Which files for a jigsaw are better for laminate. Types of jigsaw files: what and how to cut. # 1 - Hacksaw for metal

For those who have a jigsaw in their household, from time to time should purchase files for it. There are many varieties and manufacturing firms. The most common types of saws, of course, for wood, besides them there are canvases for metal, tiles. In order not to get confused in the choice, we will consider the most popular files in everyday life, from the company "Bosch". In terms of price / quality ratio - a good choice. The letter "T" in the marking designates the type of shank - T-shaped. The most common type of file.

Wood saws... There are several types, it all depends on the nature of the work being carried out.

For example, if you need to cut a bunch of boards as quickly as possible, a file with a large tooth is best. The larger the tooth, the faster the cut will be, but less accurate, the cut is not very smooth, but if you are making a fence, or building a shed, then accuracy, in principle, is not needed.

For these purposes, you can take a file with the T101D marking. It is suitable for boards up to 75mm thick.

If the board or block is up to 100mm, a 244D file is required.

For boards up to 200mm - long file 344D.

It can be seen that the larger the number in the marking, the more the file is intended for a thicker board.

It is necessary to take into account what is required for a thick board.

For a clean cut, you need a file, for example, T101B.

Clean cut file Т101B

Her teeth are noticeably smaller, respectively, the cut is smoother. This is suitable for assembling furniture, where you need an accurate and even cut, without chips.

It is often used for cutting fiberboard, plywood, chipboard.

It can also cut thick boards of course (up to 75mm), but it will take longer in time than files with a large tooth.

Laminate file.

Has an inverted tooth, directed in the opposite direction in comparison with other files. This is done in order to prevent chips from the front side of the laminate, not to spoil the appearance. Shallow tooth - for a clean cut. It is marked T101BR.

The letter "R" - stands for reverse (reverse). And so it is no different from the simple T101B tree.

Shape cut saws.

Their teeth are always small, they are used for cutting out a radius, a circle, and are used in the manufacture of furniture. In shape, they are noticeably narrower than all the others, this is done so that the file does not jam when turning the jigsaw.

From personal experience, I can say that I cut a circle in a fiberboard plate for a sink, the cut turned out to be very accurate and even.

The marking of such files with the letter "O" in the name is T119BO.

They always have a small tooth, so that it is easier to recognize them, their shank is blue. If you are sawing metal up to 3mm, a T118A file will do, it can also cut plastic, for metal up to 6mm - T123X, for aluminum - T227D, its tooth is larger.

Combined file.

You can cut both wood and metal like this. Her tooth is small on one half of the canvas and large on the other. Marking T345XF.

File for ceramic tiles... It is marked T150RIFF, T130RIFF. It has carbide spraying along the edge.

Carbide-coated

Most often, the files are clamped into a jigsaw using a 3mm hex key, sometimes there is a quick-clamping mechanism.

As for prices: the most common files cost about 25-40 rubles, long for a thick board about 80 rubles. A file on ceramics stands out from the general row, its price is 150-170 rubles. Prices are valid for 2012.

Renovation work is often associated with laying laminate flooring, which has gained popularity due to its attractive appearance, simple installation and maintenance. In the process of working on the device of the floor covering, it inevitably arises the need for trimming the lamellas. And here the jigsaw comes to the rescue. Any experienced craftsman who works with this tool knows that a laminate file for a jigsaw should be selected carefully.

The jigsaw is one of the most preferable type of tool, since with it you can get a high-quality smooth saw cut that does not have chips, burrs and other damage on its surface.

Important! When working with a thin laminate, you can use an inexpensive jigsaw, the cost of which does not exceed 2,000 rubles. It can be used to cut wood up to 7 mm thick. To cut more laminate with a greater thickness, you will need a more serious tool with a power of up to 750 W and a cost of over 3000 rubles.

If work of this kind is performed on a regular basis, then it is better to immediately purchase a more expensive but reliable tool. The table below shows the average cost for jigsaws as of July 2018.

