Screed springs shock absorbers. Fixture for quick disassembly of racks, replacement (compression) springs on them machine for compression springs racks with their own hands

One of the main procedures for repairing the front suspension is to replace the racks. This refers to cars with suspension MacPherson, when the rack is collected. That is, the rack is a shock absorber, spring and a support with a cup. All this is fixed with a nut, which is screwed onto the shock absorber rod. As a result, the rack is in constant "combat readiness", when the spring works for compression, and the shock absorber.

But in this article we want to tell not about the work of the racks, but how hard it is sometimes necessary to carunts when removing the spring. The fact is that the spring on the rack is quite powerful, which means the effort of its compression is very large. As a result, when sprinkling the nut on the spring rod can "shine", which can lead to injury. Yes, moreover, during the back assembly, the question will be asked how to assemble the rack back, that is, to squeeze the spring. To help car enthusiasts in this case are proposed mainly all kinds of springs. Usually it is a system of rugs with hooks or washers. As a result, the combination of springs occurs due to the twisting nut along the heel. This method of removing the spring is quite vital, however, has its drawbacks. The main of which is a great time to twist the sprinkling of the hairpins. In this article, we would like to offer you another alternative, perfectly asking for this task, while it requires a much smaller effort from the mechanic.

Device for quick disassembly of racks, replacement (compression) springs on them in the garage with their own hands

The principle of operation of this device is based on an increase in torque due to changes in the shoulder of the application of force. You can say a classic solution for most cases in mechanics. So the points of the support will be the wall to which the console is traditionally shred and the rack or rather spring. Here, the efforts attached to the rack will depend on the length of the lever of the shoulder. In fact, these are the knobs of our device. You can simply sit and human weight are enough to squeeze the spring. Take a look at the drawing.

And now in order, as it will be replaced, the removal of the spring from the rack. Initially, it is necessary to breed the shoulders of fixtures and install on a cup over the spring. Next, we fix the shoulders to be fixed, for example, a pipe segment.

Dale just sit down on the pipe and thereby squeeze the spring. The spring's effort can be adjusted with your own body, sitting on the lever a little further or closer to the rack. We unscrew the nut holding the rotary support and the springs cup.

Neatfully get up, thereby removing the stress of compression on the spring itself, which is still installed on the rack. After straightening the springs, we remove it from the rack.

Installation and compression of the new springs produce in the reverse order.

Summarizing the springs removal ...

It must be said that the use of such adaptation is justified especially in cases where the replacement of the spring on the racks of this type occurs often. Mostly it is car service. It should also be noted that the device is universally. It can dismantle the springs from the racks of any car, in fact changing the height of the shoulder, which is pressed the spring. Works related to the removal and replacement of the spring when applying such a device will be significantly simplified, which is perhaps the determining factor in solving the issue of making something similar in your garage.

If you need to repair depreciation racks or car suspension, then the question arises than to pull the spring of the shock absorber. To achieve this goal, use splas for springs. They are needed to squeeze and remove the spring of any type.

Spring screed equipment

Splies for springs can be two species, depending on the basic principle of operation:

Mechanical - based on mechanical action on the spring. The price of them is low, and they are often used by car traffickers.

Hydraulic - The spring action is created using a hydraulic pump. Used in large car services. The price is much more expensive.

Spring puller can also be portable and stationary. At a price, it is not very different, but they drastically differ in the method of use. If you decide to repair the vehicle yourself and do not know which puller you need, it is worth paying attention to the diameter of the compressible spring. This is the main characteristic when choosing a screed.

The car service usually buy compressors with a large range of possible sizes, as they are used to different machines. If you did not refuse the idea to independently repair your vehicle, then you need to pay attention to the fact that some models of the screeds are offered by the manufacturer specifically for the suspensions of certain types. But there may be universal.

