Homogenizer. Equipment for homogenization. Homogenizer: working principle, design and application in the dairy industry General homogenization technique

The homogenizer is intended: for multicomponent homogenization and dispersion of insoluble (immiscible) media (which cannot be overheated), in order to obtain highly homogeneous non-separable emulsions and suspensions in the food, cosmetic, pharmaceutical, chemical and other industries. In many respects, they surpass the best foreign models of homogenizers and have no Russian counterparts.

The principle of operation of the homogenizer. The medium pumped by the homogenizer is supplied to the suction pipe and discharged from the pressure pipe under the influence of supporting pressure, coarse-grained particles and mixtures to be homogenized fall on the impeller of the unit, then, having received acceleration, they fall on the homogenizing unit. In the homogenizing unit, they are crushed between the rotating and stationary calibrating cylindrical knives of the rotor and stator. Rotating and stationary calibration knives are made in the form of rings with holes. Particles (such as fat globules) falling on the homogenizing unit are squeezed out by the impeller under the influence of pressure created by centrifugal force and pass through the holes. Since the rotational speed of the impeller and one of the rings is 3000 rpm. (or adjustable), there is a gradual cutting (crushing) of the movable part of the annular knife (each hole of the rotating part) of the fat globules as they move.

Advantages.

- All parts of the homogenizer in contact with the product are made of

- high quality food stainless steel AISI 304, AISI 316

- A mechanical seal has been installed, which has an increased resource and

- preventing loss of product.

- Guaranteed operation at higher than existing analogues

- temperature conditions (up to 115°С).

- Works great in acid and alkaline environments.

- Versions with dry run protection and with

- explosion-proof motor.

- Possibility of execution of a homogenizer, with "jacket" of cooling (heating).

- Smooth adjustment of degree of homogenization and productivity is possible.

- It has the ability to connect to a single-phase or three-phase network.

Benefit. Taking advantage of our homogenizers:

You can:

- Produce a consistently high quality product.

- Achieve a high degree of dispersion.

- Achieve long-term preservation of a given product structure.

- Apply any modern technology.

- Design any production lines, combining with additional equipment from other manufacturers.

- High quality, structural stability and shelf life of the product largely depend on the amount of particle dispersion.

- The minimum particle size can only be achieved with modern homogenizers.

Homogenizer with a cooling (heating) jacket.

Designed for homogenization of media that cannot be overheated. A coolant is supplied to the jacket, which circulates to cool the layer in contact with the product. Jacket heating is used to homogenize media that solidify (or become more viscous) already at room temperature. (chocolate, icing, cream, pate, etc.). Also for those environments in which the growth (death) of bacteria is characteristic with an increase (decrease) in temperature and vice versa.

Scope of homogenizers

Dairy Homogenizer

butter, milk, cream, sour cream, yogurt, cottage cheese, kefir, condensed milk, cheese, ice cream, milk powder recovery, milk formula, margarine, mayonnaise, light and combined butter, milk products with whipped structure

Condensed milk production line

Canned milk production line

Homogenizer for the production of oil and fat products

margarine, mayonnaise, light and combined butter

Butter and margarine production line

Food pumps in mayonnaise production line

Mayonnaise plant

Milk fat production line

Homogenizer for confectionery production

cream, filling, chocolate icing, chocolate butter, chocolate nut paste, syrup

Food pumps in chocolate icing production lines

Homogenizer for the production of fruit and vegetable products

jams, marmalade, jams, purees, pastes, ketchups, sauces, mustard, tomato paste, tomato juice, concentrates, cream, jelly

Production line for fruit preserves, tomato paste, sauces and ketchups.

Line for the preparation of various sauces with pieces of vegetables (ketchups, jams, marmalades and marmalade)

Brine production line

tomato paste production line

Production line for marmalade, jam, fruit jam

Homogenizer for the production of meat products

meat and liver pates, various pastes and mixtures, sausage and sausage emulsions, meat and poultry dishes

Homogenizer for the production of cosmetic products

For the production of perfumes

cream, shampoo, balm, gel, ointment, paste, milk, lotion

Line for the production of cosmetics, cosmetics.

Lines for the production of cosmetic creams

Installation for obtaining homogeneous cosmetic products.

Pharmaceutical Homogenizer

ointment, emulsions, mixtures, viscous components, solutions

Pharmaceutical production line

Line for the preparation of sterile ointment (cream).

Line (installation) of hydrodynamic extraction from vegetable raw materials

Homogenizer for the production of household chemicals

glue, detergents, household chemicals

Dishwashing liquid production line

Line for the production of synthetic detergents (pastes)

Homogenizer for the production of paints and varnishes

paints, dyes, varnishes, coatings,

Line for the preparation of water-based paints

Homogenizer for the production of chemical products and oil refining

chemical products, aggressive emulsions and suspensions, technical solutions, technical oils, lubricants, fuels

Chemical production line

Carbon dispersion plant

Homogenizer for the production of beer and non-alcoholic products

Blending line.

Recovery Juice Production Line

Specifications homogenizer

| Homogenizer model | Single stage, unjacketed | |||||

P3 |

P 5.5 |

P 7.5 |

P11 |

P15 |

P30 |

|

| Single stage, jacketed | ||||||

P3P |

P5.5P |

P 7.5P |

P11P |

P15P |

P30P |

|

| Two-stage, unjacketed | ||||||

P 3-2 |

P 5.5-2 |

P 7.5-2 |

P 11-2 |

P 15-2 |

P 30-2 |

|

| Double stage, jacketed | ||||||

P3-2P |

P5.5-2P |

P 7.5-2P |

P 11-2P |

P 15-2P |

P30-2P |

|

| Four-speed | ||||||

| - | - | - | P 11M |

P 15M |

P 30M |

|

| Productivity, m3/h | 2 - 10 | 2 - 10 | 2 - 12 | 10 - 15 | ||

| Engine speed | ||||||

| Inlet pressure, kg/cm2 | ||||||

| Electric motor power, kW | 3 | 5,5 | 7,5 | 11 | 15 | 30 |

| Temperature, °С min - max | ||||||

| Sound level, dB | ||||||

| Kinematic viscosity, not more than, cSt (without pump - gravity flow) |

||||||

| Weight, kg | 42 | 70 | 85 | 109 | 130 | 157 |

Sema homogenizer device

APG submersible homogenizer (dispersant).

