A rich potatoes for a motoblock with their own hands. Motoblock Potatoker - Features of manufacture with your own hands Scheme of homemade potatoes for tractor

Nowadays, almost no one manually jumps out the garden sites, because modern equipment for the country's country and the preservation has become available. Now the new technique is widely used and often for them is made a potato coofer for the motoblock, self-made, below we describe several options for manufacture.

Many people who work in the field do not know what it is not easy to grow and collect their own potato harvest. To facilitate harvesting potatoes, a person came up with a special invention - a potatoes. Our ancestors used a shovel for this, a mechanical device for automatic potato collection was created for us. Purpose the potatoes in separating tubers from the soil and lay them on the surface of the earth.

Now there is a large selection of factory options for this device. But if the gardener, more or less experienced, will not be easy to assemble the potatoes, not inferior to the factory samples.

Homemade Potatoes for Motoblock

First of all, we collect a welded frame from metal plates (8 mm), iron channel (No. 8) and a special corner (63x40). Using plates manufacture Lemeh. Made of the lemch we install on the elevator casing using four bolts, and tighten the nuts.

We make the editorial assembly using two metal cylindrical cylinders.

They are made in the form of a glass and a sleeve connecting the slave and leading steel shafts among themselves. They must be easily rotating. Special sprockets are embraced on the sponge of the prismatic form, with a welded hubs. They are made of pipe, the size of which is 25 mm.

In order to avoid the cut potato, the sharpening details must be round. If you change the fastening of the casing to the frame, the slope of the elevator and the digging angle of the hole will change. To make self-made potatoes, you will need certain skills. No potatoes will no longer be without a purifier drum.

It is not easy to create it, but if you use the right approach, it will take quite a bit of time. The main design contains two roller chains having 94 links and dressed on the rods. Because of its form, this design is called "Beliche Wheel". This is a wheel, for greater strength, fixes on two bent discs. Instead of discs, you can use the rim of the bicycle wheel.

After the "Beliche Wheel" was welded to the disks, it is fixed to two welded fixed axes for its rotation. The rotation of the shaft occurs on the bearings, together with which the slave stars are spinning, leading the drum.

For the manufacture of the slider is best used fluoroplastic. In this case, it will be easy to slide the chain-rut tape. With the appearance of the ribbon looks like a "Beliche Wheel", but there are less rods and they are much shorter. As a support, we serve as a slider that protect the chain from damage.

The easiest in the manufacture of potatoes - the reverse transport hub. Based on the method of processing and planting potatoes, everyone can make it. During the creation of such nodes, there should be no particular difficulties. Such mechanisms are used in potato harvesters.

Assembling potatoes

Inserted the output axis of copulate in the left side opening of the casing. It looks like a bulb bolt. After establishing the axis, we start the installation of an asterisk with a bearing, rings for strut and intermediate spacer sleeve. Then we insert the input axis into the opening of the casing on the right.

The most popular potato growing method is Dutch. It is distinguished by high yield and extreme versatility. You will get a good potato harvest, even if the weather conditions were unfavorable. The methods used today significantly reduce the time, strength and costs due to the use of automated potato copulate for motoblocks.

Drawings and Schemes of homemade potatoes for motoblock

Homemade potatoes for motoblock video selection

Related records:

How to make a pneumatic motorcycle, insightruction, photo

How to make a pneumatic motorcycle, insightruction, photo

Coupling to Motoblock do it yourself, photos, drawings

Coupling to Motoblock do it yourself, photos, drawings

Shovel for a motoblock with their own hands

Shovel for a motoblock with their own hands

Motoblock Agros and homemade to it

Motoblock Agros and homemade to it

Motor Flower with your own hands

Motor Flower with your own hands

Make a homemade all-terrain vehicle from a motoblock photo, video

Make a homemade all-terrain vehicle from a motoblock photo, video

Make homemade caterpillars on the fiberboard: photo, video, recommendations

Make homemade caterpillars on the fiberboard: photo, video, recommendations

Soil cutter and cutters goose paws for motoblock

Soil cutter and cutters goose paws for motoblockOwners of land plots willingly use mechanized assistants in the processing of the soil and collecting grown vegetable. Another recently mechanized collection of potatoes and other root crops used only large private and state agricultural enterprises. Today, even small farmers are striving to reduce the share of manual labor.

