Earth drill electric do it yourself. Design and types of earthy drills. Making cutting part

During the pouring of the concrete solution, each layer is compacted. Make it manually by punching the mixture of the mixtures of various materials (metal, wood) with stacked layers (metal, wood). All work can be produced much faster with special devices - vibrators. But the factory vibrating plot acquired for home use is not always an economically appropriate option, because it costs expensive. Work it several times, and after leaving, so that it simply lay, it does not make any sense. In this case, you can make a vibrator for concrete from the perforator with your own hands. Homemade will speed up the process of rambling and improve the quality of work.

To implement in practice the project, the following materials and tools:

- metal (steel) plate required size, 50 to 70 mm thick;

- iron rod either fittings (rectangular either round section) of such a length so that you can get to the bottom of the displayed formwork when pouring concrete;

- perforator;

- old boring or peak, blade, chisel, even crown;

- bulgarian with metal discs;

- welding machine with electrodes;

- line or roulette;

- marker.

The minimum power of the perforator must be 1.5 kW - only such a tool will provide the required performance without overheating.

One side of the rod with a cross section of 15-20 mm is treated so that it can be inserted into the perforator cartridge. The second side welds a plate of stainless steel. This will require special electrodes.

Better so that the rod is also from of stainless steel. Concrete is an aggressive environment. The usual metal is largely exposed to chemicals, and is also faster mechanically wear.

The sequence of manufacturing nozzles for rubbing is:

- cut off with a grinder from the steel sheet of the rectangle of the required dimensions, and from a round or rectangular rod a piece of the desired length;

- weld the plate to any end of the rod;

- cut off with a slight stock seat of the borax;

- weld it to the rod.

If you do not use the old boring, the special adapter will be made under the perforator cartridge, or with the help of machine equipment to sharpen the landing place at the free end of the rod. It is easiest to immediately use the burden of the desired length. On the basis of the perforator, more complex devices can be made, for example, with a flexible shaft, which will additionally mix the working solution.

The homemade tamping for concrete of small sizes (the simplest option of manufacture) is represented in the video.

Dacha or private household owners are often faced with the need to grow holes for intake pillars or pile supports. For the drilling of the Earth, both manual tools are used and equipped with electric or fuel-powered (for example, gasoline). In the first case, the work will take longer time, and also requires large labor costs. Purchase or rental of powerful devices costs something expensive, so folk craftsmen have come up with how to make homemade jambur from the perforator.

But improvised devices, compared to factory counterparts, there are the following disadvantages:

- they can only be drilled by relatively shallow pits of a small diameter;

- to work on solid soils, they are not suitable.

Structurally homemade fixtures consist of three parts:

- perforator;

- conventional earth auger;

- adapter or gearbox.

The last 2 details of the device can be made with your own hands. Sold even special nozzle (auger) for drillingwhich is attached to a powerful perforator or drill. The working tool made in this way is shown in the photo below.

An important point is the value of power and the number of turns of the perforator, which will be used in conjunction with the drilling device. The optimal value of the first parameter for the manual model of the self-made yamobura is 2 kW. It should be taken into account that, depending on the number of revolutions, the boring can be connected directly with the perforator cartridge either through the gearbox. For models with a power of 2 kW, the latter is not needed.

The optimal for drilling is the number of turnover of the work nozzle from 60 to 300 per minute. This value depends on the properties of the soil on the site.

Drilling is performed in two ways:

- continuous;

- with periodic delivery of soil.

In the first case, you will need a more powerful tool (with a large torque).

Algorithm manufacturer of homemade drum

To make me with your own hands the bump for pits, you will need, except for the perforator, such tools and materials:

- angle grinder;

- welding machine with an appropriate metal-used brand of electrodes;

- electric drill;

- unnecessary perforator drill;

- metal fittings either rod for the manufacture of the rod;

- material for cutting part;

- cable and sockets to make the simplest extension.

Work on reworking a perforator into a device that can be used to drill wells in the ground is directly in creating nozzles. All work is performed in such a sequence:

- cut off the rod or tube using a grinder piece of the desired length (about the meter is sufficient if the power of the tool is 2 kW);

- knives are connected to the lower end (methods for connecting and features of the design of the cutting part are discussed below);

- it is cut off from the drill its base designed to install this nozzle into the perforator cartridge;

- weld the cut fragment to the tube.

The simplest option is ready to use in operation. If you do not use the base from the old perforator drill, it will be necessary to pull out the rod to the tool cartridge or under the adapter used.

Besides manual model, you can do Similarity of stationary drill installationThe possible option of which is presented in the photo below.

To ensure the power supply of homemade yamobura, you will need to purchase or make an independent extension.

The work created by the device is shown in the video.

