How to separate the angles of walls in the apartment. Decorative trim of wall corners. Just and easy. Transparent silicone corners on wallpaper

Plastic corners for walls during installation are almost always applied. After all, alignment of the corners is one of the most difficult finishing works. Here you need to have knowledge and skills.

Usually, various corners are installed to protect the corners, it depends on the irregularities and on the interior design. It is also necessary to choose the material of the manufacturer of the corner, because there are several of them. It is with this finishing material today and get acquainted. Also on the video in this article and the photo you can view options for the practical use of this material.

When the corner is needed

Corners plastic for walls are sometimes extremely necessary, and let's immediately understand, you will need this option:

- In cases where you plan to put rectangular furniture in the angle. In the aligned walls, the furniture gets great.

- Also to protect against mechanical damage. If there is a big irregularity, it is better not to level the surface. Because the space is greatly reduced. Such irregularity can be perfectly disturbed with artificial stone, it fits into any design.

- Just if the angle vertically is not perpendicular to the axis of the earth, then not a large deviation can be completely aligned with the help of a corner.

Corners and Corner Production Materials

Corses for plastic walls are chosen by the appearance of the angle.

There are two options here:

Inner corner corner | Internal angles are mainly not falling into the risk zone, since it is difficult to afford. Although it is not particularly exposed to mechanical effects, it is sometimes extremely important. |

Corner at outer corner | But the external angles are always a headache, as they are easy to damage. They do not have high strength, wallpaper can be crawled, paint. For example, the transfer of large-sized furniture or technology, there is always a risk of damage. From this we can conclude that the corners require protection. |

Corner can be made from several materials. This characteristic also depends on this.

Let's see how much PVC is suitable for you:

| Material of manufacture | Characteristics |

| Plastic | Durable, resistant to moisture, easy to install and perfectly processed; |

| Metal | It has many positive qualities, but the cost is very large, it also has not low weight and can be corrosion; |

| MDF | Durable, compare with natural wood. The impact of moisture is not acceptable; |

| Wood | It looks beautiful, but easily ignited, the wet stay is also recommended; |

| A rock | Durable, but the installation of the labor-intensive process, also has a lot of weight and therefore not always acceptable. It is also quite difficult to handle; |

| Metal galvanized profile | Resistant to moisture. Not much weighs. But there are difficulties with processing. |

Attention: the main thing is that the corners are light and durable. Then they are fixed without any problems and just change when repairing.

Why choose plastic

The choice will stop on plastic decorative corners. They are the most extended applications. To date, the market offers a variety of plastic corners. This material has a diverse color palette, and also have a good property - soft.

There are two types of plastic corners - external and internal corners. Therefore, many manufacturers are painted plastic not only outside, but also inside. They have many advantages.

Let's try to summarize, it is in a small list, noting the main:

- Have a very small weight, which increases the level of service;

- Color range is diverse - from white to black;

- You can give any shape;

- Easily cut;

- Well glued;

- Hide irregularities or disadvantages;

- Give direct lines completion;

- Shelf life more than 100 years;

- Rather low price;

- The possibility of mounting with their own hands also attracts the consumer.

ATTENTION: Corners are on sale all the same length, which helps accurately calculate the required amount and pick up the desired shade to you. But they have a different shelf, this is necessary to pay attention to this.

Corners are installed at the end after all installation and repair work performed. Corners are glued to the wall with mounting glue for plastic. If you produce this type of work for the first time, it is necessary to use the angles of the average width, and the height of the plastic corners is standard 2.5 m.

Plastic Corner Application Areas

Plastic corners will be real assistants in any interior. They emphasize all the lines that you want to highlight in the decor. Also, they help hide all irregularities or problems in twisted walls.

Consider situations when really without their help, do not do:

- When installing window slopes inside;

- When installing windows outside, to hide traces of foam, give aesthetic look;

- Framing door slopes;

- For the design of arched openings (see how the arch part: the shape of the arches and types of finishes);

- Corners of walls, oblained by wallpaper;

- At the corners that are made of plasterboard, under putty;

- When creating angles, when working with facing tiles;

- When using plastic panels indoors;

- The formation of the joints when working with siding (see everything about cladding siding or sketching about the famous).

You can also list for a long time, for what cases a decorative plastic corner is useful.

However, and from this list shows the evidence of its widespread use:

- The corner is produced by heating PVC, it gives it the desired form. Such a corner is obtained smooth and without cracks.

- Note that the corners are not standard. Width can be different. One side is wider than the other. Such plastic decorative corners are suitable for arched openings.

- Manufacturers produce a large number of monophonic plastic corners. They also depict imitation under natural material, for example, under stone or tree. You can find one corner that perfectly fit into the color gamut of the room.

Types of corners for finishing

It is possible to determine which corner is necessary, internal or external for work, after you select the type of finishing.

- The outer corner is in the amount of 90 or 105 degrees. The plastic window is edged, with the help of plastic corners of 90 degrees, if not enough, put the second shelf.

- If two shelves can be seen, then frame plastic corners of 105 degrees.

- In the internal works use such a corner, which can hide the docking of materials and irregularities.

- Corners put the final point in repair and finishing works, give a completed view of the room, after repair. The main thing is to choose the corner to your interior correctly.