If the land plot is small, then there is no need for a tractor or combine, it will help to collect a harvest of a motoblock, equipped with mounted equipment. A special demand for small household engines uses a potato coofer for a motoblock.

Additional equipment allows you to increase productivity, simplify the process and facilitate physical work.

Producers of agricultural machinery take into account all the wishes of consumers and produce different patterns of potatoes, but the purchase for a small private compound and a motor-block, and attachments to it are not always justified (this is evidenced by the annual medium prices). Therefore, private traders are resolved for the manufacture of a trailer device on their own, using technician and inexpensive materials, spare parts from old mechanisms.

Features of structures and types

Before making a potato machine for a motoblock with your own hands, you need to study the device, design features and prepare the necessary tools and materials for work. The principle of operation for all models is one: the teeth of the mechanism entered into the ground and will be uploaded to the earthen comedy together with root. The harvest at the same time can be collected in the bunker or staying on the garden. It will depend on the constructive solution of the model. Potatoes are:

- fan (fit);

- vibration (gross);

- conveyor.

Experienced masters show engineering seamless and create independently multifunctional units, which are used for landing roots, and for dipping, and for harvesting.

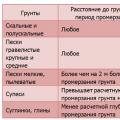

Optimal metal thickness

Attachment is collected from metal parts. The thickness of the sheet steel should be seal with the intended load: the more it is, the thicker should be the material. Experts recommend using sheets with a thickness of at least 8 mm.

Wheels for copalki

The design is equipped with moving wheels. In the manufacture of copulates in the domestic workshop, they can be borrowed from the old garden car. Wide tires will facilitate movement in beds. The best option is equipped with axis. Racks are fixed to the axis, which make stopper holes.

Alternatively, you can use metal. They will make the design harder, which will improve the work of the rollery on solid soils. Rubber will be worse to move around the wet soil, it will be better to show rubber in such a situation, but with a tractor protector.

Connection methods

All elements of the unit are connected by contact welding method (electrical or gas), as well as with the help of classic fasteners (bolts, nuts). Moreover, the advantage of the bolted compound is that, if necessary, the unit can be disassembled and assembled.

The simplest potatoes of the motoblock do it yourself

Even the simplest copper made by their own hands will make it easier for labor while cleaning potatoes by fiberboard. Advantages of homemade are obvious:

- no essential financial investments will be required;

- in the manufacture of the farmer, we will consider the characteristics of the soil of your own site and the motor-block itself, to which the equipment will be attached;

- for service and repair, professional workshop services will not need.

The stroke of a passive type potato tank is the simplest mounted mechanism, it is made according to the type of bayonet shovel from the curved sheet of iron and the rods, welded by fan, for eliminating the Earth.

Such an upgraded spell does not require the development of a detailed drawing and cope with the harvesting of the root plates on a plot with light soil. It can be made even a novice homemade master.

Materials and decisions for the feels

Fitting (fan) Homemade potatoes for the motoblock is made according to the drawings. The basis of such a copal - frame, the details of which are carefully calculated and welded. All measurements and parameters of each part of the suspended part, wheels and soils, thrust are introduced into the drawing. Master, having experience with power tools and complex equipment, it will be under power. For the manufacture of parts will be needed:

- apparatus for welding, drill, Bulgarian;

- hardware, wrenches, drills;

- a hammer;

- scissors for metal.

Small mechanization has long been present on household plots. In fact, all the devices that were used to be used for the processing of the soil and harvesting in collective farms, and today in agro-industrial complexes and farms - found use from private owners.

Of course, power, dimensions, and most importantly - the cost of these mechanized assistants is significantly lower than industrial analogues. Nevertheless, wanting to save, many gardeners and gardeners make appointments with their own hands.

How to make a plow, a cultivator, and even the motoblock - know many folk craftsmen. We will talk about such a useful tool like a potato coofer for a motoblock.

The principle of operation of this attachment is simple - to immerse the bursting nozzle into the soil Paul potatoes, remove them to the surface with minimal losses, and separate them from the soil. Properly configured homemade potatoes leaves the entire harvest on the surface, or even ship it into the container.