How to make a tie device yourself

If you calculate the price of the component puller for the springs, it will turn out to be significantly lower than the price of the finished puller. Therefore, the question arises: how to make a sprout puller with your own hands. It is possible to make springs for springs yourself. But at the same time it is necessary to have a welding machine and the ability to make something with their own hands.

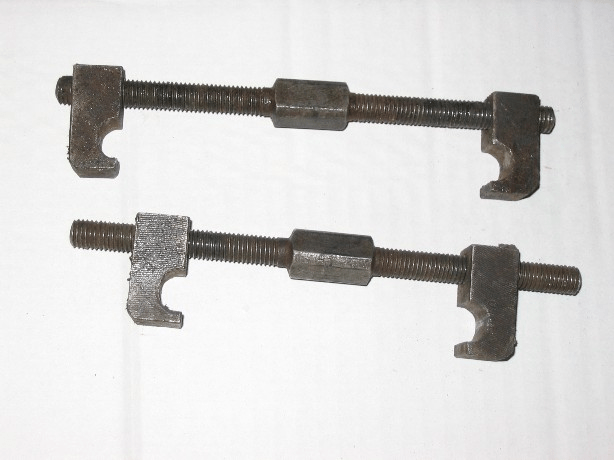

It is clear that the principle of their action will be based on the mechanical impact on the spring. For one spring, two ties, fixed from opposite sides for uniform compression. Their design is standard: a threaded rod with hooks and nuts. Rotating the key rod or nuts, can easily compress the spring. Since the design is simple, it does not require special skills in the manufacture. But it should be remembered that the device you make should be reliable because now you are responsible for your health.

It is clear that the principle of their action will be based on the mechanical impact on the spring. For one spring, two ties, fixed from opposite sides for uniform compression. Their design is standard: a threaded rod with hooks and nuts. Rotating the key rod or nuts, can easily compress the spring. Since the design is simple, it does not require special skills in the manufacture. But it should be remembered that the device you make should be reliable because now you are responsible for your health.

Required tool

So, you need to have welding machineand bulgarian. It is also necessary to purchase two thread rods with a diameter of 16 mm, four long nuts under this thread and a steel pipe with a diameter of 16-16.5 mm, reinforcement.

Manufacturing process

Consider the process of manufacturing screeds of springs of shock absorbers on points:

1.

Cut the threaded rods (2 pcs.) Of the desired size. Their length should be no less than the length of the spring in the free state. Too long rods will be inconvenient to use;

1.

Cut the threaded rods (2 pcs.) Of the desired size. Their length should be no less than the length of the spring in the free state. Too long rods will be inconvenient to use;

2. From the reinforcement, cut (8 pcs.) Billet for hooks about 30 cm long;

3. Cut the cylinders from the pipe (4 pcs.) Approximately 10 cm long;

4. From the reinforcement blanks, bend the hooks;

5. Using welding, brew two hooks to each cylinder. We produce the process of welding on the plane, achieving the symmetry of parts;

6.

We collect components (we put two cylinders with the counter direction of hooks and screw the nuts on the ends).

6.

We collect components (we put two cylinders with the counter direction of hooks and screw the nuts on the ends).

In some structures in the middle of the threaded rod, a long nut is welded. Then the compression process is made by the key, turning the rod itself for this nut. Make a screed for springs by using an old jack. The main thing is that it was reliably and safely. Consider the process on items:

1. Shorten a little feet of the jack. Watch that it does not affect the work of the jack.

2. From the subwoofers, pick up the rack holder. For example, we can take a rod head or another suitable part with car disassembly. It is necessary that it is a suitable form and could withstand heavy loads.

3. Fresh the feet of the jack and the holder. Since they consist of different materials, the use of welding is impossible. Therefore, drill holes and fix two bolts

4. On the top of the jack, we weld the top holder from the metal corner. For reliability, we make it a little longer in the form of a cut letter A and weld the additional edge of the rigidity to the housing of the jack.