Installing corners

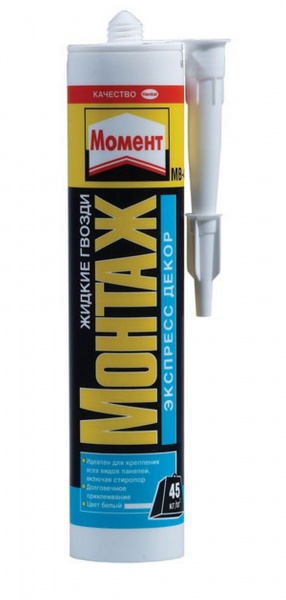

Glue is the most necessary thing for setting the corners. Since the reliability of fastening depends on it. There are many all possible glue on the market today, everyone is distinguished by the composition, properties.

How to choose the best glue? If it is wrong to choose, then you can spoil an external aesthetic appearance.

Let's look at what kinds there are and for which they are suitable:

Fastening a plastic corner on polyurethane | It has a number of positive sides - does not leave traces, elastic, has high strength. The most suitable for gluing a corner with plastic panels. But there are also disadvantages, it has a sharp smell and long gluing, about two days. It is necessary for such a glue throughout the surface of the corner, immediately do not glue. It is required to wait about 30 minutes, so that the glue slightly hardened. |

Fastening a plastic corner on liquid nails | The most popular glue. It has acquired his fame due to high strength. It is also called mounting glue. It includes sodium carbonate, which allows you to fill out empties between the corner and the wall. It is perfect for gluing plastic corners with any type of wallpaper. If you use white corners when installing, it is better to buy transparent liquid nails, with other shades of wallpaper can be used, any composition of glue. Note that liquid nails do not spoil plastic corners and wallpapers. Apply glue on a plastic corner snake. |

Krepim Corner PVC on sealant | This is a complex glue. You need to go with full responsibility. Sealant needed for fastening plastic with a tile. Note that not every sealant can be suitable for gluing plastic. Experts argue that it is better to use an acrylic sealant. It is distinguished by the strength to glue the plastic, does not have color and smell. And has increased moisture resistance. |

Attention: deciding than to glue a plastic corner to the wall, it is worth watching what you will clipped the corner. Then there will be no unforeseen circumstances and the installation will be successful. Glue is applied to the corner point.

Preparatory work

When we work with straight corners, we should not have any special problems. Plastic corner is easily cut, using a building knife or hacksaw.

But with arched works, not everything is so simple. Here we need to bend a straight plastic corner. How to do it?

- From the above, it can be recalled that at high temperatures plastic corner easily changes the form. For this we need a construction hairdryer, we heat the corner, give the desired form, fix. Works continue after plastic cools off.

- Often in the store corners stand in dust, so before work, you need to clean them, fencing, wipe dry. There should be no moisture drop on the plastic, if they still fall, the glue is badly fixed, and over time it can fall off.

ATTENTION: A corner with cuts is selected for the arch. If you took a straight line, then you need to make cuts along the contour with a hacksaw.

Plastic Corner Print Technology

For each type of material its own system for gluing plastic corners. We will analyze all the cases in detail.

So that you already knew exactly what you need to do:

- To glue a plastic corner to wallpaper, it is required to find it. It is better to choose a corner to the wallpaper, it looks aesthetically beautiful. Measure the height that is needed.

- After you need to cut off. Here it arises the biggest problem for non-professionals. Plastic corner is cut off at an angle of 45 degrees. Experts make it on the eye. But since you are not a professional in this matter, then you need to take the stood and scissors for the metal.

ATTENTION: Hiscell must be taken on the metal or with a fine tooth. Otherwise, the material will eat and turn out not even cut.

- After cut off the desired length, prepare the plastic corner itself. Wipe the dust, check if there is no water if it is present dryly.

- Now you need to prepare wallpaper, remove the wallpaper at the junction of the corners. In this case, you need to use liquid nails. However, if you have a light wallpaper, then select light glue, and if a dark shade, then any color of glue will suit you.

- Apply glue on plastic and on wallpaper evenly, but do not overdo it, as it is impossible to remove such glue from wallpaper.

Print a plastic corner to the walls in the same way as in the last case:

- Clean the wall, prepare the corner, wipe from dirt, check for moisture. Glue use another, required for painted walls, acrylic sealant. Apply gently on the inner side of the corner and attach to the wall. Exactly the same process is performed when gluing a plastic corner to the slopes.

- The most difficult type of work is the attachment of a plastic corner to the arched effect. Type of glue choose based on what type of material is posted on the wall. Next disject plastic corner, as we described above.

- Now go to the hardest - cutting plastic. On the side that goes to the inner opening, cutting an approach. And from the outside, leave the stock. Then it will be possible to fill. The method of gluing itself depends on the materials.

Now you have the initiative of the installation of plastic corners. You can safely move to practice. As you can see the installation process is not as complicated, but as invaluable. And we note that they are not high. Allow them to buy them can even people with a limited budget for repairs.

Corners will perfectly retain the primacy of the room. Since they will protect the most vulnerable places in the interior. And the room will delight you not one year.

The plastic corners to protect the angles of the walls will help you maintain the geometry of the angle even with mechanical exposure. And the instruction will help make work quickly and efficiently.

Repairs in the apartment with their own hands at least once in his life, probably, every person. Non-profescionals sometimes have difficulty cope with some tasks.

If you align the surfaces of the floor and the ceiling, you can without any problems, then finishing the corners of the walls is not the task of the lungs and requires some knowledge and skills. Protection of wall corners is necessarily necessary in the presence of small children and animals in the apartment.

After all, plaster mixes are not distinguished by durability, and it is necessary only to touch the angle as the plaster can be sneaked, especially at external corners.

Various types of corners

If the angles are strongly shivered, you will have to spend a lot of effort and material to align them.

