regularly monitor their condition, timely replace damaged parts, tint the surface, etc.

If you plan to install wooden casing on plastic windows, you need to carefully choose the pattern and color, otherwise such a design will look ridiculous. But often wood and plastic are simply incompatible. It is better to install wooden double-glazed windows, wood-like lamination or paint the platband itself white.

Types of platbands

To make carved window frames, you need to decide on the installation method and the type of the structure itself. So, there are telescopic and overhead platbands. Telescopic ones are often installed not on windows, but on doorways. Special L-shaped projections are made on them, which slide into the grooves of the box. This is a rather complex connection, but the result is a very nice and harmonious framing of the passage.

Overhead platbands are attached to window frames using weather-resistant wood glue or nailed. Very often, the cashing is complemented by carved shutters, which make the facade of the house even more picturesque and authentic.

Choice of wood

Since the encashment is placed outside the house, it must be made of the strongest and most durable wood to withstand the effects of the environment. For the manufacture of carved platbands, the material must also be pliable so that intricate patterns can be easily cut out.

What to make a platband:

- Hardwood hardwoods - ash, beech and oak. They are very strong and durable, however, it is impossible to make "lace" platbands from such a tree, since they are very difficult to process. Choosing these breeds, it is better to limit yourself to simple ornaments.

- Softwood hardwoods - aspen, linden, alder. In this case, the tree, on the contrary, is very pliable and allows you to carve unimaginable motives, but if improperly processed, all your work will deteriorate very quickly. If the finished platband is poorly coated with moisture-resistant varnish, it will crack and rot very quickly.

- Birch and pine are the best options for making carved platbands. In addition to the fact that these rocks are inexpensive, they have sufficient hardness for external use, allow you to realize rather small patterns and make neat cuts.

- Apple and cherry are mainly used for cutting small inserts, which are then applied to the main pattern of the canvas.

Choosing a template

To choose a template for a carved window frame, you need to determine what you want to achieve or demonstrate with this pattern. If you just need to "revitalize" the facade, you can choose a not too complicated pattern, especially if you need to make cashing for windows in all buildings on the site. This will save you time and effort.

If you want to emphasize with the help of carved platbands belonging to an ancient family or any nationality, to reflect the cultural heritage of your homeland, we recommend that you study traditional motives and symbols. Moreover, each region, moreover, each village or city may have its own distinctive features.

If possible, arrange all windows with the same platbands. The threads may differ slightly, but the same motifs must be present. For example, on the kitchen window there is a platband with a deer framed with flowers, a bear surrounded by the same flowers can flaunt on the window in the living room, etc.

Below we will show several examples of patterns of carved platbands, but in order not to repeat someone's work, you can copy only part of the drawing, supplementing it with your own patterns. This way you can be sure that your windows have a unique frame.

Useful: if you are dealing with wood carving for the first time, practice first on a separate piece of wood of the same species from which the platbands will be made. Hone your hand positioning skills, basic movements and cuts. Video tutorials and tutorials for beginner woodcarvers will help you do it quickly and correctly.

The easiest way to make patterns with round holes, because they are fairly easy to drill even for a beginner. If you want the platband to last as long as possible, give preference to templates with large elements, moreover, they are easier to cut. Small parts will require much more time and skills, and will become unusable earlier, since moisture and small debris will accumulate in them faster.

Important: in the upper part of each platband, it is imperative to make a slope so that snow and water do not accumulate on the surface of the tree. Just a few degrees of incline, and moisture will quickly drain down, and the surface will dry out faster.

Platband making

The laudable desire to do everything with your own hands requires not only knowledge and skills, but also special tools. In the case of woodworking, you will need a large set of chisels, a hacksaw, sandpaper of various grain sizes, a router bit, a drill, and a jigsaw. In addition, stock up on impregnation to protect the wood from insects, weather-resistant varnish or paint, stain, if you will tint the wood.

To make the same pattern on the trims for all windows, prepare a stencil. It is better to cut it on thick paper, cardboard or plastic.

Important: place the stencil pattern along the grain of the wood so that the thread does not crack, and place the places where you need to make through holes with colored dots.

There are two ways of carving:

Step-by-step instructions for making a carved wooden platband:

- Take measurements from the window.

- The wood for platbands must be thoroughly dried. The height and width of the boards can be any, depending on your preferences, but the thickness should be 3 cm for the slotted carving method, from 1 cm or more for the laid on.

- Sand the wood with sandpaper (first No. 3, then No. 1 and zero) - the surface should be perfectly flat and smooth.

- Cut out stencils.

- On the back of the casing, select a layer of wood up to 2 mm thick, leaving small edges at the edges. So the cashing will fit more tightly to the window frame.

- Draw the pattern onto the front wood surface with a simple pencil. Paint over the places where the through-slots will be.

- Start cutting out the pattern. At first, it is more convenient to do away with the through holes, and then get to work with the chisels. Use different sized drills, a jigsaw, and a router for through cuts. Make the point of entry of the jigsaw with a drill - this way the cut will be more accurate.

- Grind all holes thoroughly with sandpaper (from coarse to finer grain).

- Remove all dust from blind patterns with a brush or vacuum cleaner.

- Nail the elements of the overlaid thread to the canvas with nails without hats. For a more secure hold, apply weather-resistant adhesive to the back of the element.

- Wipe the cut out trim with a damp, clean cloth to completely remove dust from the surface. The rag should be barely damp so that the wood fibers do not rise.

- Now you can tint the platband with wood stain or immediately cover it with weather-resistant varnish. Alkyd or Yacht varnish is suitable for this - they will reliably protect the wood from burnout and moisture.

Platband installation

The durability of the cashing depends not only on the correct processing of the carved elements, but also on the correct installation of it on the windows. For this, two types of fastening are used: a deaf or through thorn. With the method, a deaf thorn in the casing is fastened with thorns, and voids of the corresponding shape are drilled in the window profile. Weatherproof glue is applied to the spike and inserted into the hole. This is a rather complex mount, but very durable and neat.

