Sliding support for rafters - how to fix right. Sliding support for rafters: Strong and movable design How to make a sliding roof

Wooden housing construction for many years retains leading positions. However, wood as a building material has some qualitative characteristics, among which there is a high percentage of shrinkage, which inevitably provokes the development of deformation changes in the design. It is for this reason that sliding rafting supports are used.

Purpose and scope

The sliding version of the support allows the design to be easily adapted to configuration changes of different character, including with geometric changes in the process of natural shrinkage.

The process of rigid fastening of the rafter design on the Mauerlat or to the beams of overlapping by the fastener elements is sometimes inexpedient.

With the tendency of the construction box to shrinkage processes, it is recommended to allow the legs of the rafter system to be freely shifted relative to the support.

Previously, during construction, a maximally durable wire system was used, with the help of the upper part of the erected cut. Under the conditions of modern home-building, such an attachment is performed by a special fastener element - a sliding support, which is characterized by the simplicity of installation, reliability and durability. It should be borne in mind that for any mobile support is characterized by the presence of a fixed framework for performing movements.

Characteristics and sizes of sliding supports

Sliding supports are perforated elements that highly effectively prevent roofing structures and the process of cutting walls in a wooden house-building.

The result of a shrinkage of the wooden rafter design is a significant weakening of the entire system and the emergence of numerous distortions. The use of sliding supports of floating rafters allows you to minimize the negative effect of shrinkage. Composite parts of such elements are represented by a metal bracket and a corner with a loop.

Main settings:

- height - 9 centimeters;

- width - 4 centimeters;

- thickness - 2 millimeters;

- length - 9 - 16 centimeters.

All elements are highly distinguished by the degree of strength and reliability, and for installation you need to use screwdriver.

Types of support

Depending on the type of erected, several methods can be applied to fasten the main elements. Most often, low carbon steel is used as a material for the manufacture of such fixtures, which has passed the hot galvanization process.

Two varieties can be used as sliding compound:

- open type of sliding compound

- closed sliding connection type

A full-fledged mounting for moving connections is performed on the basis of calculations for the uniform distribution of the loads created on the walls of the structure. In addition, it is necessary to take into account not only the weight of the rafter system, but also the entire roof items.

Open connection option

It is characterized by the presence of two open elements: a guide that is fastened to the rapid leg and is a steel curved plate with holes and a fixed corner. The number of holes for fastening on the guide may vary, and the length of the stroke is at least six centimeters and no more than sixteen centimeters. The corner has no more than five holes.

Option of closed compound

It is a single and monolithic design and mounted in the already assembled form. The corner of the stationary part has a special holder on the long side, through which the fastener bar is displayed. It is advisable to purchase rafting compounds in the finished form, which will allow you to perform the highest possible installation.

Mounting sliding rafter system

The basis of the sliding supports serve two parts represented by the guide and bent plate. When operating the guide performs sliding, the amplitude of which does not exceed the limits of the bent plate.

In addition to mobility, when installing, the reliability of the attachment is taken into account, which does not allow or carrying a log in conditions of significant roofing loads to break away.

For sliding compounds, it is characterized by the execution of fasteners perpendicular to the rafters, which causes the conduct of driving at right angles.

Installation bases are in the following actions:

- the execution of a semicircular washed on the supports of the rafter feet;

- installing spikes that allow you to remove the load from the rafter design.

Sometimes you can meet the fastening of the attachment in another way when a device of special propuls is carried out by 75% in the carrier branches. Creating minor friction of a large area allows you to keep the system in conditions of strong winds and heavy snowfalls. This method is used in the presence of a small roofing angle or under the presence of intermediate supports. In the installation process, high-quality, galvanized self-tapping screws are used.

Learn more about Montage with your own hands, see the video.

Let's sum up

- Installation of sliding compounds is possible exclusively on roofs that have a correct and geometrically correct form.

- The installation is performed only after the reconciliation of all the parameters of the structure for compliance with the sizes, which will simplify the installation work and minimize the need for "fit" of all elements.

- Mobile connections can be used not only for fastening rafters and walls, but also to arrange skate connections.