If the angles are strongly shivered, you will have to spend a lot of effort and material to align them. Internal angles are more or less protected by wallpaper, which allow you to hide irregularities. But the external angles are always in sight and hide the damage here is not easy. For this it is necessary to use a special decorative coating.

To strengthen the inner corners of the walls, the plaster of the corner itself and the wall adjacent to it is used, and the plasterboard is used to correct the corners.

Protect corners in the apartment in different ways and materials. When applying plastering, it is worth considering that this method is quite time-consuming and long time. If the angles of the walls are too smooth, then the imposition of a large number of plaster is not only at the angle, but also on the walls.

Special metal corner will help to form a smooth angle

Special metal corner will help to form a smooth angle As is known, the layer of plaster should not exceed 2 cm otherwise there will be cracks. To close the inner corner, you need to use a metal corner-contraly.

Pre-treated the angle of the wall by primer, then cover the countercultants with a layer of putty and, pressed, glued.

This metal corner has a reinforced grid at the edges, which subsequently enters the plaster and makes the angle smooth.

Use of drywall and metal angular profile

Very often to separate the corners and walls helps drywall. With a small curvature of the corner itself, a frameless method of attaching plasterboard is used, but if the curvature is more than 2 cm worth using a frame of a metal profile or wooden bars. This method allows to achieve almost perfectly smooth walls and ceilings, but at the same time the size of the room itself is significantly reduced.

Very often to separate the corners and walls helps drywall. With a small curvature of the corner itself, a frameless method of attaching plasterboard is used, but if the curvature is more than 2 cm worth using a frame of a metal profile or wooden bars. This method allows to achieve almost perfectly smooth walls and ceilings, but at the same time the size of the room itself is significantly reduced.

Separate the external angles of walls in the apartment can be using a metal corner profile. This method of protecting the angles of walls is the most optimal and allows you to protect the corner from any mechanical damage.

After completing all the repair work, this angle becomes completely inconspicuous.

After completing all the repair work, this angle becomes completely inconspicuous.

The standard length of the metal corner is 3 m, if necessary, it can be easily trimmed with metal scissors.

If the corner is direct and smooth, then you can attach the profile using small carnations, but if there are some irregularities, it is best to use alabaster or gypsum to install the profile.

Protecting metal corners allow you to achieve perfectly smooth corners in the apartment. Not even a professional can cope with their installation.

The use of plastic PVC corners

PVC accessories glued on top of the finish finish

PVC accessories glued on top of the finish finish To date, one of the most popular ways to design outer corners is the use of plastic. Such corners for walls are widely used and are suitable not only for decorating the outer corners, but also for designing window and door slopes, panels and arches.

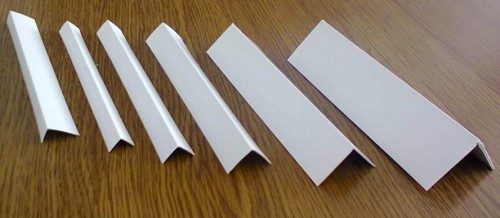

We are produced in a variety of colors, there are even transparent, have a width of 10 to 100 mm. The length of the PVC corners ranges from 1.5 to 3.0 m. They are glued to ready-made, preliminarily completed, finishing works are completed.

The advantages of PVC corners:

The advantages of PVC corners:

- affordable price;

- easy to use even for beginners in repair;

- a large variety of shades;

- visually align even very curves of the corners;

- long term in operation;

- quite simple in care.

The angle decor in this way helps to avoid destruction and mechanical damage. Before pasting PVC corners, it is necessary to establish the degree of damage to the angle of the wall so as to correctly pick up the width of the plastic corner. Then you need using a knife for plasterboard.

You can glue these corners in different ways:

You can glue these corners in different ways:

- with the help of mounting glue for plastic products;

- applying a solution of dry spacion mixture;

- glue initially can be applied to PVC corner.

Apply the adhesive composition according to the instructions on the surface of the angle and press the PVC to the wall to the wall, remove the excess glue and wait until complete drying. For a better result, it is recommended to fix plastic corners using a painting tape.

Use of wood and polystyrene corners

Wooden corners are not very plastic

Wooden corners are not very plastic The decor of the angles of walls in the apartment can also be made by applying corners of wood. The advantages of this decoration are that the tree is environmentally friendly material and has an attractive appearance.

Its plasticity allows you to apply the thread on the surface of a wooden corner, which will give the room a unique design. Using such decoration of the room, it is necessary to take into account the need to avoid a sharp temperature difference, otherwise wooden corners are deformed. Glue this type of corners can not be indoors with high humidity. About how to separate the corners with putty, see this video:

Probably the most affordable way to finish the angles of the walls of the apartment is a polystyrene foam corner. Such corners are easily mounted and can repeatedly paint. They just take care of them, as they do not absorb dirt.

Such products are used in rooms with different temperature regime and high moisture content.

Stone corners and their advantages

Synthetic stone is used to finish the corners

Synthetic stone is used to finish the corners One of the most popular ways to decorate and strengthen the corners of the walls has recently become a stone.

The premises decorated with artificial stone is becoming more and more.

With this method of registration, there is no need for, walls in the apartment, especially appropriately the use of decorative stone with strong uneven outer angles.

It is necessary to take into account that artificial stone is much easier and more affordable natural analogue and is easier to maintain and care.

You can beat the decorative stone yourself, for this it follows, cleaning them from dust and dirt. Then there is a special tile glue according to the instructions. They apply to it with a thin layer with a spatula on a stone and a thick layer with small pellets on the wall. The stone is applied to the wall and pressed, the surplus is removed. About how to separate the corners, see this video:

After the three rows were pasted, it should be stopped and allowed to dry, then you can put another three rows of decorative stones. And so gradually finish the entire surface. Thanks to the huge selection of colors and textures, a decorative stone can be selected for any interior.

