How to fold an outdoor oven with your own hands drawings. Do-it-yourself summer cottage mini-oven: simple orders and an option with a ready-made firebox. How to build a brick oven with your own hands video

Even when planning to build our own house, we think about what kind of heating to make in it. Indeed, the construction of the project will depend on this decision. If there is a heating main near your house, you have received the necessary permission to connect, then you can simply do it yourself in the house. For example, when the centralized heating season has not yet begun. And in the absence of central heating, many owners of houses, summer cottages and cottages are inclined to build a brick oven for a house with their own hands.

Brick ovens have been built in Russia since ancient times. Furnace makers have always been considered respected people. Since not everyone can meet all the requirements for it.

They put in Russia since ancient times. Furnace makers have always been considered respected people. Since not everyone can make a stove with their own hands that meets all the requirements for it. The presence of a brick stove in the house creates a special cozy atmosphere and warms with lively warmth.

What ovens are there for the home?

Brick ovens can be conditionally subdivided into the following types:

- Heating furnace. Its functions include heating the entire house or a specific room.

- Cooking oven. Her task is to prepare food, from drying fruit to cooking cabbage soup.

- Heating and cooking oven. Combines the two previous types.

The modern look of a stove for a home must have the following mandatory qualities - to warm, not smoke, be fireproof, create coziness and comfort at home.

Not everyone can do the laying of the stove with their own hands, since this is a rather responsible, time-consuming business and requires certain knowledge. Of course, a beginner can handle the laying of a stove with his own hands, but it all depends on his desire and ability.

A lot of useful information about can be gleaned from books, the Internet and consultations with professionals. Having familiarized yourself in detail with the technology of laying the stove, you can easily accomplish your plans with your own hands.

Preparatory work

Before laying the stove, it is necessary to determine the place for its installation. Professionals advise those who are laying the stove for the first time, first to practice, to make a layout of the stove.

In the process of this work, it will be clear what masonry is, and if mistakes are made, then they will be obvious, and they can be corrected. It is important that the distance separating the chimney pipe and the roof overlap (rafters) is not less than 15 cm. If this rule is observed, you can mark the place allocated for the stove foundation.

It is carried out in size larger than the main structure of the furnace. Waterproofing is required for the foundation. One more rule: when performing masonry, do not forget to constantly monitor its correctness.

Furnace walls must be made strictly vertical. The attention to the corners is special. The rest of the masonry will depend on how correctly you build them.

For work you will need:

- trowel;

- putty knife;

- level;

- plumb line;

- lacing;

- container for solution;

- shovel or perforator;

- knitting wire;

- roulette.

Brief description of the methods and order of laying the furnace

Stove masonry can be of different types. For example, undercut masonry or masonry with empty seams. Their differences are significant.

With the first method of masonry, the finished brick oven is not subjected to plastering, since all the seams are filled with mortar. The walls are laid out either in a whole brick or in half.

There is also a 3/4 masonry option.

For the laying of the stove, bricks are used, designed specifically for these purposes.

Its other name is red, full-bodied. It is not recommended to use second-hand bricks or expanded clay blocks, as well as slotted bricks.

- The first row is laid out simply with bricks, without the use of mortar. After that, the bricks are aligned, the front wall is determined, the locations of all the doors are located. After this estimate, the bricks are laid on the mortar. After that, they move on to laying the corners.

- Further, adhering to the recommendations of experienced craftsmen, you need to complete the entire furnace circuit. With the help of plumb lines, a string is pulled from the stove corners to the ceiling. These vertical lines will serve as a good guide for your work.

- The location of the places of the blower, combustion chamber, ash pan depends on which model of the stove is laid out. The blower door is equipped after 3 rows of masonry, one row after it - an ash pan.

- The next one is the firebox. The doors are fastened to the masonry using baked wire. When the turn comes for laying the furnace vault, it will be necessary to cut the bricks. Here you need a high-quality docking. The stove roof is laid after the 2nd row above the combustion door.

For the lining of the combustion chamber, a special refractory brick is used. Due to the fact that such a brick and a brick used for masonry have different temperatures, there should not be a rigid connection between them.

When installing the chimney, a special valve equipped with a good adjustment system is provided.

Technological procedure for laying the furnace

After the first row is laid, we carry out the laying of corner bricks of the 2nd row, with the control of the verticality of the corners with a level or a plumb line. As well as row 1, first we lay out the perimeter, only then the middle of row 2.

- As mentioned above, we first lay out the first brick row without using mortar, taking into account the seams in accordance with the order.

- Next, we determine the position of the bricks at the corners, put them on the mortar, checking the horizontal position using a level. Using a mallet, we upset the bricks that protrude. After the required horizontality is reached, we perform the first brick row using mortar, do not forget about the level.

- Using a tape measure, we check the size of the oven in plan and diagonal. A prerequisite is the equal value of the diagonals in the rectangle. If necessary, you need to knock out the corner bricks until the desired equality is achieved. Now you can lay a brick using mortar, the first row, more precisely, its middle.

- After the first row is laid, we carry out the laying of corner bricks of the 2nd row, with the control of the verticality of the corners with a level or a plumb line. As well as row 1, first we lay out the perimeter, only then the middle of row 2. Further, after completing 2 rows, it is necessary to hammer nails (80-100 mm) into the seam of the corners between 1 and 2 rows.

- Now we lower the plumb line in turn at all corners of the second row and make a mark on the ceiling of the points from which the lowering was made. Then, at the marked points, we hammer in nails of the same length, fix the cord (nylon) and stretch it.

The vertical position of the cords is checked with a plumb line. Elimination of deviations is carried out by bending the upper nails. Thus, you have completed the contour of the future stove in space. All subsequent rows, or rather their verticality, must be controlled by stretched cords. This will significantly reduce the time spent on inspection.

The laying of subsequent rows is performed in a similar way, each new row is checked against the order. In the process of laying, we clean the inner and outer surfaces from excess mortar using a trowel. Every 4-5 rows we wipe the walls of the chimney with a wet rag.

The seams of the oven masonry, or rather their thickness, should be as thin as possible. Thick seams contribute to the chipping of the mortar and the weakening of the masonry. The grouting of the joints must be tight, until the excess is squeezed out.

Another rule that must be observed is the brick binding rule. It implies that each vertical seam must necessarily be overlapped with a brick of the next row.