- Preventing jamming on moving systems allows the execution of a strictly parallel fastening of all supports of the sliding rafters to each other and perpendicular to Mauerlat.

The construction of rafting structures is a very responsible event, since the safety and durability of the object as a whole depends on their geometric accuracy and reliability of the attachment. Some additional difficulties occur during the installation of rafters on the buildings made of natural wood (log cabins, etc.).

In this situation, sliding rafters will be the best solution to ensure the geometry of the roof.

Features of using sliding rafters

The technology of using sliding rafters is necessary for objects erected from logs, since these buildings, in contrast to other materials, give a rather strong shrinkage during operation. Shrinkage logs continues for several years and is 5 - 8% of the volume of wood (depending on the humidity used in the construction of materials). Large danger is not the shrinkage of the structure, but the unevenness of the flow of this process.

The uneven shrinkage of the bearing walls can damage rigidly connected rafting structures, violating them geometry. After that, the rafter cannot serve as a reliable base for roofing materials, which disrupts the tightness of the entire structure, significantly increasing the danger of operation. Therefore, the sliding rafter system is the optimal yield when erecting log cabins and other objects from logs.

Constructive features of sling rafter systems

Sliding rafters are not rigidly fixed structures, since they are mounted using movable metal elements. As with the installation in the traditional way, the rafter systems are installed on the upper carriage of a log log, but instead of a rigid fixation using brackets, bolts or screws, so-called "sliding" for rafters are used.

These elements are structures from a metal strip, one part of which is fixed on the log, and the second - on the rafter

. In this case, the structural elements can be moved relative to each other by creating a moving connection.

These elements are structures from a metal strip, one part of which is fixed on the log, and the second - on the rafter

. In this case, the structural elements can be moved relative to each other by creating a moving connection.

Installation of these structures is made using special self-tapping screws, since conventional self-tapping screws will not always be able to cope with the necessary load. "Sliding" assembly sold in many building stores and are relatively cheap. They are made of galvanized steel and are supplied with ready-made mounting holes. The use of these elements makes it possible to move with rafter systems to move to the required distance during the shrinkage of the bearing walls, without disturbing the integrity of the structure.

- Slipper systems should be installed on objects that have the right geometric shape.. Otherwise, it is very difficult to perform correct roof, because there are movable elements in systems. Before starting the installation, rafters must be carefully checking the perimeter of the object and achieve its compliance with the recommended tolerances.

- The manufacture of rafting systems is made according to a predetermined pattern. This approach makes it possible to create the same structures for all elements of the roof.

- The skate compound in the rafter systems of this type is also performed using movable elements. As the mounting elements, bolts and studs that pose a connecting axis, or mobile hinges, reinforced with self-helping, can be used.

- With a significant length of the overlapping spans, it often has to resort to building boards from which the rafter structures are manufactured. If it is necessary to carry out this operation, the boards are connected by long bolts or special brackets. Board extensions are performed by a mustache for pre-drilled mounting holes. When drilling, mounting holes must be positioned at some distance (at least 10 cm) from each edge of the board. Drilling holes should be chaotic in order to prevent splitting board on holes.

- Each support sliding rafter must be installed strictly parallel to the previous and perpendicular to the carrier log of the structure. The retreat from this rule can lead to the encouragement of moving structural elements and their destruction when the task is shown.

- Installation of "sliding" is carried out on special records at an angle of 90 0 to the rafter support, which ensures the free movement of the design . When installing, these elements need to be output to the extreme, providing the maximum possible course of the rafter design during the building shrinkage.

Montage of sliding rafal

Sliding rafters cannot be installed on support logs without the use of some structural elements, as they contain moving parts and simply fall under their own weight, destroying the entire design.

To prevent this situation, the sling fastening of the rafter feet is carried out using special techniques.

On the rafter support at the installation site, a special semicircular washed, according to which the installation is made. One or two spikes are installed between the carrier and rafter foot (depending on the angle of the roof), which remove the load from the rafter system, shifting it on the support log and preventing the longitudinal shift.

Installing the rafter structures can also be in special propellers made in the carrier log (Mauerlat). This method of fastening is applicable with a small corner of the roofing rope and in the presence of additional intermediate supports.