Table 1. Average cost for jigsaws

| Illustration and model name | Power, W | Speed, strokes / min | Weight, kg | Cost as of July 2018, rubles |

|---|---|---|---|---|

| 400 | 0 – 3000 | 1.54 | 1 100 |

| 600 | 0 – 3000 | 1.5 | 1 300 |

| 650 | 0 – 3000 | 1,95 | 2 100 |

| 500 | 500 – 3100 | 1.6 | 3 400 |

| 450 | 500 – 3100 | 1.9 | 4 300 |

| 700 | 0 – 3100 | 2.8 | 12 200 |

Choosing a file

To obtain an even and smooth cut at the end of the laminate lamella, it is not enough to purchase a high-quality tool - the result depends on a properly selected file. Some manufacturers complete the tool with several types of files. It may happen that you do not need to purchase an additional file for working with laminate - it will be included with the tool.

From others, the laminate file is distinguished by its characteristic features. The shape, pitch, setting of teeth and material of the blade must be taken into account when purchasing a file. So, laminate saws from the well-known manufacturer of Bosch tools are flexible and durable, since a bimetallic blade is used for its manufacture.

By and large, if for some reason it did not work out to find a file with a marking that says that it is intended to work directly with the laminate, you can pick up another one that has fine teeth and a thin blade. You can get different results:

- A saw with a wide blade allows you to get a high-quality straight cut.

- For a curved or curved cut, choose a thin saw blade.

- A neat edge on the face of the lamella will be obtained if the cut is made from the outside.

- To carry out an even cut on the floor, choose a file with reversely directed saw teeth on the front side.

How to work with a jigsaw

The following rules will allow you to get a high-quality cut when cutting the laminate and simplify the cutting process itself:

Important! Many laminate manufacturers give information on the packaging about how it is recommended to trim the lamellas - on the front or back.

Video - How to cut laminate

Other Laminate Cutting Tools and Features

In addition to the jigsaw, there are other ways to trim laminate flooring. Having one of them available, you can not buy a jigsaw, but use what you have. You can get a neat cut without damaging the laminate board using a circular saw, a special cutter and a hacksaw for metal. How to do this, we will describe below.

Cutter

This is a professional tool that is quite expensive and is used by craftsmen whose work is associated with large volumes of orders for laying laminate flooring. Such a tool is a support structure on which a very sharp blade is attached. Trimming the board takes place in one step, like a guillotine.

With the help of such a device, cutting can be carried out in different directions - along or across the lamella, while the length of the cutting element has a decisive influence on the quality of the cut along the lamella.

Table 2. Principle of device operation

| Illustration | Description |

|---|---|

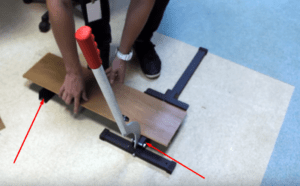

| The mechanism handle must be pulled back. |

| The lamella with the applied markings is laid on the supporting structure of the mechanism. The cutting line should be located to the right of the knife. |

| The knife handle is lowered smoothly and, pressing, the required fragment is cut off. |

On the front side of the lamella there are no undercut marks, and on the back, if necessary, the torn edges are sanded with sandpaper.

What do you need when installing laminate flooring? Look for the answer in There you will find everything: from tools to instructions for self-installation.

Hacksaw for metal

Unlike a cutter, a hacksaw is the cheapest and most affordable way to cut laminate flooring. A hacksaw is available on every homeowner's household and can be used when you need to trim a small amount of laminate flooring. The simplest hacksaw costs from 200 rubles.

In the process of cutting laminate with this tool, you must adhere to the following recommendations:

The disadvantage of such a tool when performing this particular type of work is the laboriousness of the process and the need for a skill. Laminate is a dense material, so you can practice on trimming boards or plywood that are similar in structure.

The high cost and the availability of professional skills in working with this tool, put it on a par with the cutter. The result when cutting laminate with a circular saw is very high quality.

