Calculate the gable roof area calculator. How to calculate the length of the rafters of a gable roof, taking into account the loads - calculation rules. Calculation of the amount of wood required for the manufacture of rafters

The gable roof rafter system is a fairly simple design and is available for DIY construction even for home builders. It is only necessary to first make a calculation of the gable roof rafter system, get acquainted with the stages and methods of its construction, calculate the required materials for installation. During the calculations, it is necessary to take into account that the bearing capacity of a gable roof will depend on the effect of loads on it from the weight of materials, snow, wind.

To make the process of installing the rafters of a gable roof with your own hands as simple as possible, the step-by-step and detailed installation instructions are described below.

Basic requirements for materials

To install the rafter system, the best option is selection of softwood lumber- larch, spruce or pine, I - III grade.

It is made of timber or boards of the II grade, for the rafters the material is used not lower than the II grade, the lathing is made of lumber of the II-III grade, the material of the II grade is used for the purlins and racks, this will depend on the characteristics of the roof. Grade III material can be used for linings and onlays. Tightens and crossbars are made of grade I material.

Lumber must be stored under a canopy providing protection from moisture and sun. For storage, the site must be leveled; for ventilation, shift the lumber with linings.

For the construction of the gable roof truss system, fasteners will be required: plates, ties, bolts with nuts and washers, studs, mounting tape, self-tapping screws with EPDM gaskets with a thickness of 2.9 mm, galvanized brackets.

Brackets are used to mount the Mauerlat, they are fastened with screws or nails. KR corners prevent the rafters from displacement and are necessary for fastening to the rafter Mauerlat. All material for fasteners must be protected against corrosion and be made of quality material.

Instruments

For installing a gable roof rafter system such a set of tools will be needed:

For safety reasons, all tools on the roof must be kept in a special bag.

Varieties for gable roof rafter systems

Send rafter system

It rests on racks and a Mauerlat, which are installed on the inner wall, with an equal pitch of the rafters. Additionally, to give rigidity, set struts for spans over 6 m.

Hanging rafters

If the house is small in width, then you can make the installation of rafter systems when they rest on the walls or Mauerlat without intermediate supports. The maximum width is 10 meters. In some cases, these roofs can be installed without a Mauerlat. The rafter system is installed on the wall using spacers; in this version, a bending moment acts on the rafters.

If the house is small in width, then you can make the installation of rafter systems when they rest on the walls or Mauerlat without intermediate supports. The maximum width is 10 meters. In some cases, these roofs can be installed without a Mauerlat. The rafter system is installed on the wall using spacers; in this version, a bending moment acts on the rafters.

In order to unload, set metal or wooden lining... They fix the angle firmly. For a hanging rafter system of a larger span, struts and a headstock are installed. The rafter for hanging systems is set with a larger section, and lumber is chosen not lower than grade III.

Calculation of the rafter system

An approximate calculation of the load from wind and snow is made according to the table values of SNiP taking into account the temperature zone and the height of the building. The load from the snow is equal to its weight, multiplied by a factor that depends on the slope of the slope. All these calculations are made during design.

And if you are installing a gable roof truss system for a small building, and there is no project? You need to look at the construction of the same building in the neighborhood, made according to the project, the roof area is the same as your structure. The gable roof rafter system will be used as a reference.

You can also use the online gable roof calculator, it can help you calculate the maximum roof load, the required amount of battens, the rafters slope angles, as well as the materials that will be required to build this type of roof at a given size. On the calculator, you can calculate the roof from such commonly used materials as ondulin, slate, metal tiles, bituminous, cement-sand and ceramic tiles, and other roofing materials.

Sizes of timber for rafters

The ridge fits at the top point, it is necessary to connect the rafters. The height of the ridge will depend on the slope of the roof. The choice of coating material affects the slope. The minimum slope is as follows:

The optimal tilt angle of 30-40 degrees creates a quick discharge of snow and water. In areas with strong winds, the roof is made flat, and in this case the slope angle is in the range of 25-40 degrees.