After the three rows were pasted, it should be stopped and allowed to dry, then you can put another three rows of decorative stones. And so gradually finish the entire surface. Thanks to the huge selection of colors and textures, a decorative stone can be selected for any interior.

Combine different ways to finish corners

Combine different ways to finish corners Following the listed types of finishing of corners in the apartment, you can make certain conclusions. The expensive type of finishes themselves is an artificial stone, and the intensive intensive way of finishing is considered to align the angles of plasterboard. Different types of trimming of angles can safely be combined with each other and apply when repairing at the same time. External angles with such protection will be installed "in the shield" and have aesthetic species for many years.

June 13, 2017Specialization: finishing of facades, interior decoration, construction of cottages, garages. Experience and gardener and gardener experience. There is also experience in repairing cars and motorcycles. Hobbies: the game is not a guitar and a lot more, to which there is not enough time :)

How to separate the angles of the walls so that they turn out to be smooth, durable and beautiful? Previously, I was often interested in this question, but now, by taking experience, I myself will tell you how the trim of angles is performed - the outer corners inside the building and outside. I am confident that this information will help newcomers to cope with the task.

Finishing options

The complexity of the trim of the corners is not only that they should be even. The fact is that these parts of the walls are often exposed to shock loads, so it is necessary to ensure that they are sufficiently durable.

Currently, there are several ways to solve this task. The choice of method depends on the type of wall decoration, which may be as follows:

Option 1: Plastering or Plasterboard Walls

If the walls are plastered or tinted with plasterboard, they usually use special plastering corners for finishing the corners. They are two types:

- Aluminum perforated.Used to finish smooth sections;

- Arched. Made of plastic. Their main feature is increased flexibility, which allows them to be used to finish curvilinear surfaces;

Corners are glued with plaster or putty at the stage of rough wall decoration. In the process of their installation necessarily use the level. This allows you to establish them strictly vertically or horizontally.

It must be said that this decision is used for both inner walls and facades. But, most importantly, that such a finish of the outer corners of the house allows not only to align them, but also to protect against mechanical damage.

Cost:

Keep in mind that all prices are relevant in the spring of 2017.

Option 2: PVC clapboard

Recently, PVC (polyvinyl chloride) is very popular, which is called simply plastic panels. Most often, this material is used in the following premises:

- Bathrooms;

- Kitchens;

- Hosts.

If the walls are separated by plastic, the angles can be issued in the following ways:

- Using profiles.This is the easiest way, the essence of which is to use angular profiles. They are installed on the level assistance crate, as well as plaster corners.

As a rule, profiles are fixed on the crate using a stapler. Then the panels simply come to special grooves;

- By flexing panels.To bend the plastic panel with your own hands, you need to cut the inner side along the fold line. It is desirable to even cut a thin strip, as shown in the photo-scheme above.

Before flexion, the front side is preferably heating, for example, using a hairdryer.

Cost.The price of the guards for PVC panels begins from 25-30 rubles per 3 m (standard length).

Option 3: Wooden Wooden Distributed

Not so long ago, when finishing the walls with a clapboard for angular joints, the boards sucked and fitted. At the same time, the remaining gaps spitled. Nowadays, a special wooden corner can be purchased to design the corners.

You can consolidate it on the lining with window carnations. The only thing, the Hats of the nails preferably to look so that they were invisible.

It must be said that in this way it is possible to separate not only external, but also internal angular joints.

Cost. The cost of wooden corners on average is about 50 rubles per stranded meter.

Option 4: Siding Side Facade

Many newcomers are interested - how to separate the corners of the house on the facade? As I said above, perforated plaster corners can be used for wet facades.

If the facade is trimmed by siding or other facade panels, special challenges should be used, which are usually sold complete with panels.

Such corners perform several functions at once:

- Provide fixation of panels;

- Draw up the bog panels;

- Protect ends of panels from mechanical loads;

- Serve guides for siding.

In fact, the installation of the siding corners is reminded by the installation of the guides for PVC lining. They are also mounted on the crate, just not a stapler, and self-draws. However, the level is necessarily used.

Option 5: Wooden Walls

At first glance, the design of the corners of a wooden house outside is not required, as they themselves look quite attractive and at the same time strong enough. However, far from everyone knows that the ends of lumber are areas that are the least resistant to moisture and rotting.

To protect them, use special sealants and impregnations for the corners of a wooden house.

Cost. Below are the most popular compositions and their cost:

Apply the compositions for the ends of the sawn timber is not only outside, but also in a wooden house inside.

Option 6: Wallpapers or liquid materials trimmed

Above, I already talked about the draft method of decoration of plastered walls. Finally, consider how the decorative decoration of such walls is performed.

So, there are two most common ways to solve this problem:

- Decorative lining. The finishing of external corners in the apartment implies the installation of PVC or polyurethane corners.

These products can be completed under a tree or even look like expensive baguette. The latter are usually made from polyurethane. They look rich, and apply in classical interiors;

- Decorative stone. In this case, the angles are covered with decorative stone, which can be made of plaster, cement, or even natural stone.

It must be said that this way can be used not only for the inner walls, but also for the facade.

The installation instructions for decorative corners requires the removal of the finishing coating on the site of their adjoining wall. This is especially true of severe polyurethane linings.