Appointment. The APG submersible homogenizer is designed for homogenization of liquid and viscous products in the food, cosmetic and chemical industries, for preparing mayonnaise, meat, fruit, vegetable pastes, purees, syrups, and can also be used for the preparation of water-based paints and other similar media.

Device. The submersible homogenizer is mounted on the platform of the lifting device and, using the control panel, can move freely along the vertical guide.

The submersible homogenizer is completed with a gear motor, mounted on the walls and placed in a container.

The advantages of an immersion homogenizer are the absence of mechanical seals and piping, and as a result, the ability to work at high temperatures, mobility, the possibility of immersing the homogenizer in containers of any size.

The immersion homogenizer can be equipped with a speed converter, the installation of which allows to achieve an increase in the speed of rotation.

Parts in contact with the processed product are made of chromium-nickel steel.

Scope of submersible homogenizer:

- cosmetic industry

- To obtain homogeneous cosmetic products (creams, gels), etc.

- Chemical industry

- Dairy industry

- Fruit and vegetable industry

Specifications of Immersion Homogenizer

Homogenizer (dispersant) vertical multistage.

Appointment. Designed for multicomponent homogenization of mixtures. It is used in the dairy industry, and can also be used in the cosmetic, pharmaceutical, chemical industries.

Device. It is a multi-stage homogenizer, up to 19 stages. The product, passing from stage to stage, is gradually crushed and mixed to the desired degree of homogenization (2 ... 5 microns). The effect of homogenization has a positive effect on the physical structure of milk and dairy products.

Rotor speed up to 3000 rpm as standard.

It can be equipped with a speed converter, the installation of which allows to increase the rotation speed up to 6000 rpm.

Higher degree of protection against losses through seals. It has the ability to connect to a single-phase or three-phase network.

The homogenizer allows you to achieve:

- reduction in the size of fat globules, which prevents cream sedimentation,

- more white and appetizing color,

- increased resistance to oil and fat emulsion,

- improving taste and aroma,

- increase the shelf life of dairy and sour-milk products.

Reliability. All parts of the homogenizer in contact with the product are made of high-quality food grade stainless steel AISI 304, AISI 316, an imported end seal is installed with an increased resource, the absence of wear parts (seal of plunger pairs).

In many respects, it surpasses foreign models and has no Russian counterparts

Specifications of multi-stage homogenizer

Rotary cavitation homogenizer

Designed for multicomponent homogenization of insoluble media in order to obtain emulsions and suspensions in the food, cosmetic, pharmaceutical, chemical and other industries, including for viscous products.

The special design of the homogenizer, the special geometry of the body and rotating working parts ensures high performance. The materials used are hygienic, the design of the homogenizer is practical in operation.

Rotary cavitation homogenizers

4-rotor homogenizers have no analogues in their parameters!

Advantages

- All parts of the homogenizer in contact with the product are made of high quality food grade stainless steel.

- A mechanical seal has been installed, which has an increased resource and eliminates product loss.

- Guaranteed operation at higher than existing analogues temperature conditions (up to 115°С).

- Excellent performance in acid and alkaline environments.

- Compactness, possibility of vertical arrangement.

- High degree of protection against losses through the seals (the homogenizer cover is separated from the motor cover).

Principle of operation

The processed product is supplied to the suction pipe and discharged from the pressure pipe under the influence of the supporting pressure.

In the homogenizing unit, the product is crushed between the rotating and stationary calibrating cylindrical knives of the rotor and stator. Rotating and stationary calibration knives are made in the form of rings with holes.

Particles falling on the homogenizing unit (for example, fat globules) are squeezed out by the impeller under the influence of pressure created by centrifugal force and pass through the holes, where the movable part of the annular knife (each hole of the rotating part) gradually cuts (crushes) the fat globules as they move.

Technical characteristics of rotary cavitation homogenizer*

Homogenizers (dispersants) analogue of imported

Intensification of processes 100-600%!

The homogenizer allows simultaneous dispersion, homogenization and pumping of the product with an increase in outlet pressure.

The special design of the homogenizer (two working chambers), the special geometry of the body (with no "dead zones") and rotating working parts ensures high performance. The materials used are hygienic, the design of the homogenizer is practical in operation.

The homogenizer has high productivity, allows to obtain highly stable emulsions and suspensions, provides a degree of homogenization of 80%, particle size up to 2 microns. Can be built into existing lines.

Scope of application in industry:

- Dairy - soft cottage cheese, kefir, condensed milk, processed cheese, recovery of milk powder, cream.

- Oil and fat - combined oils, margarines, mayonnaise, pastes.

- Fruit and vegetable - jams, marmalade, ketchups, sauces, jams, purees, pastes.

- Confectionery - creams, fillings, chocolate-nut pastes, chocolate icing.

- Non-alcoholic - juices, nectars, drinks.

- Cosmetic - creams, shampoos, balms, gels, ointments, toothpastes.

- Pharmaceutical - ointments, emulsions, gels.

- Chemical - detergents, adhesives, varnishes, polishes, disinfectants.

Specifications of the homogenizer*

* Specifications may vary at the request of the customer.

Vacuum homogenizer mixer.

The plant is a vacuum reactor with a stirrer, to which a homogenizer is connected for recirculation. After loading the main components into the reactor vessel, air is pumped out of the system, and the installation is switched on to the recirculation mode, during which the loaded components are crushed and mixed. The funnel built into the system allows you to add the necessary components during the homogenization process.

The main advantage of this design is that

that it allows mixing with each other such components that, when mixed in the open air, harden even during the mixing process.

Homogenizer Factory Tests

Homogenization is the mechanical processing of raw materials that have passed through milk filters, as a result of which fat globules are dispersed (crushed) under the action of an external force - pressure, high-frequency current, ultrasound, etc.

Why is homogenization necessary?

When storing poured into milk cans product, fat floats to the surface due to the fact that it is lighter than plasma (reverse). The raw material is defended. A large lump of fat, rising to the upper layers, collides with others like it. Under the influence of immunoglobulins, agglutination occurs (gluing of individual elements and their precipitation from a homogeneous mixture). As a result, the consistency changes and the quality decreases, which is not desirable. If the fat globules are broken into small pieces, they will not stick together into a film on the surface.