In our time, construction is constantly underway. New houses are being erected, which require cosmetic repairs. Nowadays, in most apartments and their houses, there is a floor covered with laminate. Laminate -

Quantity calculator

Quite economical and quick to install. To do this, you must be able to use power tools and the simplest measuring instruments. The principle of installation is so simple that you can do it yourself without the help of specialists (user reviews confirm this).

It is not difficult to lay this coating, the main thing is to understand all the features of the work and little tricks. You can improve the quality and speed up the laying with a jigsaw or jigsaw. In practice, it is noticeable that the quality of work directly depends on the quality of the cut elements. First of all, for proper cutting, you need a jigsaw file for laminate flooring. Otherwise, if the cutting edge is not correctly selected, the materials will deteriorate with chips and cracks. That is, you will be at a loss, and wasted time.

What file to cut laminate with?

Features of the choice of a file for a laminate for a jigsaw and jigsaw are divided into:

- shape;

- method of setting teeth;

- material;

If you need to cut the laminate with a jigsaw, then it is better to choose files with small teeth. In some cases, a tool with a reverse arrangement of teeth is used, which significantly reduces the likelihood of cracks and chips on the face of materials. A very important point is the shank of the file that is used in your jigsaw. However, in addition to individual models, there are "omnivorous" devices that fix cutting parts of any kind.

See video for details.

Saw model depending on the purpose and characteristics of the workpiece

The Bosh corporation is engaged in the production of saws for cutting laminates. The line of such models is called - "Especially for laminate", and has excellent strength and flexibility. Wide tools are suitable for straight cutting, but narrow for curved and curved ones.

Laminate saws for Bosch jigsaw have many popular models, including the T101BR. It is standard and has a reverse tooth arrangement. When using this file, the face of the laminate does not suffer or tear, so the cuts are neat and smooth.

- T101V. The model has fine, straight-cut teeth for a smooth cut. It is used for an accurate and even cut, without chips. In addition to laminate, it is used for sawing plywood, chipboard and fiberboard.

- T101BR. This model is practically no different from the previous one, but there is one highlight in it. The letter R in the name indicates that the teeth are directed in the opposite direction. This introduction makes it possible to exclude the appearance of cracks and chips from the front side of the panels. Thus, the appearance of the coating does not deteriorate, and the cuts are clean and neat.

- T119BO. Suitable for shape cutting (cutting circles, radii, bends) of laminate and wood. Their shape is fundamentally cast from rectilinear models, because in bends and turns it should not be clamped. However, the Т119BO model is not the only one of its kind; in addition to it, there are other models that are designed for curly cutting. Each of them has the letter "O" in the name.

These three are the most popular models, renowned for quality performance and long service life.

- The narrower the file, the more elegant and neat the cut will be;

- If you want to cut the boards as soon as possible, then a tool with large teeth is ideal for this, but the speed does not compensate for the slightly "pounded" material (rough and not very neat cut);

- The use of the Т101B model guarantees the quality of the cut, however, the thickness of the material being cut should not exceed 75 mm;

- Choose only quality products, namely Bosch.

What are the nuances to consider when laying the laminate on your own?

- The boards must take shape. After the material is delivered to the apartment where it will be laid, it must be left there for acclimatization. This is especially important when the temperature outside is low. When laying the floor, a technological gap of one and a half centimeters is always left between the coating itself and the wall, which, when the temperature changes, compensates for the possible expansion of the laminate. A cold coating when heated can significantly reduce this gap.

- When preparing the surface, you need to take care of the required stock of boards. When laying at an angle, the laminate will go more than when laying parallel to the walls.

- Elimination of visible defects in the floor surface. If the surface defects are not eliminated, the floor will sag and creak. The permissible screed may have differences of no more than 3 mm. Otherwise, if the base is made of wood, use a sander for leveling. With a concrete base, a self-leveling screed is made. As an insulating coating, a plastic wrap is placed on the concrete screed perpendicular to the laying of the laminate. Then they put a heat-insulating and sound-insulating substrate. The final layer will be laminate.

- Laying direction. If you choose a direction perpendicular to the window, then this will allow you to hide the longitudinal joints of the rows of the coating.

