Do-it-yourself sun lounger - schemes and the best ideas on how to create a comfortable and stylish sun lounger. The best ideas for making a sun lounger on your own for a summer residence Do-it-yourself beach furniture

On the beach by the sea or in the garden to relax, enjoy the sounds of nature and unwind.

And which of the pieces of garden furniture is the most suitable for comfortable relaxation and contemplation of nature? This is a chaise longue.

Among other things, a comfortable and light garden chair will be a spectacular element of the exterior, which will emphasize the style of this site. In this article, we will look at several easy-to-make sun loungers for a summer residence, among which you can choose the one that you want to do with your own hands.

Inflatable pools are probably the most popular way to cool off at your summer cottage. find out from our article.

What you need to know about a garden peony: planting and care, plant propagation. from the whole variety of varieties promising for our latitudes?

Functional need

Sun loungers are of the same type as armchairs, but lower and more stable. In them, you can be in a semi-recumbent position, thanks to which the spine and all muscle groups rest.

Another advantage is that the garden chair can be folded as needed, adjusting the angle of the back to a sitting and reclining position.

The best material for making a sun lounger is wood, as it is the most environmentally friendly, economical, and also the easiest material to use.

It is very good to observe nature in them, and they are light and comfortable, therefore they are often located in their garden or in the country. It is good to take such a chaise lounge outdoors in summer, and in winter to keep it somewhere indoors, for example, in a closet or in a barn.

In the manufacture of used materials such as:

- plastic;

- wood;

- rattan.

In the photo, a do-it-yourself wooden chaise longue for a summer residence

Popular blueprints

Rocking chair drawing

A rocking chair made of wood, which you can assemble with your own hands, will be very good. This chair is a great option, thanks to it, you can relax all the muscles of the back in a semi-recumbent state and at the same time swing (back angle 200).

The rocking chair must have great strength and in no case should it loosen during the rocking, for this it is necessary to strengthen the structure of the chair with the help of crosses and corners.

In order to increase stability, the hind legs are best left straight, not rounded. This garden chair has a rather small swing amplitude and to strengthen it, you need to make a smaller radius of curvature and wider runners.

You can also complement the rocking chair with a pendulum (for this we attach a weight of 2 kg) You can additionally create a removable table. But still, this type of garden chair is not fully a chaise longue, since you cannot change the angle of inclination of the back to a reclining state.

But, imagine how amazing a rocking chair looks in the garden and how convenient it is to read a book in it, light a pipe, drink tea and enjoy the surrounding nature around, such a chair will stand effectively by the fireplace in winter - once again imagine these pictures and you will understand that this type of sun lounger is just a fairy tale.