Making cutting part

Apply as knives:

- discs from circular saws of a suitable diameter;

- ready augers from factory motobov or agricultural machinery;

- the metal sheet from which the circles of the desired diameter are cut, dragging them and bending in the desired way.

The cutting part can be made removable (with a bolted compound) or non-removable (welded to the rod).Both options are presented in photographs below.

Cutting part designmust meet such parameters:

- to be larger diameter (5 mm sufficient) than this parameter in the created holes;

- it is necessary that the angle between the blades equal to 25-30 degrees;

- the front (cutting) part of the knives should be hidden at an angle of 45 ° -60 °.

It is desirable to make a drill from a drill designed to drill metal so that the tool is easier to enter the ground mass.

In essence, reworking the perforator in the vibrator or an earthen boring is to manufacture the appropriate on the functionality and the size of the nozzle. Difficulties may occur only, if you independently prepare on the rods the seat under the cartridge or adapter. In general, the manufacture of discussed options will not require much time and effort.

If during the excavation work on the site you need to dug a few holes well for pillars or racks, then the garden drill model Fiskars Quikdrill will help significantly accelerate this process.

Electric manual screw Jamobur bison, tornado or fiscars, is able to significantly alleviate the entire process of land. In addition, Garden Drill Fiskars Quikdrill Models can drill holes in soil at such depths as 100, 200, 300 or 500 mm.

Electric manual screw jambur bison, tornado or fiscars can form a hole in the soil for trees and shrubs.

1 Purpose and Characteristics

Currently, drilling work is carried out everywhere due to the incessant and developing country construction. In most cases, such aggregates as an earthenware Jamobur bison, a tornado or fiscars are used in drill operations at dachas and country sites.

It is worth noting that the garden drill model Fiskars Quikdrill and its analogues such as bison, tornadoes and fiscars are able to create holes in the soil for:

- Installation of fence posts;

- Mounting piles;

- Bookmarks of the pile foundation with a depth of 100, 200, 300 or 500 mm;

- Creating shallow trenches and technical openings;

- Planting shrubs of seedlings and small trees.

The screw homemade Yamobur is represented as an electrical device, which refers to the category of tools for cutting.

Such common aggregates like bison, tornadoes and fiscars have excellent feedback from users, and are able to do holes with depth indicators 100, 200, 300 or 500 mm in such materials as:

- A rock;

- Concrete;

- Brick;

- Saturated pebbles soil.

Structurally, manual earth auger homemade Yamobur, similar to a conventional drill, equipped with a shank and a spiral. Due to the presence of such a helix, such aggregates as a bison, tornado and fiscars are capable of not only to create holes in a depth of 100, 200, 300 or 500 mm, but also to make a removal from the drilling zone of the waste material.

Earthy manual screw Jamobur is made of materials with excellent performance indicators. Its cutting part is made using a alloy with a high degree of hardness.

The rendered screw manual Yamobur Tornado, bison, fiscars, and similar to them, have several configurations for sharpening the cutting edge.

A distinctive feature of such portable devices, as a hand-made namobur Tornado, bison or fiscars is the presence of an electric motor equipped with two comfortable handles.

The electric motor is equipped with a special clamping type mechanism in order to fix the drill tool - auger. The auger in such aggregates, as a manual namobur Tornado, bison or fiscars is represented as a rod with a solid screw surface along the entire longitudinal axis.

2 What are the features of the garden electric bora?

Electrobur is represented as an electric bottomhole machine, which is equipped with an electric motor that is mounted in the device pipe case.

The housing ensures the movement of the drill bit during the work. The well, created with the help of such an aggregate, can last a long time.

Reviews of the unit presented for the most part are good. All modern products are equipped with an asynchronous oil-filled engine equipped with a short-circuited type rotor.

Thus, the main parts of the electric borax is an asynchronous oil-filled engine and a spindle that is located on rolling bearings.

Inside the pipe case is a stator mechanism magnetic conductive steel package. This compartment is separated by non-magnetic steel packages in those places where radial ball supports of the rotor are located.

All rotor packets are covered with a layer of aluminum winding and included in the hollow rotational motor shaft. Inside the cavity of the engine is filled with a special variety of dry insulating oil.

In addition, the inner cavity of the engine is hermetically fenced with the upper and lower seals. When starting the system, the glands are filled with oil.

In order to compensate for oil leaks and to support constant internal pressure in the engine in the upper part of it, so-called lubricators and three glands are placed.

Each of the glands is equipped with a cable input, which is served from the edge of the contact rod, and, passing through the glands, is connected to the stator winding.

In order for the weight of the rotating shaft to be perceived by the whole mechanism, the lower part of it is equipped with a steady ball bearing installed.

