Wall facing technology with ceramic tiles - gradually and detail. Tile work: Basics of cladding technology Facing wall tiles on a given drawing

Each owner of the house or apartment is sooner or later faced with the question than to bind walls in the bathroom or kitchen. There are many options. For example, for surfaces with high humidity, and, and. But the ceramic tile is a practical and affordable material that is not afraid of temperature drops and suitable for operation in conditions of high humidity. Therefore, the cladding of the walls of the ceramic tiles (bathroom, kitchen) for many years keeps leading positions among the options for design of the premises. But that the coating serve for a long time, it needs to be correctly chosen and put. Consider the nuances of the preparation of walls to cladding, as well as the technology and secrets of laying ceramic tiles.

Choosing tile

Tile speciesHaving an idea of \u200b\u200bwhat repair you want to do, having decided on the color range, you can go for the material. Ceramic tile is a few species:

- Ordinary. Standard tile, having a corrugated surface on one side and glazed decorative - on the other. It is produced in several sizes (calibers) and is used to create the main part of the coating.

- Shaped. Such material is different from ordinary complex forms, allowing to bind uneven surface and carefully draw corners.

- Outdoor. Floor tiles with high strength and anti-skid properties. It is often used as an outdoor coating for a bathroom or kitchen.

- Mosaic. Mosaic is small fragments (with a side of 5-7 cm) of which the general picture is formed. Laying such a tile requires a creative approach and takes a lot of time and effort.

All listed species have several strength classes. This concept is consistent from the ability of the tile to withstand physical exposure and its resistance to abrasion. The highest level of strength at the tile for outdoor work, it goes outdoor, and then wall.

Another important indicator is moisture resistance. For the bathroom, the material should be purchased with elevated moisture resistance, this will prevent the formation of fungus and extends the service life of the coating. For the kitchen, the requirements for this indicator are more loyal.

Tile marking

Tile marking If it is planned to facing ceramic tiles of outer walls, pay attention to the frost resistance of the material. This property allows tiles not cracking when the temperature drops. A tile suitable for the exterior decoration of the building can be determined by the snowflake painted on the packaging.

For the harmonious design of all the premises, it is better to purchase ready-made sets in which the walls for the walls and the floor are included, made in one style, as well as borders and additional decorative elements. When buying a large tile volume in one tone, check the color match in place, since due to the specifics of the tile production it happens that the material claimed as the same, has a different shade.

Often there is a question whether to take a tile with a margin and if so, what? Manufacturers usually pack material with a 5% margin for possible damage, so you do not need to take the tile. In order not to make a mistake with quantity, pre-perform calculations of the need for material (in a special program or manually) and buy it, taking into account the fact that all the tropped tiles are considered as integers. Acquire a ceramic tile is still better in large stores or markets for repair, since in this case there is a high probability that the missing tile of the same shade can be purchased.

Tip! By purchasing tile, carefully check the information specified on the box - information about the manufacturer, name, variety, material size, its color and quantity.

Alignment of walls

You can only lay the tile on the pre-prepared surface. At the same time, special attention is paid to the deviations from the plane, that is, various flaws that violate the solidity of the walls. To identify irregularities, the walls are checked with a plumb (cord with a loader at the end) as follows:

- In the wall under the ceiling every 1.5 m clog nails.

- It is binding to the nails alternately tie a plumb and measured with a tape measure between it and the wall or determine the evenness visually.

Wall alignment Plaster

Wall alignment Plaster This method allows you to make sure the verticality, and the horizontality is more convenient to measure with a bubble level or perfectly level rack. If you use a rail, attach it to the wall and see what the gap is formed between it and the plane. With a width of a clearance of more than 2 mm, the surface must be aligned.

If minor flaws are detected, they are eliminated by plastering. When waving a wooden surface, a small metal grid is stuffed before applying the composition on the walls. It is fixed not directly to the wood, but on the pre-fixed bruks with a thickness of 2.5 cm and 3 cm wide, and the rubberoid layer is also placed under the grid. A cement mixture is applied on top of the grid with the addition of cellulose fibers, and from above - a layer of standard plaster (not thinner 1.5 cm). This significantly reduces the area of \u200b\u200bthe room, but the tile, laid on this surface, is kept tight and long.

Plasterboard simplifies wall alignment

Plasterboard simplifies wall alignment Preparation of the surface of the wall

Even if the walls are quite smooth, they still need preparation, especially for painted surfaces. First you need to remove the old coating. It is more convenient to perform this work by a perforator with a nozzle in the shape of a blade, the Bulgarian is also suitable with a picker. If the paint rests badly and peels, it is possible to remove it using a cycle or spatula.