The speed of the ascent of the fat ball depends on its size - the larger, the faster. According to the Stokes formula, it is directly proportional to the square of the lump radius. The size of fat globules ranges from 0.5 to 18 microns. After homogenization, it is reduced by a factor of approximately 10 (average outlet size 0.85 µm). This means that they will float 100 times slower. In addition, in small lumps, less than 1 micron in size, the forces of mutual repulsion are greater than the forces of attraction.

During the crushing of fat, the substance of its shell is redistributed. Part of the phosphatides passes into the plasma, and plasma proteins go to the outer cover of small globules. Thanks to these factors, the fat emulsion is stabilized in milk. With a high degree of dispersion, the settling process is not observed, fat does not float, milk flasks are filled with a higher quality product. Cream, cottage cheese, butter, etc., made from homogenized (homogeneous) raw materials, have the best organoleptic characteristics and consistency, nutrients are absorbed faster and more completely by the body.

Homogenization helps to:

- Pasteurized milk or cream, poured into stainless steel containers acquired uniform fat content, color and taste.

- Sterilized milk and cream are better stored.

- No fatty film was formed on fermented milk products, and protein clots were stronger and with better consistency.

- In condensed milk canned food, during long-term storage, the fat phase did not stand out.

- In whole milk powder, there was less free fat, without shells of protein - this leads to oxidation.

- Reconstituted fermented milk drinks, cream and milk did not develop a watery aftertaste, and the taste of the product became more intense.

- Milk with a filler (for example, cocoa) turned out to be more viscous, without sediment, with a better taste.

Homogenization mechanism

Homogenization is recommended to be done after the milk has passed through long-term pasteurization bath.

For this, different types of devices are used. The most common are valve-type units. At their core, they are high pressure plunger pumps. Fluid is passed through very small holes. At the same time, the flow rate increases sharply. Fat globules are crushed, the resulting small lumps are immediately covered with a protein shell. Why this happens will be discussed in the second part of the article.

A homogenizer is a device for obtaining homogeneous (homogeneous) dispersed systems. Systems can be single or multi-phase, i.e. in a dispersed medium, which is usually a liquid, there are particles (usually insoluble) of one or more solid or liquid substances, which are called dispersed phases. The term "homogeneous" means that the phases are distributed evenly, with the same concentration in any arbitrarily taken unit volume of the medium. The resulting system should be relatively stable. To do this, during homogenization, in the vast majority of cases, dispersion is carried out, that is, grinding of phase particles.

The use of homogenizers in the dairy industry

The milk homogenizer crushes fat globules. The speed at which they float to the surface depends on the square of their radius. Thus, after decreasing by 10 times, the speed drops by 100 times. Due to this, the product does not settle, does not separate into cream and skim. Its shelf life increases significantly.

In addition, after homogenization:

- In the manufacture of margarine or butter, water and other components are evenly distributed in the fatty medium. And in mayonnaise and salad dressings - fats in the aquatic environment.

- Cream and pasteurized milk are made uniform in color, taste and fat content.

- In condensed milk canned food, during long-term storage, the fat phase is not released.

- Kefir, sour cream and other fermented milk products are stabilizing. The consistency of protein clots improves. No grease plug forms on the surface.

- In powdered whole milk, the amount of free fat not protected by a protein shell is reduced. Due to this, its rapid oxidation under the influence of atmospheric air is excluded.

- Milk with cocoa or other filler improves the taste, it becomes more viscous. Reduces the likelihood of precipitation.

- Reconstituted fermented milk drinks, cream and milk do not have a watery taste. The natural taste becomes more intense.

Physical methods of the process and the main types of homogenizers

- Pushing through a narrow gap. Valve-type units are used, with high-pressure plunger pumps. Such devices in the dairy industry are the most common.

- mechanical mixing. Mixers with knives or spatula whisks are used, including high-speed mixers. The simplest example is a coffee grinder or a meat grinder with an electric drive. This also includes rotary pulsation apparatus (RPA). Although the effect on phase lumps is more complex in them, it is not limited to shock and abrasion loads.

- Impact of ultrasound. Ultrasonic installations operate here, which excite cavitation in a dispersed medium, due to which the phase is crushed.

Plunger homogenizer

Device

The homogenizer device is shown in fig. 1. The plunger cylinder 1 is connected to the inlet pipe through the suction valve 3, and to the high-pressure chamber through the delivery valve 4. From the chamber there is a channel to the homogenizing head 5, which has a seat 6, a valve 7, a spring 8 and an adjusting screw 11. For pressure control, a pressure gauge 10 is connected to the chamber. The channel has a branch to the safety valve 9. The plunger is driven by the pump 2.

The homogenizer device is shown in fig. 1. The plunger cylinder 1 is connected to the inlet pipe through the suction valve 3, and to the high-pressure chamber through the delivery valve 4. From the chamber there is a channel to the homogenizing head 5, which has a seat 6, a valve 7, a spring 8 and an adjusting screw 11. For pressure control, a pressure gauge 10 is connected to the chamber. The channel has a branch to the safety valve 9. The plunger is driven by the pump 2.

An enlarged view of the homogenizing head is shown in Fig.2. It has a calibrated hole (channel) 1 in the seat 5, a spring 2, a valve 4 with a stem 3 and an adjusting screw 6. The seat and valve are ground to each other.

The valve has a flat, conical with a small angle or poppet shape of the working surface. In the first case, there may be riffles (grooves) on it. If they are, then the same ones are made on the saddle. This increases the degree of phase splitting.

There are models in which the valve and seat are located in bearings mounted in a fixed housing. In this case, they, under the pressure of the product jet, rotate in different directions.

Since the liquid passing at high speed acts on the valve and seat strongly enough, they wear out quickly. Therefore, these elements are made of especially strong steels. In addition, their shape is symmetrical. With noticeable wear, it is enough to turn them over to the other side, thereby doubling the service life.

The pump is not necessarily used plunger, you can choose screw or rotary. The main thing is that it creates high pressure. Since the plunger mechanism does not provide a uniform supply, several of them are placed in homogenizers, with the start of cycles spaced apart in time. The most popular are three-plunger units. In them, on the shaft, the knees are rotated 120 degrees so that the cylinders work alternately. In this case, the feed unevenness coefficient, that is, the ratio of its maximum value to the average, is 1.047.