Spindle is attached to the bottom cover of the engine. It is equipped with a multi-row axial support that moves due to the presence of ball bearings.

In the case, another shaft is moving, which is inside the hollow, and its centering is made with a number of ball bearings. There is a connection between the spindle shaft and the main motor shaft.

It is implemented using a junction coupling of a toothed shape. In the place where the shafts are connected, there is a seal of a hinge type.

It provides a high degree of waterproofing from the flushing fluid ingress. All axial loads that are subjected to a rocking shock tool (auger) are completely absorbed by the spindle housing and are not transmitted to the motor shaft.

All types of asynchronous engines that are used by electrical workers have a sufficiently limited operating range of the rotational frequency.

Changing this parameter directly depends on the speed, which is capable of sliding the rotor relative to the stator field. Thus, the motor torque value directly depends on the voltage square at the input.

When the voltage decreases, then there is a significant reduction in the torque. Based on this, the voltage drop in short-term loads, it is necessary to compensate for the increasing voltage at the engine input by 10-15% of the nominal level.

Depending on the characteristics and variety of the engine, the voltage in the terminals of the electrical armor can be from 1000 to 1200 V. at the moment when the engine is started, a significant reduction in torque is observed is the so-called failure zone.

Then this parameter is restored after the unit output to the normal working pace. Due to the fact that the launch of the engine is made with an indicative of a small degree of load, the mask moment of all parts involved in rotation is very small.

However, even if the torque is strongly reduced, the engine is capable of accelerating the frequency of rotation of the working shaft in a matter of seconds.

By the way, the efficiency of such an engine, when testing the rated load can be about 70%. This is due to a small level of mechanical losses during the movement of the spindle at fixed points of supports.

The supply of electricity to the engine carrying the drilling is made using a partitioned cable. It is located in the inner channel of the drill column.

Current is performed using a three-time cable. Instead of a third wire, a drill column can act.

It should be borne in mind that the cable support of the electric garden drill is generally considered one of the weakest nodes of the system represented.

The voltage may fall due to the disturbed tightness of the segments of the cable and their further contamination. Disorders in the operation of electrocups is observed when the contacts made using copper are broken, in those places where they are connected to the coupling.

It is worth noting that a portable hand-made garden burden has a number of advantages that are expressed in:

- Facilitate the conditions when working a drill column;

- Reducing wear located in the well;

- Minimizing power costs at idle.

In addition, the operation of the unit does not come into contact with the fluid flow rate. Therefore, the device shows the greatest efficiency in the case when the hole in the ground will be completely cleaned from the sludge accumulated there.

In addition, the working cycle of the device does not depend on the quality and characteristics of the solution used during drilling. Such a property implies the use of the product in working with tensile solutions.

The communication channel for monitoring the work performed by the unit is presented in the form of a conductor. This allows the device to remotely carry out drill operations in some modifications.

Due to the fact that manual electrical equipment is represented in the form of an oil-filled engine, all parts of its parts lead work in an environment that is isolated from sludge.

Based on this, the rotational elements of the auger in the smallest degree are exposed to malicious corrosive and abrasive processes.

Among the disadvantages of such a device, it is possible to highlight a sufficiently high cost, compared with mechanical counterparts. The probability of obtaining damage and curvature when grabbing in the wellbore and the low degree of reliability of the cable connection.

Sergey, 45 years old, Samara:

I decided to equip my country household plot and put a grid fence. In order to make small wells for baking columns used a manual electric boring, which borrowed from a neighbor.

All the work performed in the shortest time, while not spending great effort. Excellent aggregate. I read the reviews - now many in the farm have such a thing, so I decided to buy it myself. I advise everyone!

Vladimir, 53 years old, Voronezh:

The modern market is saturated with different kind of construction tools and devices. Take, for example, Yamobur: Today you can easily find a device, the cost of which is quite accessible, and the stated characteristics are fully satisfied with the buyer. It would seem that there is nothing easier: buy and use. But do not always hurry with such acquisition. The fact is that budgetary equipment in practice does not always meet the needs of the buyer, and it is not at all capable of performing functions entrusted to it: the brunt does not hurry to enter the ground, even with a strong press, the engine turnover falls from a large load, etc.

Buy a powerful and expensive device for a small volume of building or garden work - not always appropriate. Rent - too, pleasure not cheap. Therefore, the craftsmen to apply the equipment already available at their disposal to create compact drilling installations.

Earth Drill

In most cases, the mechanized yamobur is a power plant (a powerful drill or gasoline engine), which, using a simple mechanical drive, is connected to a conventional manual brown. Bur can be made independently.

Drill from drill do it yourself.

Drill from drill do it yourself.

You can find a ready-made boring car.

skyle User forumhouse.

