Architectural features of the "comfort" project. Architectural features of the project "comfort" Free construction services include

The project of a small but cozy two-storey country house "Comfort" attracts attention with its convenient layout and spectacular architecture. The project of the house is designed for a family of five to six people, made in a classic chalet style. This house provides absolutely everything for a comfortable stay of your family.

The first floor is equipped with a spacious hall and living room combined with a kitchen-dining room, a small bedroom, a dressing room, a boiler room, a terrace and a bathroom. Common areas of the house - smoothly flow into one another, while remaining completely separate.

The second floor consists of two small and one larger family bedrooms, separated by a small inner hall. The project of the second floor is equipped with its own bathroom, dressing room and balcony. Both floors are connected by a solid, comfortable and safe wooden staircase.

The staircase to the second floor in terms of functionality meets three conditions: constructiveness, decorativeness and utility. This means that the stepped structure fits perfectly into the interior of the house, does not clutter up the space and is comfortable to use.

The construction of a wooden house - "Comfort" is carried out from a profiled bar 200 mm. At the request of the customer, solid wood of northern pine, Siberian larch or cedar, laminated veneer lumber can be used as a material for building a house.

Planting a house and pouring a foundation

- arrival of a specialist at the site for breaking the house

- trench extraction, sand cushion, pile drilling

- formwork device, reinforcement binding

- pouring reinforced monolithic foundation

- used ready-mixed concrete V-22.5 (M-300)

- installation of waterproofing on the surface of the foundation

The cost of the foundation is calculated separately *

The cost of the 1st stage of construction includes

Installation of walls and partitions

- installation of house walls and partitions made of profiled timber

- house set from dense northern forest of winter harvesting

- the installation of the log is carried out using wooden dowels

- installation of inter-row insulation "Klimalan"

- installation of a log floor from a bar 200 × 100 mm in 0.6 meters

- installation of floor beams from a bar 200 × 100 mm every 0.58 meters

Roof device

- roof structure is made of board 200 × 50 mm

- floating supports are used

- rafter pitch every 0.6 meters and lathing from a board 150 × 25 mm

- temporary roof made of waterproofing with clamping strips

- fastening of rafters in the ridge - articulated

Free construction services include

- construction crew accommodation - shed

- transport - delivery of materials to the object

- unloading materials

- garbage collection and disposal

- provision of project documentation

- individual project revisions

- individual design

- independent quality control

The construction project consists of three parts

Architectural and construction part. The design of a wooden structure always begins with the development of a sketch of the facades and a planning solution. The layouts are based on the wishes of the Customer and take into account the location of the building relative to the site and the orientation to the cardinal points. The functionality of the layout often depends on the facade solution and the size of the structure - therefore, the architect must take into account many nuances in his work. On the basis of the approved sketches, a structural part will be developed - a working draft of a wooden structure.

Constructive part. When developing the structural part of the project, it is important to take into account all the features of the material of the walls of the building. The distribution of the loads of the floor and the rafter structure is also very important. Often these moments are not given importance for the sake of the beauty of the project - but in vain. Wooden buildings without a proper image of balanced loads will cause a lot of trouble to their owner. It is worth mentioning the support of the floor beams - in our design solutions we provide for the installation of sound insulation for complete acoustic comfort.

Engineering part. Installation of engineering networks of wooden buildings is a crucial part of the work. Engineering design includes power supply planning, planning an efficient heating system and, of course, the formation of an axonometric diagram of water supply and sewerage. If necessary, you can design fresh air supply, ventilation and even air conditioning. The design of networks for structures made of timber or rounded logs is carried out taking into account external connection points.

Composition of the project of a wooden house

House project from rounded logs with a diameter of 300 mm, measuring 11.9m × 13.1m

Architectural and construction part.

The name of this project was born along with the very idea to create the most comfortable home for a large family. Therefore, the project includes even such rare premises as a laundry room and a staff room.

From an architectural point of view, Comfort turned out to be no less interesting than from a practical one. That there is only one "glass room", which is part of the living room.

House area - 360 sq., dimensions - 15 x 17.5 m.

Architectural features of the "Comfort" project

- An increased number of special-purpose premises.

- Possibility to re-plan the cottage according to your own taste.

- An original solution to natural lighting of the interior space.

The Comfort project is intended for people who know that they need to live with pleasure. Here you can forget about minor household inconveniences and just enjoy the comfort, coziness and beauty of your own home!

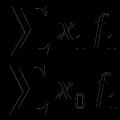

Total area: 175 m 2

Living space: 106 m 2

Dimensions: 10.0 x 13.2 m

1st floor area - 102 m2. 2nd floor area - 73.5 m2.

- advance payment 50%

- kit production time 40 days

- construction period "under the roof" 20-40 days

- we offer additionally: windows, entrance and interior doors, exterior and interior decoration of the house, work on the arrangement of communications.

- free of charge: redevelopment, mirror reflection of the house

- 3 years warranty for materials and construction works

- development of an individual house project

- construction of a house according to the client's project

The cost of the pile-screw foundation is 175,646 rubles. The price includes screw piles with a diameter of 108 mm, a length of 2.5 m, heads and strapping from a bar with a section of 150x200mm, treated with an antiseptic. Depending on the soil and the height difference at the construction site, the cross-section and length of the screw piles may vary.

The cost of a strip monolithic reinforced concrete foundation with a section of 300x600 mm is 364,500 rubles. In the manufacture of the foundation, concrete M 300 is used, a volumetric reinforcement cage with longitudinal reinforcement with a diameter of 12 mm, clamps made of reinforcement with a diameter of 10 mm. Depending on the soil and height difference at the construction site, the cross-section and band grillage may change.

Price for a house made of glued profiled lumber:

** excluding shipping costs

Price on credit: from 40 054 rubles. per month***

Installation of gyro-insulation of the foundation (roofing material).

Installation of the zero row (board 50x200x6000mm treated with an antiseptic).

Installation of a wall kit made of laminated veneer lumber.

Inset of floor beams (sawn timber 50x200x6000mm / glued beam 80x190x6000mm).

Who and how makes money on import substitution and innovations in agriculture R

Who and how makes money on import substitution and innovations in agriculture R What is the industrial production index, its role and calculation

What is the industrial production index, its role and calculation Calculation of the design population of the city Term in metallurgy

Calculation of the design population of the city Term in metallurgy