Most often, the location of the vertical seam is in the center of the brick lying in the next row. However, it does not always work out so well. Sometimes it is necessary to carry out masonry, making the overlap not in the center, but less than half of the brick. It is better if this distance is not less than a quarter of the brick length.

If the brick is cut on one side, then it must be laid with this side outside the chimney channel. Since such a surface is weakened, it can quickly collapse under the influence of high temperature conditions.

The furnace firebox is traditionally laid out with. This is due to the fact that such a brick is more resistant to high temperatures.

It is not necessary to bandage the seams of masonry made of fireclay bricks and stove bricks, since they have different coefficients of linear expansion. Either a row is laid out of fireclay bricks, or the furnace is lined with their own hands. The distance between the lining and the brick must be at least 5 mm.

Before you install the doors in their place, you need to check them for the quality of tightness to the door leaf frame. Also, the freedom of rotation of the canvas on the hinges, the presence of distortions (or their absence), the quality of the door closing, and the holes for fastening are also checked.

Before you install the doors in their place, you need to check them for the quality of tightness to the door leaf frame. Also, the freedom of rotation of the canvas on the hinges, the presence of distortions (or their absence), the quality of the door closing, and the holes for fastening are also checked. If any defects are found, they must be eliminated before installation, or the door must be replaced completely.

To complete the installation, we use a knitting wire. The required length is about 50 cm. It must be inserted into the holes located on the door, and then doubled up and twisted. In the place where the door will be installed, we process the brickwork with mortar. We carry out the installation of the door with checking the vertical and horizontal position, then we fix it with bricks. The ends of the wire are laid in the masonry seams.

Installation of the firebox door is similar to the previous version. The difference is that it is wrapped in asbestos.

To prevent the wire from burning off, we fix the upper part of the door with a clamp. It can be made of steel (strip, 25x2.0). The clamp is fastened to the door using rivets or bolts.

The problem of heating country houses and country houses is associated with the lack of a central supply of heat carrier and gas. Many have already become disillusioned with metal stove stoves, but a small brick stove - built with their own hands - gives comfort and warmth, which cannot but rejoice.

Brick stoves for country houses

Advantages

In the last two to three decades, modern metal furnaces have taken an undeniable monopoly in individual construction. This is caused by a number of factors:

- Comparative cheapness in comparison with;

- Ease of assembly and installation;

- Short terms of installation of the heating device at the place of final operation;

- High rates of efficiency and firewood savings declared by the manufacturer;

- The apparent complexity of the construction of a brick oven and the difficulties associated with finding a worthy specialist in this area, fear of independent construction of such a monumental object;

- No need for complex roofing work when installing the chimney;

- Relative compactness, which is important for a country house;

- An advertising campaign for manufacturers of metal furnaces, claiming their undeniable advantages.

However, once the owner of a metal device finds himself in a room equipped with a stone oven, his views change dramatically.

It is impossible to deny the fact that the heat generated by such a stove is incomparably more comfortable and pleasant. It is easy to breathe in the room, there is a pleasant smell, special atmosphere and coziness.

Food cooked in a stone oven is also different. The special temperature regime, smoky flavor and oven effect give it a unique taste and aroma.

In addition, there is a lot of data on some of the healing properties of heat radiation emanating precisely from warm clay heated to 70 - 75 ° C. We will not go into the jungle of physics and biology, we will note the fact itself.

So, the advantages of a brick oven, collected in a single list:

- Huge heat capacity and inertia of the device. It is enough to heat such a stove once, and it will give off heat to the room for a long time. Even in severe frosts, the number of fireboxes does not exceed two per day;

- The stove does not overheat from the outside, and it is impossible to burn yourself on it, which is extremely important for families with small children;

- The oven does not dry the air in the way that metal counterparts do;

- Heat radiation is much softer, not as aggressive and heavy as from steel and cast iron surfaces;

- Less firewood (controversial opinion, but many owners agree);

- Incomparably longer service life;

- The smallest brick oven creates more coziness and comfort than the largest metal one;

- It easily allows you to heat large volumes of water, and if you install a coil or register, there will always be warm water;

- In the oven and firebox, you can bake a large amount of bread and other flour products, as well as cook porridge and other dishes;

- Even small brick stoves look great and decorate the interior, create inexplicable coziness and special surroundings in the room.

Advice! Any wood-fired heater is a potential source of danger, as it produces carbon monoxide. Therefore, you should not take on complex large furnaces, but small brick oven with your own hands- a very realistic option.

Naturally, nothing is perfect and absolute, so it is necessary to talk about the difficulties and disadvantages of stone heating appliances.

Flaws

Since we have listed the advantages of brick stoves, let's be fair and remember the disadvantages. We do not run an advertising campaign, so we are not afraid of objective assessments.

So, among the disadvantages of stone furnaces, you can list the following features:

- A very laborious structure, especially for a person who has no experience in the construction of such products;

- Quite a costly event, especially if you involve an experienced master stove maker, the cost of the efforts and skills of these guys is definitely high;

- There is a risk of unsuccessful construction, and alteration of a stone monolithic structure, as you understand, is not an easy task;

- The danger of operating a faulty or improperly built stove is associated with carbon monoxide poisoning, which can lead to very sad consequences;

- Requires more space in the house than a metal counterpart, although today more and more projects of small stoves appear, which practically eliminate this drawback;

- High inertia is associated with a fairly long warm-up and kindling, therefore, in order to heat the room well, it may take several hours.

Advice! If you use the cottage for rare forays for a day or two in the warm season, however, in the cold season too, then it makes no sense for you to start building a brick oven, since it will take three hours to warm up, and in the meantime you are already getting ready back. A brick stove is needed for people who love a country vacation and allow themselves to spend long winter weeks in the country.

This is where the question of the purpose of the furnace arises. It is obvious that stoves are different, both in design, and in size, and in function.

Appointment of ovens

Another important point is the correct choice of the configuration, design and purpose of the stove. Since we are talking about a summer residence, we should proceed from the requirements of temporary suburban housing.

In general, there are four main types of ovens:

- Heating;

- Cooking;

- Baths;

- Mixed.

Strictly speaking, bath stoves can be attributed to a specialized subspecies of heating devices. But we will not delve into the intricacies of classification, since this occupation, in general, is useless.

Let's just say that for a summer residence I would like to have a mixed type - something like, since it is irrational to arrange a separate heater and a stove from the point of view of saving space.