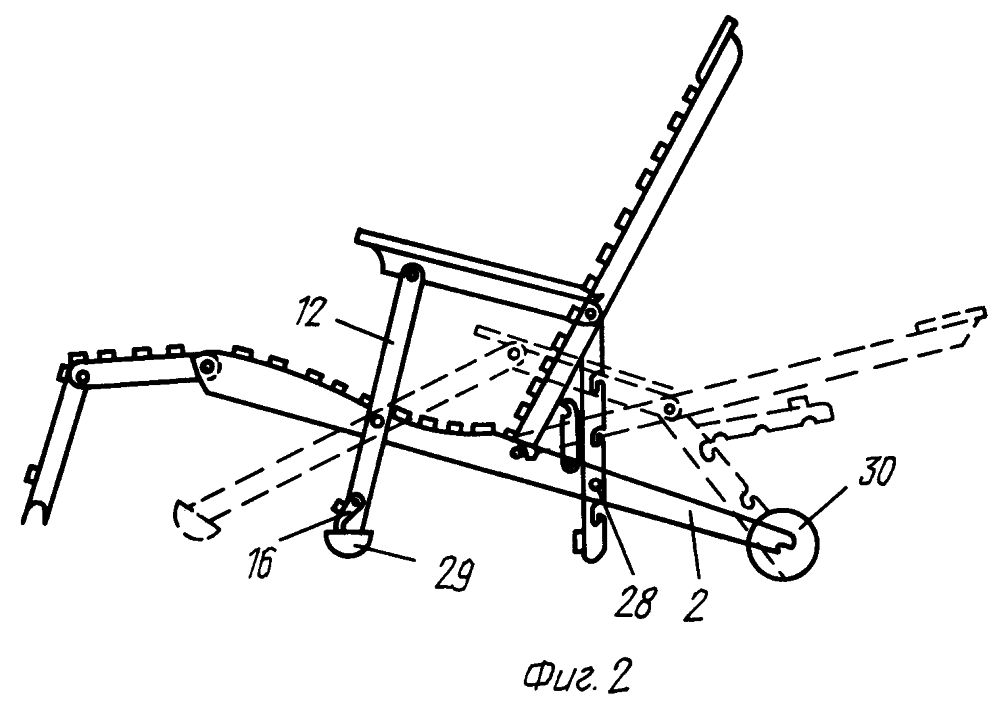

These drawings with dimensions will help you make a high-quality chaise lounge with your own hands:

Creative sun lounger with canopy

The drawing shows a creative chaise longue, which is easy to make with your own hands and which will surely become a wonderful decoration for your garden.

Creative sun lounger will cover in summer heat

This lightweight garden chair is designed with flowing lines and radii to completely relax every muscle in your body. But the most important thing is that this chaise longue is beautiful - thanks to the roof, a shade is created that covers from the scorching heat of the sun.

There are also additional amenities such as a small pillow made of natural fabric and a comfortable mattress, it also combines the advantages of a rocking chair.

Creative armchair on the drawing

There are plenty of sun loungers that you can make yourself, like beach loungers or cozy seating. Let's consider a few of the simplest options.

How to build a simple do-it-yourself chaise lounge:

Fabric armchair on a frame

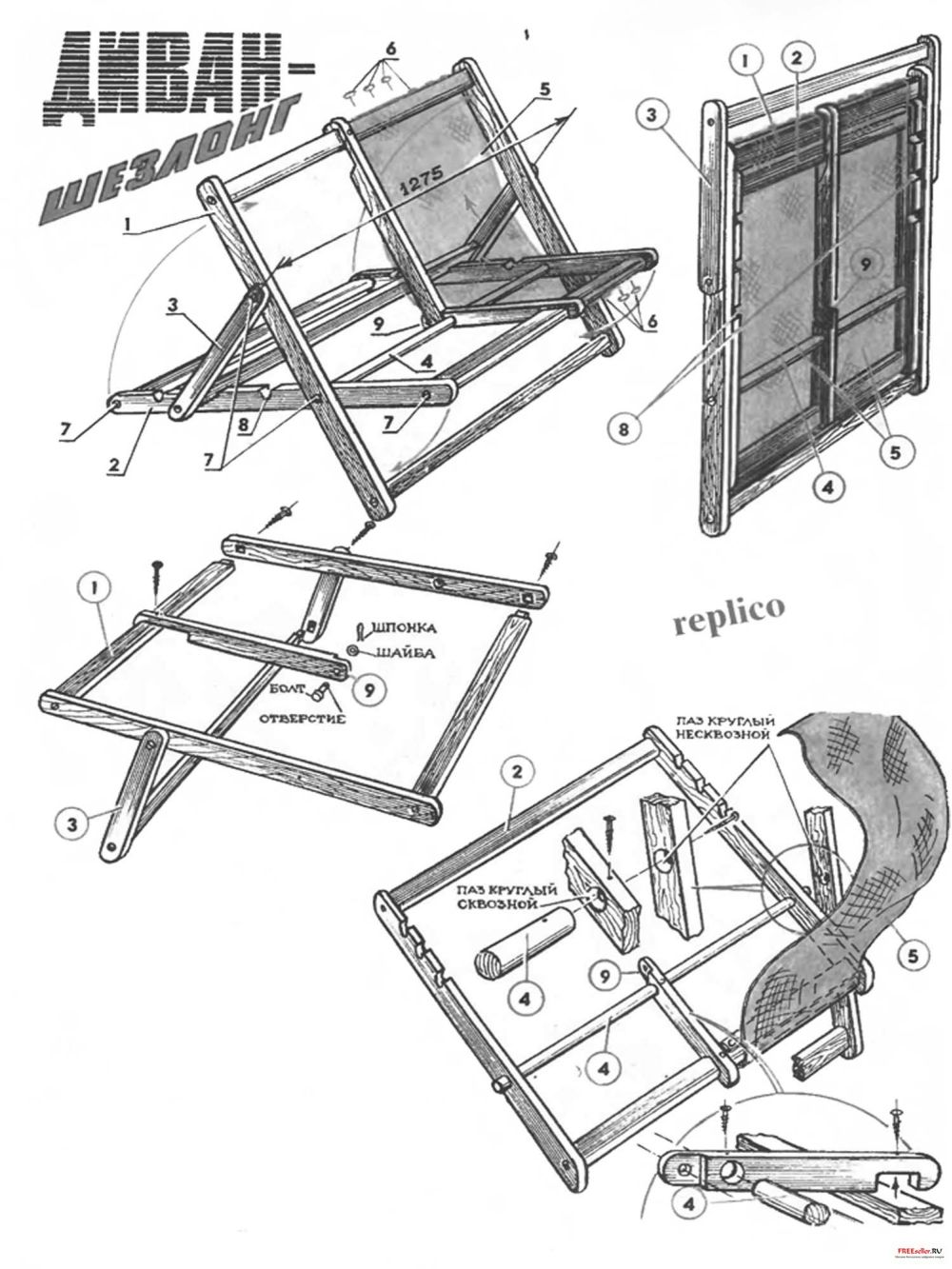

Consider one of the most convenient options - a fabric seat on a frame that can be carried from place to place and folded almost flat.

In order to make a sun lounger, you need to prepare the following details:

- furniture bolts and nuts D8 mm;

- round slats 6 (length - 65 cm, two 50 cm, two 60 cm);

- slats of rectangular section (length - 65 cm 25x60 mm);

- a piece of durable fabric 200 x50 cm;

- round file and fine-grained sandpaper;

- PVA glue;

- slats are best obtained from hardwood species: oak, beech, birch.

In order to make a chaise longue, you need to use fabrics that have resistance to abrasion and increased strength: mattress teak, tarpaulin, jeans, camouflage, canvas.

The process has begun

We cut the slats to the required length and grind them carefully.

We make the slats of the required length and carefully grind the surface with sandpaper.

At a distance of 70 and 40 cm from the corners of the structure, we drill eight millimeter holes, and then grind them with a round file. In order to be able to change the position of the back, at a distance of 7-10 cm we make 3-4 cutouts in frame B.

Then, stepping back from the two ends of the slats, we drill holes with a diameter of 2 cm in order to equip the seat. Then we take round slats (grease the ends with PVA), and install them in the holes.

After assembling the frame, you need to sew and cut out the seat. The length of the fabric depends on the possibility of folding. In order to understand what the length of the cut is needed, you need to fold the chaise longue and at the same time measure the fabric, and do not forget to make sure that the fabric is slightly stretched.

Then, a piece of fabric, which has already finished the edges, is nailed to the round slats, which are located on parts B and A.

We wrap the crossbars with the edge of the cut and fix it with small studs with thick caps. An option is possible when the cut is attached to the crossbeams thanks to the peculiar "loops".

Such a garden chair is very good because it can be used instead of a bed - what else could be for an afternoon rest?

How to make a wooden deck chair with your own hands - video tutorial.

Kentucky armchair

Consider the original version - a Kentucky chair, which is assembled entirely from bars. If necessary, the chair can be folded at any time and put away where it is needed for storage.

Kentucky armchair

In order to make a chair you will need the following material:

- 4mm galvanized wire and 16 galvanized staples to fix the wire.

- Hammer and pliers.

- Fine grit sandpaper.

- It is also necessary to take bars of 50x33 mm, which are obtained by sawing a board into three equal parts with a board of 50x100 mm. If all the bars are put together, then you should get 13 meters.

Build process

When the bars are ready for assembly, you need to process them for strength (and protection from ultraviolet radiation, moisture, weathering) and give them additional beauty.

Size & Quantity Chart

For this, the tree is treated with a stain called Beyts. To treat a sun lounger, you need to buy an outdoor stain, the best of which are based on oils and wax). Among other things, you can use parquet oils, which are ideal for all wood products.

Assembly diagram

You can apply a protective coating to the bars either with a brush or with a spray gun (the best option).

We collect the chair

The diameter of the holes must be made one and a half to two millimeters larger than the thickness of the wire used.