To make a through fastening, install the spike in the most inconspicuous place of the casing and perform fastening. This method is less reliable and durable, but it is much easier to implement it.

However, it should be borne in mind that these fastening methods can only be used for wooden windows. To fix the carved platbands on plastic or metal-plastic windows, use special high-strength glue or liquid nails so as not to violate the integrity of the profile.

At the very beginning of the article, we mentioned that earlier, carved wooden platbands were used not only as protection and decoration of the house, but also as protective amulets for residents. The application of certain symbols and ornaments protected the family and created a barrier to evil intentions and black witchcraft.

In the old days, our ancestors believed that evil power penetrates into the house precisely through doorways and windows, so they tried to protect these places by all possible methods. The most widespread and "reliable" way to protect homes was to apply magical patterns.

Even today, most of the templates for platbands posted on the Internet can be found with these protective symbols, but now they play more of a decorative role. If you want to make not only an aesthetic, but also a useful element on the windows, you can combine various security symbols with decorative elements. It should be borne in mind that each country (region, village) has its own traditions. So, for example, it was customary for the Scandinavians to apply runes, and for the Slavs, a subject image (animals, plants, birds) is characteristic.

Images on platbands helped not only protect houses from evil spirits, but also strengthen or develop certain qualities in a person. So, floral ornaments have always meant unity with nature and love before Mother Earth. Wings meant strength of mind, and the bird fully personified the unity of times. The snake symbolizes wisdom, and the cross said that the owners of the house strive to maintain harmony between the spiritual and material world.

Carved platbands: photo

![]()

Since ancient times, the main decoration of wooden architecture has been the decoration of the facade of the house with various patterns and whole drawings carved from wood. Window frames made by hand by folk craftsmen and craftsmen have always been the central element of the house's exterior decor.

This is how home-made carved platbands look.Anyone can try to revive the old practice of woodcarving and make platbands for windows with their own hands, if they are not afraid of joinery. The joy of the creative process and contemplation of the result of their labors will undoubtedly bring satisfaction to the creator.

Advantages and purposes of window frames

Window casing is a structural element designed to close the gap between the opening and the window frame.

Thanks to the platbands, it is provided:

- uniqueness and originality of the facade;

- aesthetics and completeness of the exterior;

- the noise level is reduced;

- protection against penetration of precipitation, cold and wind;

- the safety of the insulation between the frame and the opening.

Old technology for making platbands

In the old days, it was believed that carved platbands protect the house and its owners from the evil eye and evil spirits.

Exterior and decoration of the house with carved platbands

Exterior and decoration of the house with carved platbands

Each pattern and ornament was created not only as a decoration, but also as a talisman. In the upper part of the window, most often there were symbols of the sun or a cross. Plant motifs show the desire for unity with nature. Carved curls and waves are signs of water, giving life and fertility. Snakes, birds and other animals also had their own symbolic meaning.

Significance was given not only to carved signs, but also to the properties of wood. The species of wood, the place and conditions in which it grew, were also certainly taken into account by the craftsmen. For example, the trees that grew at the crossroads were never used to build houses or make any items. Ornaments and techniques for making carved platbands in each region and even in each village were unique and unique.

The following types of wood carving are distinguished:

A variant of the pattern of a homemade casing for a window

A variant of the pattern of a homemade casing for a window

Wood species for carved platbands

Different types of wood are used for carving. Their difference lies in density, hardness, fiber structure, color, pattern.

The most pliable and convenient for carving is considered to be hardwood - linden, aspen, alder. Do-it-yourself carved window frames are the easiest to make from linden. It is very easy to cut, but you need to be careful not to ruin the workpiece with an awkward movement.

Carved aspen platband Linden wood is pure light with a uniform, almost invisible texture. Soft woods also have disadvantages: their loose structure absorbs moisture very well, although this problem is solved by applying impregnations, varnishing or paint.

Carved aspen platband Linden wood is pure light with a uniform, almost invisible texture. Soft woods also have disadvantages: their loose structure absorbs moisture very well, although this problem is solved by applying impregnations, varnishing or paint.

Pine is the most common and affordable lumber, it has good performance properties, a clear, beautiful wood pattern.

Platbands made of hardwood (oak, larch, beech, boxwood, walnut) are very durable, but they are expensive and require more effort and time to process. The manufacture of such platbands will be justified in the following cases:

- the region is characterized by strong temperature fluctuations;

- in very dry air;

- for climates with high humidity.

For small elements made using the applied carving technique, you can use fruit tree varieties, such as cherry, apple, pear.

Patterns for carved platbands - creating a template

To make it symmetrical and the same on all windows, it is necessary. Creating a template for a decorative platband will not be difficult, it is more difficult to decide on the variety of drawings and ornaments presented on specialized sites and stores.

Patterns of patterns for carved platbands For those who are engaged in carving for the first time, do not choose complex patterns. A large ornament without too small and pretentious details is what a beginner needs. Ready-made templates can be copied completely or come up with something new based on individual parts and their combinations.

Patterns of patterns for carved platbands For those who are engaged in carving for the first time, do not choose complex patterns. A large ornament without too small and pretentious details is what a beginner needs. Ready-made templates can be copied completely or come up with something new based on individual parts and their combinations.

You can make templates yourself in several ways:

- Processing with a graphical editor. You can create a finished image of the desired scale using Photoshop.

- Print or make a photocopy. The selected pattern is enlarged to the desired size and printed on the printer.

- Manual method. Manual transfer of the picture to the template using linear scaling.

Best done on cardboard or heavy paper.  For all the elements of the ornament, our own template is made in full size.

For all the elements of the ornament, our own template is made in full size.

You can transfer the pattern from the template to the wooden base as follows:

- Cut out the stencil with scissors, and, attaching it to a wooden board, trace the contours with a pencil.

- Contour the drawing with carbon paper.

- If there is no carbon paper, the print of the design can be transferred to the wood by pressing firmly on the handle. A faint trace will remain, which is outlined with a pencil for clarity.

- Drawing on a wooden board should be placed across the fibers, this will save the carved elements from cracking.