Priming - Mandatory Surface Preparation

Priming - Mandatory Surface Preparation After cleaning the wall, the walls are sanding with a grinding machine and divened. Completes the preparation of applying a primer mixture of deep penetration. After its drying, you can start styling.

End of ceramic tile on the wall

Another task with which you need to cope before starting the installation of the tile is to think about the location of the series. Preference should be given to the option at which the number of trimming will be minimal. The calculation of the occurrence of whole tiles in horizontal rows starts from above, so that the trimming falls on the first floor of the floor. So they will attract less attention.

Vertical rows are considered from any of the corners. If without a trigger, it is advisable for symmetry to put two identical trimming of the tile on both sides. When calculating the series, be sure to take into account the intercutric seams, each of which usually has a width of 2-3 mm (depending on the size of the crosses used). By choosing the optimal position of the rows, go to the installation of tiles.

Wall Facing Technology Ceramic Tiles

First of all, a metal profile is fixed on the wall along the start of the second row. A tile will rely on it, because the laying is performed from the bottom upwards, and the first one from the floor, as already mentioned, laid out of the trimming last.

If you use the cement-sand mixture to fix the tile, then the tile is pre-soaked in water. This will prevent the moisture of moisture from the solution. When laying on tile glue, such preparation is not required.

By kneading glue, follow the instructions specified on the package. So that the mixture is homogeneous, it is better to use a drill with a mixing nozzle. By consistency, the adhesive solution should remind a thick sour cream, not spread and not be too tough.

Glue distribution

Glue distribution The prepared composition is applied and distributed to the toothed spatula, covering at a time the surface corresponding to the area 3-4 tiles. Stacking starts from the starting row, gradually lifting up. Between the tiles are inserted by plastic crosses that regulate the size of the seams.

Note! Crosses are removed after the completion of the cladding, but before the glue is completely dry.

Having finished laying out one row, the installation of the laying is tested by the construction level. If protruding tiles are detected, they are neatly deepened, closing the rubber hammer. Too deeply lying tile is removed, they apply more glue and set back. The order of work is repeated for each row until the cladding of the walls will be completed.

Beginning of work

Beginning of work In places location of sockets, pipes or other objects, the tile is cut along the desired form of a tile cutter or a drill with a diamond-crown diamond. About how and what to cut ceramic tiles correctly, read in a separate one. The latter lay down the lower row. If you finish working in one day, it fails, before the break, the lined surface is purified from surplus of the solution and removed the crosses.

After styling, defects are sometimes detected, one of them is incomplete filling and no docking of seams. The deviation of up to 2 mm is corrected by a grouting mixture, but with greater discrepancy, the tile is removed and stacked again.

Grouting or Fuggement of Intercine Shvi

Completes the installation of the tile processing of seams. It is performed after the day after the end of the facing, when the adhesive composition is completely dry. Grout Protects the seams from the penetration of moisture, reproduction fungus and performs a decorative function, hiding the color of glue. With a properly chosen mixture (fugue), ceramic tiles for walls not only serves longer, but also looks harmonious.

Shave formation

Shave formation In front of the grout, the interlocking seams are cleaned from excess glue with a thin spatula or sewer and wipe with a wet sponge. The composition (more often polymer cement) is bred with water in the proportions indicated on the package and applied with a wide rubber spatula. Press the seams a neat form will help trim the cable with a round cross section or a special tool for the bunch.

The composition is left to dry for 2 hours, after which they are removed on the surface of the material the divorce moistened in water with a sponge or rag. The finished coating is recommended to be treated with a special polyrolon.

Attention! If you already have lined surface tiles in the house, then you can update the old coating, simply reinstalling the seams. This will not only improve the appearance of the coating, but also help get rid of the fungus, which can be dangerous to health.

The finished surface is wiping and polished

The finished surface is wiping and polished As you can see, cladding the walls with ceramic tiles, although it requires care and a certain skill, for everyone. Good repair!

Facing the walls tile requires certain knowledge and special tools, there is an opinion that any person can perform this type of work, but it is not. There are many technologies and nuances, inaccessible to the ordinary master, applying and following which a professional will perform styling in accordance with a single SNiP standard.

Do not forget that the installation of a ceramic "shirt" is the final stage of improvement, a kind of face of the room. Therefore, it should be not only a practical element of the decor, but also to perform protective, water-repellent, flame retardant functions. The main part of the work remains invisible, but it is from them that the quality of the finish depends.