The insertion into the body of Mauerlat is carried out by no more than 3/4 of its diameter, in order to avoid weakening the design. Such a method of installation creates additional friction on a larger area, reliably holding the design details when installed.

The basis of the wooden roof of the house is a frame that holds the roofing coating. It contains a large number of elements, each of which is necessary and is intended for a specific function. One of them is a support for a rafted sliding, which serves to prevent the roof deformation during a wooden house shrink, when its geometry changes.

Shopping wooden house

In one year, the log house can be lower by 15%. On average, the shrinkage is 8%. At the same time, it can occur unevenly, which negatively affects the state of the rafter system. The change in the size of the wooden structure takes place all year round. In the rainy summer season, wood swells, and in winter the material dries. In addition, the walls are gaining and losing moisture in different ways, depending on the illumination and roses of winds. In the presence of support on the central bearing wall of deformation, it and outer walls differ significantly, which also affects uneven changes in the geometric size of the house. In the heating period of the wall, especially the central, decrease in samples from the drying.

In the absence of a central wall there may be more important problems. If the rafter system is not assembled as a farm, its rigidity is significantly lower. As a result, not only vertical, but also horizontal load acts on the walls. Under the influence of pressure, they can cross outwards, and the house in terms will acquire the shape of the barrel. At the same time, the roof is deformed and will be kept in a skate. "Pyatirenka" allows you to get rid of this problem or significantly reduce it.

Application of screw jacks

To compensate for the processes of precipitation and seasonal skills of the house, screw jacks can be installed. They must be located on all vertical supports in the house. Combining jacks with the help of compensation for mobile structures.

The purpose of the application of sliding supports

It is not always advisable to hardly fasten to Mauerlat or nails, brackets, etc. In the event that the box of the house can give a shrinkage, it is necessary to create the capabilities of the rafters to shift relative to the supports. Previously, this was done with a wrought-iron wire, which was created to compound with a certain degree of freedom of structural parts.

Since then, the technology has changed, and more advanced devices have become applied, such as the support for the sling sliding. It is attached to the walls as follows:

- to the top crown of the cut;

- to the upper strapping of the frame structure;

- to the beams of overlapping;

- to Mauerlat.

Why are the supports are made by sliding?

The sliding support makes it possible to compensate for the roof skews during operation. When drying wood, a change in the geometric sizes of structures occurs. The width of the house at the same time decreases, but due to the slip on the beam overlap or cutting the roof, leading to the subsequent leaks, does not occur. The reason for the fallout inwards may be different, but it is impossible to underestimate the influence of deformations from the shrinkage.

Advantages of sliding supports

- Creating a reliable connection of the base with the roof.

- Ensuring the mutual movement of wooden structures in the shrinkage of the base, preserving the strength and tightness of the roof.

- Easy device, reliability and durability.

- The small cost and the possibility of manufacturing with your own hands from the girlfriend. In this case, the steel plates should be a thickness of at least 2 mm and are protected from above with an anti-corrosion coating.

Constructive features of Lropil

A pair of rafted a bone roof is made by one sample. The connection in the skate make online, with a gap or brass. Metal plate with bolts and nuts are connected to each other. The main feature of the design is to create sliding fasteners in the lower supports. The rafters are placed on the Mauerlate from above or with an insert for fixing the design in the vertical plane.

Support for rafted sliding, which serves fastener, is made of two parts:

- planck fixed on a rafter foot;

- corner with loop attached to the bearing brusche (Mauerlat or supporting beam).

There is an even simpler version of how the sliding support can be made for rafters (photo below). This uses a corner with a slot. It is fastened on the rafter along its axis, and in the slosses with the gap there is a bolt head, screwed into the body of Mauerlat.

This support for rafters (sliding - Kucis 120x40x40) is only about 25 rubles per piece and easier others in the installation.

Devices are made of steel galvanized plates. They are attached with one or two sides of the rafted. The double-sided version is preferable for roofs with high wind and snow loads and a small mass of roofing design. Fasteners are applied with coated against corrosion, so as not to spoil wood. The length of the stroke depends on the expected displacements and ranges from 6 to 16 cm.