- Slotted areas on the workpiece can be painted over with a pencil.

When it comes to window frames, the first thing that pops up in my memory is a wooden house in the village with my grandmother with carved window frames on the facades.

Memories dear to my heart. From time immemorial, Russian wooden architecture was famous for a variety of decorative wood carvings on the facades of buildings, and later on window frames.

Each region (province, uyezd) had its own masters with their own style, which differed from the masters of the neighboring town.

"Platband" - "on the face", decoration and functional part of the window on the facade of the building.

Today, lovers and connoisseurs of Russian architecture, enthusiasts who are not indifferent to the history of Russian architecture, traveling across the regions of Russia, photograph windows with various trims (preserved or in a dilapidated state) so that their descendants could see them. On the Internet you can find the sites of these people.

What is window trim? First of all, it is still a structural element of the window, closing the gap between the opening and the window frame, preventing dust from entering the room, protecting it from precipitation, noise, and drafts.

But in the old days it was still a protection from the evil eye, magic spells of the pagans were encrypted in bizarre patterns, charms in the form of various figures, only they were applied to the valances, moorings, and later on the window frames. Patterns were passed down from generation to generation, repeated in embroidery on towels, clothes, new designs were invented.

Today, the platband has become more of a function of protecting living quarters from external atmospheric influences and decorating facades. But the craftsmen still put love and knowledge into the creation of the casing, relying on the experience of their ancestors.

Looking at any window you like, framed by a platband, you involuntarily compare it with the face of a Russian woman of past centuries. Even the upper decoration of the window is named in the same way as the female headdress - "kokoshnik". The peasant woman had a more modest dress, and the noblewoman had a more refined kokoshnik, richly decorated with stones and embroidery.

The same thing happened with the windows: various - simple and complex shapes, with rich carvings or very modest shapes. The lower part of the window was decorated with a "towel", like a towel with bread and salt in women's hands.

Platbands were made from tree species resistant to weathering and temperature extremes... Larch is the least susceptible to rotting, but this breed is not suitable for making carved openwork overlays, since it is fragile enough. But linden is an excellent material for openwork decor, soft, pliable, but requires special impregnation and processing, as it easily absorbs moisture.

Oak wood is the most resistant to all atmospheric influences and temperature extremes, but it is difficult to process. But after working hard on this material, you will get a durable product that will be admired not only by your children, but also by your grandchildren.

Currently, platbands are made made of wood, composite materials - laminated MDF or plywood, PVC, polyurethane and metal (aluminum, steel).

Wooden platbands the most environmentally friendly, elegant - an excellent decoration of a log house, but less durable. However, with proper care, they will last long enough. Periodically, the platband must be treated with a fresh layer of waterproof varnish or paint.

MDF platbands – This is a slab veneered with various types of wood, decorativeness lies in the color of a particular species.

Plastic platbands are made of PVC, are not subject to decay, more often they are installed on plastic windows. They have a wide range of colors and are UV resistant. The color of the platband can be matched to the color of the plaster or siding with which the house is sheathed, or set in contrast to the facades.

Polyurethane platbands lightweight and unpretentious in operation. Round-shaped windows can be framed with such a product, which is difficult to make from other materials.

Metal platbands or cover plates installed to protect the assembly seam from the inside or outside of a window or door, connecting it to the profile box into a single whole.

According to the method of installation, platbands are overhead and telescopic. The telescopic platband has an L-shape, made of wood, veneered with MDF, a modern type of platbands. Its advantages lie in the method of installation - there are no traces of fasteners (nails, screws), it fits tightly into the grooves of the window frame.

The platband installed on the window will become not only a functional finishing element, but also a decorative component of your facade. Simple rectangular, carved or curved arched window covers can be purchased from manufacturers, or you can make platbands yourself. But hand-made products will become the hallmark of your home and increase your self-esteem.

Making and installing window frames with your own hands

It is possible to make templates for platbands and platbands themselves. Possessing any computer program for drawing, you can make and calculate any template, select a scale and print it on plain A4 paper. At the same time, it is not necessary to have any artistic skills, it is enough to find and load the photo of a window with a pattern or a fragment of a drawing you like into the program and circle it, changing or copying with accuracy, and then rescaling the scheme to fit your window sizes.

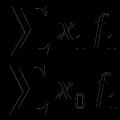

If you have several standard sizes of windows, then it is recommended to perform a scheme with an intermediate rapport, which can be repeated as many times as necessary. The diagram below shows how to do this.

The rapport can be repeated from the same elements or two fragments located alternately.

You can fix it with nails, screws or special synthetic glue. The horizontal and vertical parts are often joined together at an angle of 45 o, after having made the cuts with a hacksaw using a miter box.

There are several ways to make wooden platbands.

The first method is a slotted casing - perhaps the most decorative and delicate. A platband made of light wood tones or painted with white paint on a darker background of the facade looks very refined and sophisticated, like Vologda lace. There is something mysterious and fabulous in such a casing.

The next manufacturing method is a laid on thread. Individual cut-out elements are superimposed (nailed or glued) onto a solid board. The feeling of a three-dimensional pattern is created. Thus, you can decorate a simple platband.

The protruding part of the pattern is often painted in a contrasting color or shade. You can combine both threads in one product.

Existing, but already dilapidated platbands can be repaired by removing old elements that cannot be restored by replacing them with new ones. Clean old paint and paint with a fresh coat of moisture resistant wood paint or varnish.

Useful video

All windows are always equipped with platbands. They are not only a beautiful addition to the window, but also perform a number of protective functions, both for the room and for cleaning the window frame.

Platbands for windows in a wooden house are a versatile attribute that protects the house from dust and improves insulating properties. Therefore, they are essential for installation in any wooden house.

Platband function

Many people perceive the platband as part of the decor for the window frame. And indeed it is. It gives a finished look to the window opening and hides leaks between the frame and the wall of the house. This is the protective function of the platbands.