Cost of lining wall tiles

Having ordered the facing in San Sanych, you can not only save on the purchase of material, but also to get highly qualified services at an affordable price. Thanks to a variety of constructive, stylistic forms, modern ceramics can be laid in the bedroom, living room, kitchen, bathroom. It all depends on the main goal, as well as the financial capabilities of the customer.

| Name of works | Units. change | Price per one. |

|---|---|---|

| Facing the walls with ceramic tiles of standard sizes with grouting seams, on the finished base | m2. | 633 rub. |

| Facing the walls with ceramic tiles of non-standard sizes with grouting seams, on the finished base | m2. | 782 rub. |

| Facing wall tile under the brick, stone on the prepared surface | m2. | 748 rub. |

| Facing of slopes, pillars, semi-column ceramic tiles | mP | 748 rub. |

| Facing walls with porcelain stoneware over non-standard sizes | m2. | 978 rub. |

| Facing wall marble plates | m2. | 1093 rub. |

| Installation of panels from tile, porcelain stoneware | m2. | 1001 rubles. |

| Installation panel mosaic | m2. | 1783 rub. |

| Installation of border, plinth, corner, facade, window tiles | mP | 127 rub. |

| Facing the floor with ceramic tiles with grouting seams, on the finished base | m2. | 610 rub. |

| Facing the floor with a stoneware, with the grout of the seams, on the finished basis | m2. | 748 rub. |

| Laying tile ornament | m2. | 679 rub. |

| Facing steps with tiles, porcelain stoneware | m2. | 771 rub. |

| Facing of walls, floor mosaic tiles, from | m2. | 978 rub. |

| Installation of layouts on corners | pC. | 58 rub. |

| Audit Luke Door Device | m2. | 1093 rub. |

Surfaces in the apartment decorated with material from ceramics are practical, durable, unpretentious in care. The extensive color palette allows you to pick up a cladding for a specific destination of the room.

The final cost of cladding the walls with ceramic tiles is made of:

- Market price, dimensions.

- Cost of consumables.

It is necessary to understand that finishing work using small, as well as the extra-class tiles will cost more, as the service time is increasing and the risk of damage compensation in the event that individual elements of the material are deformed or corrupted.

When ordering a comprehensive landscaping services, you can get a discount from the work of work.

The glue tile installation is the most reliable way to seal the surface of the walls, while making them more beautiful. This type of wall finishing does not require any special skills and even allows you to do without helpers.

But starting to work with your own hands, you need to remember that there are certain rules of cladding with ceramic tiles. If you want to get a high-quality durable coating, they must be observed.

Cognitive information about ceramic tiles

When it comes to finishing the outer walls of the house, the wonderful properties of ceramic facing tiles acquire a special value, because the service life of the supporting structures with such a coating increases significantly. Modern finishing materials produced so quickly develop that in a rather short time, new items appear, as well as traditional products, but somewhat enhanced.

- This tendency and ceramic coatings are not bypass - all the well-known materials that retain their popularity. In this chapter, we will describe everything about the facing ceramic tiles: the composition of the raw materials used in the production, methods of molding, options for coating the front surface. Your attention will also be presented video on this topic.

Methods of production

Construction ceramics produced in three main ways:

- First and main way - This is a semi-dry pressing of powder raw materials whose humidity does not exceed 7%. Almost all the front tiles produce this way, it turns out as strong as possible and frost-resistant.

- Second way - casting. It uses a gloa aqueous suspension, which has humidity to 33% as raw materials. In this way, the tile for interior decoration is made.

- Third Method of Production Tiles It is carried out by plastic molding of products from the masses whose humidity is in the range of 15-20%. It is used mainly for the manufacture of brick and stone imitation.

In clay raw materials, mineral additives are present in the form of quartz sand, field spat, vermiculite, perlite, glass or slags. As a result of the technological processing of the raw material: molding, drying and firing - single or double, varying degrees of sintering, facing ceramic tiles acquire a variety of properties.

Accordingly, it is determined by the purpose of the tile:

- In order to obtain higher quality products, building ceramics manufacturing technology is constantly improving. All production stages are modernized, ranging from raw material processing, and ending with the decoration of finished tiles. Many producers have their own original recipes, allowing both strength and improve the quality of the face surface.

- Some are injected into the raw ground porcelain, or rather, the waste of its production. Others add enriched coal, the third uses glass components. The dimensions of the facing ceramic tile are also vary, but within the standard installed on these products.

- GOST 13996-93 regulates the production of 15 sizes of the facade tile, the largest of which is 300 * 150 * 9 mm. This case is about tiles intended for adhesive editing. Ceramics cladding can be performed on the system of ventilated facades, where the panels are hung on the frame.

- For this purpose, on the contrary, large modules are used more often, the length of which can reach and six meters - but today we are not talking about them. Adhesive cladding with ceramic tiles of large format on vertical surfaces is not welcome.