The roof does not end at the level of the walls, it must be extended outward by 50 cm. In this case, water does not fill the foundation and does not fall on the wall.

Step-by-step installation of the structure of the gable roof rafter system

The gable roof rafter system consists of the following elements:

Mauerlat installation

Mauerlat evenly distributes the load on the walls of the house, its installation is carried out in several ways:

- common and simple option for ordinary roofs, wire rod fastening;

- studs are installed in the masonry;

- to be attached to the wall through a reinforced concrete belt with studs.

What is used for a beam with a section of 10 × 10 cm, 15 × 15 cm or 20 × 20 cm. Which section to select will depend on the roof covering and its dimensions. The Mauerlat is joined along the length, for which you need to make a wash down with a length of 50 cm, 10 cm each, lay the bars and fix with pins.

Mauerlat in the corners is tied in half a bar with cuts, fixed with bolts or brackets. Mauerlat at wooden structures is the last crown. On the brick walls, you need to make a reinforced monolithic reinforced concrete belt, 40 × 30 cm in size.Install pins with threads 12 mm in diameter along the belt for fastening, every 1.2 cm.

In the Mauerlat for a gable roof, it is necessary drill 12 mm holes, lay it down so that the pins enter the holes. Tighten with nuts from above. We pre-lay several layers of roofing tar paper or roofing felt under the block. On the outside of the wall, you need to lay the Mauerlat brick. The Mauerlat is laid on an even base, vertically and horizontally. It is necessary to check the diagonals and the level to determine the horizontalness of the surface. If necessary, align with shims.

Installation instructions for racks, beds, braces, struts and rafters of a gable roof

Do-it-yourself installation of a gable roof rafter system produced in this order:

The rafter legs are connected to each other on a skate... Let's describe the most common joints of the rafter system:

- Cuts are made near one leg and washed down near the other. Install one leg in the cut with the other and fix it with a bolt.

- The linings are installed metal or wooden.

- The girder is fastened with bolts or nails with the help of notches.

Do-it-yourself installation of the crate

The lathing is arranged along the roof rafters. It is required to distribute the load from snow and roofing material to the rafters, and also serves as an air gap between the rafter system and the roof.

The design of the battens will depend on the roofing material used:

Pine of the first grade is usually chosen as lumber for the manufacture of lathing. It is recommended to take the width no more than 15 cm. With a larger width, the boards can deform and damage the roofing. The length of the nails should be 3 times the thickness of the sheathing. Boards are laid along the ridge.

A continuous crate is made along the roof slope... The first layer is laid by the board along the ridge, from it with a step of 50-100 cm the next one and then everything is repeated. The next layer is to lay the crate along the rafters. The joints between the boards are made at a distance and only on the rafters. The nail is completely sunk into the wood with the head.

Eaves overhangs

Eaves overhangs need to be made to protect from atmospheric precipitation, these elements fulfill an aesthetic role. They must be installed tightly without gaps. This is the final stage in the arrangement of the gable roof.

Gable

The gable roof has two gables, which look in the shape of a triangle, with the apex near the ridge, while the sides should coincide with the slopes of the roof. The gables enclose the attic space and support the rafters, stabilize the roof and protect it from rain and wind.

The gable roof has two gables, which look in the shape of a triangle, with the apex near the ridge, while the sides should coincide with the slopes of the roof. The gables enclose the attic space and support the rafters, stabilize the roof and protect it from rain and wind.

In wooden structures, the pediment is made frame. In brick structures, brick or frame. Gables made of aerated concrete or bricks are made before the roof device and at the same time require a fairly precise execution. Frame gables are installed in the prepared opening when the rafter system has already been assembled.