- Laying the first row of laminate boards. It is always better to adjust the first row to the unevenness of the wall. Walls in apartments and houses are often deformed. With this in mind, it is best to leave a centimeter of clearance. For reliable fixing of the gap, it is better to use purchased or manufactured wedges against which the laminate boards rest. The locks snap in more easily when the laminate is laid towards itself.

- The second row of laminate starts with the last piece of the previous row. For better fixing of the locks, the boards are placed at an angle.

- After laying three rows of the floor, you need to check how smooth it is.

- The final stage of styling. To keep the last board as flat as possible, it is best to use a clamp.

The installation of the skirting board completes the work. Attach the plinth to the wall using fasteners, self-tapping screws or special plinth glue.

Tool requirements

- have a compact size;

- be lightweight;

- be easy to use;

- hacksaw;

- cutter;

- circular saw;

- jigsaw.

Hacksaw

The laminate should be marked out prior to cutting. Before cutting the laminate, measure the required length on the panel and draw a cutting line. To obtain a better edge, file the bottom layer from the back side.

Electric jigsaw

Professional cutter

The tool works without noise and dust. The device allows you to cut the laminate quickly and efficiently. The principle of operation of the cutter is similar to that of the guillotine.

How to cut chipboard without chips

The knife blade is lowered onto the panel by means of the handle, cutting off the excess in one motion. The cut is perfectly flat.

A circular saw

Dust and noise generation;

... the smell of burnt wood;

... availability of skill.

When using any tool to cut laminate flooring, it is important to calculate the applied forces correctly.

Excessive pressure is fraught with the formation of cracks or chips on the surface of the panel. Competent calculation of the required amount of material will allow you to cut the laminate with minimal waste.

Planks and beams are one of the main building materials. But not everyone has the financial ability to buy ready-made boards. In such situations, one of the solutions is to independently engage in timber harvesting on a plot taken in the forestry.

The advantage of a chainsaw as a sawing tool

You can cut a log using a sawmill, a petrol or electric saw and additional devices. When choosing one of these tools, you should consider the amount of work to be done. The cost of the cheapest stationary sawmill together with all the accessories is 150 thousand rubles. The chainsaw is much cheaper. It is more convenient than an electric saw for the following reasons:

- Electricity is not required to operate the tool - this makes it possible to use the chainsaw on plots.

- More powerful than an electric saw.

- Starts smoothly and allows convenient speed control, which reduces the chance of chain breakage.

- The overrun brake responds faster than a saw.

- Long operating time without interruption - up to one hour.

- Can be used in high humidity conditions.

Types of working attachments

When sawing logs with a chainsaw, various attachments are used.

- Rip saw attachment. It is used for sawing a log lengthwise, the process takes place in a horizontal position. After work, the master gets the same thickness for the product. The finished materials undergo a drying process, after which the boards are used in construction.

How to cut laminate

In appearance, the device is a small frame, it is attached to the tire on each side.

- Drum debarker (gummer). With the help of such a nozzle, it is easy to dissolve the log, it works due to the V-belt transmission. Attaches to belts on both sides using special pulleys. The speed of rotation of the shaft depends on the size of the pulleys, so the performance of the nozzle is easy to change. This technology forces the master to carefully monitor each stage of the process; some specialists use an assistant during this cut. But this option requires increased security measures.

- Sawing with a lightweight nozzle. The method is not very efficient, but it is used quite often. The element is fastened from one side, but the workpieces are slightly uneven. Such materials are needed to build barns or fences.

Features of sawing with a homemade tool

Sawing a log into boards can be easily done using a self-made tool. It is not difficult to make it. To do this, follow these steps:

- As a support, you need to use a frame from a school desk or a pipe with a cross-section in the form of a square, its optimal size is 20x20, and more is allowed.

- It is necessary to build two clamps, mount a cross member with two holes for tie bolts at one end, and make a projection for the tire in the middle.