Large weight requires anchor fixation, otherwise it will not last for a long time. The price of the coating is also increasing - and this is not beneficial to anyone.

Most often, the front tile mimics the shape of the brick, and is approximated by size. The pictures given for example are the best proof of that.

Decor for tile

The core properties of the tile acquires its basic properties after the decorative layer is applied. It is he who makes a shard waterproof and unresponsive to pollution. Well, of course, the aesthetics of the product also depends on it.

- Decoration of ceramic products is performed by the most in many ways. For example, it looks to the tile: after a single firing, a thin layer of aqueous dispersion of the glass powder is applied to it, but the undercurious layer is applied to the surface.

- It is done to improve the clutch of the glaze with a shard, as well as to prevent education in the glaze of gas bubbles. After that, the product is sent to the oven for the secondary firing. Mineral pigments are added to the raw material mixture to obtain a colored tile, and also apply under the glaze or on it, heat-resistant dyes.

- Thanks to the computerization of industries, in recent years and the formulations of the glaze, and methods for its application, have been subjected to significant changes. If earlier it was believed that the double firing tiles are of the best quality, today the situation is radically changed.

- Many European manufacturers prefer a single downhill. The aesthetics of tiles are improving and due to repeated introduction to the raw material mixture of pigments of different colors with layered pressing.

- To obtain a color scheme inherent in natural stone, soluble salts are injected along with mineral pigments. Ceramic base, by analogy with a laminate, can be compressed with decorating material having a given drawing. This method is often used in the production of porcelain.

In the production of facade tiles, as well as furnace tiles, a relatively new invention is also used, which is called the ceramic mass for cladding. This is a raw material mixture, which includes a lightweight and refractory clay; porcelain and glass fight; Sand scattered vermiculite and sulphite-yeast mug.

Such masses allow you to obtain more durable and lightweight tiles with excellent thermophysical properties.

Facing work

Choose a beautiful and high-quality tile - it is only half. The main thing is that Ceramic cladding technology has been observed in accuracy. Only in this case and the result will delight, and there will be no extra cost.

The instruction presented in this chapter is to help those who are faced with this work for the first time:

- Lining the facade of the house, it is not the same thing that the walls of the walls in the kitchen or the decoration of the bathroom. First of all, the volumes of work are distinguished. Consequently, that the process of their execution does not become too time-consuming and did not delay in time, it is necessary to purchase a tile.

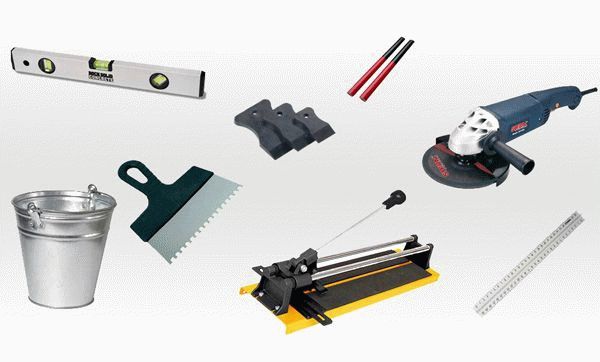

In addition, you will need a drill with a cooler and a member "Mixer"; Tile plugs; rubber hammer; rule with the level; Marking cord and plumb; toothed spatula; Curved extending and brush - and even better a spray gun. And, of course, you should take care of the subject or forests that allow you to work at the height.

The quality of glue is a pledge of durable coating

The main consumable material used in the execution of facing works is a glue solution. It can be made independently, but you can buy.

- The second is somewhat more expensive, but with minor volumes of work, this difference is not too significant. If the building is large and it is supposed to bind completely, it is more advantageous to mix the solution yourself. Pay your attention to some essential nuances.

- A binding substance of the solution for installation of ceramic tiles is cement. When it comes to outdoor work, the cement used brand should be not lower than M300 - in any case, when the base is concrete or brick.

- Lightness is permissible only for mounting tiles along the plaster, insulation or with the facing of asbetic partitions inside buildings. Here is one of the rules adopted in construction, which should be observed: the strength of the adhesive solution should be approached by the strength of the base.

- In order to strengthen the strength characteristics of the adhesive layer, the modifying additives must be present in its composition - they are in factory mixtures. So that you do not have to dose certain additives during the independent manufacture of the solution, it is easiest to buy a plasticized portland cement.

- The necessary additives are used in its production, while the cement brand rises to M400 or M500. The plasticizing effect is necessary to reduce the share of water in the solution, and, consequently, increase its density. At the same time, the composition acquires frost resistance and water-repellent properties.