Many say that they bought just such a screw and secured it is a powerful low-robust electric drill.

Engine characteristics

Recommendations relating to the number of revolutions of the power plant and its other characteristics deserve separate consideration. Let's start with the fact that the power plant can be connected to the brown both directly and through an additional gearbox. The need to use the gearbox each determines for itself. As practice shows if the rated power of the drill is 2 kW, then there is no need for the reducer of the gearbox (especially if the installation does not have a special bed, and in the process of work it is necessary to keep it).

jumper_at_home. User forumhouse.

At first, the gearbox was planned, but after the field tests with the scheme - "Drill - Auch" was decided from the gearbox to refuse. The moment is that the operator does not notice at all (if you drill with your hands).

Power index - 2 kW - not happened by us. It is such a drill most often use the participants of our forum in the manufacture of mechanized yamobur.

Tri.dr.e. User forumhouse.

There is experience in building a column foundation with painter. Used a 2 kW and auger drill, calculated on the diameter of the pit - 30 cm (the diameter of the boosa is somewhere equal to 29.3 cm). For deeper drilling used an extension from a conventional steel pipe. The ground in me on that place is not sugar: the earth, then clay, then some kind of lens with beach sand, then again clay with sand, and then blue clay (at a depth -1.8 - 1.9 m).

In order for the units of the required depth in the land, the user had to build a compact drill unit (with a bed, winch and other auxiliary devices).

But now we are talking about the power of the power unit, and from the presented description it is easy to understand what a drill is capable of a rated power of 2 kW (even without a gearbox).

A bit of theory

If we consider the relationship between the power of the drill (or gasoline engine) and the torque on the shaft of the borax, it is determined by the following dependence:

- N - Power (W).

- M - torque (NM).

- n is the number of revolutions (rpm).

- 9549 - Special coefficient.

Theoretically torque on the working shaft of such an installation during revolutions of 500 rp should be 38 nm (64 nm - at 300 rpm). But to calculate the torque, it is always necessary to consider the losses that define the efficiency of the device. The fact is that most of the manufacturers of the power tool indicate only the power consumption of their devices, and the output power (on the working shaft) by 1/3 ... 1/4 less consumed. Accordingly, less and torque. A 2 kW dry drill at 300 rpm will create a torque on spindle, equal to 64 nm, and approximately 48 nm.

Choosing a power unit for his yamobura, you can view devices with a power consumed less than 2 kW. But then seriously will have to think about the introduction of a lowering gearbox in the construction of a drill unit.

uVL77 User forumhouse.

Regarding the gearbox: the gearbox is good, because it allows, without changing the power, proportionally change the number of revolutions and torque. That is, reducing the number of revolutions through the gearbox, we proportionally increase the torque. And in this case the power remains a generalized characteristic (constant).

Focusing on a torque that creates a 2 kW drill (without an additional gearbox), you can choose a suitable device for your yamobura. In other words, knowing the drill power, the number of turns of its spindle and the gear ratio of the gearbox used, you can calculate the torque value that you get at the output of the power plant. But it should be understood that the speed of the rumble can not be greatly reduced.

uVL77 User forumhouse.

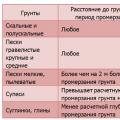

The optimal frequency of revolutions during drilling is from 60 ... 100 to 200 ... 300 rpm. Mode Depends on the type of soil, the method of drilling, varieties of drilling nozzles, the well diameter, etc.

In the above quote, drilling methods are mentioned. There are all two: continuous drilling and drilling with a constant removal of soil. For continuous drilling, the installation should ensure a large torque.

During drilling with a constant removal of the soil of the auger, driving into the ground to a certain depth, rises to the surface. In this case, the loosened soil located on the working blades of the auger is also extracted out.

The operation is repeated until the drilling system reaches a given depth. The process is time consuming, but it does not require large torque.

As we said, choosing a power unit for a drill unit, it is better to focus on a low-definite drill with a power of 2 kW (that is, to the torque that it transmits to the working shaft). Judging by the numerous reviews of Forumhouse users, these devices managed to prove well. Power of gasoline engines should also comply with the specified indicator.

Reducers for Yamobur and their varieties

The assembly of any mechanism in most cases is characteristic of the use of primary materials, devices and nodes that have long been idle, because they are not worthy of a worthy application. The experience of our users suggests that the reduced mechanical transmission can be made of a wide variety of details: from the spare parts to the moped person, from the uncomplicated chain or worm gear, from a suitable gearbox of unknown origin, which accidentally closed on the old shelf in the garage and so on.

Ensuring drilling gearbox, the main thing is not to forget about the optimal turns of the borax and that it is necessary to ensure a sufficient torque on its working shaft.