Platbands give a finished look to the window

Functions of platbands:

- Minimization of heat energy losses to the environment;

- Reduction of drafts;

- Dust protection and sound insulation;

- Moisture protection

Platbands on the windows will protect the house from dust and moisture

In ancient times, platbands served to decorate a dwelling and were a kind of amulet. They were carved with patterns that symbolized protective creatures, and they were also decorated with bright colors.

Carved platbands on windows in a wooden house

Platbands for windows in a wooden house are very important, since over time the tree undergoes deformation, dries out, and the gaps between the wall and the window can increase. It is the installation of platbands that will help reduce the activity of the deformation process, as well as minimize the consequences of existing gaps.

Varieties of platbands

For the design of window openings in wooden houses, several types of platbands are used. Basically, they are similar in design and differ in the materials used. All types of platbands are distinguished by the method of their installation and there are 2 main types:

1.platbands of the overhead type;

Overhead platbands on windows in a wooden house

2. telescopic platbands

Telescopic platband for windows in a wooden house

The first type of platbands has been used for a long time and is the most common. It is very easy to install such a platband. It is enough to fix it on top of the frame. The platband fixed in this way protects the room from the penetration of sunlight, dust and moisture.

Installation of overhead platband

Telescopic platbands are modern. This type of platband is placed in the space between the window frame and the wall. For fastening the platbands, you do not need additional fasteners such as screws or bolts. In connection with this method of its placement, the platband is reliably fixed along the width and height of the window.

Installation of telescopic casing

It is better to use telescopic platbands in wooden houses. They are very convenient and reliably protect the room and prevent the deformation of window frames. The main problem of its installation is that for its installation it is necessary to remove the frame, and in wooden houses it is quite difficult to do this. Therefore, many experts recommend installing overhead platbands that are easy to mount.

Materials used for the manufacture of platbands

Platbands for windows in a wooden house can be made of various materials. In most cases, wood is used. It is the wooden platbands that are in perfect harmony with the walls made of that material.

Carved wooden platbands on the windows

But it is possible to use the following materials:

- wood;

Wooden platband

- plastic;

Plastic platband

MDF platbands for windows

Platbands made of wood

Platbands made of natural wood are very practical and can be used in any interior. Such platbands can perfectly complement the style of the house with an interesting detail and emphasize its individuality. On wood platbands, you can apply a beautiful ornament or pattern.

Platband made of natural wood for the window

Designer's advice: To make the platbands and walls of the house look harmonious, it is better to use one type of wood. With the same texture, you can give the platbands a different color with special paints or compositions.

Wooden platbands fell in love with designers because of the possibility of diversifying their shape or applying decorative reliefs. Platbands made of other materials are difficult to process.

Platbands made of wood can be given any shape

Despite all the advantages of wooden platbands, there are still several disadvantages in their use. Wood is quite susceptible to temperature extremes and high humidity. At low temperatures, its deformation and structural change are possible.

Plastic platbands

You can find windows in wooden houses that have plastic frames. This material is practical and convenient, both in operation and in manufacturing. Platbands made of plastic can have any shape and color, their color can even imitate natural wood.

Plastic trims for windows in a contrasting color

The obvious advantage of plastic trims is its resistance to deformation caused by moisture, high or low temperatures. Also, its service life is much longer than that of a tree.

Plastic platbands have a long service life

As for its installation, it also does not cause any particular difficulties. Here you can do without additional fasteners. Platbands are attached to built-in elements and no traces of nails or screws are visible on the front side of the platbands.

Installation of plastic casing on the window

It is worth noting one significant drawback of plastic. These are its artificial components that make up the composition. Rarely does the owner of a wooden house agree to install plastic trims on the windows, thereby reducing its environmental friendliness.

Platbands from MDF

Platband made of MDF is an intermediate option between platbands made of solid wood and plastic. MDF boards are made from wood residues and waste. This guarantees the naturalness of the materials, and the special composition with which the board is impregnated guarantees a long service life and resistance to moisture.

Simple platbands for windows from MDF

Often, window frames in a wooden house are additionally laminated, which additionally protects them from the effects of negative environmental factors. The disadvantage is the low strength of the material compared to wood and plastic platbands.

Platbands for windows in a wooden house made of MDF

Each home owner independently chooses what material to choose for the manufacture of platbands, because they all have both advantages and disadvantages.

Preparation for the installation of platbands

The installation of platbands on windows in a wooden house is preceded by a preparation stage. First, all the necessary measurements are taken from the already installed window. It is important to choose the right platband width. It must completely cover the contour of the window frame. Secondly, before installation, all the necessary work is carried out with wood or other material that is used for platbands.

Stages of installing platbands on windows in a wooden house

If wood is used as a material, then cut-to-size platbands are processed before installation or decor is applied to them. As a treatment, compounds are used that reduce deformation and protect against insects from penetrating the wood. Platbands made of MDF and plastic do not require pre-treatment before installation.

Installation of plastic platbands on windows in a wooden house

Expert advice: it is important to use completely dried wood for platbands. If the wood is still wet, deformation is possible during the drying process.

After the platbands are cut out and prepared on them, it is necessary to determine the places of fasteners and mark the places where they will be joined to each other. If there are any holes, they must be prepared in advance. Platbands made of any material must be well sanded before installation.

After the platbands are prepared, it is necessary to prepare the place for their installation. The joint between the window and the wall must first be insulated, since after stopping the platbands this will no longer be possible.

Installation of MDF platbands on windows in a wooden house

Before proceeding with the installation of platbands, it is necessary to decide on the method of their fastening.

There are several types of fasteners for overhead platbands:

- with nails;

- deaf thorn;

- through thorn.

Fastening with nails is the simplest, but at the same time traces remain on the platbands that are difficult to hide. Also, this method of installation can spoil the material or create an additional load on it during installation.

Fastening the platbands with nails

Mounting on blind spikes implies the presence of small protruding parts on the window frame itself and holes for them on the platbands.

Installation of platbands on blind spikes

A through thorn is the same type of fastening, only the hole on the casing is made for its entire thickness.

Connection of parts of the platbands through thorns

Platband installation process

After all the preparatory work is completed, it's time to start installing the platbands. All parts of the platbands are interconnected and fastened with nails, thorns or glue. Glue is often used as an additional material for joining parts of the casing.