An indicator close to one means that the flow through the homogenizing head can be considered stable with a small error. Thus, during the homogenization process, the valve is always in the weighted (open) position. Between it and the seat there is a gap for the passage of fluid. Its size can also be taken constant, not taking into account a slight deviation from the average level. In many modern devices, the flow from each plunger goes to “its own” head. After phase splitting, they are connected in the output manifold.

The pressure gauge is equipped with a throttling device. This reduces the oscillation of the instrument pointer.

Operating principle

The principle of operation of the homogenizer is as follows. When the plunger works for suction (in the figure it moves to the left), milk enters cylinder 1 through valve 3. Then the plunger works for pumping (moves to the right) and pushes the product into the chamber through valve 4. After that, the liquid enters through the channel from the chamber to the homogenizing head 5.

When the valve is in the non-working position, spring 8 presses it firmly against the seat. Pressurized milk lifts the valve so that a small gap forms between it and the seat. Passing through it, the fat globules are crushed, the product is homogenized, and then goes into the outlet pipe.

The gap usually has a size of not more than 0.1 mm. Milk particles move in this zone at a speed of about 200 m/s (only 9 m/s in the injection chamber). The size of fat lumps decreases from 3.5-4.0 microns to 0.7-0.8 microns.

The pressure generated by the plunger pump is very high. Therefore, clogging of the channel in the seat can lead to the destruction of parts. To avoid breakage, a safety valve 9 is installed.

The unit is adjusted with screw 11. One of the main characteristics of homogenization is pressure. When the screw is tightened, the spring presses the valve harder against the seat. Because of this, the size of the gap decreases, as the hydraulic resistance increases. The setting of the device is carried out according to the readings of the manometer 10.

According to the instructions for the homogenizer, the temperature of milk should be in the range from 50 to 65 degrees C. If it is below this range, the process of settling fat lumps will accelerate. If higher, whey proteins will begin to precipitate.

Increasing the acidity of the product negatively affects the efficiency of the process, since in this case the stability of the proteins decreases. Agglomerates are formed, the crushing of fat lumps is difficult.

At the time of passage of the liquid through the valve gap, due to a sharp narrowing of the cross section of the channel, there is a throttling effect. The flow rate increases many times, and the pressure drops due to the fact that potential energy is converted into kinetic energy.

After the passage of milk through the head, some of the crushed particles again stick together into larger conglomerates. The efficiency of the process drops. To combat this phenomenon, two-stage homogenization is used. The device is shown in fig. 3. The fundamental difference from a single-stage one is the presence of two pairs of working bodies, the first stage 4 and the second - 12. Each has its own pressure spring with a control valve 6.

After the passage of milk through the head, some of the crushed particles again stick together into larger conglomerates. The efficiency of the process drops. To combat this phenomenon, two-stage homogenization is used. The device is shown in fig. 3. The fundamental difference from a single-stage one is the presence of two pairs of working bodies, the first stage 4 and the second - 12. Each has its own pressure spring with a control valve 6.

The second stage, auxiliary, further increases the degree of phase crushing. It is designed to create a controlled and constant back pressure in the head of the first stage, which is the main one. This optimizes the process conditions. And also for the destruction of relatively unstable formations. The pressure in it is set lower than in the first.

Single-stage homogenization is designed for products with low fat content or high viscosity. Two-stage - with a high content of fat or solids and low viscosity. And also in those cases when it is necessary to ensure the maximum possible phase splitting.

Separate technology

In the dairy industry, homogenization can be complete or separate. In the first case, all available raw materials are passed through the unit. In the second, it is first separated. The resulting cream 16-20% fat homogenized, and then mixed with skim milk. And sent to the next stage of processing. This method provides significant energy savings.

The mechanism of the phase dispersion process in a valve-type apparatus

According to N.V. Baranovsky, based on the study of hydraulic factors affecting the crushing of fat lumps during milk homogenization in a valve-type apparatus, the following process scheme was proposed (Fig. 4).

According to N.V. Baranovsky, based on the study of hydraulic factors affecting the crushing of fat lumps during milk homogenization in a valve-type apparatus, the following process scheme was proposed (Fig. 4).

At the point of flow transition from the seat channel to the gap, between the seat and the valve, the flow cross-sectional area sharply decreases. So, according to one of the basic laws of hydraulics, the speed of its movement U also quickly increases. More specifically, U0 on the way is several meters per second. And U1 at the entrance to the slot is 2 orders of magnitude higher, several hundred m/s.

A fat drop does not move from the zone of low to the zone of high speeds at once "all at once". The front part of the ball first enters the stream moving in the cracks with great speed. Under the action of the fast-flowing liquid, it is pulled out (the back is still moving slowly) and torn off. The remaining lump continues to move slowly (of course, the concept of "slowly" in this case is relative, since the entire cycle of the drop passing through the slot takes 50 microseconds) to move towards the velocity interface, and the part, now turned out to be in front, is extended in the same way as the previous one, and also comes off. Thus, the entire fat drop is gradually torn into pieces, passing through the boundary section. This occurs at a sufficiently large difference between the velocities U0 and U1.

If this difference turns out to be less than a certain threshold, then, before the detachment of particles, an intermediate stage takes place - the drop is first stretched into a filament. If the difference is even smaller, then the fat lump will pass through the speed boundary without destruction. But the impact of a high flow rate will still lead it to an unstable state, due to the formation of internal deformations. Therefore, due to the forces of surface tension and mechanical shocks of the jets of flow, the ball will still fall apart into smaller fractions.

Oil homogenizer

To obtain a homogeneous consistency of butter or processed cheeses, a plasticizer homogenizer is used. During processing, the aqueous phase is dispersed and evenly distributed throughout the volume. As a result, the product is stored longer, its taste improves. In addition, the time spent on defrosting is reduced, and water loss is reduced during packaging.

To obtain a homogeneous consistency of butter or processed cheeses, a plasticizer homogenizer is used. During processing, the aqueous phase is dispersed and evenly distributed throughout the volume. As a result, the product is stored longer, its taste improves. In addition, the time spent on defrosting is reduced, and water loss is reduced during packaging.