We pass the wire into the bars

After preparing the required number of blocks, it is necessary that the edges are carefully processed with fine-grain sandpaper. We begin to assemble the structure.

You can also use galvanized studs (the edges are secured with eight nuts and washers) instead of staples and galvanized wire.

After assembly, carefully raise the chair.

Beauty at the summer cottage

A chaise longue is the best furniture for outdoor recreation or in the country, it gives the garden a special style and atmosphere of comfort.

In this article, we examined several designs and drawings of sun loungers, any of which can be done by hand, we have sorted out many of the nuances associated with the assembly.

Take some time to assemble a wonderful garden lounge chair at your summer cottage, and you will enjoy the fruits of your labor and creativity for a very long time.

At the moment, there are a huge number of variations of making a sun lounger made of wood with your own hands. Some of them will be discussed below.

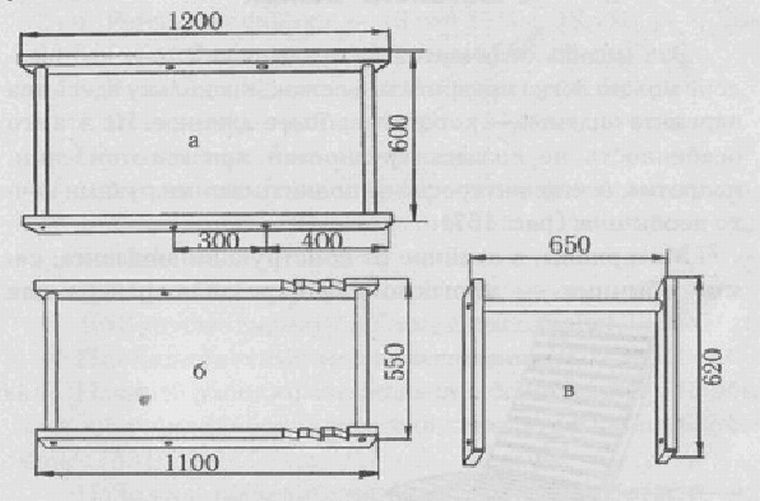

Deckchair made of wooden lattice

This model of a sun lounger is very common in seaside resorts. Now the owners of country houses and summer cottages will be able to enjoy their rest on such a piece of furniture. The chaise longue is essentially flat with an adjustable backrest. The only thing that makes it difficult to move around the site is its severity. But the problem can be solved if you mount rollers or castors to it.

To collect this piece of furniture with your own hands you will need:

- Slabs with a thickness of 1.8 cm;

Important! Boards are best used from softwood as they are weather resistant.

- For the frame of the bars measuring 45 * 45;

- For covering the sidewalls of a board with a thickness of 2.5 cm;

- Screwdriver and jigsaw;

- For working with wood, several drills with a diameter of 4 cm;

- Screws (it is better to take those that have a countersunk head);

- Mounting corners for the bed in the amount of 4 pieces;

- Ten-centimeter rollers in the amount of 4 pieces;

- Sanding sheet with grit from 120;

- Decorative coating (varnish, paint).

The master himself can independently choose the size of the chaise lounge that suits him best. The standard sizes are considered to be 60 * 190 cm. For a start, it is best to prepare drawings.

The algorithm for making a sun lounger with your own hands is as follows:

In addition, you can watch the video on how to make a sun lounger out of wood with your own hands:

Wooden deck chair with fabric seat

This chair is also very popular. It is convenient because it is very convenient to move this piece of furniture around the site, it does not cause any problems during transportation and storage, as it folds into a compact flat shape. Making such a sun lounger with your own hands is not difficult.

For such a sun lounger you will need:

- 6 slats with a rectangular section of the same size 25 * 60 cm, but of different lengths: 2 x 120 cm, 2 x 110 and 2 x 62 cm.

- Five slats with a circular cross-section of 2 cm. The quantity depends on the length: 65 cm - 1 piece, 60 and 50 cm, two slats for each length.

Important! Reiki should be used from wood such as birch or beech. They are more durable.

- Durable fabric in sizes 200 * 50 cm. Canvas, jeans or tarpaulin are perfect.

- Bolts and nuts for furniture with diameters of 8 mm.