- For longitudinal sawing of logs into boards, you need to make a support frame, its width should be less than the length by seven to eight centimeters.

- Then, two parts ten centimeters long are welded to both sides, holes for bolts are made, a handle is attached in the middle for ease of use.

- Then you need to insert the clamps into the grooves, install the bus, fix everything carefully.

It is not difficult to work with a homemade tool, this will require goats, they will serve as a support. In addition, you need to prepare a metal rail or board to use as a guide. A log is laid from below, the required height for work is set.

The procedure for performing preparatory work

To cut a log lengthwise, you need to perform the following sequence of actions:

- Take two straight boards and attach one to the other at right angles. The result is a solid flagship range.

- To support the made ruler, you need to make stops from the boards.

- The movement of the trunks must be carried out using a turner.

- The log should be placed on a comfortable base.

- On the tire of the chainsaw using nuts, you need to fix the frame.

- Lead ruler supports must be attached to the ends of the log, checking the horizontal position with a level.

- Self-tapping screws must be used to fix all brackets and structural elements. Nails are not suitable for these purposes, since they are difficult to remove in the future without causing damage to the details of the structure.

- The guide ruler must be attached to the supports using staples and its height must be adjusted so that the cut will not go along it, but approximately one centimeter higher.

- The log must be rotated and the second plank must be secured in such a way that it rests on the ground and supports the log.

The order of the main work

- Now you need to start the chainsaw and make the first cut.

- Next, you need to free the log from stops and boards and attach a leading ruler on the cut surface of the log in the direction of the next cut. The ruler is attached directly to the surface or to the ends of the log using supports. The second cut is made perpendicular to the first cut.

- The log must be turned and secured with a board point-blank to the ground.

- You do not need a leader ruler to complete the next steps. One of the cut sides serves as a guide.

- It is necessary to adjust the thickness of the cut on the frame and saw off the log from the other side in such a way that you get a bar with bark left on only one side.

- This bar must be turned over and fixed in such a way that the attachment point of the fixing board is as low as possible.

- Then you need to adjust the frame to the required thickness of the board and cut the timber into boards.

Safety rules when performing work

- Do not use a circular saw without a protective cover.

- Wear headphones, gloves, goggles, heavy clothing and a respirator.

- Fuel should not be poured into the hot tank of the instrument; you must wait until it cools down.

- Children must not be allowed at the work site.

- The tool must be started on the ground with the chain brake engaged, which must only be released before starting sawing.

- Always have a first aid kit on hand.

- When working, you need to hold the chainsaw by the handle of the arc, moving it forward along the guide. You should not press on the chainsaw with great effort - it should move freely.

- Right-handers should place the log on the right side of themselves, left-handers on the left.

The choice of flooring is largely determined by quality and price. In this regard, laminate has the most acceptable ratio. The material owes its popularity not only to practicality, but also to the ease of installation. Anyone can install the floor covering with a tool. Accordingly, the question arises - how to cut the laminate?

Tool requirements

For laying the flooring, the material must be taken 10-15% more than the area of the room. The panels will not only need to be connected, but also cut. To fit the dimensions, use a hand or power tool. When used at home, it should:

- have a compact size;

- be lightweight;

- be easy to use;

- make an even cut without chips.

The last characteristic when choosing a method for many repair lovers is key. But its importance is somewhat exaggerated. The presence of chips up to 5 millimeters will hide the skirting board.

Both professionals and DIYers use to cut laminate flooring:

- hacksaw;

- cutter;

- circular saw;

- jigsaw.

Hacksaw

Since the material is made up of sawdust, it is easy to cut by hand. Use hacksaws for wood or metal. It is important that the hacksaw has fine, sharp teeth. This will allow you to cut panels without chipping or scuffing. In case of minor damage to the edge, the ends will cover the skirting board.

The laminate should be marked out prior to cutting.

How to cut laminate flooring?

Before cutting the laminate, measure the required length on the panel and draw a cutting line. To obtain a better edge, file the bottom layer from the back side.