5. Using paint, give the design aesthetic look.

This holder is much more convenient to use than purchased. The described methods for making screed springs of the shock absorber are not the only one. They may differ in sizes used by materials and infrident means. It is worth incorporating fantasy and properly adjust unnecessary details in your garage at first glance, and this creative process will bring you pleasure not only financial, but also moral.

How to pull the spring

Since the process is a bit dangerous, then we list all the items, of which the springs consists in order to secure it completely. Follow the main points:

1. Raise the car to the jack and from opposite sides, install two ties on the spring;

2. Rotate the nuts with your fingers to the reliable hook hooks and springs;

3. Continue to rotate the nuts with the key. Moreover, the rotation must be carried out in small steps on different rods alternately. The spring must shrink symmetrically on both sides.

4. Remove the spring if you are surely convinced that it is reliably compressed with tie.

Using the device for compressing the springs of the rack with their own hands, stick Rules:

Threaded connections lubricate with solidol before using springs for springs.

Never shoot ties with a compressed spring, even if it is pulled by an extra strap or wire. It may be dangerous.

Care carefully. It is important that devices made by their own hands were safe to use.

Sometimes there are such cases in which the repair has to be performed in the field. And then the presence of screeds for springs is very problematic. There is a question of how to pull the spring of the rack with a screwdriver. And this is possible.

Sometimes there are such cases in which the repair has to be performed in the field. And then the presence of screeds for springs is very problematic. There is a question of how to pull the spring of the rack with a screwdriver. And this is possible.

If you removed a rack with a shock absorber and want to compress the spring of the shock absorber for further repair at home, you can use seat belts.For this you need two belts. We produce them through the springs springs one opposite the other and tie a bunter each. At the same time, the extreme springs turns should not participate in the compression process. Next, two reinforcement rods or two metal pipes are needed, or just strong wooden sticks. They will serve as levers.

We put the spring on the side, go under the lever under the belt and tighten the belt several times in the middle of the lever. For fixation, we bring the lever with the help of the wire to the coats of springs. We turn the design to the other side and with the help of another lever we do similar actions. If the spring is not complicated, then alternately twisted the levers and do not forget them to fix them.

After the spring is compressed, we carry out further repair work. At home, squeezing the spring of the shock absorber can be used by various means: using vice, etc. All the ways are good, if only they achieved the ultimate goal and were safe for you. After analyzing all the options, you must choose for yourself the optimal, which will bring you a satisfactory result.

Sometimes it is required to squeeze the suspension spring without removing it from the car. For this you need ties. In a simple case, two or more rods are supplied with so-called horses. Hooks with their hooks cling to the spring outside. All ties, as a rule, are placed from the opposite sides of the spring. And then, rotating the key threaded rods, you can easily compress.

Of course, there is a special equipment used in the repair of a network of a certain brand. For compression springs, however, universal ties are used more often. The appearance of these devices is shown in Figure:

Branded springs

It is clear that the set of universal screeds can be bought in the store. However, the cost of such equipment is higher than the price of all composite elements in the amount.

Cooking screeds yourself

In general, the screed springs of the shock absorbers makes sense to make it yourself. How to do it, is considered further.

Four nuts and two threaded rods

Metal products listed below are easy to find almost in any supermarket. For example, you can buy two rods with M16 thread. You will also need four elongated nuts, as well as steel plumbing pipe. Its inner diameter is 16-16.5 mm.

As a result, it will turn out what is shown in the drawings. It will also be needed by a steel rod that goes to the manufacture of reinforcement. Consider how tags are made:

- Two identical cylinders are cut from the pipe, the length of which is 80-120 mm;

- Threaded rods can be shortened if necessary;

- From the reinforcement is made by 8 rods of about 30 cm;

- With any bending equipment, the rods are bent so to get hooks;

- Four rods weld to two nuts, four more - to pipe segments;

- The set of components at this stage is fully ready for use.