Cost. Below is the cost of some materials for the design of the corners:

Output

Now you know what ways and materials is performed finishing the corners of the outside and from the inside. Additional view video in this article. With all questions on this topic you can contact me in the comments.

June 13, 2017.If you want to express your gratitude, add clarification or objection to ask the author - add a comment or tell me thanks!

A huge selection of finishing materials allows you to arrange walls, ceilings, doorways of an apartment or a house in the most bold and interesting variants of the decor, but there is one condition. You need to think in advance how to strengthen and protect the angular lines of the walls. The peculiarity of the modern wall decoration is such that the first angles of walls are the first and losing the appearance.

In some cases, without protective plastic corners for walls, it is easy to do not do, as in the case of cladding with tiles or wall panels. Therefore, people who are knowledgeable in matters of major repairs, choosing a finish, be sure to look after plastic corners to protect the angles of the walls.

Where and how profiles are used to protect the angles of walls

With the first variant of the profile corner, it is necessary to get acquainted at the stage of plastering or aligning the surface of the walls using drywall. Installing a plastic corner under the wallpaper makes it possible to solve two problems at once:

- Strengthen the finishing layer of putty;

- Posted by outer corner perfect geometry, at least visually the link of the joint of two planes looks quite smooth.

All who, at least once, had to glue wallpaper on the walls with clarifiers, would appreciate all the benefits and practicality of the simplest plastic profile.

For your information! With a wall plastic corner, you can easily remove external and internal angles even on the most uneven walls.

The main difference of corner profiles from decorative plastic corners is that the mounting option always has perforation over the entire length. The corner does not need to glue, it is simply imprinted in a layer of putty or plastering. Even professional plasters always use plastic corner.

But the use of mounting profiles for alignment of the walls does not solve the problems of the appearance of the angular edges, both internal and external, especially if the walls are separated by light choppers. Therefore, in addition to the perforated profile, plastic corners are installed in addition to the perforated profile.

What does it give:

- Full protection of corners. No matter how carefully, the owners with decorative trim on the angular joints of the walls, after a few months, the maximum of the year will appear traces, scratches and chips of facing;

- Eliminate gaps and gaps between the wall panels, especially on the corners of the walls and plinths, on the curvilinear surface;

- Cardinal improvement of appearance. Colored plastic corners for walls will help with minimal costs to transform and significantly refresh the wall decor.

It is not necessary to be limited to external angles of the walls, although they are what is called, in sight and require protection in the first place. Often, a plastic corner at the angle of the wall has to be installed post-finish, it costs to make a permutation of furniture with the transfer of the most overall interior items. Weakness and pollution can still be withdrawn or washed, but chipped and deep scratches on the walls have to hide.

The internal angles also have to close to disguise the transition from one type of finishes to another, for example, while simultaneously facing the walls of the corridor with plasterboard, MDF or DFP panels, and residential rooms with wallpaper and wall plates.

Plastic profile for sealing angles

For decorative purposes, corners of polychlorvinyl, polystyrene, polyurethane and even silicone are used. If the walls of the room are decorated with wood or tile, then a corner will be required from a similar material, a plastic profile for such a decor looks unnatural. For all other cases, the list of the most suitable materials is invariably heads the PVC corner, it remains the most sought-after. Almost everyone who has come across the problem of finishing and protecting the corners of the walls by an overhead profile is unanimous in their choice, it is a PVC profile.

The exceptions are metallic and MDF Corners used as ostels covering the window opening line from the street. At the same time, a plastic outer corner of polychlorvinyl is often used for balcony doors.

The reason for the popularity of the polychlorvinyl profile is determined by three essential properties:

- Beautiful appearance, problems with the selection of the desired shade of colored plastic corners to protect the corners of the walls almost does not happen;

- Plastic material has high flexibility and "democratic" when installing. There are no problems with the fitter, as in the case of polystyrene or polypropylene corner profiles;

- Easy processing when fitting the size of the corners. The material can be cut without problems with scissors, the "bread" knife or, best of all, the metal cannon.

For your information! Good material workability does not exclude the capabilities of the profile cracking, especially if the plastic corner was kept for a long time on the balcony or in the garage at low temperatures.

In this case, before cutting the plastic corner, it must be kept for an hour at room temperature.

Size of plastic corners

The pluses of a plastic corner can be attributed to the low value of the material. Depending on the height of the shelf, the price of a plate of 2.7 m long ranges from 50 cents for size 10x10 mm to $ 1.7 for profile 50x50 mm. For lining of home walls and angles, a corner with a shelf is 20 mm and 15 mm usually use, their cost is in the range of 0.7-1 dollars. For the standard bar in 2.7 m.

In the PVC market, profiles are represented by three types of plastic corners:

- Standard Equal Option, which has both shelves of the same size;

- Double corner or T-profile used to decorate interpanel and interputric seams;

- Mr. or arched plastic corner with different shelves height.

As if the masters neither try to align the plane of the walls, all the same, with time, a slot is formed in the corner, which is necessary to somehow mask the installation of a plastic corner to the angle of the wall. Otherwise, the ugly line of transition of one type of finishes remains in another. For the case when it is necessary to close on the wall of the joint between wallpaper and decorative plaster, quite the smallest profile, 10x10 mm. The same shelves size is selected under the outer corner for plastic plinth. The biggest profiles, 50x50 mm are used to install on the corners of the facades of the building, the size 20x20 and 25x25 are the most running for internal work.

Options for using an angular profile for finishing the corners

At first, most apartment owners are quite restrained to use the corner profile when designing the corners and the wall of the walls of the walls. First of all, the well-established classical opinion is prevented that the use of PVC materials in the apartment needs to be limited and used primarily where it is simply impossible to do without it. For example, for entrance doors in the bathroom or in the kitchen.