Electric jigsaw

What to cut the laminate with, everyone determines based on the availability of tools. But, if there are no devices, the most practical would be to purchase a jigsaw. It will allow you to cut panels in all directions, including various shapes. An electric jigsaw is lighter than a circular saw, less overall than a cutter, more convenient and faster than a hacksaw. Everyone is capable of mastering a jigsaw, since it does not require special skills.

For a good cut, it is necessary that the jigsaw file has the opposite direction of the teeth. Usually a blade for cutting laminate is included. To avoid defects, markings are applied on the back of the panel. It is better to cut the protective film with a clerical knife. The board is fixed face down and sawn off.

How to cut a laminate with a jigsaw without chips:

An electric jigsaw will cut your laminate flooring with a minimum of dust. The jigsaw has a special container for collecting sawdust. For curly carving, use narrower canvases. And masking tape glued to the front of the panel before sawing is guaranteed to get rid of chips.

Professional cutter

The tool works without noise and dust. The device allows you to cut the laminate quickly and efficiently. The principle of operation of the cutter is similar to that of the guillotine. The knife blade is lowered onto the panel by means of the handle, cutting off the excess in one motion. The cut is perfectly flat.

Using the cutter is effortless and effortless, allowing large areas of flooring to be laid. The cutter is especially in demand among professional repair crews and perfectionist craftsmen. The disadvantages of the device are the high cost and limitation of cutting, because it is possible to cut only across the panel.

A circular saw

Despite the fact that laminate is easy to saw by hand, using a power tool makes the task much easier. Sometimes a hand-held circular saw is used for this purpose. Like a hacksaw, fine-toothed blades are used here. Before sawing the laminate, markings are applied to its reverse side, since the movement of the disc occurs from the bottom up. The board is securely fastened to a workbench or table, leaving the trimmed part on the weight. Then, along the marking line, an unnecessary piece is smoothly sawed off.

When using a grinder, the laminate is placed face up, since the movement of the teeth occurs from top to bottom. This will eliminate the appearance of cracks and chips. Which side to cut the laminate on determines the direction of movement of the teeth. Among the disadvantages of cutting with a circular saw:

Dust and noise generation;

... the smell of burnt wood;

... availability of skill.

When using any tool to cut laminate flooring, it is important to calculate the applied forces correctly. Excessive pressure is fraught with the formation of cracks or chips on the surface of the panel. Competent calculation of the required amount of material will allow you to cut the laminate with minimal waste.

How to cut laminate flooring correctly, see the video:

About choosing a tool

Knife

Hacksaw for metal

Jigsaw

A circular saw

What does a professional use

Laminate is a floor covering that is increasingly found in every home. Its installation always requires adjustment in length and width, because the lamellas should be laid, observing the rule of brickwork. Accordingly, this gives rise to the question: "How to cut the laminate at home?"

What you need to know about a jigsaw and file to cut quality laminate flooring

In this article, you will learn about the different tools and how to fit using them.

About choosing a tool

Knife

Hacksaw for metal

Jigsaw

- Draw the lamella.

A circular saw

What does a professional use

The principle of working with the machine:

Conclusion

About choosing a tool

Knife

Hacksaw for metal

Jigsaw

A circular saw

What does a professional use

About choosing a tool

Cutting the laminate must be done with good quality so that the cutting line is straight and even and the edge remains intact. All of these steps are fairly easy to accomplish by choosing the right laminate cutting tool. An example of the right choice is the fact that not every person can cope with a professional tool, so he should use simpler tools with which he will do this work more accurately.

Knife

The simplest tool that absolutely everyone has, but it is not the best solution. A laminate knife is only suitable if you want to make a small cutout for a ledge in the wall. If it is still possible to cut the lamella across it, then it is almost impossible to do it along it, because you will spend a lot of time and effort, and the cut will turn out to be of poor quality and curve.

If you decide to use a knife, then check its sharpness, because with a blunt sheath you will do much more flaws in your work than with a sharp one.