Mehanik020. User forumhouse.

My broken moped was lying around, I took the rear gearbox from him. Sawned the gearbox to the Turbine (the back of the aluminum case with the gearbox), then across the gear gear fixed to this gearbox, the electric motor from the old electropulum with a capacity of 2 kW. The engine with the gearbox gave the ratio - 13: 1 (at the output it turned out about 300 rpm).

About the chain transmission: possessing the famous fraction of the smelting, it is possible, without making great efforts, to build a completely reliable yamobur with sufficient power. The idea presented is not new, and many successfully apply it in practice (if there is a need for this).

jumper_at_home. User forumhouse.

There is no gearbox, although it was planned to manufacture from the GHM chain of the VAZ 2101 and its same asterisks. Transmission number - 1: 2. Tests showed that it is not needed. Is that at all solid soils to use it, but we have no such.

The application of the above mechanisms requires a non-standard approach to the build of a drill unit. If you have a small serial reducer (or it is possible to purchase it inexpensively), then the task becomes much easier. Here, for example, the photo of the gearbox shown by the user Melomandk.

Melomandk. User forumhouse.

Here is such a gearbox. That's just a gear ratio large - equal or even a little more than 1:40. Sizes (by body) - somewhere 15 x15 cm.

As it turned out, the device has quite suitable parameters.

di Griz User forumhouse.

My Yamobur based on such a gearbox. While I am very pleased. Engine - Bulgarian (3000 revolutions at the exit). Bulgarian power - 2 kW. Claine did not try, but a tough rammed land with the inclusions of the rubble and rotten roots of Yamobur took. A screw diameter - 160 mm, self-made knives on it - from the springs.

Stanina

If there is a lot of work, if you need to drill deeply, and it is very difficult to keep the installation in the hands, then the equipment can be fixed in a special bed.

Constructive execution at homemade stanis, as well as under low mechanical gears, may be the most diverse. But there are structural elements that are used in the overwhelming majority.

Lifting mechanism

As a lifting mechanism, you can use a chain transmission installed inside the central rack. Lifting and lowering is carried out either using an additional electric motor or with a handle (as in the photo from the user jumper_at_home.).

jumper_at_home. User forumhouse.

Major plunged by 1.8 m (auger + extension cord). I did not need deeper. Homemade winch - 2 gears and a chain from a motorcycle.

In order for the stove with the main electric motor without moving freely along the vertical tube, four rollers can be installed on the carriage.

Another lift design involves the use of steel cable and winch with an additional electric motor.

Mehanik020. User forumhouse.

On the square tube up and down the main electric motor of the drill rides. He moves at the expense of the winch (which I already had). This winch is needed in order to pull the boring of the ground from the well.

For convenience Mehanik020.made a remote controlling the winch and rotation of the boraxy during operation.

The drill, along with the soil on it, can create quite large loads on the winch. At a great depth, it will work on the principle of the piston, creating a vacuum and exacerbating the situation when lifting up. Therefore, the more powerful the winch is used, the better.

Dmitryevg. User forumhouse.

My winch is designed for 250 kg (500 through the polyspaster). Power - 1kW.

Lower support for the bed

The bottom support of the bed can be equipped with two wheels (for convenient movement within the construction site). If everything is done correctly, the installation by a simple tilt of the bed will be translated from the transport position in the working.

It is desirable to install adjusting screws on the support elements of the bed, which will help to put the car in accordance with the vertical level before starting work.

Materials for the manufacture of beds are chosen due to considerations of strength. Independently performing a complex calculation of the design of the structure is far from everyone, but anyone can take advantage of the experience of the participants of our portal.

So, user. Tri.dr.e.made a bed from a corner 50 * 50 * 5. Vertical supports and upper transverse bar are made of two bonded corners of the specified size.

User jumper_at_home. Lined in the design of the bed different metal profile with a thickness of the walls - at least 3 mm. The plot under the power plant was made by it from a steel sheet with a thickness of 10 mm.

But the installation photo that was created by the user Pwrww."From what was" (as he himself says).

Pwrww. User forumhouse.

The most difficult thing was to find two smooth solid three-meter pipes with a diameter of 60 mm. If they were not, I would buy a profile pipe for 80 or 100 mm. Below used a piece of channel 80 and a corner of scrap metal. Also among the scrap found 4 P-shaped plates of suitable length.

Ideally, the carriage should be made in such a way that, if necessary, the drill installation operator was able to become. It is especially important to comply with this condition on solid soils.

jumper_at_home. User forumhouse.

This is what was used to protect against drill turning: a stubborn corner of steel - 6 mm is screwed to the hole under the handle, which is available on the drill case. Everything is pulled by bolts with a sufficient plane of surfaces. If you want even more reliable - Provide a clamp under the planting protrusion, which is available on the drill convey.