The design of the device can be considered on the example of one of the most popular models M6-OGA (Fig. 5). It consists of a housing and a frame (Fig. 6), a receiving hopper, under which the feed screws are located, and a rotor with 12, 16 or 24 blades. An electric motor is used as a drive. The screw speed is controlled by a variator. The angular velocity of the rotor is constant.

The operation of the homogenizer is as follows. Butter is placed in large chunks in the hopper. The augers rotate in different directions, when viewed from above - one towards the other. With their help, the oil is forced through the rotor, after which, through a rectangular nozzle, it goes into the receiving hopper (not shown in the figure). So that the oil does not stick to the working bodies, they are lubricated with a hot solution. Rotary-pulsating apparatus

Recently, rotary-pulsation apparatuses (RPA) are increasingly used for milk processing. Such a homogenizer is similar in design and principle of operation to a centrifugal pump. The main difference is in the working bodies.

The RPA is organized as follows. An electric motor serves as a drive. Rotor in the form of a perforated cylinder is rigidly fixed on its elongated shaft. From the end of the cylinder, from the side of the cover, there can be an impeller. Perforation is not required. Inside the cover there is a similar cylinder, fixed, it plays the role of a stator.

The RPA is organized as follows. An electric motor serves as a drive. Rotor in the form of a perforated cylinder is rigidly fixed on its elongated shaft. From the end of the cylinder, from the side of the cover, there can be an impeller. Perforation is not required. Inside the cover there is a similar cylinder, fixed, it plays the role of a stator.

Milk is fed through the axial nozzle on the lid and enters the impeller. This part produces primary phase crushing and accelerates the working mixture. The latter then passes through the perforation of the movable cylinder, is again partially dispersed under the action of shear and abrasive loads, and ends up in a homogenizing cavity between the rotor and the stator.  Here, in addition to shock, other forces act on fat globules.

Here, in addition to shock, other forces act on fat globules.

In a turbulent flow moving at a high speed (this is exactly what is observed in the RPA working zone), microvortex flows arise. If a small spherical whirlpool collides with a drop of fat, it destroys it. There is also a hydroacoustic effect. Intense cavitation, which leads to the collapse of air bubbles, generates shock waves against which the lumps of the phase cannot resist either.

The maximum impact of the apparatus on the particles is achieved at the moment when resonant vibrations occur between the rotor and the stator. To ensure this effect, it is necessary to calculate the diameter of the movable cylinder, the speed of its rotation, as well as the gap between it and the stator.

After the working area, the milk passes through the holes of the stator and, already homogenized, is discharged through a tangential outlet pipe, usually directed upwards, so that it is easier to connect pipelines for reloading the hopper in the recirculation system.

To increase the degree of crushing, the apparatus may have several pairs of "rotor-stator". After installing the cover, they are arranged alternately. There are models in which, instead of an impeller, a perforated disk is placed. RPA homogenizers can also be submersible. Optionally, the unit is equipped with the following devices:

- Dry run protection.

- Explosion-proof motor.

- Casing with heating/cooling jacket.

- The regulator of smooth change of frequency of rotation of the motor.

- Loading device (screw feeder), for viscous, poorly soluble, inhomogeneous emulsions and suspensions or free-flowing components.

- Unloading unit, for draining into a third-party container when working according to the circulation scheme.

- Mechanical bellows shaft seal made of silicon carbide ceramics - increases the service life of the unit, even when working with aggressive liquids or those containing abrasive inclusions.

RPA are single- or three-phase. All parts that come into contact with food are made of stainless steel AISI 304, AISI 316 or their domestic counterparts. Since the dispersed liquid leaves the apparatus under pressure, the RPA homogenizer simultaneously works as a centrifugal pump.

Ultrasonic homogenizers

Device (using BANDELIN as an example). The ultrasonic homogenizer consists of (from top to bottom in Fig. 15) an RF generator, an ultrasonic transducer, “horns” and probes (waveguides). The RF generator is connected to a household network with a current frequency of 50 or 60 Hz. It amplifies this parameter up to 20 kHz. The ultrasonic transducer, equipped with an oscillating circuit with a measuring piezoelectric element, transforms the current energy generated by the generator into oscillations of ultrasonic waves of the same frequency. The generated amplitude remains constant. Ultrasonic - increases due to the use of "horns" of a special shape. Probes are inserted into them, transmitting vibrations to a vessel with liquid. Depending on the volume of the working medium, they can be flat, in the form of cones or "micro", with a diameter of 2 to 25 mm.

Device (using BANDELIN as an example). The ultrasonic homogenizer consists of (from top to bottom in Fig. 15) an RF generator, an ultrasonic transducer, “horns” and probes (waveguides). The RF generator is connected to a household network with a current frequency of 50 or 60 Hz. It amplifies this parameter up to 20 kHz. The ultrasonic transducer, equipped with an oscillating circuit with a measuring piezoelectric element, transforms the current energy generated by the generator into oscillations of ultrasonic waves of the same frequency. The generated amplitude remains constant. Ultrasonic - increases due to the use of "horns" of a special shape. Probes are inserted into them, transmitting vibrations to a vessel with liquid. Depending on the volume of the working medium, they can be flat, in the form of cones or "micro", with a diameter of 2 to 25 mm.

Domestic industry also produces ultrasonic homogenizers. Of the latest models, the development of 2015 I100-6 / 840 can be noted (Fig. 16). The device has digital control, pulse mode, amplitude control and a set of probes.

Operating principle. When ultrasonic waves pass through a liquid, they alternately, 20,000 times per second, create high and low pressure in it. The latter is practically equal to the internal vapor pressure of the liquid, as a result of which bubbles filled with vapor appear in it, the liquid boils. When the voids collapse, a pressure drop occurs, fast-flowing turbulent microflows are formed that destroy fat droplets.

Some experts believe that, under ultrasonic exposure, lumps disperse not from cavitation, but due to the fact that the wave, passing through the fat drop at different points, causes accelerations of different magnitude and direction. As a result, multidirectional forces arise, trying to break the ball.

Homogenization is an important step in the processing of milk and other products. With its help, the structure improves and the shelf life increases, and the taste becomes more saturated.

Homogenization has become a standard manufacturing process commonly practiced as a means of keeping the fat emulsion from separating by gravity. Gaulin, who developed this process in 1899, gave it the following definition in French: "Fixer la composition des liquides".