Varieties of potato harvesting devices

Two main types of attached equipment differ:

- Passive type. Upgraded shovel of a special concave shape, deepened into the soil at 5-10 cm below the level of the tuber, and pulls them on the surface along with the ground. Thanks to a properly selected angle of inclination, a comer of the soil together with the crop turns out to be loosened. The quality of the separation of land and potatoes in such a design is not too high, so a certain amount of physical effort is spent on the final fee of the crop. Of course, such work is not a comparison with the corop of potatoes by an ordinary shovel, but still a family team is coming behind the motoblock, which collects from the surface of the harvest. The inconvenience is compensated for simplicity of manufacture and low cost of fixture (in case of purchase);

- Active devices. The potatoes of the motor-block of this type has its own frame on which the shovels are placed to extract the harvest, and the adaptations of the vibration discrade land (so-called roar).

The knife raises the soil with tubers, which, under the pressure of the following portions, moves to the grille connected to the vibration mechanism. It can be a separate drive from the shaft of the power of the motor-block, or just a rod rod from the wheel.

Due to the constant shaking, the House of Land is separated from potatoes and wake up. Tubers can accumulate in the grid or fall out behind the gauge. Harvesting in this way is significantly easier, but also the attachments are more complicated in manufacturing and more expensive when purchasing.

Important! If you during the ripening of potatoes were performed - to set the depth of the immersion of the lemuma, taking into account two crop tiers.

Potato coofer for the motoblock with their own hands, how appropriate is the manufacture?

Make a potato cleaning is easier than many other homemade fixtures. For the manufacture of a passive type design, you will need:

- Sheet iron for lemis. Thickness 3-5 mm. It is desirable from durable steel so that the shovel is not so quickly tupped;

- Steel circle or armature with a diameter of 8-10 mm for a screening grid;

- Channel or steel strip 10 mm thick, for suspension;

- 30 mm corner for strengthening design;

- Arc welding machine;

- Drill, fasteners.

In the fall, it is time to dig a potato.What is a gross potatoker with your own hands (the drawings will be slightly lower)? Previously, they dug the potatoes manually. Nowadays, many use the digger, which they tray to the motoblock.

What is potatoes

The potatoes is a device for separating tuber plants from the soil. Potatoes are issued to the surface of the Earth. Such aggregates can be purchased in the store. But they are very expensive. Many try to build a mechanism with their own hands. All units for digging tubers can be divided into:

- scanty;

- conveyor;

- universal.

Scaffold copulates consist of a trunk, lemhery and drive. Their performance is quite high. A gross potato glass operates in the following principle. Soil with potatoes picks up and served on the table. The table vibrates, the soil wakes up through the slots, the root plates on the other hand fall to the ground. It remains to pick them up and put them in Tara.

Conveyor copulates are arranged more. They include a lemeh, conveyor and drum. Universal coullas are single-row fan-type devices.

All these copulates are trayed to the motoblock. You can attack other nozzles. They will help plant potatoes, raise virgin, dip plants, sort the vegetables cleaned in the fall.

Do copal with your own hands

A gross type potatoes can be made with their own hands. To do this, you need to own some knowledge and skills. The principle of its action:

- metal knives cut the soil;

- tubers fall on the lattice;

- from the lattice, they fall on the ground or in the container.

All the details of the copulate are very important, they affect the durability of the device and on its strength. Basic details of potatoes:

- frame;

- lattice;

- shafts;

- lemeh;

- transport node;

- wheels;

- other details.

Frame is the basis for all other details. The grill is the vibrating part of the unit, which throws the soil and leaves the potatoes on itself. Shafts serve to create a lattice vibration. With the help of the transport hub, the spell moves along the site. It may include discs, rods, chains, bearings, asterisks. A homemade potatoes for the motoblock works well on areas with light and medium severity with soil.

For the manufacture of an aggregate you need to cook:

Image 3. A potato device.- frame from corners or pipes whose dimensions are 63x40 mm (Image No. 1);

- schweller number 8;

- pipes whose length is 130 cm;

- metal sheet thickness from 7 mm;

- armature with a diameter of 10 mm;

- chain;

- racks;

- wheels;

- metal drum;

- bolts and nuts by 10 mm;

- welding machine;

- spanners;

- a hammer;

- drill with drills;

- copal drawings (Image No. 2).