Open and closed supports

Sliding supports for rafters ("sliding") of an open type, consisting of two parts, can be made with your own hands, but at the same time you should use the template. All items must be fitted in size. An open connection consists of a curved plate (fastening plate) and angle with mounting holes (at least five).

In the closed, the plane is inserted into the holder of the corner with the possibility of moving, but is not taken out of it and is intimidate. The collected design allows you to perform the installation better. In the event of the efforts of the separation of rafters from Mauerlat under the action of wind loads of the loop may raise, and the sliding support of the rafted closed has greater durability.

Important! The rapid system with the possibility of slipping relative to the base is advisable to make only for a symmetric bone roof. This is its advantage, because reliability increases at low costs. Supports can be used for a single roof.

for rafters: dimensions

The support includes two components - guide plate and corner. From the size of the product depends the value of the permissible movement of the rafter foot.

The popular sliding support for the open and closed type rafter kucis has a width of the plates of 40 mm, the height of the support is 90 mm, the length is up to 160 mm. Metal for plates is taken with a thickness of 2-2.5 mm. They are profiled by cold stamping from low carbon steel, which has good plasticity. Corrosion protection is a zinc coating applied with a hot way. By purchasing products without a coating, they should be painted paint so that the material does not rust.

Corner is attached to the reference bruster. If its surface is round, for mounting is prepared to a flat platform, having a wood on a log under the size of the M-shaped part of the part. In the photo below shows a similar sliding support of the rafted closed (PAZ). Both types of products are made of stamping and cost inexpensively.

Guides are attached to the rafters in the extreme position to ensure maximum movement. Since when the roof shrinkage, the angle of inclination changes relative to the skate, in the upper part of the rafter it is necessary to make a hinge, special plates with perforation can be used here.

Installation

Support for rafted sliding when mounting the roof frame is applied as follows.

- The rafters are made of 150-200 mm wide width and 50 mm thick. In case of insufficient length, the rafter legs are lengthened by increasing the brass with a chaotic arrangement of fastening elements to prevent cracking.

- From above, a run is placed - carrying a bar located horizontally and perpendicular to sliding rafters.

- At the bottom of the rafter feet are fixed on the wastes performed in Mauerlat. It does not allow them to join. But at the same time, the pressure must hold the boards from transverse distortions. The presence of Mauerlat evenly distributes the load on the entire building. With its absence, the local pressure on the walls from the rafter becomes greater.

- The fastening details of the appropriate sizes are selected depending on the shift range of the rafter.

- By corner on the support log is preparing a playground.

- The corner is attached perpendicular to the log to ensure the free movement of the plate.

- The guide is inserted into the corner loop and is attached to the rafter along its axis. The installation is made to the extremely lower position, since the wall below will shrink and decrease in size. At the same time, the rafter foot will fall down.

- The rafting boards are connected on top of the articulated way.

Conditions guaranteeing strength, reliability and durability of the roof

- Compliance with the necessary mechanical properties and sizes of sliding supports for rafters.

- The location of the guide support parallel to the axis of the rafter, and the corner is perpendicular to ensure reliable slip.

- The cross-section of the rafaling board should not be less than 150x50 mm.

- The roof frame must be processed by an antiseptic and fire-resistant composition.

- Compliance with the correct roof frame proportions.

- Production of the entire rafter system by template.

- Creating a hinged skate connections.

- Building should be made alternately at the bottom and upper parts.

Sliding support for rafters: Application for other purposes

Wood shrink compensation is applied not only on roof frames. It is used everywhere, where you need to create the possibility of moving parts of wooden structures, for example, when erecting partitions in wood houses. If you need to separate the wall in the bathroom with ceramic tiles, it is impossible to see it with sheet material.

It is necessary to install a "floating" frame, fixed on top to sliding supports, and then fix the plasterboard to it, to which the tile will be labeled. Moreover, the sewing is done not until the ceiling. When the walls are deformed, the framework will remain fixed, and the facing will not collapse.

Conclusion

Sliding supports for rafters in wooden houses are necessary to prevent the roof deformation when shrinking at home. It is especially active in the early years after the construction (about 8%). The correct installation of the rafter will provide a constant tightness and strength of the roof.