First, homogenization leads to the splitting of fat globules into much smaller ones (see Fig. 1). As a result, creaming is reduced and the tendency of the balls to stick together or form large agglomerates can also be reduced. Basically, homogenized milk is produced mechanically. It is driven at high speed through a narrow channel.

The destruction of fat globules is achieved by a combination of factors such as turbulence and cavitation. As a result, the diameter of the balls decreases to 1 micron, and this is accompanied by a four to sixfold increase in the area of the intermediate surface between fat and plasma. As a result of the redistribution of the shell substance, which completely covered the fat globules before their destruction, the newly formed globules have insufficiently strong and thick shells. These membranes also include adsorbed milk plasma proteins.

Fox, along with his colleagues, investigated the fat-protein complex obtained by homogenizing milk. He proved that casein is the protein component of the complex and that it is possibly associated with the fat fraction through polar attractive forces. He also found that casein micelles are activated as they pass through the valve of the homogenizer, predisposing them to interact with the fat phase.

Process Requirements

The physical condition and concentration of the fat fraction during homogenization affect the size of the fat globules. Homogenization of cold milk, in which fat is mainly present in a solidified state, is practically not feasible. Processing milk at a temperature of 30-35°C leads to incomplete dispersion of the fat fraction. Homogenization is truly effective when the entire fat phase is in a liquid state, and at concentrations that are normal for milk. Foods with a high fat content tend to form large fat globules, especially at low whey protein concentrations with a high fat content. Cream with a fat content of more than 12% cannot be successfully homogenized at standard elevated pressure, because due to the lack of membrane material (casein), fat globules stick together into clusters. For sufficiently effective homogenization, one gram of fat should have 0.2 grams of casein.

High pressure homogenization processes result in the formation of small fat globules. With an increase in the homogenization temperature, the dispersity of the fat phase increases - in proportion to the decrease in the viscosity of milk at elevated temperatures.

Usually homogenization is carried out at a temperature of 55 to 80°C, under a pressure of 10 to 25 MPa (100-250 bar), depending on the type of product being processed.

Flow Characteristics

When the flow passes through a narrow channel, its speed increases (see Fig. 2). The speed will increase until the static pressure decreases to a level at which the liquid boils. The maximum speed mainly depends on the inlet pressure. As the fluid leaves the slot, the velocity decreases and the pressure begins to rise. The boiling of the liquid stops and the vapor bubbles explode.

Homogenization theories

Over the years of application of the homogenization process, many theories have arisen that explain the mechanism of homogenization at high

pressure. Two theories explaining the dispersed oil-water system by analogy with milk, where the diameter of most droplets is less than 1 micron, have not become obsolete to date.

They provide an explanation of the influence of various parameters on the efficiency of homogenization.

The theory of the destruction of balls by turbulent whirlpools (“microvortices”) is based on the fact that a large number of turbulent microflows arise in a liquid moving at high speed.

If a turbulent microflow collides with a drop comparable to it, the latter is destroyed. This theory makes it possible to predict changes in the results of homogenization with changes in the applied pressure. This link has been found in many studies.

On the other hand, the theory of cavitation states that fat droplets are destroyed by shock waves that occur when steam bubbles explode. According to this theory, homogenization occurs when the liquid leaves the gap. Thus, the back pressure required for cavitation is of great importance in this case. This has been confirmed in practice. However, homogenization is possible without cavitation, but in this case it is less effective.

Fig.3 Destruction of fat globules at the first and second stages of homogenization.

1 After the first stage

2 After the second stage

One-stage and two-stage homogenization

Homogenizers can be equipped with one homogenizing head or two connected in series. Hence the name: single-stage homogenization and two-stage homogenization. Both systems are shown in figures 5 and 6. In single-stage homogenization, the entire pressure drop is used

in a single step. With two-stage homogenization, the total

the pressure is measured before the first stage P 1 and before the second stage P 2 .

For optimum homogenization efficiency, a two-stage variant is usually used. But the desired results can be obtained if the ratio P 2: P 1 is approximately 0.2. One-stage version is used for homogenization

- low fat products

- products requiring high viscosity (formation of certain agglomerates).

- in products requiring low viscosity

- to achieve maximum efficiency of homogenization (micronization).

Figure 3 shows the formation and destruction of accumulations of fat globules in the second stage of homogenization.

Influence of homogenization on the structure and properties of milk

The effect of homogenization has a positive effect on the physical structure

and properties of milk and is manifested in the following:

- Reducing the size of the fat globules, which prevents the cream from settling

- Whiter and appetizing color

- Increased resistance to fat oxidation

- Improved aroma and taste

- Increased safety of fermented milk products made from homogenized milk.

However, homogenization also has certain disadvantages. Among them:

- Impossibility of separation of homogenized milk

- Slightly increased sensitivity to light, both from the sun and from fluorescent lamps, can lead to a so-called sunny taste.

- Reduced heat resistance - especially pronounced when testing the first stage of homogenization, homogenization of skim milk and in other cases that contribute to the formation of accumulations of fat globules

- The unsuitability of milk for the production of semi-hard and hard cheeses, since the clot will not separate whey well.

Homogenizer

High pressure homogenizers are usually required to ensure maximum homogenization efficiency.

The product enters the pumping unit, where it is pressurized by a piston pump. The level of pressure generated depends on the back pressure, determined by the distance between the piston and the seat in the homogenizing head. The pressure P 1 always means the pressure of homogenization. P 2 is the back pressure of the first stage of homogenization or the pressure at the inlet to the second stage.

Fig.4 The homogenizer is a large high pressure pump with a back pressure device.

1 Main drive motor

2 V-belt drive

3 Pressure gauge

4 Crank mechanism

5 piston

6 Piston seal

7 Cast stainless steel pump block

8 Valves

9 Homogenizing head

10 Hydraulic system

Fig.5 Single-stage homogenization. Schematic of the homogenizing head:

1 valve

2 Impact ring

3 Saddle

4 Hydraulic drive

High pressure pump

The piston pump is driven by a powerful electric motor (pos. 1 in Fig. 4) through the crankshaft and connecting rods - this transmission converts the rotation of the engine into reciprocating motion of the pump pistons.

The pistons (pos. 5) move in the high pressure cylinder block.