The process of work is divided into several stages:

Image 4. Drum cleaner.- from pipes and channels welded a frame with a length of about 120 cm;

- welded to the frame of the channel or pipe for the installation of regulating parts;

- prevory racks and lattice bar (Image No. 3);

- the lemche is welded or bolted;

- a grill or drum cleaner (Image No. 4) is welded;

- shafts are installed to drive the lattice;

- the transport hub is going.

The potato coofer for the motoblock is made of metal. Its optimal thickness is 5-7 mm. The construction will be pretty light and durable. Connect details with welding or bolts. Welding in this case is very unreliable. When vibrations on some soils, seams are divided. Therefore, it is better to use drill and wrench. This is a great solution, as the design can be disassembled at any time. This may be needed to transport the device for distance. The rack is best to take from the holder of an old plow or use steel strip for its manufacture.

Wheels can be applied:

- rubber ordinary;

- with tractor pattern of tread;

- metal.

The most stable wheels - with tractor treads.

The drum cleaner is required (Image No. 4). It consists of 2 chains with 94 links, clamped on discs or a bicycle wheel.

Conclusion on the topic

Potato harvester has long been used on the fields. In private areas, you can use a potato chipset that trays to the motoblock. It can be purchased in the store or make it yourself.

The homemade design will cost much cheaper, about 17 times.

For its manufacture, you need to purchase several pipes, steel rods, wheels from old agricultural machinery, chains, bolts and nuts. When working it is necessary to simply move the unit along the rows of potatoes, the removed area will remain behind. If tubers are not going to the container, you have to raise them from hand manually.

Drawings and diagrams of this unit are given above. If the plot under the potatoes is several acres, it is worth work hard and make such an aggregate with your own hands. It will save a lot of time in the fall and remove the harvest in the shortest possible time. It is possible to provide a change in the depth of immersion in the soil of lemhery using screw connections. The design gives a lot of space for engineering thought. Operation of this potato complex requires the implementation of some elementary safety rules.

People living in the countryside and summer houses are engaged in a potato harvest. This process is quite time consuming, especially if manually cleaning. To simplify the potato collection, many acquire special potatoes for motoblocks. However, some owners refuse such a purchase and try to make such a design on their own. However, before the potatoes will be made with her own hands, it is necessary to familiarize themselves with the types of copulates and the peculiarities of their manufacture.

Before creating a potatoes, it is necessary to study more detailed, it is used to be used for it. Using such an attachment should be used with the fiberboard. It is used to dig in potatoes and digging earth in the fields and household sections.

The main function of the potatoes - separation of tubers from the soil and their laying on the surface of the Earth. It is for this that many vegetables and farmers buy or independently make such adaptations before harvesting.

Varieties

Any potato fleet for a minitractor is manufactured for loosening the Earth and digging potato tubers onto its surface. However, despite the fact that all potatoes for the motoblock perform the same function, such structures may differ anyway. There are several kinds of diggers that can be done or purchased in the store.

Vibration or richnoe

A rich potatoes is made of vibration sieve and lemhery. The vibration product has a fairly simple principle of action. During operation, the digger is placed in the soil and gradually removes the ripe tubers from there. Together with the soil, they fall on a sieve to shock unnecessary soil. Such a copper of potatoes has a serious drawback - it is very difficult to do it yourself.

Simple or fan

Such a fan potato fleet for a minitractor has the simplest design. It is made of a plow to which you need to attach several arrows. During the harvest, the motor-cultivator with an installed simple dump truck will be deepened in the ground and the dried tubers will begin on its rods. The advantages of this copal can be attributed to its versatility. It can be installed on any model of motoblocks and minitractors.

Transport

A potato copper of the transport type is perfect for the motoblocks of such a model, as "Neva" and therefore it is necessary to use it with them. The design of such a digger is very simple and consists of only a mobile conveyor and lemhery. The conveyor has a special hook, which keeps the tubers and helps to separate them from the ground. The transport copper for potatoes should be used only on areas with heavy soil, as this model does not dig up from the soil with a small degree of density.