Modern construction includes the construction of buildings of various types, but at the same time the roofs with several slopes continue to maintain leadership as the most promising. In the case of wooden buildings, the probability of shrinkage is high, which leads to the deformation of the structure. This means that a design element is needed that allows it to adapt to changing the configuration. Such an element is a sliding support for rafters.

What do they imagine?

With the help of such supports, the rafter are attached to the bearing brusade, so that it is possible to obtain a balanced design. This item is also used in other cases - if necessary, connecting several sliding elements with a fixed base.

If you are interested in how you can look at our site.

Read more about the truck system of a single garage roof in a separate.

In addition to imparting the design of the rafted additional strength, sliding supports have a lot of advantages, one of which is the ease of installation that does not require special tools and skills.

The use of a sliding support reduces manual labor costs during the construction of the roof, since in this case there is no need to carry out manual balancing of the roof design details.

Functions and characteristics of sliding supports

The appointment of sliding supports is their attachment to Mauerlat during the construction of log and brusade houses. These perforated elements have repeatedly confirmed their effectiveness: the sliding method of fastening prevents the roofing structures and cutting the walls of a wooden building.

The appointment of sliding supports is their attachment to Mauerlat during the construction of log and brusade houses. These perforated elements have repeatedly confirmed their effectiveness: the sliding method of fastening prevents the roofing structures and cutting the walls of a wooden building.

Absolutely all the buildings created from solid wood arrays (they include chopped and rounded log and profiled timber) are subject to natural shrinkage. As a result of the shrinkage of the rafter system of the structure of the tree, there is a weakening of the structure, there are significant skews. Made using sliding supports floating rafters solve this problem.

The components of these fastening elements are a metal bracket and a corner with a loop. Basically, they possess the following parameters:

- height: 90 mm;

- width: 40 mm;

- thickness: 2 mm;

- length: from 90 to 160 mm

Since the rafter system must withstand heavy loads, all used fasteners, including sliding rafters, must be made of durable and reliable materials. Low carbon steel, which is the material for the manufacture of sliding fasteners, complies with these requirements.

The process of installing roofing structures using these fasteners does not represent complexity: it requires only a screwdriver.

Sphere use support

The process of shrinkage of wooden houses is particularly intense during the first few years of operation. The change in the forms and sizes of the structure is mainly due to changes in the temperature background and the level of humidity. In this case, the height of each individual log or bar is changing, the result of which becomes the overall change in the height of the wall, which consists of changing the parameters of each element separately. From the above, it can be concluded that as the height of the wall increases and the degree of its shrinkage during operation increases. The maximum height is located under the skate of the wall - it means that its shrinkage is the greatest.

The process of shrinkage of wooden houses is particularly intense during the first few years of operation. The change in the forms and sizes of the structure is mainly due to changes in the temperature background and the level of humidity. In this case, the height of each individual log or bar is changing, the result of which becomes the overall change in the height of the wall, which consists of changing the parameters of each element separately. From the above, it can be concluded that as the height of the wall increases and the degree of its shrinkage during operation increases. The maximum height is located under the skate of the wall - it means that its shrinkage is the greatest.

Walls serving the support for the rafters located along the edges are subject to smaller shrinkage. Over time, this process leads to a change in the angle of inclination of the roof. For this reason, it becomes necessary to take into account the data of geometrical changes in the fastening of rafters and ensure the mobility of the compounds.

The lines of rafters are created by rotating relative to each other, fastening them from two sides using metal plates manufactured by metal.

The lower edges of the rafter represent a certain complexity, because during shrinkage they are not only rotated, but also shifted relative to the wall. The device of rigid and still fixed fastening of the rafter to foot to the wall will lead to it as a result of shrinkage.

For rafters, it is necessary to ensure the possibility of not very large, but still tangible turning and a certain shift along the wall without reducing the fastening strength. In previous times, the annealed wire was used for this purpose. With its help, the top log was tied to the rafter foot. This technique ensured the mobility and reliability of the attached attachment..