Therefore, you can voice the requirements for a summer cottage brick oven based on the above:

- Simplicity of construction, so that you can master the construction with your own hands;

- Compact size, this is a summer house, not a castle or residence;

- Multifunctionality, that is, a mixed-type oven with which you can cook food, heat up water and warm up the house.

Construction of a brick country oven

We need a clay-sand mortar, a building brick (double silicate brick M 150 will not work, you need a clay brick), a trowel, a bucket, a mixing trough, a plumb line, a level, an asbestos cord, fireclay bricks, doors, latches and other stove accessories, steel galvanized wire, hammer with a pickaxe, grinder with a disc for concrete.

The stove will take up 0.4 m², while its weight will be insignificant, so you can do without a foundation. If you have a weak floor, then it is better to make a screed under the masonry.

So, laying a small country stove in steps:

- On the place chosen for the stove, we put roofing material or glassine with a size of 530 × 780 mm for waterproofing;

- Pour one centimeter thick sand on top and level it;

- According to scheme No. 1 (picture at the beginning of the paragraph) we lay out the first row of bricks, without fastening it, and level it with a level;

- Apply a thin layer of clay mortar. We take the blower door, wrap it with a double layer of asbestos cord and fix it with twisted wire.

- We spread the second row of bricks.

- We take fireclay bricks and lay out the third row. After its formation, we install the grate. We observe the gaps for thermal expansion of materials up to 1 cm.

- With a brick installed on the edge, lay out the fourth row. We make supports for the internal partition inside the chimney. We put the "knock-out bricks" of the back wall without clay with a slight protrusion outward.

- We install a furnace door, pre-wrapped with asbestos. We fix it with twisted wire and temporarily fix it with two bricks: we put one on the back of the priest, the other on it and the door on top.

- We spread the fifth row flat along the contour of the fourth, and the sixth on the edge. We wipe the chimney walls with a wet rag.

- We put the seventh row flat from the three-quarters (we cut off 3/4 of the whole brick with a grinder) for a bundle with the eighth row. The back wall is back to the edge.

- In the eighth row we close the furnace door with two bricks above it. Above the firebox, we install a beveled brick to center the flame under the burner.

- We put the ninth row with a backward shift (small) to keep the door open. Before laying, lay out a wet asbestos cord to seal the joints of the brick and the hob.

- With the tenth row, we begin the formation of a chimney, which will gradually expand backward. We will make the pipe attached so as not to shift the center of gravity of the structure, or a mounted one made of light iron.

- In the eleventh row, we lay the valve, seal it with an asbestos cord coated with clay.

- Next comes the chimney into a quadrangle, which is joined to a light metal pipe.

- Now we take out the knockout bricks and clean the lower part of the chimney from debris.

- We close the gap between the first row of bricks and the floor of the metal L-shaped sleeve and nail the plinth.

- We whitewash the stove or cover it with stove varnish, seal all joints between metal and brick. Metal parts can be painted with black fireproof paint.

- We make a test furnace with paper and small branches, then give 2 weeks to dry.

As you can see, all the manipulations are not so difficult to do on your own. Material and labor costs are relatively small, the structure does not take up much space.

At the same time, we received a heating and cooking device that will perfectly heat a small country house, give your cooking a unique taste and aroma of smoke, create a pleasant atmosphere and comfort.

Advice! If there is an opportunity to invite a person a little bit experienced in the furnace business, at least as a consultant, be sure to use it, since it is quite difficult to build stoves from a book, it is better to see it once.

Conclusion

Brick stoves are considered bulky, expensive, and difficult to build. However, it is easy to make sure with specific examples that these opinions are somewhat exaggerated, and you can build an inexpensive compact country stove made of bricks, and on your own.

In the video presented in this article, you will find additional information on this topic.

Ecology of consumption. Manor: A small stove for a summer residence of bricks can be made in a short time and with your own hands, without the help of a professional. We will tell you about the preparation of the foundation, what materials are better to choose for laying the stove, and how to properly prepare the brick and clay so that the stove will serve for a long time and heat your home well.

Very modest requirements are put forward for a brick oven for a brick dacha with their own hands. Long breaks between visits, a relatively small volume of heated space, maximum efficiency and the use of local fuel - all these criteria indicate the choice in favor of a wood-burning stove. Contrary to popular belief, it is quite possible to do it without the services of a master stove-maker. Let's take a closer look at how a small brick oven for a summer residence is designed and built.

Preparation for work

It is unlikely that it will be possible to make a complex and highly efficient stone stove for giving out of bricks with your own hands without building experience. Too many nuances and secrets are hidden in the work of a professional master stove-maker. But a small in size and simple in design, vertical stone stove for a summer residence - it may well be built even by an unprepared person. The main thing in this process is to do everything very carefully, accurately and in accordance with our recommendations.

Selection of building materials

Since the described small brick stove for summer cottages is fired with wood, it is not intended for intensive and prolonged heating - it can be folded from ordinary, not refractory bricks. Although, it is better to use a heat-resistant material for the combustion chamber.

List and required amount of materials:

- red ceramic solid bricks - 700 pcs.;

- grate grate - 1 pc .;

- furnace door - 1 pc .;

- blower door - 1 pc .;

- soot cleaning channel doors - 2 pcs .;

- gate valve - 1 pc.

For a wood-burning stove with your own hands, you need to choose a full-bodied kernelsamic bricks, which do not crumble from the average blow of a hammer, and at the same time emit not a sonorous (this is a hot brick), but a booming sound. It is desirable that the side faces of the bricks are smooth.

Clay will be needed for the solution. Stoves prefer to choose "fatty", from which the solution is soft, like butter, and plastic, like soft plasticine. Such clay for building a stove for a summer residence can be found with your own hands in hardware stores or, after consulting with local residents, you can simply dig up in the area.

Tool

With a good tool, a stove for a country house is built quickly and easily. For work, you should prepare a level, a plumb line, a trowel, a bricklayer's hammer and dishes for preparing clay mortar. You need a grinder to cut bricks.

Preparing the foundation for a brick oven for a summer residence

Whatever a small brick oven for a summer residence with your own hands, its weight is several hundred kilograms. Therefore, you cannot put it on the wooden floor of the room, but you will need a foundation.

To choose the right place for the foundation, you need to project the stove plan onto the ground in such a way that its pipe falls between the floor beams and the roof joists. If a chimney is provided in the wall of the house, then the stove for the country house should be located near it. When building a new house, a stove for a summer cottage can be built into the wall between rooms. This option is very convenient: both rooms heat up equally quickly, but in one of the rooms, even under the most unfavorable conditions, there will never be smoke.