How to make potatoes with your own hands

Before making a potato machine for a motor-block with your own hands, you need to familiarize yourself with the instructions for the manufacture of such products. First you should familiarize yourself with the list of tools that will be useful to create manual potatoes. To make a homemade potato fleet will be needed:

- reinforced rods;

- iron plate;

- engraver;

- welding;

- bulgarian;

Creating a Rama

The basis of the self-made homemade on the motor-block or the tractor is a frame of potatoes. To make a high-quality frame, you need to familiarize yourself with the main steps of its creation.

Welding fastening rectangle

The fastening rectangle shapes the frame of the entire device and therefore it is necessary to make it very carefully. For the manufacture of the frame you will need a square iron pipe with a length of at least four meters and a width of about 50 cm. It is cut into four different parts, two of which should have a length of 100-120 cm, and the remaining - 80-90 cm. All cut pipes are welded in this way So that the result is a rectangular design. After welding, a manual grinding of edges should be performed to remove sharp corners.

Mounting jumper

The potatoes for the motoblock must adjust its level of inclination and it is for this that a jumper is installed for mounting special thrust. It is mounted in the center of the rectangular frame. On the opposite side, two small pipes are installed with a length of no more than 10 cm and a diameter of 25 mm. The tubes are mounted on the frame so that in the future they can be attached to the wheels. They are installed from the outdoor side of the frame in one of its corners. After attaching pipes, in each of them, with a drill, small holes are made with a diameter of 10-15 mm.

Installation of vertical racks

To make a more reliable framework for the motoblock with their own hands with their own hands, you will have to attach several vertical racks to the frame. First, it is necessary to retreat from the jumper 5-10 cm along the frame and perpendicular to it to weld a small metal square with a size of 35x35 cm. Then it is necessary to retreat 15 cm and attach iron racks with a length of 30-35 cm. As a result, the finished design externally should be similar to an inverted staircase.

Connection Stand

The final stage of creating a framework, from which the tractor potatoes will be consisting of the edge of the edges of the racks. To do this, it is recommended to use metal strips with a thickness of 0.5 mm. Each of such strips is welded to racks at an angle of 45 degrees, after which they should be connected to the edges of each other. The finished design will have a triangle shape.

Rail and scope board

Having finished with the frame, you can start creating a scope board and a rally. These made pieces made of potatoes for motoblock are used to dig tubers from the soil and their cleaning from the ground. For an inexperienced tractor driver and gardener, the creation of such elements may seem very difficult work. Therefore, before proceeding with the case, you need to become familiar with the peculiarity of their manufacture.

Welding Rala

To create this item, it will be necessary in a small iron sheet with dimensions of 30x30 cm to make two small holes for installing M12 bolts. They will also have to be made in each of the racks at a distance of about 45 cm below. When all the holes are prepared, it will be possible to screw the metal sheet.

Then from the opposite side, we place another iron sheet. In this case, a metal with dimensions of 60x30 cm and a thickness of 0.5 mm are used. In the center of the attached sheet must be 2-3 times well hit by a sledgehammer to form a cone.

Welding a scope board

The fixture for the coppe of potatoes must necessarily have a scope board and therefore after welding the rollery should be engaged in its manufacture. To create a scope board, you need to prepare one twig with a diameter of 10-15 mm and about one meter long. One of his edge is welded to the newly created round, and the second must go beyond the base of the potato digging for the motoblock.

There are cases when a welded twist begins to stagger and have to create an additional support for him. For this, at the end of the frame is welded a riser with a length of 25-30 cm. Then the square tube is attached to the riser, to which three twists will have to be welded to provide additional stability of the design.

Installation of adjusting cray

A homemade potatoes for the motoblock must be equipped with adjusting traction. They are set to ensure that in the future you can independently adjust the slope of each rod installed. It is necessary to mount them to the first cross in the framework of the product. To reduce the angle of inclination, the installed thrust will have to get out so that its rods began to stick out. To increase the angle, you will have to screw the rods back.

Mounting wheel

To the potatoes attached to the motoblock with their own hands, it was better moved along the site, you need to install several wheels on it. To do this, you can use any wheels from the wheelbarrow, the load capacity of which should not exceed a hundred kilograms. To each wheel you need to weld the mount and install them to the potato.

What is a hot water supply of an apartment building

What is a hot water supply of an apartment building Water supply of an apartment building

Water supply of an apartment building Calculation of the Load for the foundation Installed Electrical Instruments

Calculation of the Load for the foundation Installed Electrical Instruments