Slingers for rafters have become effective, most convenient in terms of installation and satisfying all the requirements for the replacement described in the described method. When using it, the rafter foot is reliably fixed on a timber or a Maurolalate log. If the linen bar is used in the system, this method becomes the only one, providing simultaneously necessary mobility and strength. The location of the mount is the site along the beam offset. For this, the wood of the upper bar is stepping. As a result, a platform is obtained - on it and the fixed bottom of the support is attached.

When performing installation, the support should be located in such a way that the supply of its turn to the shift is the maximum possible.

As a rule, the attachment of the rafter is made on two sides of the rafter legs, however, with a low roofing and a small magnitude of the roofing slopes can be limited to one fastening.

The rafter foot having intermediate supports between the Mauerlalate bar and the skate must also be fixed with a sliding support.

Making sliding supports

These parts in most cases are operated with high humidity and are often contacted with water, condensate penetrating under the roofing skate. In the manufacture of sliding supports, it is necessary to take into account the strong impact of these and other negative factors of the external environment. For this reason, they are pre-coated with a layer of zinc melt, additional alloyed by other substances to reduce the exposure of corrosion and improve strength characteristics, which increases the overall carrying capacity of the structure.

These parts in most cases are operated with high humidity and are often contacted with water, condensate penetrating under the roofing skate. In the manufacture of sliding supports, it is necessary to take into account the strong impact of these and other negative factors of the external environment. For this reason, they are pre-coated with a layer of zinc melt, additional alloyed by other substances to reduce the exposure of corrosion and improve strength characteristics, which increases the overall carrying capacity of the structure.

The manufacture of the sliding supports themselves is made by the method of cold stamping based on a rather durable and plastic material - low carbon steel grade 08 PS. The percentage of carbon in it is 0.08%, which makes it possible to high-quality stamp material. Balancing the strength characteristics of the element is carried out by the method of deoxidation.

Types of sliding type supports

All currently applied sliding supports are divided into two groups:

Open type - Such structures are compiled by two separate elements. The first is the guide attached to the rafter foot. This is a curved steel plate with holes at the ends. At each end there may be two or three, the specific amount depends on the manufacturer. The magnitude of the movement of the moving element is also changing. The smallest value should be 60 mm, the largest - 160 mm. Corner (motionless part of the element) has up to 5 holes.

Closed type - This type of support does not understand the components and is a holistic design. Installation is made assembled. With this embodiment, the fixed part has a form of angle with a special holder on the long side: it is tracked in the attachment bar.

Installation

Sliding rafters are mounted in the case when the material for the frontones are logs or a bar, and the fastening of the ridge of the skate is carried out in the front of the fronton. Such a requirement is necessary to prevent the cutting of walls with a change in the value of the roof of the roofing angle during the shrinkage.

Sliding rafters are mounted in the case when the material for the frontones are logs or a bar, and the fastening of the ridge of the skate is carried out in the front of the fronton. Such a requirement is necessary to prevent the cutting of walls with a change in the value of the roof of the roofing angle during the shrinkage.

The rafters are stacked on the ski run from above and are fixed with the help of a hinge compound. In this case, the ability to change the angle under which the plumbing legs are connected.

The manufacture of such a compound is made on the basis of the perforated plates connected by studs. The second option is the superimposition of the upper parts and the connection with spills with washers and nuts.

In this case, some conditions must be observed:

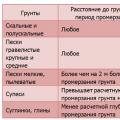

- Mauselalate compound (in this case, the upper crown of the cut) with rapid legs is carried out using sliding supports. As a rule, their dimensions correspond to the following parameters:

- 90 x 90 x 40;

- 120 x 90 x 40;

- 160 x 90 x 40;

- 270 x 90 x 40 mm

The choice of length is determined by the estimated value of the displacement of the rafter feet.

Other ways to use sliding supports

Sliding fasteners can be used everywhere, if there is a need to ensure the movement of parts of wooden structures - for example, when creating sewing and partitions of wooden buildings.

CONCLUSIONS:

- The sliding support for the rafters is a very important element of roofing design that allows you to compensate for the skewers of the rafted system that occur during operation due to wood shrinkage.

- With the help of such supports, the rafter are attached to the bearing brusade, so that it is possible to obtain a balanced design.

- A sliding method of fastening warns the roofing structures and sawing the walls of a wooden building.