The depth of the foundation must exceed the depth of soil freezing. However, if the country house has its own deep foundation, then a combined base can be made near the stove for a summer residence. To do this, four lightweight concrete posts, such as those used for fences, are vertically dug into the ground. The posts should protrude from the ground just below floor level.

Between them, right on the surface of the soil, a gravel or sand cushion is poured into a half-brick. Then a layer of roofing material or other sheet waterproofing is laid. A reinforcing metal mesh is laid on top, and a concrete foundation with reinforcement is poured on top of it. The top of the foundation must be level with the floor and perfectly horizontal!

Let's start building a furnace

On top of the foundation, you need to lay another layer of waterproofing, and on it - a metal sheet. The dimensions of the sheet should exceed the projection of the stove by 10-15 cm. Moreover, from the side of loading firewood, it is better to make a larger release. Then random sparks from the blower will fall not on the wooden floor, but on the metal.

During operation, the stove for the summer cottage heats up quite a lot. If the nearby wall is made of wood or other flammable materials, it must be protected with thermal insulation. The simplest protection is an asbestos sheet painted with heat-resistant paint or covered with a thin plaque. Asbestos cannot be kept open, as its dust is considered very hazardous for inhalation. Instead of asbestos, a do-it-yourself stove for a summer residence can be insulated from wood with a slab of hard mineral wool. The material must be heat resistant. Facade building wool is not suitable for this, since it has a too low temperature limit.

Preparing clay mortar

The country stove is built on clay, not cement. Clay mortar is prepared from good clay and clean river or sea sand. If the clay is not purchased, but was dug somewhere in the neighborhood, then you should first check its quality. To do this, we make several trial batches with different proportions of clay and sand. Roll the finished clay dough into small balls, rollers, cakes, and leave to dry for two weeks at room temperature.

Dried products must be tested: thrown from a height of human growth, try to crush them with a board under the weight of a kettlebell, etc. The composition of the most durable clay sample is taken as a standard. In the picture shown, the best batch corresponds to samples "b".

Preparation of bricks and clay

A do-it-yourself stove for a summer residence is built from pre-soaked bricks! For this, it is kept in water for at least 8 hours. During this time, all the air will go out, and the clay will be good for the brick in the masonry. Clay needs to be cooked quite a bit, so that about 20-25 pieces are enough for stacking. bricks. Without the necessary experience, you can't put more at a time. The thickness of the clay mortar in the masonry must not exceed 5 mm.

Features of stove masonry

In order for a stove in the country, laid out with your own hands, to serve for a long time, each row should be checked for right angles and horizontal surface. The stacking sequence is visible in the ordering drawing.

The cast-iron doors of the blower and combustion chamber are fastened with steel wire, which is walled up in the masonry. The cuts are made with a grinder. As a last resort, you can do it in the old fashioned way - with a mason's hammer-pick, but at the same time a lot of waste is possible. The grate area should be slightly larger than the grate itself. Then, when heated, the metal will not move the brick.

The mortar is applied to wet brick. Experienced stove-makers do this not with a trowel, but with their hand. A good solution is applied as easily as soft butter is spread on bread.

Important note

If, during laying, the brick sagged lower than necessary, it should be removed, cleaned the mortar and laid on a fresh one. Otherwise, the new stove in the country will smoke heavily and let through soot. Unlike cement mortar, it is categorically impossible to move a brick along the clay mortar!

When building a stove in the country, try to make the inner walls as smooth as possible. Then soot will not linger on them, and it will be easier and less likely to need to be cleaned. Outside, the country stove should also be neat and beautiful. Outside seams should be carefully sewn up with a jointing or finger. In places where arches and horizontal partitions are formed, there should be no gaps either. It is better to lay such rows slowly, one a day, so that the lower rows have time to grab, and the upper ones do not crawl.

Outcome

Despite the small size and simple design, brick country stoves are very popular for small houses, as they show very good results. They heat up quickly, and the heat is enough for the whole day. A small brick oven for a summer residence is notable for its low cost and availability for self-production, but with permanent residence in the winter, it will have to be heated twice a day - in the morning and in the evening. published by

Folding the oven with your own hands for a beginner can be an overwhelming task in our age of developed industry and high technology. The cost of construction work, especially if it requires some special knowledge and skills, is high.

It is understandable that many developers are trying to get by on their own. Where one's own qualifications are lacking, advice from acquaintances or specialized reference publications help.

The downside of this approach is that not all demanded professions are very common. It is often a problem to find a specialist in a specific field. Alas, some types of work are already so scarce that they have passed into the category of art or are striving for that.

Therefore, they are overgrown with some kind of myths and inaccuracies, which are extremely difficult for a non-professional to weed out. The stove business has ceased to play an important role, so many of its nuances, quite recently understood by every inhabitant, slip out of sight of a modern person - there is not enough daily practice.

The big picture

Furnace drawings can be found in abundance on the Internet or on the pages of monographs dedicated to this case. This is not the difficulty. It is much more difficult to choose the best project that best suits the specific conditions, requirements and expectations of the developer.

And observing the subtleties of technology can be an overwhelming task for a beginner - as in many traditional crafts, experience plays an important role in the furnace business. Too much in the technological chain is tied to some kind of tactile sensations, intuition. It is almost impossible to teach these nuances remotely - too much is transmitted only through personal contact between the master and the student.

Fortunately, the load on stoves is no longer the same as before, when they were the main way to heat a home in the cold season. Now these designs play the role of fun or an additional, backup heater. Consequently, the former thoroughness of their installation is no longer so in demand.

The stove, not so often used and not with such intensity, does not require careful observance of technological subtleties during masonry. Although, of course, one should strive for this.

Stoves are no longer installed in cities - engineers have long come up with better and cheaper ways to warm a home. But outside the city, at the dacha, a stove that is simple in design and unpretentious in maintenance may still be in demand.

Choice of design

Before finally dwelling on any design, it is necessary to clearly localize the range of tasks facing the future furnace system. What is expected of it, how often it is planned to operate and for what purpose. And then make a choice.

Traditionally, all ovens are divided into two main classes according to their functional characteristics. The design can be:

- heating;

- heating and cooking.

The difference is clear from the name of each class. Heating stoves are highly specialized and can only heat. True, everything in their design is subordinated to the fact that they perform their task as efficiently as possible.