- The mandatory element of tile glue is also sand, and it would be a mistake to think that its quality does not affect the quality of the solution. Affects, and how! For the manufacture of facing solutions, sand should have a medium or large fraction and the content in it should not exceed 1% of the total mass.

- The ratio of cement and sand in the solution depends on the cement brand. If it is M500, then dry ingredients are combined 1: 6. Water is added until a convenient consistency is obtained - it is approximately 30% of the total mass of dry aggregate. By the way, repairing cladding from ceramic tiles can be performed as the same solution.

The amount of glue made in one kneel should be such that it can be time to work up to the loss of plasticity. To reanimate the frozen mixture by adding water to it useless.

Preparation of base and facing

The durability of the facade ceramic finish depends not only on the quality of the tile and the right solution for its installation. An important role is played by the quality of the foundation to be awarded.

So:

- That the result ultimately pleased, the vertical surface should be carefully cleaned, if possible, aligned and primed. External corners in cladding ceramic tiles are of paramount importance. They must be even, and otherwise it will be difficult to mount the angular tile elements.

- Especially sinning the irregular angles, as, however, the walls of brick houses. Therefore, the first thing you need to do after stripping is tooling. That is, with the help of a plumb and the rule, it is necessary to identify the surface deviations from the vertical, circulating them with chalk. All recesses of a depth of more than 1.5 cm must be attached - for this you can use the same solution as it will be used for tile sticking.

- If irregularities are more significant, cladding technology with ceramic tiles provides pre-installation of a plaster grid. Do it all over the area or only in those places where there are excavations, you need to focus on the situation. To align the corners, it is better to use a plastering corner with a grid.

- In any case, the grid will improve the clutch of the solution with the base base and make the facing more durable. If the walls are very uneven to remove their surface into a single plane, you need to install beacons before plastering. How it is done correctly, you are easy to understand, looking at the video. After the walls are aligned, the tile sticker becomes, as they say, the work of technology.

- The main thing that you need to pay attention is the thickness of the adhesive layer. It must be at least 7 mm and should not exceed 15 mm. The minimum and maximum thickness is established by construction standards. The fact is that when cladding, especially in hot weather, water from the solution is actively absorbed by the heated surface of the walls.

Note! The thinner the glue layer, the faster it loses moisture, and therefore the strength of the screed will decline. As a result, the tiles will be flawed from the walls - if not immediately, then in the near future. Therefore, the veneer surfaces are not subject to the sun.

- Excessive thickness of the adhesive layer also contributes to the loss of tiles. In this case, the reason is the shrinking deformation of the solution. That is why when cladding the tiles are not mounted close, but leave horizontal and vertical seams. Their uniformity is ensured due to the installation between the tiles of crosses.

- The allowable width of the seams is also regulated by the rules and depends on the format and thickness of the tile. The horizontal of seams is ensured by mounting a wooden plank or a metal corner along the bottom perimeter of the wall. After all, the facing is lowered up, starting from the corners, and the starting plank is supported for the first row of tiles.

- If the wall is long, ensure the horizontal of the remaining rows to the eye is quite difficult. For a reference, specialists use the moist cord. The vertical of the rows is controlled by a plumb.

You do not need to make tiles before the sticker. The solution is applied to it with a rotary spatula, roll up and pressed to the base. The position of the tile in the facing is adjusted by light tapping of the rubber hammer, and the surplus of the solution is removed.

Then, without waiting for solidification of the solution, from the interlocient seams using a curved branch, a sample is made. Subsequently, these notches will be filled with grout.

Facing the walls with tiles is a rather complicated event that requires compliance with a certain technology that allows you to create a truly reliable and beautiful coating. Of course, currently this material is used much less than in the old years, but its popularity is steadily returns. This is due to the fact that the tile has numerous advantages that cannot be underestimated.

Some time ago, this material was used exclusively for lining of bathrooms and shower rooms, as well as a kitchen zone. The arrival of new materials to the market pins the tile from its rightful place. In addition, the product was distinguished by a rather dull decorative species. Now the situation has been extremely changed. What is the reason?

- Wear resistance. What other material boasts that within fifty years can save its qualities.

- Strength. There is a small load on the walls, but it is capable of spoiling any decorative coating. Finishing with tiles is an excellent solution that will avoid almost any problems.

- High hygienic indicator. This property remains unnoticed when it comes to other, more expensive materials. But the human health depends on it. The tile does not absorb foreign smells and pollution, which prevents pathogenic microbes.

- Excellent moisture resistance. No wonder it is used in rooms with high humidity.

- Absolute environmental friendliness. Ceramics does not allocate substances harmful to health.

- Fire safety. Due to the technology of manufacturing the material used - the product does not burn and does not contribute to the spread of fire.