- PVA glue.

- The file is round.

The work is carried out in the following sequence:

This completes the work on assembling the frame, now we turn to sewing the seat. Before that, you need to measure how long to take a piece of fabric. To do this, you need to fold the chaise longue and measure the amount of fabric. In this position, it should sag a little, not be taut.

In order to fix the fabric on a chaise longue, you first need to process the edges on a sewing machine, and then, wrapping the transverse round bar, nail them with small nails. On both sides.

It is also possible to make loops on both sides and attach the fabric on them to the crossbars.

Kentucky folding armchair

This original made chair is assembled from bars, folds easily and does not take up much space during storage.

To make it you need to prepare:

- Bars size 45 * 30 The size 50 * 33 cm is also used.

- Galvanized wire with a cross-sectional diameter of 4 mm or studs with washers and nuts.

- Staples for clamping 16 wires.

- Fine-grained sandpaper.

- Nippers and hammer.

For work, the total sum of the lengths of the bars is 13 meters. All cuts and holes in the bars must be carefully sanded.

The work is carried out in the following sequence, as shown in the drawings:

Conclusion

A chaise longue is a very comfortable piece of furniture that gives home coziness and a certain charm to the site. It is a pleasure to rest in such an armchair.

You don't need to buy ordinary plastic chairs on the site that look too simple or buy expensive garden furniture, just take a little time to create your own unique pair of sun loungers, so you can save your budget and develop the skills of a carpenter, and make an original decoration of the site with your own hands, what then will be proud. You can make several sun loungers of the same type, or you can try yourself in making all the models at once and place them throughout the garden so that you can relax anywhere.

How pleasant it will be to lie on a comfortable hand-made sun lounger after a hard day at your personal plot. Currently, there are a large variety of sun loungers made from a wide variety of materials. And now we will tell you how you can make sun loungers yourself from wood and fabric, as well as how to properly monitor them so that you can enjoy your vacation in the country for more than a dozen years.

Chaise lounge for a summer residence - a description of the design, types of products and their characteristics

Chaise lounges have their own special design, the frame of the backrest, seat and armrests, so that a person feels as comfortable and comfortable in it as possible. We are talking about both a reclining and a semi-sitting version of a sun lounger, which contribute to the maximum relaxation of all muscles of the human body.

These are the qualities that a classic rocking chair possesses, which you can make yourself, having in stock all the necessary drawings with calculations and design sketches.

Due to the lightness of the design, the country sun loungers can be moved to any place in the personal plot, depending on whether you want to lie in the sun or in the shade. Folding products made of wood and fabric are very convenient, as they can be removed in the rain in the room, and they will not take up much space.

Wooden sun loungers have a high level of durability and are renowned for their long service life when properly cared for.

Today, having a competent and accurate drawing in your hands, you can make the most folding or lightweight hanging chaise lounge, which will quite aesthetically fit into the exterior of the entire personal plot.

Types of sun loungers and sun loungers

Depending on the type of construction, sun loungers can be conditionally divided into several types:

- Monolithic frame. This is a street chair in which all the elements are connected to each other "tightly". Such a product is very durable and can withstand even the heaviest loads. It is absolutely safe even for young children under 1 year old. But, meanwhile, such a product during its operation may create some inconvenience. It is impossible to make your own adjustments to such a chaise lounge and change the angle of the backrest, it does not fold and therefore it is inconvenient to move it from place to place, as well as store it in small rooms (storerooms, closets, etc.).

- Monolithic armchairs with special inserts have an excellent appearance and are characterized by a high degree of decorativeness. They are equipped with additional inserts, which are made of materials of different characteristics, which reduce the degree of strength of such a structure. But, meanwhile, they look very aesthetically pleasing and effective.

- Portable folding designs of chaise lounges have special movable mechanisms that allow you to quickly change the position of the back at your discretion. This applies to the entire deck chair as a whole. If necessary, a person can easily change the degree of inclination of the backrest, headrest, and lower legrest. You can take portable folding sun loungers with you on a trip due to their extremely compact folded size. They practically do not get dirty during long-term operation.