The heating and cooking design is already universal. You can still cook food on it. It doesn't matter what exactly is added to the ability to heat the dwelling: oven, bread chamber, stove, smokehouse. The important thing is that the oven has become dual-use.

In the dacha sector, heating and cooking stoves are most popular, since it is simple and practical - as a rule, this is the only stove in the house, and therefore its versatility will not interfere with it.

Also, the increased popularity of suburban areas, if not created, then revived a class of stoves, rare to this day, intended only for cooking. They are now united under the very vague and widely interpreted name "barbecue".

Although it would be more correct to define them in the group of stove complexes, since they can include not only a primitive brazier, but also an additional set of services, limited only by the desires and capabilities of the owner. And they cannot be ranked as a single stove organism - this is really a complex created from a kind of set of stove modules.

Accordingly, a country stove with equal success can stand on the street (garden oven-grill) or be designed exclusively for the home, therefore, there is simply no universal step-by-step instruction - home and outdoor varieties of stoves are only partly related, but structurally they are completely different types. Therefore, the technology of their masonry is slightly different - one of them requires increased moisture resistance, for which cement is added to the masonry mortar, which slightly reduces the fire resistance of the array.

About home ovens

They don't just put a stove in the house. It is a tool. And the main requirement for it is this: to replenish the heat loss at home. Accordingly, the size of the stove must correspond to the living space heated by it.

In theory, hoping that the dacha will be operated only in the warm season and quite a bit in the off-season (late spring-early autumn), you can slightly cut the required indicator and fold the stove less than would be required according to theoretical calculations. But practice shows that in 99% of such cases there is a temptation to visit a house in the wilderness at least once a year. As a result of an attempt to warm up too large an area, the small furnace cracks - its capacity is initially insufficient.

And almost always a small furnace structure is operated with constant overload - often such forcing occurs involuntarily, unconsciously. They are just trying to create comfortable living conditions at least for a while. So the result is quite natural: the masonry cracks and quickly collapses.

The point here is not the viciousness of the chosen design or violations in the construction technology. The reason is the inconsistency of the dimensions of the furnace with the tasks assigned to it.

In the villages today you can find many different stoves, including outdated, archaic designs. And it is important to understand that the age of the scheme does not always indicate its quality. Unfortunately, many old stove fantasies are not suitable for a number of parameters for repetition in modern realities.

For example, the once popular Dutch woman was once (in the 17th century) a truly revolutionary notion. But a lot of time has passed since then, and this scheme is very inconvenient today, from the point of view of safety and ease of use. The long length and the total number of successive smoke flows lead to intense soot deposition and the appearance of cracks in the furnace mass - the difference (gradient) of heating of different parts of the structure body is too large.

A traditional Russian stove also does not always meet the conditions of a country house - first of all, because it takes up too much space. In addition, the body of such a design, even if it is an improved one, is too massive. As a result, there is a large thermal inertia.

That is, the stove will have to be heated for a long time to warm up. Although it will take a long time to cool down. But this may turn out to be pleasant and necessary with permanent residence, but with irregular visits it will only interfere and annoy.

Probably, the best choice for the summer resident will be the so-called Swede - a simple universal brick oven with a hob for one or two burners, limited by a cooking chamber and with an oven powered by one with a firebox stove. Structurally, the Swede is a slightly modified typical kitchen fireplace with a heating shield.

The Swede is distinguished from the basic idea by a cooking chamber - a niche above the stove. Accordingly, a certain volume is formed above the cooking chamber (this is the name of the niche in which the stove is enclosed), which can also be somehow used. Sometimes stove-makers place a dryer there, but it is more practical to include this array in an active block involved in heat transfer.

It is about this scheme that will be discussed below. Moreover, the ordering is not so difficult and is quite understandable for a beginner.

Outside stove - feral home stove

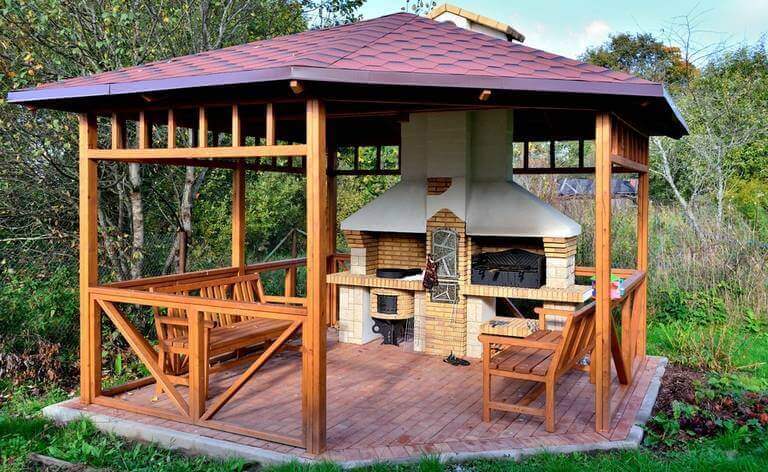

A garden oven only conditionally has the status of an outdoor one. In fact, an open installation of a brick oven leads to its rapid failure - any moisture in the masonry (even capillary), frozen in winter, will lead to ruptures. Therefore, barbecues are placed in gazebos or under a separate shed to protect from precipitation.

At the heart of any garden stove complex is always a kitchen stove in one variation or another. This can be a blind repetition (with the exception of masonry mortar - cement is added to it) of a typical kitchen hearth, but more often (for ease of execution and economy of materials) the need to warm up the room is simply ignored and all elements that carry only the heat storage load are removed from the structure. The bottom line is only pure functionality: some kind of kitchen element for the heat treatment of food and a smoke oven (although it is sometimes donated to it, although it is extremely rare).

The versatility of an individual element of a furnace complex is generally avoided. Only if it bodes well for the layout plan - more services in a smaller area. If you need to add functionality, then a new block with such a service is standardly attached. The only exception is probably the Russian stove included in such a complex. But it in itself is already universal from the very beginning.

Another moment. No matter how planned in advance, but in life, the decision to cook a particular dish on the stove complex is almost always spontaneous. Therefore, it is worth considering that the start-up of the furnace takes a minimum of time and does not require any preliminary complex manipulations. This is a stone in the garden of those linkers who try to combine all the achievements of culinary thought in a Russian oven.