How and what to cut laminate flooring - the choice of tools and the nuances of sawing laminate flooring

Hacksaw for metal

A hacksaw for metal is what it will be profitable to cut the laminate with, because the tool is one of those that are in almost every home and you do not have to run to the store.

It is very convenient to carry out small cuts with a hacksaw for metal due to the fact that:

- Laminate is easy to cut by hand;

- The fine tooth of the hacksaw guarantees no chips;

- If you do damage the edge, you can easily close the flaws with a skirting board.

Remember that a hacksaw for laminate flooring is only suitable if the volume of work is small, and there is no other tool at hand, and if you do not have a hacksaw on hand, then it is better to buy a jigsaw in the store, which will be mentioned below.

Sawing should be done according to the following instructions:

- First, make a clear marking on the lamellas, remembering that it should be bright, because when sawing it will be covered with a thin layer of dust.

- To get a good edge, cut the sheet face up.

- Do not apply too much force to the tool in order not to damage the edge to be finished.

Jigsaw

This is a more expensive tool, but its choice is the best answer to the question of what is the best way to cut laminate flooring. A jigsaw is worth buying only if the volume of work is too large to saw everything by hand, or if you do not mind the money for its purchase.

How to cut a laminate with a jigsaw:

- Install a reverse fine tooth blade into the jigsaw. If the canvas comes with an expensive and high-quality tool, then you can use it, otherwise purchase it separately.

- Draw the lamella.

- In this case, the lamellas must be sawn, laid face down and secured to a hard surface.

Another advantage of the jigsaw is that it can be sawed not only in a straight line.

A circular saw

A circular saw is not something that you can cut a laminate with at any time, however, if you are a happy owner of such equipment, then feel free to start sawing:

- Slide a fine-toothed disc onto the shaft.

- Draw a cut line on the slats.

- If the cut is made along the plank, then set the width on the machine.

- Saw the lamella by pushing in front of you.

The main advantage of the circular saw is its speed of operation, which allows you to saw the lamella lengthwise in a matter of seconds, however, due to the dimensions that you can see in the photo, it is rarely used, in addition, you will not be able to cut certain pieces of laminate on it, for example, under a column or a ledge in the wall.

What does a professional use

In any business, an amateur can be easily distinguished from a professional, not only by the speed and quality of work, but also by the tool used. This also happens with the installation of laminate flooring. Professionals use a laminate cutter that can cut in a very short amount of time.

As you can see in the photo, this cutter is a manual machine equipped with a sharp blade that is fixed to the base. The blade is easily adjustable for different types of cuts. With the help of the machine, it is possible to cut slats lengthwise, across and at various angles, without spending a lot of effort and energy.

The principle of working with the machine:

- The lamella is placed on the machine support in a horizontal position.

- The cutter adjusts to the layout.

- The builder applies force to the handle and the blade gradually cuts the lamella.

A professional machine is something that makes it very easy to cut a laminate without chips, so everyone who is engaged in laying laminate is trying to get it.

Conclusion

You can use any of the tools presented, but remember that the most important thing in sawing laminate is the quality of the edge. Remember the tip: in order to make as few chips and irregularities as possible, do not put much force on the sawing tool, because this will force the tool to pull the fragments out of the material body, and not cut them out.

Now you know all the sawing methods, so you can decide on your own the question of how to saw off the laminate.

About choosing a tool

Knife

Hacksaw for metal

Jigsaw

A circular saw

What does a professional use

Laminate is a floor covering that is increasingly found in every home. Its installation always requires adjustment in length and width, because the lamellas should be laid, observing the rule of brickwork. Accordingly, this gives rise to the question: "How to cut the laminate at home?" In this article, you will learn about the different tools and how to fit using them.

About choosing a tool

Cutting the laminate must be done with good quality so that the cutting line is straight and even and the edge remains intact. All of these steps are fairly easy to accomplish by choosing the right laminate cutting tool. An example of the right choice is the fact that not every person can cope with a professional tool, so he should use simpler tools with which he will do this work more accurately.

Knife

The simplest tool that absolutely everyone has, but it is not the best solution.