Destroy distrust of plastic corners is possible only if people see the difference between the walls of the walls without a corner and after installing a plastic corner profile. The difference in perception even with the simplest decor is essential.

Finishing of slopes of doors and windows

The most visible example of the advantages of installing corner PVC profile remains windows and doors of a modern apartment.

With the replacement of an old wooden window frame on a double-glazed window, as a rule, it is necessary to compose a new way, search for a method and material to close the external angle to the walls of the room.

Traditionally, the window slips are made on the basis of sheets of plasterboard, with an enhancement of an external angle with a perforated metal corner, a photo.

This makes it possible to perfectly align the plane and achieve the maximum smooth corner line, but still the edge will remain the risk zone. The window uses quite often enough, so even the curtains or curtains often cause damage to the edge. If the finishing of the slopes using MDF or PVC panels, then without installing a plastic corner to the slopes simply not to do. First of all, it will be necessary to close the end of the facing panel, otherwise the entire decorative effect from the use of the finish will be lubricated. The dimensions of the plastic corner for slopes depend on the height and width of the window opening.

A plastic corner for drywall and wallpaper is selected 20x20 mm, for an angle at the MDF plate transition - the wallpaper is installed with a corner profile of 25x25 mm. In the latter case, if you wish, you can hide the installation of the protective profile, for this it will be necessary to simply choose the proper plastic corners on the slopes. It is painted polychlorvinyl rather difficult, so the option with repainting is used if everything is planned to paint with slopes and corners.

In addition to finishing the outer edge, it is necessary to install plastic nachets between the window frame and the sloping plane, as well as close the cross-side crossing line with the walls. For these purposes, it is best to use a T-shaped profile with a deflection in the central part.

At first glance, the crossing line of the intersection and the windowsill can be not covered with a plastic corner, but it is not quite so. The plastic window sill quite strongly spring even under a small load, so after a few months the material that was covered with an angular joint, can simply get out of the gap, so it is better to close it in advance in advance.

The same plastic corners are often used for the decorative seal of the seam line between the bathroom and the wall, lined with tiles. Polychlorvinyl is perfect for a wet atmosphere of the bathroom.

The second section of the walls, where it is almost impossible to do without installing a decorative plastic corner, entrance doors are considered. If entrance doors change in the house or apartment, it means that the owners have a big front of work on finishing and decorating tambura and door slopes. Since the entrance door always remains the most dusty place in the house, the doorway slopes, with a rare exception, are traditionally separated by MDF, clapboard and PVC panels, most often under a tree or natural stone.

After the walls of the door tambour will be attached and covered, you can lay a cladding. Any master can confirm that after finishing work on the corner of the intersection of the walls of the corridor and the slopes plane will be visible ends of the facing panels. They must be closed to achieve the finished appearance of the doorway and eliminate the accumulation in the creams of dirt and dust.

If the tambour facing was performed by a direct sticker of PVC tiles or panels on a plastered surface, then in order to close the slots, there will be a plastic corner with a width of the shelf 30 mm. For decorative finishes, laid on a pre-bought crate or galvanized profile, a corner plastic profile is 40-50 mm in size.

Arched doorways

Among the sets of interior opening options, the arched scheme is considered one of the most beautiful and expressive. The arch is most often collected on the basis of a metal frame with facing plasterboard sheets, or laying out of light wall foam blocks.

One of the problems with which you have to encounter when assembling the arched arc is associated with the inflexibility of plasterboard and galvanized profile. And the other is almost impossible to be a smooth curve. In order to get an arc, the carrying frame has to gain from a dozen short segments - chord. The inner surface of the arch is also recruited from short drywall segments.

You can simplify the task, for this, the arch of the arch plastic corner is performed in the form of several rectilinear sectors, a photo.

Solve the problem of the maximum smooth profiling arch can be in two ways:

- Installation of finished arched plastic corner photo. It will only be necessary to adjust the size of the opening under the finished profile, install and secure the polypropylene frame;

- Putting the walls of plasterboard walls with a curved arc carved by pattern. The inner part of the slope is placed by polyurethane foam, and the edge is trimmed with a decorative plastic arched corner.

The use of a decorative plastic profile allows you to close the junction and an angular transition from drywall to the slope. This method of arched passage is cheaper and easier. But there is one condition, you need to know exactly how to get a plastic profile under the arch. At first glance, bend the soft polychlorvinyl profile does not make much difficulty. One of the simple descriptions, how to bend a plastic corner on the arch, given on the video

An ordinary plastic corner is not suitable for these purposes. Any attempt to stick or nurtures it to the edge of the drywall leads to the fact that at the top of the decorative profile leaves the wall and breaks into two parts. It is necessary to cut one of the shelves of a regular corner to segments of 25-30 mm long or, more convenient, use a special plastic corner for the arch.

Most often, a profile of 17x5 mm is used for the arched doorway. Due to the reduced side shelf of the plastic profile, the corner is broken almost without skew, and therefore, when laying the material on the glue, the risk of delay from the edge of the wall will be minimal.

If the arched opening arc radius is quite small, the plastic profile has to bend so much that even a special decorative corner begins to combine. In this case, you can use the "hot" way of bending. The corner is fixed at one end of the arch with a clamp or clamp. Next, the phenom is heated by a polychlorvinyl profile to a temperature of 60-70 o C and pressed to the edge of the drywall. While the material cools, it is rolled into place with a soft painting roller.