They are made from high strength material. The pistons are equipped with double seals. Water is supplied to the space between the seals to cool the pistons. Hot condensate can also be supplied there to prevent re-contamination of the product with microorganisms during the operation of the homogenizer. It is also possible to use hot condensate to maintain the conditions of aseptic production of the product during the operation of the homogenizer.

Homogenizing head

Figures 5 and 6 show the homogenizing head and its hydraulic system. The piston pump raises the milk pressure from 300 kPa (3 bar) at the inlet to a homogenization pressure of 10-15 MPa (100-240 bar), depending on the type of product. The pressure at the inlet to the first stage before the mechanism (homogenization pressure) is automatically kept constant. The oil pressure on the hydraulic piston and the homogenizing pressure on the valve balance each other. The homogenizer is equipped with one common oil tank, regardless of whether it is a single-stage or two-stage version. However, in a two-stage homogenizer, there are two hydraulic systems, each with its own pump. The new homogenization pressure is set by changing the oil pressure. The homogenizing pressure is indicated on the high pressure gauge.

The homogenization process takes place in the first stage. The second mainly serves two purposes:

Creating a constant and controlled back pressure towards the first stage, thus ensuring optimal homogenization conditions

Destruction of sticky clusters of fat globules that form immediately after homogenization (see Fig. 3).

Note that the homogenization pressure is the pressure before the first stage, not the differential pressure.

The parts of the homogenizing head are machined on a precision grinding machine. The shock ring is seated in its place in such a way that its inner surface is perpendicular to the slot exit. The seat is beveled at a 5 degree angle to give the product a controlled acceleration, thus preventing the accelerated wear that would otherwise be inevitable.

Milk under high pressure penetrates between the seat and the valve. The gap width is approximately 0.1 mm, which is 100 times the diameter of the fatty pressure produced by the piston pump, converted into kinetic energy. Part of this energy after passing through the mechanism is again converted into pressure. The other part is released as heat; every 40 bar pressure drop after passing through the mechanism raises the temperature by 1°C. Homogenization consumes less than 1% of all this energy, and yet high pressure homogenization is still the most efficient method available today.

Fig.6

two-stage homogenization.

1 First stage

2 Second stage

Homogenizing efficiency

The purpose of homogenization depends on how it is applied. Accordingly, the methods of evaluating effectiveness are also changing.

In accordance with the Stokes law, the growing speed of a particle is determined by the following formula, where: v is the speed

q is the acceleration due to gravity p is the size of the particle η hp is the density of the liquid η ip is the density of the particle t is the viscosity

Or v = constant x p 2

It follows from the formula that reducing the particle size is an effective way to reduce the increase in velocity. Therefore, a decrease in the particle size in milk leads to a slowdown in the rate of cream settling.

Analytical Methods

Analytical methods for determining the efficiency of homogenization can be

divided into two groups:

I. Determination of the cream settling rate

The oldest way to determine cream settling time is to take a sample, let it sit for a certain amount of time, and then analyze the fat content of the different layers. The USPH method is based on this principle. For example, a one liter sample is aged for 48 hours, after which the fat content in the top layer (100 ml) is determined, as well as in the rest of the milk. Homogenization is considered satisfactory if the mass fraction of fat in the lower layer is 0.9 times less than in the upper layer.

The NIZO method is based on the same principle. According to this method, a sample with a volume of, say, 25 ml is subjected to centrifugation for 30 minutes at a speed of 1000 rpm at a temperature of 40°C and a radius of 250 mm. The fat content of the 20 ml bottom layer is then divided by the fat content of the entire sample and the result is multiplied by 100. This ratio is called the NIZO value. For pasteurized milk, it is usually 50-80%.

II. Fractional Analysis

The size distribution of particles or droplets in a sample can be determined by a well-established method using a laser diffraction setup (see Fig. 7), which sends a laser beam into the sample in the cuvette. The degree of light scattering will depend on the size and number of particles contained in the milk under study.

The result is shown in the form of particle size distribution graphs. Fat percentage by mass is presented as a function of particle size (fat globule size). Figure 8 shows three typical fat globule size distribution graphs. Note that as the homogenization pressure increases, the graph shifts to the left.

Energy consumption and its effect on temperature

The electrical power input required for homogenization is expressed by the following formula:

Homogenizer in the production line

Usually the homogenizer is installed at the beginning of the line, i.e. before the final heating section in the heat exchanger. In most pasteurization plants for the production of drinking milk for the consumer market, the homogenizer is located after the first regenerative section.

In the production of sterilized milk, the homogenizer is usually placed at the beginning of the high-temperature treatment process in an indirectly heated system and always at the end of the process in a direct product heating system, i.e. in the aseptic part of the plant after the product sterilization section. In this case, an aseptic version of the homogenizer is used, equipped with special piston seals, gaskets, a sterile condenser and special aseptic dampers.

The aseptic homogenizer is installed after the sterilization section of plants with direct heating of the product in cases of production of dairy products with a fat mass fraction of more than 6-10% and/or with a high protein content. The fact is that at very high processing temperatures in milk with a high content of fat and / or proteins, accumulations of fat globules and casein micelles are formed. An aseptic homogenizer located after the sterilization section breaks down these agglomerated particles.

Complete homogenization

Full homogenization is the most common method for homogenizing drinking milk and milk intended for the production of fermented milk products. The fat content of milk, and sometimes the content

dry fat-free residue (in the production of yogurt, for example) are normalized before homogenization.

Separate homogenization

Separate homogenization means that the bulk of the skimmed milk is not homogenized. Cream and a small amount of skimmed milk are homogenized. This homogenization method is usually used for pasteurized drinking milk. The main advantage of separate homogenization is its relative economy. The total energy consumption is reduced by up to 65% due to less milk passing through the homogenizer.

Since the highest homogenization efficiency can be achieved if the milk contains at least 0.2 g of casein per 1 g of fat, the recommended maximum fat content is 12%. The hourly output of a plant in which separate homogenization is carried out can be determined by the following formula.

The production of pasteurized normalized milk (Q sm) per hour will be approximately 9690 liters. If we substitute this figure into formula 2, we get,

that the hourly output of the homogenizer is approximately 2900 liters,

that is, about a third of its total performance.

The scheme of flows in the installation for partially homogenized milk is shown in Fig.10.