Very convenient in theory and extremely awkward in life is someone invented a variation, according to the recommendations of which a cast-iron stove with burners is embedded in the lowered pole, and a welded barbecue box is perched on all this. And, before using the stove or the furnace crucible, you have to pull back and forth a completely not light iron brazier and each time look for a place for it. It is much easier when there is a separate, specialized module for such tasks.

Materials and other general points

First, let's talk about ovens as a typical phenomenon, without particulars. Points to be observed regardless of layout, size and location:

- foundation. It is better when the stove in the house has one of its own, independent of the foundation of the house. But laid to the same depth as the foundation of the walls. Although the option with a common grillage and a covering plate is also quite acceptable. For a barbecue, it is better if the gazebo and stove are based on a common stove. Waterproofing in two layers is required. The first is at the level of the soil, the second is at the level of the final floor or slightly below;

- mortar from red clay and quarry sand. Normal fat content - the ratio is selected empirically. For laying fireclay bricks, a mortar is used - this is a ready-made mixture of fireclay (ground shards of fired ceramics) and refractory clay. It is worth adding cement to the grout for masonry barbecue - about one trowel per bucket of masonry mortar;

- brick. Apply corpulent, red, ceramic, wet plastic molding. The brand is not lower than the M150. A higher frost resistance class is better - no less than 50. In critical places (firebox and the first smoke circulation), it is better to replace ceramic bricks with fireclay bricks. Any oven masonry is carried out exclusively on soaked red brick. Fireclay is only rinsed from dust;

- permissible thickness of the masonry joint 1–5 mm for ceramic red and 1–3 mm for fireclay refractory. Fireclay and ceramic bricks should not be tied up in the array;

- imported iron casting with fine grain, you can put it back in place right away. Domestic castings with coarse grains (means that the casting went into an earthen mold, and not a metal chill mold) is better (not necessary) to be annealed before installation to eliminate internal stresses - to heat up to about 250 degrees and leave to cool without forcing the process;

- the oven must not be used immediately after laying- the structure must be completely dry. It is better if it happens naturally. Another thing is that there is not always such a luxury - not everyone has the opportunity to wait a month and a half or two until the massif is completely free of moisture. So they often use artificial drying, for which they heat the stove daily with small portions of absolutely dry fuel - literally with a bunch of chips. Firewood is placed in a hut in the firebox - this will give a high, but not hot flame.

Swedish oven

There are a lot of Swedes. Every stove-maker has in his arsenal at least one variation of such a stove. The differences of most of them lie in small insignificant details, but each author is inclined to ascribe to his own vision of the issue a lot of originality and innovation.

In fact, it’s not like that. Everything is almost the same. Therefore, the disputes that it will be correct to arrange the chimneys in this way, and any interference in their mutual arrangement is akin to desecration of shrines, is fundamentally wrong. The Swede is a stove that allows a free approach to layout without sacrificing efficiency.

In the first rows, the Swedes bring out an ash pan, a channel under the oven and a passage connecting the lowering and lifting channels. They put the cleaning doors and one blower.

It is better to bevel the corners of the brick protruding into the internal channels so that the resistance to gases is minimal and there are fewer eddies.

The oven is placed one row below the hearth. The oven cabinet is made independently - the industry does not produce the required size.

The firebox must be lined with masonry on the edge or with longitudinal halves of bricks. This will help equalize the heating of the array.

The partition between the firebox and the oven is a row below the stove - through this hailo, gases from the firebox leave under the stove above the oven, and then go around it, and already under the oven they are directed into the vertical system of smoke circulation.

When laying the side walls of the chamber above the slab, make sure that they do not pinch the cooktop slab - otherwise, the expanding metal will either burst or break the brickwork.

The niche above the slab is covered with steel corners. It is worth saying that sometimes doors are placed in it. It is very convenient, since this not only allows you to isolate the camera from the kitchen space, but also creates a kind of oven, only a large one. While such a step is possible, it is still not required.

The gases in the chamber above the stove are forced to pass through the dividers before going out into the pipe, which also work as struts supporting the ceiling. At the same time, they increase the heat storage capacity of the furnace.

The stove is overlapped with three rows of masonry - this is the standard safe overlap thickness for household stoves.

The stove can be slightly adjusted to the parameters of the room in which it is installed. Simply add or remove rows of the same type above or below the slab.

In support of the thesis about the existence of a large number of Swedes, we demonstrate a video, where the scheme is basically the same, but embodied a little differently.

Simple Garden BBQ Oven

And it makes sense to consider this design in detail, step by step, with an explanation of the main points of the diagram.

Materials:

- corner 32: 1.7 m for faience - 1 pc., 1 m for barbecue overlap - 4 pcs., 1.25 m for countertop overlap - 4 pcs.;

- oven brick- 1300 pcs.;

- half-door blower 130x140 mm - 1 pc .;

- furnace door 240x280 mm - 1 piece;

- cast-iron stove under the cauldron single-burner 705x530 mm or 600x600 mm - 1 pc.

Additionally:

- asbestos or basalt cord (kaolin wool can be used) for fastening the firebox door;

- knitting wire;

- clay;

- cement;

- sand;

- sheet asbestos (one sheet) or kaolin wool - for installing a plate under the cauldron;

- metal brazier.

Garden barbecues have recently become popular among the owners of summer cottages. Most people are content with commercially available metal variations of these outdoor stoves. It's easier this way, you don't need to build some kind of special shed to protect the structure from bad weather, and less space needs to be allocated on the site.

Meanwhile, many people prefer something more stationary and monumental. It's about a brick barbecue oven.

The very concept of "barbecue" is polysemantic. This is a dish cooked on charcoal (the usual kebab is also, in fact, a kind of this dish), and the culinary process itself, and an oven specially adapted to a specific method of culinary processing.

Most often, this is the name of the street stove complex in the garden, equipped with a barbecue, which does not interfere with putting it in large kitchens in cottages (or on the veranda). Moreover, by today's standards, a heating function is not always required from a stove - an outdoor barbecue, as a tool, is very utilitarian and is more "sharpened" specifically for cooking.

This does not interfere with equipping the structure with all sorts of additional options. The brazier can be supplied with Russian ovens or "Pompeian" for pizza, ovens with ovens or smokehouses - everything, right down to washbasins and dish cabinets. It depends on prosperity, rampant imagination and the availability of free space.

The most common set can be considered a brazier, a cutting table and a stove for a cauldron. We will consider this configuration in the most simple version for independent execution. Let's add only a firewood - a niche for firewood under the barbecue.