Installation of platbands on windows with liquid nails

If the fastening of the platbands takes place on hidden or through thorns, then the installation work is carried out as follows:

1. on the window frame and platband, the places where the spikes and holes for them will be located are marked;

2. studs are installed on the window frame. Spikes can be made by yourself or purchased from a store;

3. holes are drilled on the casing in the previously marked places;

4. the last stage - the platbands are fixed with thorns.

Installation of platbands on windows in a wooden house with self-tapping screws

At the first stage, it is important to evenly distribute the hole for the fasteners and the spikes themselves. This is necessary so that the load is evenly distributed along the entire perimeter of the platbands. After that, holes are drilled for the thorns, and they themselves are installed on the window frame.

The actual process of mounting the casing consists in aligning the holes for the spikes with the spikes themselves. It is important that all the pins line up with the drilled holes. In order to securely fix the spikes in the holes, you can use special glue. It will give reliability to the structure and fix the platbands well.

Installed platbands on windows in a wooden house

Often, ordinary screws are used to fasten the platbands. This, of course, will simplify the process of their installation, but at the same time spoil the appearance of the product. When installing in this way, all holes should be treated with a special compound, which will prevent deformation when moisture enters.

There are no special problems with the installation of platbands made of any material. For this, basic skills in working with tools are enough.

After installing the platbands in a wooden house, it remains only to periodically look after them and monitor their condition. In order for them to serve for a long time, experts advise to take the stage of preparation of platbands before installation with great responsibility and use high-quality means as impregnations.

Platbands on windows in a wooden house

Thanks to high-quality preparation and installation, window trims in a wooden house will last more than one year and will protect the house from moisture, dust, heat loss, cold and drafts, and will also decorate the house and give it a unique look.

Photo gallery - platbands on windows in a wooden house

![]()

Do-it-yourself window frames are a wonderful decoration for the facade of a house (ready-made stencils and templates will be given in the article below). They make the house look like no other, visually change its proportions.

Today, having certain skills, you can independently create graceful frames for windows in a wooden structure. Moreover, they can be made not only from wood, but also from other materials.

When the owner decides to install platbands, he seeks to arrange traditional decor in his possessions.

When the owner decides to install platbands, he seeks to arrange traditional decor in his possessions.

Platbands have the following advantages:

- Excellent decorative function. This is how the building visually increases.

- Complementing the overall style of architectural design.

- A defense of the space between the window opening and the wall plane from moisture and dust is created.

- Heat losses and noise levels are reduced.

- The individual features of the house and the style of the chosen era are highlighted.

The platbands have some drawbacks:

- Wood needs a certain treatment against high humidity and deformation.

- Products need regular care and treatment.

- They are not in harmony with metal-plastic windows. In this case, platbands are made in one color scheme.

Self-creation of templates

Today there are many platbands. Their types are determined by the way they are mounted to the window. According to this criterion, there are two types:

Today there are many platbands. Their types are determined by the way they are mounted to the window. According to this criterion, there are two types:

- Telescopic. Their specifics: L-like protrusions coinciding with the grooves of the window frame.

- Overhead. Installation takes place on the window frame. Fasteners - construction glue or nails with screws.

The installation of carved products is considered an exquisite solution. Self-realization of such ideas is possible only with the availability of special equipment.

Popular materials

- The most common material for platbands is wood. Products made from it have an elegant and harmonious appearance.

- Plastic versions are also often used. They are characterized by strong resistance to temperature extremes and ultraviolet radiation. Plastic options are sold ready-made.

- Another popular material is MDF. It is prepared from wood waste. It is more environmentally friendly than plastic. In addition, products made from it are characterized by a look reminiscent of natural wood.

- Polyurethane. Variations from it are highly practical. Facade stucco molding is often made from this material.

The nuances of choosing the right wood

As already noted, wood is the most popular material for platbands. And the performance characteristics of wooden platbands depend on the type of wood used.

As already noted, wood is the most popular material for platbands. And the performance characteristics of wooden platbands depend on the type of wood used.

Here, they usually pay attention to such options.

- Hard deciduous. These varieties include ash, oak and beech. They are very durable. But it is quite problematic to create patterns on them.

- Soft deciduous. These are: linden, aspen and alder. They are easier to process. On their surface, patterns are even created by hand. And such surfaces are thoroughly processed with special means.

- Sweet cherry and apple tree. They are optimal for creating small components that can be attached to the base.

- Pine and birch. They are also easy to handle. And they have excellent working qualities.

- Various combinations of wood varieties. The use of special protective compounds for powerful impregnation is mandatory here.

With the help of high quality wood, a beautiful original design of the window opening is obtained.

The nuances of creating templates with your own efforts

The basis of the work comes down to the creation of stencils and designs.

Self-printing of stencils is quite feasible for everyone. It is important to achieve a combination of the selected ornament with the entire style. Mixing geometric and floral patterns is not allowed.

The following subtleties are taken into account when working on platbands:

- There should be a harmony of the color palette of the walls and decorative elements.

- The appropriate parameter must be selected correctly. Platbands should not be very wide or small.

- A high-quality version of the coating is selected. Special paints and varnishes are used.

- A template is required for the manufacture of external carved components.

- The drawing is correctly positioned on the workpiece. Details follow along the wood grain.

When it is possible to achieve the color combination of the platbands and the plane of the walls, a holistic and harmonious facade is obtained.

Manufacturing stages

Before creating a window decor, carved platbands are selected from photographs. You need to make a template in advance. It should turn out to be the same for the decoration work of all openings.

Typically, the following methods of creating patterns are used:

- Overhead thread... It has separate elements of the pattern. They join the same base.

Installation of overhead components should be done on the base in accordance with the template.

- Slotted thread... A see-through ornament is made here. It looks like wood lace.

For all methods of work, the presence of stencils is mandatory. This is how they look:

Also, the work requires the presence of such tools:

Also, the work requires the presence of such tools:

- Jigsaw.

- Hacksaw (oriented for wood).