- Wide selection. There are various types of wall tiles. But pleases the other, a great many diverse decorative options have appeared, which allow you to create real masterpieces.

There are some drawbacks:

- Bad sound insulation. Indeed to create reliable sound insulation will have to use additional materials that are pre-surface.

- Difficulty in working with walls. If you want to hang on the wall a locker or a shelf, then you have to try. After all, the tile is quite fragile, the wrong abuser will lead to its damage.

- High price. Yes, the cost of the product is satisfied high. Elements with a pattern that are sold piece or square meters are especially expensive. But the plot lined with a cafeter - always looks winning.

It should be noted that one of the shortcomings is the complexity in the work. A certain skill requires that the perfect surface is really. It is not necessary to count on the first time. But it is not necessary to despair, any work can be done yourself. The main thing is to attach the necessary efforts and certain persistence.

What is required for high-quality laying

Naturally, you should prepare a tool that should be in perfect order. The required list is standard, but if need arises, each device can be replaced with a suitable option.

Use:

- Separate water tank. The volume should be more than five liters.

- Tar for kneading a solution. It should be convenient for the preparation of the mixture and for its fence.

- Master OK. This tool can be replaced with a metal spatula.

- Rubber spatula. Need for grouting seams.

- Toothed spatula. They apply a mixture.

- Various measuring devices - roulette, level, cord.

- Kiyanka. Many use a wooden hammer, but the rubber weapon is much better.

- Passatia. Conventional nippers are suitable.

- Spray.

- Platekorez. The tool should be reliable, some cheap options are simply failed.

- Set of dowels.

Separately acquired a solution (mastic) for sticking and grouting.

Independent preparation of solution

The mixture for laying tiles can be prepared independently. This does not mean that it is impossible to trust purchased options. It simply makes it possible to determine the cost savings.

The most common composition that is used to work is cement. It serves as the basis for which sand (sacred) and water is added. Their ratio may vary.

There is a standard option that suits almost all types of work with tiled material. For the mixture you will need:

- Cement (M400) - one part will be required.

- Sand (shallow fraction) - Two and a half is taken.

- Water is half.

On a note! For one part - a conditional indicator is taken, the container in which the ingredients is set. For example, a liter children's bucket.

Mixing begins with dry components. They are poured into one container and stirred. It is required to achieve a homogeneous composition. Next, begin to add water. It is better to do parts, kneading every time.

Check the quality of the prepared mixture

To make sure that the solution turned out to be reliable and high-quality, it is checked. It's just done:

- a separate ceramic element is wetted with water (it is convenient to use a pulverizer);

- apply the prepared mixture;

- tile turn over and shake;

- from the wrong side should remain a layer of cement at least three millimeters.

If it was not possible to achieve such a result, then re-kneading and adding the necessary ingredients (cement or sand).

Conducting facing works in rooms with high humidity - use special tile glue. This will avoid possible problems, as well as to preserve the necessary properties of the material longer.

Surface preparation

Proper technology of wall cladding with ceramic tiles requires mandatory preparation. This procedure can only be ignored in the case when the surface has already been subjected to all necessary manipulations.

It is believed that the permissible vertical error is about six millimeters (two meters of the wall). Check this indicator is simple enough. The two-meter aluminum rail (level) is applied to the surface. Different gaps can be formed between the two planes. If they make up more than six millimeters - marked, these sites should be treated with a plaster mixture.

Tip! When laying a tile, no need to bring the wall to perfection. Small roughness that remains after applying plaster - will even be useful. This will provide a better clutch of the material with the surface.

The general procedure for preparing is:

- All old coatings are removed. It is believed to paint, wallpaper is removed.

- The work plot is carefully closed. This uses a small hammer. It is necessary to determine whether there are voids. In such places, the finish will need to remove and apply a new layer of plaster or cement mixture.

- Fat stains are cleaned. Otherwise, nothing will be kept. Degreasing is carried out by a special solution of hydrochloric acid (three percent). It is applied and left for three to four minutes. Next, we are well washed with water and give dry.

- Breaks that are more than three to four millimeters are knocked down.

- If there is an opportunity, the surface is better to fully shock, removing the old layer. Of course, it will be longer and more expensive, but for old houses, it is the guarantee of the reliability of the coating.

- Be sure to make notches. They are applied in random order on the whole wall. They must be a small depth and will serve for a good fixation of the solution.

- When everything is ready - progress.

On a note! It is not always possible to remove the old paint, while the base remains strong enough. Such a plot must be covered with multiple deep scratches. Only so can ensure that the mixture will hold.