Mechanical drive

The design of the mechanical drive connecting a drill or other engine with an earthen drill with a working shaft is not different. To create it, there is enough adapter, which is inserted into the cartridge drill (Morse cone, etc.) and the cylindrical sleeve, one end of the bark is welded to the adapter, and the other is dressed on the boome shaft. In order to increase the depth of the drilled hole between the drill and the brown, it is possible to insert removable knees made from the same material as the rod of the bora.

In order to prevent breakdowns when encamping the working body, the drive and the boron should be connected using a special protective heel. The stud is made of metal bar - 4 ... 8 mm. Testing the installation is better with a stud with a minimum diameter (4 mm).

Almost prof User forumhouse.

Imagine if you have a boring to stumble onto a stone and commit. I have a nail of 4 mm as a slide stiletto, and it never cut it. But if an obstacle meets, then he gives his hand in his hands.

Homemade

As we said, the working body of the installation (boring) can be purchased in a specialized store, but it is quite possible to make it yourself. Here, for example, homemade drill with removable blades.

For its manufacture, we will need a thick-walled pipe of a suitable diameter (30 mm), as well as material for blades and for their base. The bases to which blades will be screwed can be made from a thick metal sheet (6 ... 10 mm). The blades themselves should be made from high-strength heat steel (Art. 65g). If you need a small-diameter garden yamobur, then you can use ordinary springs from the truck.

For the manufacture of blades, you can use discs from a circular saw.

The diameter of the borax should be 5 mm more than the diameter of the drilled holes.

We present to your attention a sketch drawing of the product.

Throwing the upper handle, we get exactly what we need.

The design of the homemade drill must comply with the following parameters:

- The angle between cutting blades (between blades) can vary within - from 25 ° to 30 °.

- The front edge of the blade is sharpened at an angle of 45 ° ... 60 °.

- To the lower end of the bora, it is desirable to weld a thick drill on the metal, thanks to which the installation will be easier to enter the tight soil.

As a garden borne to fix in a drill.

As a garden borne to fix in a drill.

Electrical equipment for earthworks is successfully used in cases where it is necessary, for example, drill a hole under the pile, make a trench or recess for the installation of the fence columns, drill the pit for planting a tree or shrub, etc.

Brief description of the device and the benefits of equipment

By its design, electrical trains for earthworks are an electric motor that has two handles, as well as a clamping mechanism used for the clamp, this tool is most often manufactured in the form of a screw. It is worth noting that the nozzles are removable and can be different diameters, which allows you to adjust the size of the opening that will be drilled. It is also worth noting that there is a conditional separation of the bers on types, depending on their purpose. Garden, earthy and pile tools are distinguished.

Electrical equipment for earthworks is a rarity among people with country sections, despite the fact that it has some advantages. If you compare it with a manual type, then, of course, plus is that the main rotational force occurs due to an electric motor, not a person's strength.

If you compare a device with a gasoline unit, then the benefits include silent operation, environmental friendliness and readiness for work (to start it as gasoline, not).

Application of equipment

As mentioned earlier, one of the greatest advantages in the plan of using the Bura was that it could easily cope with the arrangement of deposits under the pile. Of course, it is possible to do it with a manual type of unit, but the electrobore for earthworks will cope with this task much faster. In addition, the presence of small stones or roots inside the soil will greatly difficult to dig a deepening, if it passes manually, it is not a hindrance for an electric motor.

Another convenience of using the equipment is that it is more compact than an ordinary boring, and therefore its operation in places with limited space is most acceptable. Small dimensions and high functionality of the aggregate are its main positive qualities. It is also worth adding that in comparison with gasoline models, the weight of the electric bora is less, which makes it easier to work with it.

Models and disadvantages

Large models of earthwinds are used for roaring wells, for example. Types with a smaller diameter nozzle are used for home use (planting plants, installation of columns, etc.). However, it is worth noting that in the line of models there are multifunctional types that have removable nozzles. This makes it possible to use them depending on the needs, as well as from the quality and type of soil, with which you have to work.

Naturally, the main disadvantage of the Bura is that its operation in places where electricity is missing is impossible. Yes, when buying a device, a battery usually has a battery, but there is enough charging for a short period of time.

Principle of operation of the aggregate

Electric car is an electric motor and a shaft having a type. When applying such equipment, the hole in the ground will have even edges and a clear diameter of the auger. The direct drilling process is carried out due to the fact that the auger has a very sharp tip, as well as pointed vintage blades. When the equipment starts, the electric motor starts to rotate, transmitting its force to the shaft to which the auger is attached. Thus, drilling occurs.