Welding is easier to perform, placing the blanks on the plane. The essence of these words is illustrated in the picture:

How to breed rods hooks

Actually, the film is then given, where the technology is shown "from and to". The author even solved the problem with the lack of a bending machine: To bend one rod, two of the same rods welded to the steel profile are needed.

If the reader believes that the use of welding is difficult, it is better not to risk. Welded connections are withstanding a significant load, but only if they are fulfilled in all the rules. Screed springs can be made without welding. The appropriate drawing is given below.

Two ties in 10 minutes (video)

How to pull the spring?

We list what steps turns on the screed of the shock absorber springs, carried out by their own hands. Everything looks simple:

- When the body is held by the jack, the spring brings two ties from opposite sides;

- Rotating nuts with hands, achieve confident engagement of hooks and springs;

- Using the key, nuts on different rods rotate in turn;

- It is better to be restrained and secured the sprayed spring with straps or wire.

Video screed springs on shock absorber

Explanations are not required here. The result is shown in the photo.

Spring compressed by tie

Using self-made and even purchased equipment, adhere to simple tips:

- Before using screeds, threaded compounds are lubricated with cyatim or solidol;

- With a compressed spring, it is impossible to remove the screed, even if it is fixed additionally;

- Conducting work, observe maximum caution. It is better to sacrifice body details than your own health.

Features of car suspension Lifan are treated in these articles:

Drawings of universal threaded screed

Let's return to the question of how to make a device for scrolling the springs of shock absorbers. The appearance of the finished devices is shown below:

Threaded ties made at the factory

On one side of the rod, the left thread is cut, on the other - right. Thread step is used standard, M18. But buying threaded rods do not do here. And to cut the threads themselves, you will need special equipment.

Drawings of the nodes constituting the entire design are given here:

Threaded screed (3 parts)

To make parts, you need to have turning, drilling and, probably, the milling machine. Perhaps it is easier to contact the workshop. Print the drawing by downloading it from the site.

Most likely, there are no other drawings of universal screeds on the Internet. And the fact that is shown above is taken from the repair of domestic cars. You can use.

Suppose the screeds were made according to the drawings and all the details are suitable for each other. But then the advice on the use of lubricant remains in force. It is necessary to take solidol or cyatimes and apply this material on the threads of the nuts.

Packaging cyatim-201, 20 gr.

Catimit-201 lubrication - the material is quite expensive. You can reduce consumption, mixing it with machine oil in a proportion of 50/50. Good luck.

The article will be told how to make a useful device for every car and motto amateur.

Sometimes it becomes necessary to overdo the old shock absorbers, replace the gland or other worn parts. True, they need to be disassembled for this, and it is not so easy to remove the springs from them and install them back after repair. Of course, there is a large selection of ready-made, factory farmers, but they are pretty decent, and there is no need to use them as often.

Here are the factory extractors:

The design of the puller presented in the article is extremely simplified, as they say "all ingenious simply!".

To create fixtures, you will need:

- hairpin and nuts to her;

(The thickness of the stud depends on the thickness of the springs that will need to be removed, the author used the stud thick 12mm)

- Two crescent on the hairpin;

- tube on the diameter of the stud;

- Bulgarian;

- Welding machine.

First you need to cut off two pieces of studs of the desired length, the more, the more universal puller will work.

Such sites are welded to the crescents to increase the area of \u200b\u200bcontact with spring:

On the other hand, the puller dresses such such a bracket. A springs retainer welded on a suitable diameter of the tube. The bracket does not have threaded connections, and freely slides on the heel:

To squeeze the spring, the nut is screwed over the bracket, and is dragged to the desired springs compression.

Here are photos of the finished puller. As you can see, the mechanism works.

Why you can not give icons

Why you can not give icons Is it possible to give icons as a gift: Signs, the opinion of the Church

Is it possible to give icons as a gift: Signs, the opinion of the Church A year ago left her husband, and now I do not know what to do

A year ago left her husband, and now I do not know what to do