Furnace location and foundation

The entire system weighs over five tons, so it is important to understand that an appropriate base will be required. Of course, this massiveness is to some extent compensated by the large supporting surface. And still, the foundation must be solid.

It is important to protect the masonry from rain and other troubles, especially from getting wet in autumn and freezing in winter. So, whatever one may say, but in our climate it is better to hide barbecues in a gazebo. The degree to which the latter is closed is at the discretion of the owner. The main thing is to have a roof.

This restriction on the location has its advantages - you can use a plate common with the gazebo as a foundation. The main thing is to provide for reinforced reinforcement when pouring it in place of the future furnace, in comparison with the rest of the floor of the gazebo.

If there is no concrete floor near the gazebo, as such, then you can cast a separate area on a sand cushion or use the option with screw piles. It is important to remember the wish: either the oven and the gazebo do not play, or they do it together, synchronously. In a word, as it happens on a slab foundation.

Composition and preparation of the solution

It is customary to lay the stoves on a clay solution with a weaker made of sand (for red clay) or chamotte (ground shard for refractory clay). But barbecues can be difficult because of the street location.

A cement-based solution is more suitable for the street. The downside is that it does not endure fire very steadily. The way out is in a compromise: add cement to the kiln clay-sand composition, about a trowel on a bucket of mortar. But above the roof, they still put the pipe on cement-sand.

The sand is taken from the quarry. River or sea is not suitable - its grains are rounded, which has a bad effect on the strength of the solution. Sand must be sown through a mesh with a cell up to 3 mm.

Clay is taken as ordinary red. It is pre-soaked until small lumps disperse. Then filter through a sieve with a mesh of about 2 mm to remove any stones and debris.

Further, the fat content of the clay and the need for sand are determined - the proportions necessary to obtain a normal solution. Typically these ratios range from 1: 1 to 1: 6 (clay: sand). It all depends on the fat content of the clay, which, in turn, depends on the geology of the field. Simply put, in each place the clay has its own fat content.

Too greasy solution cracks due to strong shrinkage. Skinny (loam) does not hold firmly and crumbles out of the seams.

There are many methods for determining fat content, but we can recommend this tactile one: we make several tests in different proportions and wipe everything between the fingers (thumb and forefinger). The winner is the lot where solid grains will be felt, but the feeling of greasy, oily will not disappear.

If you come across oily areas without grains of abrasive, then it is worth adding a softener. If the grains glide poorly under the fingers, then add clay dough.

Final quality check: throw a lump of mortar the size of a fist on a sheet of iron (shovel bayonet, bucket sidewall, and something like that). You should get a cake 3-5 mm thick, as well as the optimal masonry joint for the oven. Dry the cake in the shade from twenty minutes to an hour.

Then we try to pick it off from the iron sheet. It peels off like a pancake from a frying pan - you need sand. Crumbles like dry soil from shoes - add clay. It can be torn off with difficulty and has no cracks - you guessed it with the proportion.

The solution can be prepared in advance in a large container and covered during the break to reduce water evaporation. But cement is added to it directly into the bucket immediately before laying: a trowel on a bucket, that is, a handful of ten liters of mortar.

For refractory bricks (if there is one in the structure), a refractory masonry mortar should be taken. It's easier with him - it is sold dry in hardware stores. The same amount of cement is added to it.

Features of buying bricks

The easiest way is to buy a refractory (fireclay) brick. It is about the same everywhere. More difficult with red ceramic.

You should take only corpulent (without any pits and voids) and only plastic molding. Find out this characteristic specifically from the seller. And steer clear of the dry-pressed variety.

Next, pay attention to geometry and integrity. No cracks, no deformations. When tapped, such a brick emits an even sonorous sound, without any admixture of hoarseness and dull tones. Its brand is usually M150 and higher.

And we pay particular attention to such a line in the specification as "frost resistance". A good brick can withstand at least 50 winter-summer cycles. More is better.

The clinker, for example, holds 100 and above, but it "bites" at the price. So, if there is no particularly loose budget, then we take at least 50 cycles. But from such a brick you can fold the entire array of barbecue.

In extreme cases, in critical places, instead of red, we use fireclay bricks. But that, too, it should be noted, is not cheap. And he also does not like moisture - it crumbles over time, like old polystyrene.

As already mentioned, before laying the red brick, we must soak it - we immerse it in water and keep it there until the air bubbles disappear. It's three or five minutes. Then we take it out and let the excess water drain. It's about a minute. And only then we carry out the masonry from it. The soaking step is required, otherwise the masonry will be fragile.

Fireclay requires less preparatory effort. It is simply rinsed out of dust.

If two types of bricks (chamotte and red) are used in the masonry of the array, then no dressings are made between them. And the fireclay massif, hidden inside the red one, is made 3-4 centimeters lower. This is done because when heated, the expansion coefficient for these types of building stone is different.

All doors are fastened with twisted knitting wire cords or with riveted metal plates - clamps. The frame of the furnace door is pre-wrapped with a basalt or asbestos cord soaked in clay solution. You can use kaolin wool. They do this in order to compensate for the same CTE during heating - the linear expansion of the metal is several times higher than that of any type of brick.

Masonry stages

Let's start laying. We make the seams no thicker than 5 mm (on fireclay - 3 mm). We check the verticality and horizontalness at each row. We do not allow voids in the solution.

We put the solution on the bed with a margin. We squeeze out the excess - on a wet brick it is not very difficult - and cut it off. We are not in a hurry so that the masonry does not float.

The given ordering is not the final version, but one of them. The main thing for a beginner is to understand the logic of organizing voids inside the furnace.

The order is presented in two angles. The first picture is the location of the bricks in only one row. The second figure shows the big picture.

There are no internal cuts and other additional frills - practice shows that beginners only get confused with such a presentation of material. But, having traced all the layers of the order, you can easily understand the design of the stove. Fortunately, it is not so difficult.

Waterproofing is necessarily arranged under the stove, even if such is provided at the foundation.

1 row

It's simple. This is the base of the oven. A kind of marking the heel of contact.

The length of the table can be shortened. It depends on desire and appetite. You can also reduce the width of the barbecue, but no more than a brick, otherwise it will be inconvenient to use. It is not worth reducing the depth of the space for the barbecue - you need to leave room for manipulating the skewers.