Favorable service of the device

The price of electrical husband for earthworks is also one of its advantages. The approximate cost of the device is 1,000 rubles. It is important to note that for this amount, the device is purchased and the basic nozzle coming in the kit. And then you can acquire separate augers of different diameters if necessary. Thus, it is highly increased to the functionality of the equipment for the minimum cost. Also save will help and the right choice.

If you plan to operate the device in the garden, that is, for garden needs, it will be enough and the capacity of 1.5 kW. If you plan to drill hole holes (pile foundation), you will need a device with a power of 2 kW. If there is such a need, the electrical units can be used for drilling ice.

Reviews of the electrical equipment for earthworks are mostly positive. Of the main qualities that allocate buyers, it is worth highlighting ease of operation, low weight, device quality and its relatively low cost.

There are negative reviews. However, they are most often left by people who did not understand the rules of its operation and acquired, for example, a less powerful model than was required to work with a specific type of soil. Naturally, the result was bad.

From this, it should be concluded that it is necessary to investigate the soil with which you will have to work, decide for which type of work the tool is purchased, and only after that it is bought. It is also recommended to purchase products only verified firms. It is better to pay somewhat more expensive, but buy a better thing than to pay less and buy equipment in a year.

Motobura from "Hitachi"

Electric workers for earthworks "Hitachi" are fairly high-quality and reliable products. The manufacturer of this equipment is Japan. However, it is worth noting that the product range is not too large. From electrical models there are only garden types. This means that electrical models with high power manufacturer does not release. High power rates have only gasoline models from this brand. To date, three main qualities can be distinguished, thanks to which products from "Hitachi" have become quite popular.

- The quality assembly of the aggregates is very high.

- The efficiency of these devices is also high.

- The service life of devices is sufficiently long.

Product Choice and Operation

When buying an earthen Motobur, it is best to always go to a specialized store where you can help with the choice. However, there are several recommendations that should always be followed. Three parameters should always pay special attention - power, the size of the screw head and the engine volume (if it is a gasoline model).

Quite often, when working this tool occurs in such a way that the borne is buried in the ground. For this reason, almost all new models are equipped with a security system that turns off the engine if it happens. This system protects the technique from breakage. To avoid such a disconnection, it is necessary to periodically stop the operation and clean the auger from the dirt.

It is also designed to protect the unit from a random launch or protect a person with a loss of product management.

To create a well or holding another type of earthwork work, not only large-scale drilling rigs managed by specialists can be applied. With a small scale and sufficient amount of time, you can use easier equipment.

One such tool is an earthen car - a device that appears in a variety of variations and variations. With garden and country work, it is most in demand, is also used in the industry of various directions.

1 Design and Purpose of Bura

The bur for earthworks is a device that is used to create cylindrical holes in the ground (to be more accurate - the upper layers of it are placed). It consists of a rod (rod), handle and drive. The side of the rod is located a guide tip and a screw blade, which is mainly manufactured in the form, or cutter.

All stools can be divided into two categories: devices requiring manual strength, and automatic borants equipped with engines.

2 Types of boots

The classification of portable drilling devices, depending on the type of actuator, is performed on three groups: electric bob, hydraulic earth drill, and gasoline devices.

Gasoline borants are the most extensive category of equipment. Gasoline land bur (it is the motorobur) is the optimal option for domestic use, if the possibilities of a conventional manual bera is not enough. It disrupts the soil layers with a depth of 2-3 meters, in fact, the depth of the well limits only the size of the rod extension.

In addition to devices for economic use, there is a category of heavy benzobuurs for construction: this is quite overall mechanisms that are managed by two operators. They are equipped with high-power engines that allow you to make wells in problem soils: solid soil, sandy soil, or the ground with a high content of mountain enclosures.

The main feature of such devices is that all engines are equipped with a gearbox, by means of which the engine torque is transmitted to a thorough-separating element. Depending on the class of the device, two types of gearboxes can be installed on it: for heavy drills - worm, for the lungs - coaxial gearboxes. As a fuel is usually used mixed with oil 92 gasoline.

The Motobura Construction consists of the following items:

- Drive: in heavy - 3-4 clock engines, in the lungs - two-stroke;

- Handle for keeping;

- Control elements: power adjustment, speed switching;

- Screaks are usually used as a poodle element.

The cost of domestic devices begins with 10 thousand rubles. When buying, first of all, it is worth paying attention to such manufacturers as Hitachi, Husqvarna, Stihl - these are well-proven firms whose products have the optimal price ratio and operational characteristics.

There is also a large number of firms where it is possible. In general, rent is a great option if you only need a device for several days. Today, rental, on average in the market, costs about 1000 rubles per day, plus it will be necessary to make a deposit of 5-10 thousand.