Laying tiles

Facing with ceramic tiles begins with pre-markup of the surface. This is done using a cord. Immediately determines the height of the floor. It is necessary to calculate this indicator in advance. Having calculated all the values, taking into account the size of the seams (it can be different), installed on the edges of the wall of the dowel with self-draws, and stretch between them the cord.

Preliminary marking is done in the case when the laying scheme is quite complex or not necessary skills.

The overall work order looks like this:

Tip! The lower area is better to leave until the last moment of the finishing process. That is, they begin to engage after laying the floor. If necessary, the tile can be quickly cut with stoveturis.

End stage - filling of seams

It should be understood that wall cladding tile is only part of the required process. Followed by .

This way is coming:

- Give tiles to be cured within a day. Mazzka picks up the required color.

- With the help of a rubber spatula - the mixture is transferred to the seams. It is necessary to do it confidently, carefully filling all the intervals.

- Immediately pick up too much and wipe the face of the material. But it is impossible to touch the seam itself. If this is the final stage, you should form a beautiful gap. To do this, you can spend between the elements of the finger. Although when work is to have a lot, this is not the best option. There is a special tool that allows you to work faster.

On a note! For the formation of seams, the cutting of an electrical cable can be used. It is important to choose the necessary diameter so that it does not remove the excess grout. - If the work is carried out at the objects of high humidity, the sealant is additionally used. It is applied with the help of a pistol. Pick up such a composition that will be suitable for a specific process.

- When the seams are frozen - remove excess. This is done with a damp cloth.

Facing tiles allows you to get a beautiful and reliable surface. The main thing is that everything is done in compliance with the necessary rules and without excessive rush.

Facing the inner walls with ceramic tiles is one of the common ways to finish the premises with high humidity. Ceramics is distinguished by strength, durability to all sorts of exposure, it does not absorb moisture and smells, and with a wide range of its forms, colors and textures can not be compared any kind of facing. The ceramic tile is the cheapest material, but it fully copes with a decorative, sanitary and hygienic and protective function. On the benefits of ceramics, nuances of its choice and technology finishing of walls with its help - today's material.

Benefits of cladding ceramic tiles

When choosing a material, it is necessary to make sure that it meets the requirements of the operating conditions in the room where the repair is to be reached.

The advantages of tiles include the following:

- the versatility of the material - ceramics can be used in the premises of any destination;

- ceramics is environmentally friendly, safe material;

- facing is not afraid of temperature differences, therefore, it can be used in unheated premises;

- ceramics is not afraid of high humidity and direct water drop, so it is used in pools, baths, shower;

- ceramic tile forms on the wall a durable, durable coating due to high adhesion with the base;

- when compliance with the technology, facing can be done independently;

- you can find a ceramic tile of different shapes and size. Some collections are presented with original products in the form of rhombuses or polygons. In addition, ceramics is distinguished by a large assortment of colors, drawings and patterns, as well as imitation of the surface of other materials;

- ceramics durable and fireproof, so it is used to clamp walls in the kitchen. The material does not absorb pollution and odors, is easily cleaned;

- this is a hygienic material, so it is used for cladding of walls in medical institutions and laboratories.

Varieties of material

There are several varieties of ceramic tiles for internal work. This allows you to choose material, quality and operational properties and which corresponds to the conditions of a certain room.

Table 1. Types of material

| Illustration | Features |

|---|---|

| It is manufactured by dry pressing method. The surface of the tile is covered with opaque icing. Due to the use of double firing technology, the material is pretty durable and wear-resistant. It can be used as a facing in the premises of any destination. |

| A distinctive feature is white. It is made from expensive high-quality clay using double firing technology. Used as the interior decoration material. |

| Material with a porous structure without glazed coating. It has high strength and wear resistance. It has a rich assortment of shades. |

| It is produced by the technology of sintering of clay raw materials. The finished product has high mechanical resistance. It can be used as an external facing material. Color and gamma is limited to brown and yellow shades. |

| Not kaolin clay is applied as raw materials. The finished product has no glazed coating. Made by pressing. The structure is homogeneous, so the policy has a high mechanical strength. It can be used in high-load facilities. |

In size, the tile is small 5 x 5 cm, the average 10 x 10 cm, 10 x 15 cm and large, when one of the sides comes to 40 cm.

A separate category of material - mosaic. Small elements are pasted on the substrate. This allows laying quickly. Mosaic can be applied as the main finish or for registration of an accent wall, niches, columns - a flexible substrate allows you to build the structures of any form.

The more junctions between the tile, the less the surface lined with it is resistant to moisture. The joke is a potential risk. For interpatch seams, it is necessary to carefully monitor, clean and if necessary to update.