2 row

You don't have to build a barbecue area - just put it on the foundation slab. But with a small area under the whole complex it is more convenient. From the second row on the site, we outline the main functional elements of the structure - its nodes.

We put the ash-pan door on a wire and a clay solution, without a compensating cord - it does not heat up.

3 row

We outline the course for the gases of the stove.

4 row

5 row

We install the grate freely, without fixing anything. We choose a nest for it in a brick, with a clearance of about 5 mm on each side. We do not fill the gap with anything, in case of thermal expansion.

6 row

The lining (additional inner lining) of the firebox is uneven. This is explained by the fact that most barbecues are attached to the wall. You can increase the back wall lining, but then the plate will move too far - it will become uncomfortable.

The lining of the rear wall can be done by masonry. But it is better to lining it in halves - with bricks loose along it.

The lining can be made of fireclay bricks. We put the firebox door, as mentioned above, with a refractory winding around the frame.

7 row

We continue to masonry. Especially carefully we let the console of the right wall be poured - the table top of the cutting table will rest on it.

8 row

The woodshed niche is covered with 32 corners. Some shelves are made of it, a seat for bricks. If there is a desire to reduce the visibility of this power element, then the first corner is shifted inward to the outer edge, and a cut is made in the brick, in which the corner is drowned.

9 row

Make a small overlap under the barbecue. This makes it easier to use the barbecue. When you approach the barbecue niche, the socks of your feet do not rest against the wall.

10 row

Increase barbecue overlap slightly. Overlapping the firebox door is also done by letting in the side walls. If it doesn't work out - with a wedge bridge, that is, like an arch, but going along such a wide arc that the deflection is invisible.

At the corners, overlap the table top of the cutting table.

11 row

They make a niche for the barbecue. That should not reach the side walls. You need a margin of two or three centimeters - for expansion. Also, the grill should not occupy the entire niche in depth - you need at least 5 cm so that the skewers do not rest against the back wall.

Now you can make the barbecue box itself. Actually, this is a metal box (wall thickness is about 3-5 mm), in which the coals are placed. Its height is 15 cm or so. A lower height will give dryness to a kebab, a higher one - smoked meat.

It would be nice to let an additional strip of metal of a slightly thicker thickness around the perimeter of the box. It will not let the walls warp when heated.

At a height of 5 cm from the bottom, holes of 15 mm (plus or minus) are made in the walls of the box along the entire perimeter every 5–6 cm - for air to enter the combustion zone.

In general, there are structures with some kind of complex niches, equipped with an air injection system. But only in execution they are complicated, and in operation they are inconvenient. The option with a plug-in sheet metal barbecue is, whatever one may say, the most practical.

A little about the surface of the countertop. You can leave it that way or put on some durable ceramic tiles like porcelain stoneware. Any option will do.

12 row

Install the stove. Ideally, 704x530, but 600x600 is also possible. Changes may then need to be made, but they will be minimal.

Corner faience is a must. This is the name of the corner that protects the edge of the masonry from destruction. It lies freely, but its edges go into the masonry and press against it.

The slab is placed on a layer of clay mortar with the addition of soaked sheet asbestos. You can cut a recess under it. But again the rule of free installation: about a centimeter on each side for the difference in expansion. No commit.

Asbestos is ripped up and thrown into the water. There it quickly becomes soaked, turning into gruel. This is what is added to the solution.

Second option. The masonry under the slab is thinly greased with a mortar, on which a strip of kaolin wool about 5 mm thick is placed, and the slab is already thrown onto this pillow.

An important point: the Finnish plate (differs in the technology of casting in a metal chill mold) can be installed immediately. It is better to anneal the domestic stove (it is poured into the ground - you can see it by the coarse grain in the structure) at the stake to relieve internal stresses. Otherwise, there is simply a chance that it will burst unexpectedly. They simply heat the stove over a fire (or in a thermal oven, if possible) and leave it to cool, not forcing the cooling in any way.

You can install a slightly smaller plate, but you will have to modify the seat for it in advance.

13 row

The wall behind the slab is not folded onto the side - the masonry is protected by faience. At the cutting table, the back wall folds over and holds the outermost bricks. Then it comes to naught with ledges.

14 row

15 row

16 row

17 row

18 row

A small console is produced to support the overlap of the barbecue niche.

19 row

20 row

You can overlap with an arch or a straight lintel. The niche can be made slightly lower than in the order. The main criterion: when approaching the barbecue niche, you need to see the far edge of the barbecue - this will come in handy during operation.

The hearth is the heart of buildings that are not connected to centralized networks. It generates the warmth necessary for life and provides energy for cooking. The microclimate in the building and its service life directly depend on its performance and efficiency, and these are very important factors in the operation of the unit, do you agree?

The article presented by us describes in detail how to correctly build a brick oven for a home. The schemes of building a hearth are given, technological nuances are thoroughly disassembled. We offer carefully selected, scrupulously verified, practice-proven information on the selection and arrangement of brick stoves.

Novice stove-makers and country property owners wishing to control the work of hired craftsmen will be helped by the information we offer, based on construction requirements. Photo images and video tutorials will be an excellent help in mastering the material.

The constructive abundance of brick ovens is not easy to understand. However, owners of suburban real estate who want to equip a house with a brick unit, this difficult issue should be studied. It is better to determine in advance the option that is optimal for the purpose and device than to rebuild and modernize.

The division of brick stoves into types is carried out according to the following aspects:

- Appointment.

- Gas movement type.

- Performance.

- The frequency of the furnace.

- Geometric data.

Ideally, a perfect oven for you is selected according to two or three of the most important criteria. Let us analyze what should be attributed to the aspects that are significant in your opinion, which will become the basis for choosing the optimal brick unit.

Image gallery

Calculation of heat loss will make it possible to determine the furnace productivity, which should be slightly more than the calculated value, but not more than 15%. In the event that the power of the brick unit is greater than the specified limit, a different design should be selected.

To facilitate the process of choosing the most suitable brick stove for masonry in a low-rise building, nomograms have been developed. The graph below, which simplifies the calculations for the selection of a stove, is created for rooms with one outer wall.

Image gallery

HTC One X: specifications, reviews, prices, description of NTS X

HTC One X: specifications, reviews, prices, description of NTS X Review of HTC One X - a peppy old man One X

Review of HTC One X - a peppy old man One X Samsung GT-B2710 Xcover - Special Purpose Phone

Samsung GT-B2710 Xcover - Special Purpose Phone