Gallery of sun loungers and their types

Designer chaise longue - rocking chair with durable metal hoops instead of legs  An original chaise longue for a country house

An original chaise longue for a country house  Folding sun lounger with canvas seat, plastic handrails and metal frame

Folding sun lounger with canvas seat, plastic handrails and metal frame  Plastic folding deck chair with soft mattress

Plastic folding deck chair with soft mattress  Wooden sun loungers for summer cottages

Wooden sun loungers for summer cottages  Original chaise longue made of wood with soft mattresses in the form of a spiral

Original chaise longue made of wood with soft mattresses in the form of a spiral  Rattan chaise lounge with adjustable backrest

Rattan chaise lounge with adjustable backrest  An original design chaise longue that you can make with your own hands from a chipboard sheet

An original design chaise longue that you can make with your own hands from a chipboard sheet  Chaise lounges with a spring seat on a metal base

Chaise lounges with a spring seat on a metal base

Preparation for creation: select a drawing and determine the dimensions

Before you start making a sun lounger for your home, you need to decide on the optimal design and choose the most optimal and uncomplicated option, which you can easily do yourself without the help of masters.

The main thing is to find accurate and competent drawings that will make it easy to cope with such work and, as a result, get a convenient and most reliable design for a summer vacation in your personal plot, as well as near a river or lake.

Choosing materials for assembling a convenient and durable structure: tips for choosing

Let's look at what types of country sun loungers are, as well as the types of materials from which they are made. Their advantages and disadvantages, as well as what materials can be purchased for their manufacture.

- Sun loungers made of wooden planks and beams are considered the best, since wood is an environmentally friendly natural material. Today, you can see a variety of options for sun loungers and sun loungers, ranging from ordinary outdoor chairs with a movable back to the most comfortable models that exactly follow all the contours of the body of the seated person. Since the back of such a chaise lounge can be fixed in several different positions, a person can always take the most comfortable position for him while resting for sleep or contemplation of nature. It should be noted that wooden sun loungers are quite heavy, so usually their frame is equipped with two wheels for convenient movement of the product around the personal plot. As a convenient addition, fabric mattresses with soft padding can be sewn, which will be attached to the frame using ordinary rope ties. Since the tree is afraid of water, it is not recommended to put such sun loungers near pools, rivers or lakes, where they can constantly get water or they will absorb a large amount of moisture. Water will promote the swelling of the wood, as well as its deformation. Even if the boards and beams are well treated with various means, covered with a water-repellent deck varnish, it is still not worth the risk. When buying lumber for the manufacture of a frame, it must be borne in mind that the most durable and high-quality boards and beams are larch, oak, birch, teak, hazel, spruce. Pine is the cheapest, but it must be well dried and thoroughly treated with antiseptic agents.

- Plastic sun loungers are a budget option and are usually found near pools, city beaches, and other public places. They cannot be made at home, but they have an affordable price, are easy to care for, and are also not afraid of moisture.

- Deck chairs in the form of swings and rocking chairs can provide wonderful rest for both adults and children. Chaise longue frame - the swing clings to a strong hook on a reliable metal support, and then simply sways in the air. At the top of the counter, an umbrella or large canopy is usually placed, which protects vacationers from the hot sun rays.

- A very unusual option can be called a designer model of a rocking chair, which has round supports in the form of two strong iron hoops. Such a chaise longue can be easily folded and moved to another place.

- Wicker loungers are a great option for outdoor seating furniture that is made from natural materials such as the popular rattan, bouncy vines or sturdy hemp. Also, products can be made from synthetic fibers. Since wicker loungers are considered premium furniture, their cost is quite high. Rattan products are distinguished by their beauty, design delights and excellent style solutions.

- Chaise lounges made from pallets or pallets, which are used to move and store goods, will be an excellent cost-effective inexpensive option, since such wooden structures can be bought at a bargain price if they have already served their life and are unusable. They will need to be slightly repaired, sanded and painted with multi-colored paint, and then you can assemble a sunbed - a chaise longue for your home. The base of the structure is made from two pallets bolted or self-tapping together, and an inclined back is made from the third. They look very beautiful and aesthetically pleasing, and also have a long service life.

- Fabric sun loungers on a wooden or metal frame are the most comfortable, comfortable and easy to use. The basis here is a frame made of wood or metal, on which a seat made of dense fabric (canvas, tarpaulin, jeans, teak, mattress fabric or camouflage) is worn.