Modern thicker materials have high resistance to moisture and mechanical effects, so long time retain a neat appearance and reliably protect the bases from moisture.

Suitable bases for ceramic tiles

By type of base, which can be used under ceramic tiles, the material is universal. Ceramics can be attached to the CSP, concrete, cement screed, drywall and old and tiled facing. The foundations themselves are divided into those that are specifically prepared for stamping policies and universal. Most of the surfaces need preliminary preparation.

Cement plate

Cement plates form ready-made tiles base. Of all sheet materials, this is the most expensive option, but high strength makes such a base suitable for ceramic facing. CSPs can be laid on the floor and secure on the walls in any rooms, including high and humidity, where the base material is protected by waterproofing.

Gypsum fiberglass

Fiberglass plaster is not familiar GWL or G CLEV. This material is specifically designed as the basis for ceramic facing. The load that such a base withstands is somewhat lower than for CSPs due to less hardness and strength is worth considering. The feature of the structure of the plate is the presence of a core impregnated with water-repellent composition and moisture-resistant coating. Therefore, such a slab is used in rooms with high humidity. Fiberglass in the cooker additionally strengthens it. So that the base was moisture-resistant, do not forget about the high-quality sealing of the joints with silicone sealant.

G Clac

Moisture-resistant plasterboard is made in green or blue. This is a universal base for painting, covering panels and sticking with wallpaper. Despite the name, G Clac to some extent vulnerable to moisture, therefore requires waterproofing protection when used in the bathroom.

GVL

Normal plasterboard is used as a base under ceramic tiles in rooms with dry and moderately humid microclimate. With high humidity, it is necessary to perform high-quality waterproofing.

Note!Ceramic policy is a rather heavy material that affects the basis. So, the plasterboard sheet with a thickness of 12 to 15 mm will not be enough. The walls are sewn with a double layer of plasterboard with a thickness of 12 mm each.

Concrete

Concrete base is one of the universal types, designed and breeds ceramic tiles. The laying process does not cause difficulties with the levels of foundation.

Important!The composition of concrete should not include film-forming substances, which will reduce the level of adhesion between tile glue and base.

Cement strainer

This type of base is a reliable and durable option for tiles. In this case, the screed itself is manufactured on any basis. The screed is made if you need to align the floor and walls, as well as for the device of the shower in the shower. The screed may be required when forming the base of the wrong shape, such as a round column. The disadvantage of this option of the base device is long drying of the screed.

Existing ceramic cladding

Laying a new ceramic coating directly over the existing old one is possible for cement mortar. This will save on the cost and time of work. The main condition is the old cladding should be firmly fixed throughout the wall, while the vertical surface must be perfectly smooth. It is worth remembering that the thickness of the coating will increase as a result of this laying. In order for the new policy to firmly entrenched on such and the base, the old is treated with sandpaper, thereby providing better adhesion with cement mortar.

Features of the choice of ceramic tiles

Ceramics is the best finish option for combined bathrooms, toilets and bathrooms. With its choice, not only decorativeness and the ability to create an optical effect of an increase in space, but also the operational properties of the material are taken into account.

Note!First choose a tile, and after it is a plumbing and accessories.

Ceramic tile is divided into wall and outdoor. The second is characterized greater thick and size. Often ceramics in the store are offered in the form and ready collection with elements for floors and walls. In this case, the combination of textures and shades is thought out by designers, the collection is made in a single style, and therefore it looks organically and naturally.

With an independent selection of the material, it is recommended to give preference to classic shades that have a pleasant shade and universal in combination with other materials. These include pink, light blue, beige color, as well as a tile with a pattern that imitates marble or stone.

How many tiles will need

The tile - the material is not cheap, so it should be decided immediately with its amount. Calculations take into account several nuances. Acquire the tile is recommended with a slight margin, given the likelihood of marriage formation during trimming. In this case, the material must be from one batch. Otherwise, it is possible to distinguish with shades.

When measured, it was necessary to pay attention to the geometric parameters of the room, namely on the evenness of walls and angles.

A scan of walls drill on a sheet of paper. Each of them note the layout of the tile of the selected size, the decorative inserts, borders, the thickness of the interputric seam are drilled. Considate the method of laying - "aims" or "seam in the seam". The layout is performed so that the elements were cut in the corners were not too narrow. When the calculations are made, another 10% is added to the resulting value - marks, trimming and inaccuracies in the calculations.

Why you can not give icons

Why you can not give icons Is it possible to give icons as a gift: Signs, the opinion of the Church

Is it possible to give icons as a gift: Signs, the opinion of the Church A year ago left her husband, and now I do not know what to do

A year ago left her husband, and now I do not know what to do