What is the best way to cut laminate flooring?

A laminate knife is only suitable if you want to make a small cutout for a ledge in the wall. If it is still possible to cut the lamella across it, then it is almost impossible to do it along it, because you will spend a lot of time and effort, and the cut will turn out to be of poor quality and curve.

If you decide to use a knife, then check its sharpness, because with a blunt sheath you will do much more flaws in your work than with a sharp one.

Hacksaw for metal

A hacksaw for metal is what it will be profitable to cut the laminate with, because the tool is one of those that are in almost every home and you do not have to run to the store.

It is very convenient to carry out small cuts with a hacksaw for metal due to the fact that:

- Laminate is easy to cut by hand;

- The fine tooth of the hacksaw guarantees no chips;

- If you do damage the edge, you can easily close the flaws with a skirting board.

Remember that a hacksaw for laminate flooring is only suitable if the volume of work is small, and there is no other tool at hand, and if you do not have a hacksaw on hand, then it is better to buy a jigsaw in the store, which will be mentioned below.

Sawing should be done according to the following instructions:

- First, make a clear marking on the lamellas, remembering that it should be bright, because when sawing it will be covered with a thin layer of dust.

- To get a good edge, cut the sheet face up.

- Do not apply too much force to the tool in order not to damage the edge to be finished.

Jigsaw

This is a more expensive tool, but its choice is the best answer to the question of what is the best way to cut laminate flooring. A jigsaw is worth buying only if the volume of work is too large to saw everything by hand, or if you do not mind the money for its purchase.

How to cut a laminate with a jigsaw:

- Install a reverse fine tooth blade into the jigsaw. If the canvas comes with an expensive and high-quality tool, then you can use it, otherwise purchase it separately.

- Draw the lamella.

- In this case, the lamellas must be sawn, laid face down and secured to a hard surface.

Another advantage of the jigsaw is that it can be sawed not only in a straight line.

A circular saw

A circular saw is not something that you can cut a laminate with at any time, however, if you are a happy owner of such equipment, then feel free to start sawing:

- Slide a fine-toothed disc onto the shaft.

- Draw a cut line on the slats.

- If the cut is made along the plank, then set the width on the machine.

- Saw the lamella by pushing in front of you.

The main advantage of the circular saw is its speed of operation, which allows you to saw the lamella lengthwise in a matter of seconds, however, due to the dimensions that you can see in the photo, it is rarely used, in addition, you will not be able to cut certain pieces of laminate on it, for example, under a column or a ledge in the wall.

What does a professional use

In any business, an amateur can be easily distinguished from a professional, not only by the speed and quality of work, but also by the tool used. This also happens with the installation of laminate flooring. Professionals use a laminate cutter that can cut in a very short amount of time.

As you can see in the photo, this cutter is a manual machine equipped with a sharp blade that is fixed to the base. The blade is easily adjustable for different types of cuts. With the help of the machine, it is possible to cut slats lengthwise, across and at various angles, without spending a lot of effort and energy.

The principle of working with the machine:

- The lamella is placed on the machine support in a horizontal position.

- The cutter adjusts to the layout.

- The builder applies force to the handle and the blade gradually cuts the lamella.

A professional machine is something that makes it very easy to cut a laminate without chips, so everyone who is engaged in laying laminate is trying to get it.

Conclusion

You can use any of the tools presented, but remember that the most important thing in sawing laminate is the quality of the edge. Remember the tip: in order to make as few chips and irregularities as possible, do not put much force on the sawing tool, because this will force the tool to pull the fragments out of the material body, and not cut them out.

Now you know all the sawing methods, so you can decide on your own the question of how to saw off the laminate.

Poroshenko Petr Alekseevich

Poroshenko Petr Alekseevich Premonition of the Apocalypse: World War III in the predictions of analysts and the Holy Fathers

Premonition of the Apocalypse: World War III in the predictions of analysts and the Holy Fathers Hereditary prisoner petr poroshenko-waltsman

Hereditary prisoner petr poroshenko-waltsman