- Knives and chisels.

- Drill.

- Milling technology

Platbands must be created from prepared materials. The working stages are as follows:

- Meticulous measurements are carried out.

- The selected tree must be dry. If it is wet or damp, it must be brought to dry condition. The width of the boards is determined by the parameters of the window opening. The material reaches a minimum of 3 cm in thickness if a slotted thread is made, and at least 1 cm when an overhead thread is made.

All workpieces are pre-treated with a protective compound. They are cut using templates. And the cutting of ornaments is done using a jigsaw. It is better to use different types of files with this tool.

All workpieces are pre-treated with a protective compound. They are cut using templates. And the cutting of ornaments is done using a jigsaw. It is better to use different types of files with this tool.

To work with an electric jigsaw, you need certain skills and special care. The holes created must be wiped. An excellent tool for this is sandpaper. After powerful grinding, the part is treated with a special impregnation.

Next, all the prepared parts are installed to the base. Here you need to use glue or special nails. In such work, it is better to refuse the use of self-tapping screws. They will cause cracking of the products.

Installation specifics

The created platband can be attached to the desired position by the following methods:

The created platband can be attached to the desired position by the following methods:

- On a dull thorn. The installation of such parts is on the inside. Holes should be made specially for them in the frame. The glue is applied and distributed evenly on the spike. The spike is inserted into the groove. Such fastening protects the platbands from dust and moisture.

- With the use of a through thorn. The butt area is thoroughly varnished here.

These techniques are justified when working with a wooden window. For attachment to metal-plastic, a special powerful liquid glue is used.

Required care

The installed platbands need constant attention and care. For processing, special preparations are used - powerful impregnations. They create high-quality protection against:

The installed platbands need constant attention and care. For processing, special preparations are used - powerful impregnations. They create high-quality protection against:

- wood pests;

- the appearance of cracks;

- sudden fire.

Carved options must be covered with a primer, then varnish or paint. The intensity of such treatments is once every 3-5 years. Thus, the operational life of the products will be seriously developed, and at the same time their attractive appearance will be preserved.

When installing plastic or metal products, no careful maintenance is needed. For products, it is necessary to arrange high-quality corrosion protection. Periodic paint renewal is also required.

Thus, it is very possible to independently make platbands of extraordinary beauty with graceful patterns. Certain skills of a carpenter, carpenter and working with tools are required. So you will decorate the window openings with a very original method and add an elegant twist to the chosen architectural style.

Platbands on windows do-it-yourself templates stencils: drawings, sketches and drawings for cutting out, photo gallery, manufacturing instructions

Do-it-yourself window frames are a wonderful decoration for the facade of a house (ready-made stencils and templates will be given in the article). They make the house look like no other, visually change its proportions.

Carved window frames: templates, photos

Old Russian architecture is invariably associated with carved window frames. This form of home decoration is distinguished by a variety of species. A few decades ago, craftsmen lived in each region with their own style of creating decorative elements. Today's return to basics is accompanied by a resurgence of interest in carved window trims.

Purpose of framing

The word "platband" itself speaks of its location - "on the face", that is, one of its functions is to decorate the facade of the building. Therefore, people tried to express their individuality through him and decorate the windows with carved frames. In addition to the decorative role, window trims, first of all, perform a constructive function, closing the gap between the frame and the opening. This prevents dust from entering the house, protects against precipitation, drafts and extraneous sounds.

In the old days, magical properties were also attributed to carved platbands. It was believed that framing the window with a certain shape of the bar protects from the evil eye and serves as a kind of amulet. Therefore, in the bizarre patterns, various figures and plants were seen, bearing a specific semantic load.

In modern architecture, the functional purpose of window trims is as follows:

- A well-chosen carved design allows you to visually stretch a low structure or expand a narrow wall.

- An opportunity to show individuality and design a building in accordance with the spirit of a particular era.

- Allows you to achieve a single architectural ensemble between all buildings on the site.

- Protection of cracks from the penetration of external negative factors (precipitation, noise, dust).

- It is one of the elements of thermal protection at home.

Carved finish, especially made of wood, has a number of features that should be taken into account during operation:

- Dependence on the influence of atmospheric factors. Moisture and temperature extremes invariably damage the decoration.

- When choosing a frame, one should take into account the properties of the breed from which the platbands are made, and take care of high-quality processing. Timely preventive measures prolong the life of the window product.

- Difficulties often arise when combining carved wooden elements with modern plastic frames. With this combination, it is preferable to install windows that imitate a wooden texture.

The value of the carved elements

The desire to comply with ancient traditions requires knowledge about the meaning of the various elements of the carved platbands:

- The sun is usually placed on a kokoshnik. It symbolizes life and energy.

- The personification of wisdom and fertility lies in the image of a snake.

- The symbol of harmony between spiritual and material striving is a cross in a carved casing.

- The sense of unity with nature is emphasized through the vegetation.

- Earrings testify to the hospitality of the owners of the house.

- The connecting element of all times is the silhouette of a bird on the window.

Characteristics of materials and shapes

For the production of window frames, natural and artificial materials are used. Traditionally, the carved elements were made from weather-resistant wood. Characteristics of the properties of individual breeds will help determine the most suitable species:

- Larch is minimally susceptible to decay processes, however, it is not suitable for the production of carved frames due to its fragility.

- Aspen, alder and linden are the most convenient species for creating openwork window decoration. However, the pliable and soft wood of the carved platbands needs special treatment due to its ability to absorb moisture well.

- Platbands for windows made of oak, ash or beech are characterized by resistance to negative atmospheric influences, but the processing of carved elements is weighed down by difficulties, overcoming which you will get a durable decor.

- A good choice would be birch or pine wood, which allows for neat carved decor. At the same time, the platbands have sufficient strength for external use.

- Small carved window decorations, which are fixed to the main elements, can be made from cherry or apple trees.

What other materials are used in the production of window coverings and what are their features, we will consider below:

- Laminated MDF allows you to accurately simulate the color of any type of wood, but is intended exclusively for indoor use.