The frame is made from boards or bars... All parts of the frame are connected to the floor of a tree or on thorns, everything is fixed with nails. Sheathed by nailing siding, lining or boards, observing the colorist in finishing the facade of the house. To equip the window opening, an additional frame must be made in size for it. When the attic is insulated, the pediment must also be insulated. The insulation must be laid in the middle of the frame. Insulation is used mineral wool with low flammability. From the outside, the frame is upholstered with a windproof membrane or a hydro-windproof film, a vapor-proof membrane or a vapor-proof film is nailed under the finishing material from the inside.

Summarizing

As you can see, despite the apparent simplicity and lightness, the plan of the rafters of the gable roof contains many different pitfalls. However, relying on the above recommendations and installation methods, you can easily build a reliable structure with your own hands.

We offer a professional free calculation of the gable roof truss system using an online calculator site, 3D visualization and detailed drawings. Detailed calculations of the roof and roof, all materials, lathing, rafters, Mauerlat. Try calculating a gable roof now!

Our online calculator rafter system will calculate the gable roof:

- calculation of the length of the gable roof rafters

- number of rafters and step

- calculation of the area of the gable roof and the angle of inclination

- calculation of the roof lathing

- the number of sheet roofing materials (for example, corrugated board, metal tiles, slate)

- parameters of vapor barrier and insulation

To form the calculation of the gable roof calculator, you need to measure and enter the following dimensions in the appropriate windows:

The section (thickness x width) and the pitch of the rafters depend on the angle of inclination of the roof, its type, the length of the rafter leg, the maximum withstand basic loads, as well as the type and weight of the roof covering, and even to some extent on the width of the insulation. If you do not know where to get the standard parameters of rafters and battens, our article will help you " Optimal cross-section, pitch of the lathing and rafter legs, depending on the type of roof ».

The calculator calculates the materials for the roof, starting from the dimensions of the roofing sheet you entered and from the calculated value of the roof area. We advise you to buy the amount of roofing materials for the roof, boards and beams for the rafter system with a small margin, it is always better to hand over the leftovers to a hardware store than pay a lot of money for the delivery of a missing pair of boards.

Be careful! From how accurate the values you enter, the online calculator will be able to calculate the gable roof so reliably.

Simplify your calculations and save time, the program will draw itself rafter plangable roof and will display the results of calculating a gable roof according to the data you entered in the form of a drawing of a gable roof in different viewing angles, and its interactive 3d model.

On the tab “ 3 D- View»You can better see your future gable roof in 3D. In our opinion, visualization in construction is a very necessary feature.

If you have a gable roof with different slopes in your project, you should calculate using the calculator twice - for each slope separately.

The online gable roof calculator will help you calculate the rafter tilt angles, the required amount of lathing, the maximum roof load, as well as the materials required to build this type of roof for the given dimensions. You can calculate the roof from such popular roofing materials as slate, ondulin, ceramic, cement-sand and bituminous tiles, metal tiles and other materials.

The calculations take into account the parameters given in TCP 45-5.05-146-2009 and SNiP "Loads and Impacts".

A gable roof (also known as a gable or gable roof) is a type of roof that has two sloping ramps that run from the ridge to the outer walls of the building. This is the most common roof type today. This is explained by its practicality, low construction costs, effective protection of premises and aesthetic appearance.

The rafters in the gable roof structure rest on each other, connecting in pairs. On the front side, gable roofs are in the shape of a triangle, such ends are called tongs or gables. Usually, an attic is arranged under such a roof, which is illuminated with the help of small windows on the gables (attic windows).

When entering data into the calculator, be sure to check the additional information marked with the icon.

At the bottom of this page, you can leave feedback, ask your own question to the developers, or suggest an idea for improving this calculator.

Explanation of calculation results

Roof angle

The rafters and roof slope are inclined at this angle. It is understood that a symmetrical gable roof is planned. In addition to calculating the angle, the calculator will inform you how the angle corresponds to the norms for the roofing material you have chosen. If you need to change the angle, then for this you need to change the width of the base or the height of the roof rise, or choose another (lighter) roofing material.