Tip! If it was not possible to avoid the desired arc profile for two or three warming up, then the bent must be stopped, since the material after several heating cycles becomes hard and brittle.

Before sticking the plastic corner on the arch, it is necessary to determine the profile adjustment points to the surface of the walls, in order to apply glue in these places. If you do this "blindly", most of the adhesive material applied to the plastic profile will be spent without benefit.

Installation of plastic corner with your own hands

The process of laying a decorative profile at an angle or on the edge of the Arch does not represent much difficulty, requires accuracy and gentle handling of plastic. Polychlorvinyl is easily scratched and loses glossy shine. Often the facial part of the plastic corner is sealed with paper to avoid damage and contamination with glue. After pouring the adhesive base, the surface of the corner can be polished with a soft cotton cloth.

One of the advantages of using the PVC profile is the fact that in production, the staining of the material takes place throughout the mass, any scratches and scratches do not lead to a change in color or shade. So polish the material can be an infinite number of times.

How to stick a profile on an angular joint

Working with a corner profile is no different from similar operations with polyurethane stroke or plinth. Initially, before gluing plastic corners on the slopes, you need to do a small preparatory work.

First, the roulette measure the length of the polychlorvinyl profile for each corner of the slope. Since the window opening has a rectangular shape, then all plastic corners will be shrinking between themselves at right angles. The joint line will cut at an angle of 45 oh. For other designs - arches or polygonal arches, the corner of the corner will need to be determined at the place of the sticker.

After marking, you need to cut off the plastic strips for the performed measurements. It is necessary to do it as much as possible, since the corner is quite thin, only 1-1.5 mm, so the material with irregular cutting can be easily split.

Experienced masters cut a profile with a construction knife for a ruler or well-sharpened scissors. If there is no appropriate cutting experience, it is better to use a joinery for angular jams. Polychlorvinyl is perfectly cut by the usual hacksaw blade.

After cutting, we carefully remove the burrs and perform the finishing fitting of the cut blanks at the place of the sticker. This will require scotch and construction level. Having attached to the gluing place the harvesting of a plastic corner, align its position in terms of the level and fix several scotch strips. Similarly, set the upper corner bar.

Only by setting all the cut cuts of the Corner Corner and aligning them along the construction level, it becomes clear how correctly the angle was made. Typically, fans on the joint line forms a gap of 1-3 mm wide. It is clear that it is impossible to glue a plastic corner with such slots.

Tip! When cutting the corner profile, add a 2-3 mm allowance to the calculated size. This stock during fit will help to correct the situation without any particular consequences.

To get rid of the slots at the joints of the walls, it will be necessary to clarify the passage of the line for all three billets. For this, the pencil is performed by a correction line and disassemble the structure for fitting the corners. The line was waged to be cut with scissors or apply to a piece of sandpaper, wrapped around a wooden shelter.

How and what to glue

It remains to paste a plastic corner on the angular edge of the slope. First of all, you will need to choose than to glue the plastic corner to the wall. In the salons and construction stores, the glue composition "Liquid nails" will recommend as the most suitable agent. From the positive characteristics, you can only be called comfortable packaging in the form of tubes.

Everything else - on the conscience of the manufacturer. This composition can be glued with light polyurethane boves or plastic corner of 10x10 mm in size per interpreter joint. In addition, the white glue mass over time becomes beige-gray, so the traces of glue are very clearly visible on the seams and joints.

Sunsions on the windows, at the entrance doors it is necessary to glue silicone, you can transparent, but if you wish, you can easily choose the color version of the sealant. Not all adhesive materials are well adhere to the smooth surface of the polychlorvinyl corner. Silicone sealant is a pleasant exception, it does not drain and does not give a shrinkage.

But the main advantage in obtaining a durable and elastic seam. If you have to stick something on the door jamb, on the light partitions that vibrate with each slam of the doors - choose silicone. Any other adhesives that give the most durable and hard seams, vibrations can not withstand and rock, especially if it comes to a plastic corner.

The technology stickers of the corner plastic plank is quite simple. We apply glue with thin lines on the inner surface of each of the shelves. If glue is very thick, then the adhesive mass can be applied to the wall with short oblique lines or points. You can not cover the entire surface of the wall with a solid layer. First, such a plastic profile will not be able to press in place, and secondly, 50% of the adhesive mass will be extruded uselessly beyond the boundary. Too liquid glue simply run out of the plastic plank.

Prepared plastic corner with glued with glue carefully put on the place of gluing. In order for the adhesive seam to be durable, you need to carefully press the bar in place. A small amount of adhesive mass can be squeezed from under a plastic profile, but you should not hurry to clean it - you must first align the corner. The polychlorvinyl profile is very flexible, and it will not be able to focus it, so the stacked corner leads to a straightforward state with the help of a metal line and construction level. In order to the moment of complete drying of the glue, the plastic corner did not fall off from the wall and not slipping down, you need to fix it with several scotch strips.

The next plate of the plastic profile is glued in the same way, but before laying in place you will need to apply a small amount of glue on the joint line. After sediment, part of the adhesive will perform on the junction, all excess can be removed only after the final drying of the adhesive mass. While the glue is not drying, any attempts to remove its surplus will lead to the formation of spots on the wallpaper.

Sometimes there is a problem with an arched corner length. The maximum length of the plastic strip is 3 m. This may not be enough if the arched opening is made on the entire width of the room, the length of the corner profile on such an arch can reach 3.5-4 m. In this case, the arched arc has to be drawn by a small piece. It is best to make the central part of the arc of whole, on the sides add two small segments, and the joint line should be sealing with silicone sealant in the color of plastic material.