- The components of these fastening elements are a metal bracket and a corner with a loop.

- Making sliding supports is made by cold stamping based on low carbon steel grade 08 Ps.

- Sliding supports are open and closed types.

- "Sliding" are mounted under a 90-degree angle with respect to the rafal support on special records. This method ensures the unhindered movement of the design.

- Sliding supports are fixed using safety coating screws.

- To ensure the possibility of slipping at the maximum possible length of shrinkage, the guide line of the sliding support must be laid parallel to the rafter foot, and the installation of the corner is performed perpendicular to the leg at the top.

How does the hard and moving connection rafter, find out from the video.

The sliding support for the rafter is the necessary part of the frame of any roof with sloping slopes.

Sliding supports or sliding are a kind of fastener, which allows the rafyles to slide along the crossbar on which they are fixed.

It is necessary so that during the shrinkage of the house of the rafter did not break out "with meat".

Application area

Over time, the building sitting down. This process is uneven character - one walls are seated faster, others are slower.

This leads to a change in the angle of inclination of the skates. These changes must be taken into account at the stage of the roof device. Sliding supports allow you to fix rafters movably.

Sliding holders attached to skates allow the rafters to turn relative to the crossbar on which they are fixed.

It is more difficult to create a moving connection on the heel of rafters, as this item should be able not only to rotate, but also move in parallel wall.

If on the building, prone to shrinkage, fasten the rafter stationary, then after a while, this element of the roof is deformed, which will lead to the destruction of the entire design.

By providing rafters at least a small rotation and the ability to move along the wall, you can get rid of this problem. It is important that the holder of the rafter does not lose its strength.

Previously, the rafters were fixed with a moving method of burning wire, which simply tied a rafter foot to the crossbar.

The wire fastened the line and at the same time allowed it to shift to several centimeters.

Now, with the same purpose, sliding supports for rafters are methies manufactured by an industrial method.

Such fasteners are more convenient in the installation and a stronger wire. It is reliably fixed on Mauerlat or Konk.

If the details of the rafter system are made of glued timber, then sliding supports become the only way to firmly fasten the rafted.

The holder is fixed on the site along the shift of the crossbar. For this, a small area is stepping on the bar. On the resulting flat platform, a fixed part of the holder is fixed.

Sliding supports are installed on both sides of the rafter foot, on more flat roofs it is permissible to use one mount on each rafying.

In the change system, sliding holders are fixed on Mauerlate, skate and in intermediate supports.

Sliding supports can be divided into two types.

Open - such a holder consists of two parts: guide and attachment itself.

The guide is fixedly fixed on the line - this item is an expedited metal plate, at one end of which there are holes for threaded fasteners.

The guide includes a movable part of the sliding support, which is called "Corner". It should be able to move around the rail to the distance from 6 to 16 centimeters.

The closed sliding support is established in the assembled form. In the corner there is a hole-holder - it is focused on the bar and secure both of its end on the rafting stationary. In this case, the rafters will be able to move both to the right and left and up-down.

Making sliding supports

Roofing fasteners are operated in adverse conditions. In some cases, it is in contact with water. A condensate that is formed in the underfloor space can fall on it.

Therefore, sliding supports are made from durable metal - alloyed steel - and coated with an anti-corrosion zinc layer with the addition of alloying substances that increase the coating corrosion resistance.

Strong and reliable hardware increase the carrying capacity of the rafter system.

The sliding holders themselves are manufactured by cold stamping from steel 08 Ps. A small carbon content in the metal allows you to hardly stamp products. To increase the strength, the detail is deasured.

If there is no galvanic coating on the fastening product, then before installing it you need to cover the oil paint layer.