- Plastic windows are harmoniously combined with platbands made of a similar material (PVC), which is not subject to decay, has a wide color palette that is resistant to solar radiation. The color of the platbands is selected taking into account the finishing of the house to match or contrasts with the facade.

- For round windows, polyurethane products are ideal, which are characterized by ease and unpretentiousness in maintenance.

- Metal strips are attached to protect the assembly seam, connecting them into a single whole with the profile box.

There are two main ways to install platbands:

- Overhead is the most common method for decorating windows. For fixing, special glue or nails are used.

- The telescopic method assumes an L-shaped form of manufacturing the casing, which allows you to fix the product by entering the grooves of the box. It is more often used for finishing doorways. Its characteristic difference is the absence of traces of fasteners.

Thread patterns and types

The carved forms of the platbands give the window individuality, but in order to make them, you will definitely need templates. The presence of woodcarving skills allows you to choose a complex ornament. If the ability to work with wood is not enough, it is better to find a light pattern for the trims on the windows. We propose to study:

- options for templates of single elements and their general appearance;

- top, bottom and side decoration details.

You can copy them in full or add your own details to the pattern. The picture of the carved platband you like or a fragment of it must be scaled up taking into account the size of your window. For the manufacture of carved templates, fiberboard, thick cardboard or paper are used. It is advisable to decorate windows with platbands with the same thread. Please note that making small carved elements is much more difficult, and they become unusable faster than others. In this case, a partial replacement of the frame will be required.

The upper part of the window casing is called a kokoshnik, the lower one is a towel. The most widespread in the ornament of carved platbands were the contours of plants, images of animals and geometric figures.

The key drawing details for any window trim are:

- lower bar or sill girdle;

- vertical rail;

- top bar.

The scheme can also contain all kinds of hangers, vases or tiaras. A detailed description of the names of the carved decor elements is presented in the diagram below:

If your windows are of different sizes, experts advise making a drawing with an intermediate rapport, repeated as many times as necessary. For rapport, you can select one or two elements that repeat in turn. An example of such a scheme is shown in the photo below:

There are several ways to make carved wooden frames for windows:

- The most decorative and openwork are characterized by slotted platbands. The product is made of light wood or subjected to subsequent coating with white paint. Such window decoration on a darker wall looks sophisticated and refined, remotely resembling Vologda lace.

- With a laid-on thread, separately cut parts are fixed to a solid board by gluing or nailing. This technique allows you to design a window with a simple platband. The protruding elements are often covered with a contrasting paint.

Sometimes both types of threads are combined.

Manufacturing process

Having decided on the pattern, material, type of thread and the method of fastening the platbands, you can directly proceed to the manufacture of carved frames for the windows.

Places of the pattern, where it is necessary to make cuts, it is better to mark with color. The work on the manufacture of platbands consists of the following stages:

- Taking measurements from the window.

- For slotted carving, boards with a minimum thickness of 30 mm are selected, the overhead method allows the use of wood with a thickness of 10 mm. All work is carried out with dry lumber.

- Blanks are cut out.

- For a snug fit of the carved platband from the inside, the wood is selected to an insignificant depth (1-2 mm).

- The pattern applied using the template is cut out. To form holes, drills of various diameters are used, a jigsaw will be needed to make slots. To create a beautiful cut, the jigsaw insertion point is marked with a drilled hole.

- All carved elements of the window casing are smoothed with sanding paper. Wood dust is removed from blind holes with a vacuum cleaner.

The overhead thread provides for fastening the finished elements to the wide casing on nails with the heads removed. Strengthening the strength of the connection will allow the glue applied from the seamy side of the casing. The use of self-tapping screws is not recommended due to the risk of damage to the carved section of the joint.

Carved platbands are installed on wooden windows using blind or through thorns. The first option is distinguished by a reliable connection and a complex installation process. The second method is simpler, but less reliable. Installation of carved elements on a plastic window is carried out using liquid nails.

Pre-treatment of the carved frames and regular preventive maintenance will ensure the long-term preservation of the attractive appearance of the window.

Carved window frames

Carved window frames: templates, photos Old Russian architecture is invariably associated with carved window frames. This form of home decoration is distinguished by a variety of species. More

Stencils for window frames. How to make carved platbands?

Platbands on windows, despite their simplicity, are of great importance in the decorative design of the facade of the house. They not only create a neat look and add an element of individuality to the structure, but also perform a more mundane task of eliminating the gap between the wall and the window frame. In addition, platbands must withstand the influence of weather factors without losing their qualities.

The function of window frames and a little history

The platband was first mentioned as an element of the house back in the 15th century. Now the platbands have lost some of their relevance, but their function is still unchanged, regardless of the building material and its decoration. Due to the design features of the windows of high-rise buildings and in cases where glazing is used, their presence is inappropriate.

Platbands appeared many years ago

Platbands appeared many years ago

In simplified terms, the platband is a wooden frame with a width of 30-40 mm, which frames the window.

The aesthetic function of this part is important, but the main task is to close the gap formed by the window frame and the wall, which increases thermal insulation and prevents the penetration of dust and moisture from the external atmosphere, as well as reduces the noise level. In some cases, with shutters, it acts as a frame.

Types and types of trims for windows

Their shape can be:

They are characterized by simplicity of production and low cost, flat-shaped platbands. Convex platbands are made using special machines and, in this regard, the price of products increases significantly. Carved platbands are of great aesthetic value and significant value.

Platbands are classified according to the installation method:

- telescopic. They have special projections that fit into the corresponding cavities of the box;

- waybills.

An important factor when choosing the profile of this window element is the slope, which is performed at the top of the casing. Its purpose is to remove sediment.

Modern materials and requirements for the elements of houses have determined the trends in the needs of homeowners. The most popular are carved platbands made of plastic.

Requirements for the material of platbands

In addition to high aesthetic qualities, the casing must meet practical requirements. Its important qualities are its ability to withstand temperature fluctuations and high humidity. In addition, the material must withstand wind load.