Roof surface area

The total area of the roof (including overhangs of a given length). Determines the amount of roofing and insulation materials that will be needed for the job.

Approximate weight of roofing material

The total weight of the roofing material required to fully cover the roof area.

Number of overlapped rolls of insulation

The total amount of insulating material in rolls that will be required to insulate the roof. The calculations are based on rolls 15 meters long and 1 meter wide.

The maximum load on the rafter system. The calculations take into account the weight of the entire roofing system, the shape of the roof, as well as the wind and snow loads of the region you specified.

Rafter length

The full length of the rafters from the beginning of the ramp to the ridge of the roof.

Number of rafters

The total number of rafters required to build a roof at a given pitch.

Minimum cross-section of rafters, Weight and Volume of timber for rafters

The table shows the recommended cross-sectional dimensions of the rafters (according to GOST 24454-80 Softwood lumber). To determine compliance, the type of roofing material, the area and shape of the roof structure, and the loads exerted on the roof are taken into account. The adjacent columns show the total weight and volume of these rafters for the entire roof.

Number of rows of crate

The total number of battens for the entire roof. To determine the number of rows of crate for one slope, it is enough to divide the resulting value by two.

Uniform distance between battens

Use the value shown here to install the battens evenly and avoid unnecessary overruns.

Number of battens with standard length

To frame the entire roof, you will need the number of planks shown here. The calculations are based on the standard 6-meter board length.

The volume of lathing boards

The volume of boards in cubic meters will help you calculate the cost of the crate costs.

Approximate weight of crate boards

Estimated total weight of the sheathing boards. The calculations use the average density and moisture values for coniferous wood species.

-> Calculation of the rafter systemThe main element of the roof, which perceives and resists all types of loads, is rafter system... Therefore, in order for your roof to reliably withstand all environmental influences, it is very important to make the correct calculation of the rafter system.

For self-calculation of the characteristics of the materials required for the installation of the rafter system, I give simplified calculation formulas... Simplifications are made in the direction of increasing the strength of the structure. This will cause some increase in the consumption of lumber, but on small roofs of individual buildings, it will be insignificant. These formulas can be used when calculating gable attic and mansard, as well as pitched roofs.

Based on the calculation methodology below, programmer Andrei Mutovkin (Andrei's business card - Mutovkin.rf) for his own needs has developed a program for calculating the rafter system. At my request, he generously allowed to post it on the site. You can download the program.

The calculation method is based on SNiP 2.01.07-85 "Loads and Impacts", taking into account "Changes ..." from 2008, as well as on the basis of formulas given in other sources. I developed this technique many years ago, and time has confirmed its correctness.

To calculate the rafter system, first of all, it is necessary to calculate all the loads acting on the roof.

I. Roof loads.

1. Snow loads.

2. Wind loads.

The rafter system, in addition to the above, is also affected by the load from the roof elements:

3. Roof weight.

4. Weight of subfloor and battens.

5. The weight of the insulation (in the case of an insulated attic).

6. Weight of the rafter system itself.

Let's consider all these loads in more detail.

1. Snow loads.

To calculate the snow load, we will use the formula:

Where,

S - the required value of the snow load, kg / m2

µ is a coefficient depending on the slope of the roof.

Sg - standard snow load, kg / m².

µ is a coefficient depending on the slope of the roof α. Dimensionless quantity.

You can approximately determine the slope angle of the roof α by dividing the height H by half the span - L.

The results are summarized in the table:

Then, if α is less than or equal to 30 °, µ = 1;

if α is greater than or equal to 60 °, µ = 0;

if a 30 ° is calculated by the formula:

μ = 0.033 * (60-α);

Sg - standard snow load, kg / m².

For Russia, it is accepted according to map 1 of the mandatory appendix 5 SNiP 2.01.07-85 "Loads and Impacts"

For Belarus, the standard snow load Sg is determined

Technical Code STANDARD PRACTICE Eurocode 1. IMPACTS ON STRUCTURE Part 1-3. General influences. Snow loads. TKP EN1991-1-3-2009 (02250).