After a couple of years, due to the shrinking processes, the seams may slide, but still the arch will retain initial effect. If you increase the length of the plastic corner on one side, the place of the junction will be perceived as a stain, and spoil the impression of the whole design.

Conclusion

Plastic corners are successfully used not only for residential premises. For example, for a cottage or a bath, covered with clapboard, for a country house from a bar always remains relevant protection of angular joints of the outer walls. This is not so much a matter of aesthetics of the appearance of the construction, how much the urgent need for protection against moisture penetration. In this case, under a plastic corner of 50x50 mm, two bearing wooden rails are stuffed, which is stuck plastic corner profile.

When you make repair with your own hands, if you are not a professional in this matter, there are many questions that require immediate and proper decision. It applies to finishing the corners in the apartment. Corners are external and internal, rectangular and not very. And now there was a problem, how to put them in order, that is, it is possible to correct and decorate. Internal angles are often not very noticeable by their curvature, because they are hidden under wallpaper or under decorative plaster and are forced furniture. Other business corners external. They usually always in sight. But let's try to figure out and find ways to solve this problem: while repairs to correct the curvature of the corners allowed during construction and somehow transform the corners.

So, internal anglesthe walls can be aligned with several ways and here are the two most common:

- by plastering the angle and adjacent wall

- correction of angle with plasterboard

Plaster Any surfaces, as you know, the process is quite time consuming, dirty and long. If you decide to go exactly this way, calculate all the pros and cons. You need to look at, much is the corner of the distance from perfection (90 degrees). If the error is too big, then there is a lot of work, because together with the angle there will have to stucked most of the wall. And more than 2 cm, the plaster cannot be applied, otherwise the thick layer crackles. And you will have to do this work several times, imposing a layer behind the layer. You need to estimate, so you need this ideal angle, and maybe you can leave everything as it is, limiting it with decorative trim. If you still decide to stucked, use a metal corner, which is called the countercultuary. The angle is pre-ground and countercultants are glued onto the shtclotch, slightly pressing it into another soft plaque mixture. This corner will provide the desired straight angle. The countercultuary is equipped with both sides along the edges of the reinforced grid, which will go under the plaster and thereby make an angle strong and smooth.

With help gypsum Carton You can align a variety of irregularities on any surfaces. If the curvature of the angle is small (up to 2 centimeters), then a frameless way of mounting sheets of plasterboard sheets is used. If more than 2 cm, then the framework of wooden bars or metal profiles is built and plasterboard is attached to them. Plus this method of aligning the corners and walls is that with the help of sheets of plasterboard, you can achieve almost perfectly smooth walls and straight corners in the room.

But there is a big minus room becomes less.

Which way to choose, decide for yourself. Do or not level alignment of corners and walls-this question, too, everyone is solved for himself. And if you think that the decoration of uneven angles will be enough, read the article on.

If there are children or pets in the house, the external angles are especially vulnerable. Wallpapers will dug, decorative plaster on the corners will fall off. Unpleasant picture. But is it possible to exclude this process somehow? Sure! After all, now there are many decorative building materials that allow it to do.

I chose plastic corners for itself to protect against damage to external corners in your corridor. This is an external angle, hoveed by wallpaper. We recently made repairs and wallpapers still fresh.

But if you look close, then the angle looks like this: an ugly junction between different wallpaper.

I measured the height of the corner from the floor to the ceiling and bought a plastic corner in the construction store. He cut off with ordinary scissors the desired size and inside smeared it with liquid nails.

And finally, glued to the corner. Agree, so much better. Of course, it was possible to choose another color to the corner, but I wanted contrast.

That's how it looks close. The angle in our corridor began to look careful and hid small irregularities.

As you already understood, the outer angle can be aligned and protected from damage using plastic corners. Now we are talking about those corners that glue right on top of the wallpaper. In construction stores, they are represented in different colors. Corner length is usually 3 meters, but the width is different: from the very narrow to wide. You need to choose in width, depending on how much the angle is heavily.

The more flaw, the wider there will be a corner. Look in the photo below, in stores you can find rectangular and even semicircular corners. Before you buy, think about which corner is suitable in your case.

The more flaw, the wider there will be a corner. Look in the photo below, in stores you can find rectangular and even semicircular corners. Before you buy, think about which corner is suitable in your case.

But there are also such corners that stick to external or internal angles even before the walls are pasted on the walls. These corners are glued into the inner or outer angle, put off and thanks to this angle becomes much smaller. The wallpaper is pasted on top, decorative plaster or other finishing finish is applied.

As already mentioned earlier, a plastic corner can be closed both external and inner corner and even a bog between the wallpaper. But then it will not be a corner, but a plastic strip. Some decorative plastic corners are equipped with a sticky ribbon, removing the protective layer from which, without using glue, stick plastic on the wall.

Plastic corners look good on the walls with wallpaper. But with the tiled plastic, it does not really fit. But if you are not against the combination of plastic and tile, you can use them together.

There are plastic corners that are decorated for metal, such corners can come to almost any tile.

Ceramic corners can be used to finish the external and internal angles of walls with ceramic tiles.

If an external (or internal) angle is completely far from perfect, you can hide it flawed under decorative stone.

In construction stores you will find that shade and shape of an artificial stone that you like.

Why you can not give icons

Why you can not give icons Is it possible to give icons as a gift: Signs, the opinion of the Church

Is it possible to give icons as a gift: Signs, the opinion of the Church A year ago left her husband, and now I do not know what to do

A year ago left her husband, and now I do not know what to do