Electric boraxes are less popular option, compared with the previous one, but also common and well-known.

The only structural difference of such mechanisms from the benzoburov is an electric motor - all other elements are identical. The use of the electric drive adds the device such as pros and certain disadvantages.

You can include their silent advantages of electrical workers, since, as opposed to a gasoline engine, the electric drive is practically not heard.

The deficiencies are as follows: Electrical engines have a relatively lower power than gasoline, that is, for the same money you can purchase more powerful benzobur than a device with an electric motor.

For domestic use, this is not particularly important, but in the event of professional use, this factor can become critical. It is also worth remembering the mandatory connection of the device to the network, which slightly narrows its portability, as any batteries have an unpleasant feature to sit at the most inopportune moment..

The cost of high-quality electrical equipment begins with 15 thousand. Main manufacturers - Makita, Mora, Hitachi. Rent - from 1000 rubles per day.

Hydraulic borants - a category of serious industrial installations. The main advantage of such drills in front of gasoline and electrical devices is the function of the reverse, which makes it possible to drill both behind the hour and counterclockwise. Thanks to her, the problematic layers of the soil is much easier.

In addition, hydromotors, in comparison with electric drives, differ in 2-3 times smaller dimensions and much less weight, which makes the hydraulic earth drill more convenient in operation.

But even with the same drive sizes, the hydraulic earthwood will always have a greater power. The hydraulic motors provide the most flexible adjustment of the rumble, which allows you to choose the optimal drilling mode to different soil layers.

The only substantial disadvantage of hydraulic engines is the "tenderness" of the drive. It is always necessary to maintain its purity, since mechanical contamination inside the drive significantly reduces the resource of the device.

Hydraulic earth drill, in comparison with the analogs, differs several times more cost. So, the average price is 30-35 thousand. Rental of hydrobuses will cost you from 1.5 to 2 thousand per day. It is also possible to rent a hydrobamp with operators, in which case one hour of time is paid. Such rental will cost you about 1 thousand rubles per hour.

2.1 How to make a car with your own hands?

If you do not want to acquire what you can make yourself, or you do not suit the costly rental of equipment, you can try to make a mechanical earth drill with your own hands.

To create homemade bobes need such tools:

- Welding machine;

- Bulgarian (with metal circles);

- Small repair inventory - hammer, metal brush, pliers, sandpaper.

It is also necessary to acquire materials from which the design will be manufactured:

- For stock - Armature with a long 150 cm, with a diameter of 15 mm. (adjust the height of the bora, depending on your growth);

- For handle - fittings, or a metal pipe with a long 40 centimeters, with a diameter of 20 mm;

- For cutter - disk from a circular peel, or a metal sheet with a thickness of 3-4 mm;

- For the "needle" (guide element) - the metal drill with a diameter of 15 mm.

Homemade handberry for earthworks is manufactured as follows:

- We make cutters (blades) of the bora. If you take a disc from the circular to this, then you can save a significant amount of time and strength.

- To make a cutter from such a disc, cut it in half, and at each half the blades, which were originally equipped with a disc. At first, it is not necessary to sharpen the edges of the cutter, so as not to cut down in the process of welding - the sharpness is given after the completion of all connections.

- In the case of using the usual metal, make an approximate markup on the sheet and cut two blanks with a grinder. Their size depends on what purpose of the manual car for earthworks will be used - for, or well under the planting of trees.

- If there is no clear target, the optimal option "for all occasions" are cutters from 15 to 20 mm.

- Prepare the reinforcement for the rod. It is not recommended to make a rod of two small pieces of fittings, cooked with each other, since sooner or later, due to the resistance of the soil, their connection will disintegrate.

- By the end of the stock, welded the drill on the metal, it acts as a homemade guide element (the optimal length of drill from 7 to 10 centimeters)

- To the location of the reinforcement and drill on the rod welded the cutters. It is necessary to do it so that between them was an angle of 30 degrees.

- We take the grinder, wear an abrasive circle on metal, and drag the edges: remove the upper and lower layers of metal on the outer edges of the semicircles.

- We make a handle: to the top of the rod perpendicularly welds a piece of fittings, or a steel pipe.

You can also make a slightly advanced design - homemade handberries for earthworks with an extended rod. To do this, the bolt is welded to the bolt handle, and to the top of the rod - nut. A piece of metal pipe is used as the extension, on the edges of which a bolt and nut, identical in size, are welded to the handle and stock.

What is a hot water supply of an apartment building

What is a hot water supply of an apartment building Water supply of an apartment building

Water supply of an apartment building Calculation of the Load for the foundation Installed Electrical Instruments

Calculation of the Load for the foundation Installed Electrical Instruments