The effect of homogenized dairy products on the human body

In the early 1970s, the American scientist K. Oster (K. Oster) came up with a hypothesis that the homogenization of milk allows the enzyme xanthine oxidase to penetrate through the intestines into the circulatory system. (Oxidase is an enzyme that catalyzes the addition of oxygen to or the removal of hydrogen from a substrate.) According to Oster, xanthine oxidase contributes to the process of damage to blood vessels and leads to atherosclerosis.

This hypothesis was rejected by scientists on the grounds that the human body itself produces thousands of times more of this enzyme than homogenized milk could theoretically bring into it.

So, there can be no harm from homogenizing milk. From a nutritional point of view, homogenization does not bring any special changes, except, perhaps, that fat and protein are broken down faster and easier in homogenized products.

However, Oster is right that oxidation processes can be harmful to the human body and that diet is important for health.

This method of mechanical processing of milk and liquid dairy products serves to increase the dispersion of the fat phase in them, which makes it possible to exclude the settling of fat during storage of milk, the development of oxidative processes, destabilization and churning during intensive mixing and transportation.

Homogenization of raw materials contributes to:

in the production of pasteurized milk and cream - the acquisition of uniformity (taste, color, fat content);

sterilized milk and cream - increasing storage stability;

fermented milk products (sour cream, kefir, yogurt, etc.) - increasing the strength and improving the consistency of protein clots and eliminating the formation of a fatty plug on the surface of the product;

condensed milk canned food - preventing the release of the fatty phase during long-term storage;

whole milk powder - reducing the amount of free milk fat, not protected by protein shells, which leads to its rapid oxidation under the action of atmospheric oxygen;

reconstituted milk, cream and fermented milk drinks - to create a full taste of the product and prevent the appearance of a watery aftertaste;

milk with fillers (cocoa etc.) - improving taste, increasing viscosity and reducing the likelihood of sediment formation.

Dispersion of fat globules, i.e., reduction in their size and uniform distribution in milk, is achieved by exposing milk to a significant external force (pressure, ultrasound, high-frequency electrical processing, etc.) in special machines - homogenizers.

The most widespread in the dairy industry is the homogenization of milk by forcing it through the annular valve slot of the homogenizing head of the machine. Fat globules, passing through this gap, are dispersed. The required pressure is generated by a pump. In the production of whole milk, the size of fat globules decreases from 3-4 microns to 0.7-0.8 microns.

The main unit of modern valve-type homogenizers is the homogenizing head. It can be one or two stages. The second stage usually operates at a lower pressure than the first.

The use of one- or two-stage homogenization depends on the type of dairy products being produced.

Two-stage homogenization with a large pressure drop on both stages is used in the production of high-fat dairy products (cream, ice cream mixtures, etc.).

It allows you to disperse (break) the resulting accumulations of fat globules. For the production of other types of dairy products, including drinking milk, one-stage homogenization can be used.

Heat treatment of milk

Heat treatment is one of the main and necessary technological operations of milk processing, carried out for the purpose of disinfection. The efficiency of heat treatment is related to the heat resistance of milk, which is determined by its protein, salt composition and acidity, which, in turn, depend on the season, lactation period, physical condition and breed of animals, feeding regimes and diet, etc.

During heat treatment, milk and dairy products undergo complex changes in biochemical and physico-chemical properties, as well as modifications of the components of milk. The purpose of heat treatment is diverse, namely: reducing the total number of microorganisms and the destruction of pathogenic forms, inactivation (destruction) of milk enzymes to increase stability during long-term storage, providing specific taste, smell, color and texture, creating favorable temperature conditions for fermentation, evaporation, storage, as well as mechanical processing processes, etc.

Heat treatment of milk is a combination of temperature exposure modes (heating or cooling) and exposure time at this temperature. Moreover, the duration of exposure at a given temperature should be such that the desired effect is obtained. In the dairy industry, heat treatment is carried out at temperatures up to 100 and over 100 °C.

When heated to 100 °C, only vegetative forms die in milk, and at temperatures above 100 °C, vegetative and spore forms die. The main processes of heat treatment of milk, causing the suppression of the vital activity of microorganisms, are pasteurization and sterilization. Hot water and saturated water steam are used as a heat carrier for pasteurization, and saturated water steam is used for sterilization.

In addition, during heat treatment, milk is subjected to cooling, heating (heating), thermal vacuum treatment.

The mode of heat treatment of milk for the production of each type of product is determined by the technological instruction. In this case, the milk is heated to the pasteurization temperature, and then kept and quickly cooled to the required temperature. The combination of heating and cooling operations is dictated by technological and sanitary requirements, as well as the possibility of using the heat of a hot product.

To do this, the hot product is sent to a special section of the apparatus (plate or tubular) for preheating the cold product entering the pasteurization. This operation is called heat recovery, and the apparatuses or their parts are called regenerators or regeneration sections. The use of this operation allows you to get some savings in thermal energy spent on pasteurization.

The efficiency of the regenerator is characterized by the regeneration coefficient. It represents the ratio of the amount of heat returned by the regenerator to the amount of heat required to heat the product from the initial to the final temperature, i.e., at which the product begins to reverse movement through the regenerator.

Cooling and heating

Dairy raw materials are cooled at the enterprises in order to preserve its quality and limit the growth of the number of microorganisms before processing. In table. 4.1 shows data showing the growth of the number of microorganisms in milk depending on the temperature of cooling and the duration of storage.

Storage of milk at temperatures above 4.5 °C leads to an increase in the number of microorganisms. In practice, milk for short-term storage is cooled to 6--8 °C. For long-term storage (10-14 hours), milk is pasteurized and then cooled. In order to increase the shelf life of dairy products, they are cooled during the manufacturing process.

Heating (heating) does not play the main role, but most often performs an auxiliary (preparatory) function in the process of milk processing. Heating of milk is used before separation, homogenization, as well as in the production of various dairy products. During separation, heating milk reduces its viscosity properties, which has a positive effect on the separation of fat globules from the milk plasma and the formation of cream.

How to store porcini mushrooms after harvest and for the winter

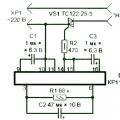

How to store porcini mushrooms after harvest and for the winter Speed regulator for grinder - to make the machine more reliable and functional

Speed regulator for grinder - to make the machine more reliable and functional choice of strategic alternatives

choice of strategic alternatives