General rules of operation and installation of sliding rafter systems:

- sliding rafter systems can be installed on the building of the correct geometric shape;

- there are mobile parts in the system, so before starting the roof mounting, the perimeter of the box is measured and check its compliance with the project;

- the rafters themselves make one template - it allows you to get the same details;

- in sliding rafter systems, a mobile node, as a rule, is made on Mauerlat, and sometimes also the skating overlap;

- for the creation of movable nodes, studs and screws are used as connecting axis;

- long spans are overlapped with increasing lumber, while the compound is carried out with a mustache using brackets or screws;

- when building sawn timber in them, mounting holes are made in advance;

- the distance from the mounting holes to the edge of the board is at least 10 centimeters;

- for the strength of the connection of the opening is drilled in chaotic order;

- each support of the sliding rafters is set parallel to the previous one and at an angle of 90 degrees to the bearing of the beam - this will protect against the jamming of moving elements;

- sliding supports are fixed perpendicular to rafyroid;

- the sliding support is attached with nails or self-drawing with anti-corrosion coating;

- the length of the rafter in the support should correspond to the calculated value of the shift of the walls during shrinkage;

- the insertion in Mauerlat cannot be deeper than 1/4, so as not to weaken this essential detail of the rafter system.

As a rule, sliding supports are issued by the following sizes (in centimeters):

- 9x9x4;

- 12x9x4;

- 16x9x4;

- 27x9x4.

Hinged connection raftered over the skate log

There are several ways to fasten the rafted on the skate log:

- jack;

- vansel;

- on the pursuit and / or skating timber.

When fastening, make a moving attachment rafters is impossible. The top ends rafters are based on each other and are fixedly fastened with metal plates that will not allow them to be shifted.

When fixing the rafted on the run, they not only fasten over the skate of the jack, but also fit into the cutting bar and run, that is, the rigidity of the attachment rafter increases.

If the rafters are attached to the skate bruse of the methods of jack and on the run, then the sliding support is installed at the scene of the connection of the rafter with Mauerlat.

This can be done in one of the following ways:

- run the stroke and put on Mauerlat;

- connect the elements onto two nails;

- fix with one nail, driven down from top to bottom to Mauerlat through the leg;

- instead of nails, use steel plates with holes;

- fasten your leg to Mauerlat using a bracket;

- release a rafter foot behind the wall and fasten the mounting plate;

- use special fasteners - Salazki.

All these fastening methods will allow the rafter to rely on the base beam, but when moving the elements of the box, the parts of the rafter system will be able to move, which will prevent the seed and deformation of the roof or the upper part of the walls.

For a moving connection suitable for the waist method. In this case, you can use not sliding supports, but a hinge connection.

The rafters above the skate bar are connected not to the ends, but the sides and fasten with each other bolt or hairpin, which allows them to shift relative to each other in the vertical plane.

Step-by-step algorithm for mounting sliding elements on Mauarelat:

- in the upper part of the Mauerlat, they make a depth of approximately one quarter of the height of the bar;

- in the propyl put insert a rafter foot - it should be firmly included in the clearance prepared for it;

- on the right and on the left of the rafter foot, the sliding open supports of the open type are fixed, one on each side;

- first fix the guides by screwing into the holes located at the ends of the details, galvanized screws.

Important: Guides are screwed down not to the upper or side plane of Maurolalat, but to its edge. To do this, the finger is shy, so that there is a flat area in the place of the straight angle.

Similarly, fasten the sliding support on the other side of the leg. All, movable rafter knot is ready.

When operating the power tools to securing one sliding support, no more than three minutes goes, on the device of the entire moving node, including operation with an electric saw - ten minutes.

What will happen if in the construction exposed to the shrinkage, fasten the rafter fixedly? The consequences for the building will be the most deplorable. The form of deformation will depend on the type of roof.

For example, when a bounce roof, after a shrinkage, the facade, along with the fronton between the wall and the roof, a through slot is formed, into which the hand freely will pass.

But even worse, if the side walls will be seen - in this case, the rivets will acquire a concave position and will have to rewor all the roof to return to her normal appearance.

Sliding rafters allow the roof frame to see simultaneously with the shrinkage of the frontones, which contributes to the preservation of the walls is safe.

Sliding fasteners designed for rafters can be used not only in roofing works, and wherever mobile connections are required: during the construction of wooden partitions, finishing the walls of wooden houses with a cafeter, etc.

What is a hot water supply of an apartment building

What is a hot water supply of an apartment building Water supply of an apartment building

Water supply of an apartment building Calculation of the Load for the foundation Installed Electrical Instruments

Calculation of the Load for the foundation Installed Electrical Instruments