It is important that the material has sufficient strength and is not prone to chipping and cracking. The use of MDF or plywood is out of the question. The properties of these materials are such that they are able to absorb moisture, are prone to cracking, the paint on them peels off over time. All this is a sign of the fragility of products made from these materials.

In this regard, MDF as a material for platbands can only be used inside the dwelling. The manufacturability of the material determines its simplicity and its relatively low cost. In addition, it does not take a lot of time to receive the finished platbands. Such platbands on the facade will require constant maintenance and additional processing.

Our ancestors made platbands from wood for many centuries. Oak and beech are the most common woods used for this. Pine and birch have found less use for the production of platbands. Wood tends to absorb moisture, therefore protective coatings are necessary to increase the product's life and appearance. In addition, over time, the tree tends to darken, therefore, the restoration of the original shade of the material is required.

When using gypsum as a decorative facade element, they also face the problem of the interaction of the material with moisture. When the water that has penetrated into the gypsum freezes and thaws in the process of temperature fluctuations, such architectural details are destroyed.

Certain requirements are imposed on the materials

Certain requirements are imposed on the materials

The use of glass fiber reinforced concrete and polymer concrete makes it possible to avoid the negative effects of temperature and moisture. Their use is limited by a significant mass of products. In some cases, when installing such platbands, the increased loads on the wall are taken into account and make it more powerful.

Polyurethane compares favorably with other platband materials. This is due to the fact that its use does not allow the problems described above, and also its characteristics allow you to create additional thermal insulation. In addition, its weight is comparable to the weight of wood, which facilitates the installation of these facade parts.

How to make stencils for window frames?

Choice of wood

Wood for the production of platbands can be used in various ways. These can be certain types of it, a combination of rocks by gluing or other connection.

Simple and shaped stencils for window trims are best made of pine.

The production of carved platbands requires the material to be soft. Linden has this quality. The material requirements are due to the manual processing of wood.

The choice of wood must be done carefully.

The choice of wood must be done carefully.

Climatic conditions associated with high humidity or significant dryness, as well as significant temperature fluctuations during the day, determine the use of wood with a dense and solid structure. These include oak and birch. Manual processing of them is difficult, therefore, the use of milling machines is necessary. Such products have a long service life.

Required tools

Before solving the problem of how to make carved platbands, you need to decide on the tool used for these works. The main tools for this are knives and chisels, different in shape and size.

Tools for the job

Tools for the job

For independent production of platbands, devices for manual milling, jigsaw, drill are used. When performing such work, a jigsaw is almost indispensable, since with its help you can create almost any pattern. In some cases, a homemade device can be used, which includes a step-down transformer and nichronomic wire.

In addition, it may be necessary to make a tool for filing corners. To make such a device, it is necessary to fix two hacksaw blades with a fine tooth between three wooden slats. When working with this device, the thorns are sawn with one blade, and the eyes of the product with the other.

How to choose patterns for the platband?

Using a slotted carving technique suggests that aspen, alder, linden or softwood is the best choice. The thickness of the board should be between 5 and 50 mm. It is necessary that the selected pattern of the pattern for the platband is well distinguished at a distance, and act as a single whole of the architectural ensemble. Therefore, it is not desirable to create an image with a lot of small elements.

Platband options

Platband options

For a long time, at the top of the casing there is a kokoshnik with the image of the Sun. If desired, the top of the casing can be extended using spikes as a connection. Towels - this is the name given to the bottom of the casing. The design must necessarily include the presence of a drainage bevel. The bottom plank should be 10 mm thicker than the plank at the top of the plank. It is important to maintain the unity of the style of both parts.

To avoid cracks in the threads, the parts should be positioned along the grain of the wood. As a rule, thin ends and openwork bends have significant fragility.

Structural diagrams

Structural diagrams

The simplest cut can be obtained by drilling a round hole with a drill. That is why it is advisable to make a choice on a pattern with a predominance of round holes. In most cases, the ornament is made up of repeating elements, each of which is made up of holes and cutouts that have a more complex configuration.

Drawings of platbands for windows contain the following elements:

- lower bar or profiled belt;

- vertical slats or frame;

- top bar.

Part names

Part names

To get a stencil, you need to stretch the pattern along its length. For this purpose, a life-size image is applied to paper. Places that suggest the presence of slots should be highlighted in color. Then, the resulting pattern is glued to the workpiece. Using a drill, drill holes of the appropriate diameter. If necessary, work with a jigsaw, make small holes where necessary.

Manufacturing of platbands for windows

The direction of opening the window must be taken into account. In the case when it opens outwards, the platband should be installed at a distance of 30 mm from the window sashes. In addition, the platbands should not interfere with the opening of the window frame. Other parameters depend on the geometric dimensions of the windows.

At the initial stage of the production of platbands, it is necessary to plan a dry board, the dimensions of which are in the range: thickness up to 30 mm and width 75-150 mm. In this case, the width of the platbands should exceed the corresponding size of the window box by 25-50 mm. For a better fit of the platbands to the wall surface, choose a groove or make a gap of no more than 2 mm so that it is at a distance of 10-15 mm from the edge.

When operating a power tool, do not use excessive force, as if helping it. This can lead to its failure. If you have any difficulties with cutting wood, you should pay attention to the sharpening of the blade. Long cuts are recommended with a wide blade.

How to mount carved platbands

Fastening of platband parts is carried out by means of blind or through thorns. Moreover, it is believed that the use of the first of them is preferable, since there is no need to decorate the places where the connection takes place.

The grooves for the tenons are made by drilling several holes, the depth of which is slightly deeper than the tenon. Removal of partitions between the holes is done with a drill designed for metal. The entry of the cleat must be firm, however, without the use of force.

The thorns are fixed with dowels made of solid wood. It is not advisable to use glue. This is due to the fact that adhesives are not able to work for a long time under the influence of an aggressive atmosphere.

Installation of platbands: features

Installation of platbands is carried out without the use of glue using nails. They are driven in with a pitch of 400-500 mm so that the head is recessed into the wood. Most often, platbands are attached tightly to the box. In some cases, an indent of 5-20 mm is made to the side, which depends on the direction of opening of the flaps.