For example,

Brest (I) - 120 kg / m²,

Grodno (II) - 140 kg / m²,

Minsk (III) - 160 kg / m²,

Vitebsk (IV) - 180 kg / m².

Find the maximum possible snow load on a roof with a height of 2.5 m and a span of 7 m.

The building is located in the village. Babenki, Ivanovo region RF.

According to map 1 of compulsory Appendix 5 SNiP 2.01.07-85 "Loads and Impacts", we determine Sg - the standard snow load for the city of Ivanovo (IV region):

Sg = 240 kg / m²

Determine the angle of the roof slope α.

To do this, divide the roof height (H) by half the span (L): 2.5 / 3.5 = 0.714

and from the table we find the slope angle α = 36 °.

Since 30 °, the calculation µ is produced by the formula µ = 0.033 · (60-α).

Substituting the value α = 36 °, we find: μ = 0.033 · (60-36) = 0.79

Then S = Sg · µ = 240 · 0.79 = 189kg / m²;

the maximum possible snow load on our roof is 189kg / m².

2. Wind loads.

If the roof is steep (α> 30 °), then due to its windage, the wind presses on one of the slopes and tends to overturn it.

If the roof is flat (α, then the lifting aerodynamic force arising from the wind around it, as well as turbulence under the overhangs tend to raise this roof.

According to SNiP 2.01.07-85 "Loads and Impacts" (in Belarus - Eurocode 1 IMPACTS ON STRUCTURE Part 1-4. General effects. Wind effects), the standard value of the average component of the wind load Wm at a height Z above the earth's surface should be determined by the formula :

Where,

Wo is the standard value of the wind pressure.

K is a coefficient that takes into account the change in wind pressure along the height.

C is the aerodynamic coefficient.

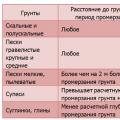

K is a coefficient that takes into account the change in wind pressure along the height. Its values, depending on the height of the building and the nature of the terrain, are summarized in Table 3.

C - aerodynamic coefficient,

which, depending on the configuration of the building and the roof, can take values from minus 1.8 (the roof rises) to plus 0.8 (the wind presses on the roof). Since our calculation is simplified in the direction of increasing strength, the value of C is taken to be 0.8.

When building a roof, it must be remembered that wind forces that tend to lift or tear off the roof can reach significant values, and, therefore, the bottom of each rafter leg must be properly attached to the walls or to the mats.

This is done by any means, for example, using an annealed (for softness) steel wire with a diameter of 5 - 6 mm. With this wire, each rafter leg is screwed to the matrices or to the ears of the floor slabs. It's obvious that the heavier the roof, the better!

Determine the average wind load on the roof of a one-story house with a ridge height from the ground - 6 m. , slope angle α = 36 ° in the village of Babenki, Ivanovo region. RF.

According to map 3 of Appendix 5 in "SNiP 2.01.07-85" we find that the Ivanovo region belongs to the second wind region Wo = 30 kg / m²

Since all buildings in the village are below 10m., The coefficient K = 1.0

The value of the aerodynamic coefficient C is taken to be 0.8

standard value of the average component of the wind load Wm = 30 · 1.0 · 0.8 = 24kg / m².

For information: if the wind blows at the end of this roof, then a lifting (tearing) force of up to 33.6 kg / m² acts on its edge

3. Roof weight.

Different types of roofing have the following weight:

1. Slate 10 - 15 kg / m²;

2. Ondulin (bituminous slate) 4 - 6 kg / m²;

3. Ceramic tiles 35 - 50kg / m²;

4. Cement-sand tiles 40 - 50 kg / m²;

5. Bituminous shingles 8 - 12 kg / m²;

6. Metal tiles 4 - 5 kg / m²;

7. Decking 4 - 5 kg / m²;

4. Weight of subfloor, battens and truss system.

Rough flooring weight 18 - 20 kg / m²;

Lathing weight 8 - 10 kg / m²;

The weight of the actual rafter system is 15 - 20 kg / m²;

When calculating the final load on the rafter system, all of the above loads are added together.

And now I will tell you a little secret. Sellers of some types of roofing materials note their lightness as one of the positive properties, which, according to their assurances, will lead to significant savings in lumber in the manufacture of the truss system.

As a refutation of this statement, I will give the following example.

Calculation of the load on the rafter system when using various roofing materials.

We calculate the load on the rafter system when using the heaviest (Cement-sand tile

50 kg / m²) and the lightest (metal 5 kg / m²) roofing material for our house in the village of Babenki, Ivanovo region. RF.

Cement-sand tile:

Wind loads - 24kg / m²

Roof weight - 50 kg / m²

Lathing weight - 20 kg / m²

Total - 303 kg / m²

Metal tile:

Snow loads - 189kg / m²

Wind loads - 24kg / m²

Roof weight - 5 kg / m²

Lathing weight - 20 kg / m²

The weight of the rafter system itself is 20 kg / m²

Total - 258 kg / m²

Obviously, the existing difference in design loads (only about 15%) cannot lead to any tangible savings in sawn timber.

So, we figured out the calculation of the total load Q acting per square meter of the roof!

I would like to draw your attention to the following: when calculating, carefully follow the dimension !!!

II. Calculation of the rafter system.

Rafter system consists of separate rafters (rafter legs), therefore, the calculation is reduced to determining the load on each rafter leg separately and calculating the section of an individual rafter leg.

1. Find the distributed load per running meter of each rafter leg.

Where

Qr - distributed load per linear meter of rafter leg - kg / m,

A - distance between rafters (rafter pitch) - m,

Q - total load acting on a square meter of the roof - kg / m².

2. Determine the working section of the maximum length Lmax in the rafter leg.

3. Calculate the minimum cross-section of the rafter leg material.

When choosing a material for rafters, we are guided by the table of standard sizes of sawn timber (GOST 24454-80 Sawn softwood. Sizes), which are summarized in Table 4.

| Board thickness - section width (B) | Board width - section height (H) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 16 | 75 | 100 | 125 | 150 | |||||

| 19 | 75 | 100 | 125 | 150 | 175 | ||||

| 22 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | ||

| 25 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 32 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 40 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 44 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 50 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 60 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 75 | 75 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 |

| 100 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 | |

| 125 | 125 | 150 | 175 | 200 | 225 | 250 | |||

| 150 | 150 | 175 | 200 | 225 | 250 | ||||

| 175 | 175 | 200 | 225 | 250 | |||||

| 200 | 200 | 225 | 250 | ||||||

| 250 | 250 |

A. We calculate the cross-section of the rafter leg.

We arbitrarily set the section width in accordance with the standard dimensions, and the section height is determined by the formula:

H ≥ 8.6 Lmax sqrt (Qr / (B Rben)), if the roof slope α

H ≥ 9.5 Lmax sqrt (Qr / (B Rben)), if the roof slope is α> 30 °.

H - section height cm,

B - section width cm,

Rben - bending resistance of wood, kg / cm².

For pine and spruce Rben is equal to:

1st grade - 140 kg / cm²;

2nd grade - 130 kg / cm²;

3rd grade - 85 kg / cm²;

sqrt - square root

B. We check whether the deflection value is within the standard.

Standardized material deflection under load for all roof elements should not exceed L / 200. Where, L is the length of the working area.

This condition is satisfied if the following inequality is true:

3.125 · Qr · (Lmax) ³ / (B · H³) ≤ 1

Where,

Qr - distributed load per linear meter of rafter leg - kg / m,

Lmax - the working area of the rafter leg of the maximum length m,

B - section width cm,

H - section height cm,

If the inequality is not met, then we increase B or H.

Condition:

Roof slope angle α = 36 °;

Rafter pitch A = 0.8 m;

The working section of the rafter leg of maximum length Lmax = 2.8 m;

Material - pine 1 grade (Rben = 140 kg / cm²);

Roof - cement-sand tiles (Roof weight - 50 kg / m²).

It has been calculated that the total load per square meter of the roof is Q = 303 kg / m².

1. Find the distributed load per running meter of each rafter leg Qr = A · Q;

Qr = 0.8303 = 242 kg / m;

2. Let's choose the thickness of the board for the rafters - 5cm.

We calculate the cross-section of the rafter leg with a cross-sectional width of 5 cm.

Then, H ≥ 9.5 Lmax sqrt (Qr / B Rben), since the roof slope α> 30 °:

H ≥ 9.5 2.8 sqrt (242/5 140)

H ≥15.6 cm;

From the table of standard sizes of lumber, select the board with the closest section:

width - 5 cm, height - 17.5 cm.

3. Check if the deflection value is within the standard. To do this, the inequality must be observed:

3.125 · Qr · (Lmax) ³ / B · H³ ≤ 1

Substituting the values, we have: 3.125 · 242 · (2.8) ³ / 5 · (17.5) ³ = 0.61

Value 0.61, which means the cross-section of the rafter material is selected correctly.

The cross-section of the rafters, installed with a pitch of 0.8 m, for the roof of our house will be: width - 5 cm, height - 17.5 cm.

A gable roof is a complex, large building structure that requires a professional approach to the design and implementation of work. The largest costs go to building materials for rafters, battens, insulation, waterproofing, roofing material. Our gable roof calculator allows you to calculate the amount of material.

Using a calculator saves time for roof design and your money. The final 2D drawing will guide the work, and the 3D rendering will give an idea of what the roof will look like. Before entering data into the online calculator, it is necessary to have an understanding of the roof elements.

Rafter parameters

To calculate the rafter system of a gable roof, you need to take into account:

- roof load;

- step between the rafters.

- type of roofing

- 100-150 mm with a span length of no more than 5 m, and with additional props .;

- 150-200 mm with a span of more than 5 m, with a step of more than 1 m, and if the angle is not large.

Important! The distance between the rafters of a gable roof is usually set to 1 m, but with a roof slope of more than 45 degrees, the pitch of the rafters can be increased to 1.4 m.With flat roofs, the pitch is 0.6-0.8 m.

The rafter legs are attached to the Mauerlat, which runs along the perimeter of the house. For it, either a board with parameters 50x150 mm is taken, or a bar of 150x150 mm (for load distribution)

Sheathing parameters

For metal tiles, a sparse crate is created with a board, the width of which is 100 mm, and the thickness is 30 mm. The board is packed with a pitch that must correspond to the longitudinal axis of the metal tile module - 35 cm (supermonterrey).

For shingles, the sheathing is performed with a large step, since OSB or plywood will be laid on top of it with a solid carpet.

Important! When choosing materials, pay attention to the indicators of moisture resistance and minimum thickness.

When installing warm roofs, a counter-lattice is made between the waterproofing and the roof with a bar, the thickness of which should be 30-50 mm.

Roofing parameters

- To calculate the roof of a gable roof, you need to know the dimensions of the roofing material and the size of the overlaps.

- Metal tiles for rigid roofs are produced with a width of 118 mm (working 110), but the length can be different. The manufacturer can cut any length to order.

- Flexible shingles for soft roofs have different sizes, so you need to look at the specific material

- As for the choice of insulation, for Russia a minimum thickness of 100 mm is recommended, and the correct one will be 150-200 mm.

What is hot water supply for an apartment building

What is hot water supply for an apartment building Water supply of an apartment building

Water supply of an apartment building Calculation of the load on the foundation Installed electrical appliances

Calculation of the load on the foundation Installed electrical appliances