Wood and fabric are environmentally friendly materials, so such a chaise longue will be an excellent option for a summer cottage where there are small children. The disadvantage of such a street design is the fragility of the fabric, but if it breaks or loses its aesthetic appearance, you can always replace it with another one and the chaise longue will again be like new. The wooden frame can be sanded and recoated with varnish or paint, and the metal frame can be sanded with sandpaper and also painted with a special water-repellent paint for metal.

It is best to buy a metal profile seamless, since the frame of the chaise longue will have to "hold" a sufficiently large weight of a person, and it must be strong.

Whenever possible, purchase stainless or galvanized pipes that are least susceptible to corrosion and have a long service life.

Calculation of the required amount of material for the structure: working tools

In order to make a wooden chaise lounge with a fabric seat at home, we do not need complex and expensive tools, so even an inexperienced novice master can make such a structure for his summer cottage or suburban area at the lowest cost.

For the backrest device, we need wooden boards of the following sizes:

- Two pieces 19x38x1219 mm;

- One piece 19x38x610 mm;

- One piece 19x38x648 mm;

- One piece 19x64x610 mm.

For the manufacture of a seat frame, boards of the following sizes are needed:

- Two pieces 19x38x1118 mm;

- Four pieces 19x38x603 mm;

- One piece 19x38x565 mm;

- One piece 19x64x565 mm.

To manufacture the back support of the structure:

- Two boards 19x38x381 mm;

- One wooden round dowel with a diameter of 12 mm (length 648 mm).

To make a fabric seat, we need:

- Two pieces of awning, denim, camouflage, mattress or other durable fabric (a piece measuring 1372x578 mm);

- Two wooden dowels with a diameter of 12 mm (length 559 mm).

For fastening the structure:

- Four bolts with nuts size 6x50 mm;

- Twelve washers for nuts;

- Wood screws size 4x50 mm;

- Regular PVA glue or special glue for wood products.

As tools we will use:

I would like to give recommendations to the hostesses. The fabric seat is easy to remove and therefore washable as it gets dirty. This way, your chaise longue will always be clean and tidy. If you want, you can sew several options for a fabric seat and change it depending on your mood and other factors.

Wooden elements need to be sanded again once every two or three years, covered with protective agents, varnish or water-repellent paint, and then the chaise longue will serve you much longer.

Video: Making a simple lounger

Video: How to make a wooden chaise lounge with a movable back with your own hands

Video: How to make a metal structure with your own hands

A wooden chaise longue with a fabric seat will be the lightest construction to manufacture and convenient for a summer vacation in the country. If you make several designs with your own hands, then you can not worry that you will have nowhere to rest on warm summer days with your large and friendly family. Both adults and children can comfortably stay on the territory of the personal plot or near the river that flows nearby and enjoy the beautiful views of natural landscapes and flowing water.

A chaise longue is a comfortable and lightweight chair design that is used in recreation areas: on the beaches, by the pools, an integral part of the dacha decoration. It can be used to relax after a hard day at work, caress yourself in the sun or take a nap under the shade of the local trees, away from the prying eyes of the inhabitants.

In this article, we will talk with you about how you can make an ordinary wooden deck chair, we will give examples of photos, videos and instructions.

How to make a sun lounger with your own hands?

First, we choose the appropriate type and modification of the sun lounger. The main material can be plastic, wood, synthetic fabric and aluminum. We have chosen the most affordable version of a sun lounger made of wood.

Type of tree for a sun lounger

The choice of a tree is based on the following principles:

- material opportunities;

- preferences of the future owner:

- garden style;

- available materials at hand.

Choosing the future wood for your chaise longue, you pay attention to the mechanical properties of a particular type of wood. For example, the most durable wood species are: ash, oak, larch and beech. With them, the design will delight you for many years. Wood is distinguished not only by the durability of its service, but also by its aesthetic component.

In turn, finished products from noble wood species are not the cheapest pleasure for the buyer. Such a thing is not always available to the average consumer who is trying to save any extra penny, because money is not superfluous. Before assembling the sun lounger with your own hands, look at the blueprints for the sun lounger.

Type of wooden deck chair

A hand-made chaise longue will not only be an example of prudent spending of the family budget, but will also add a zest to the appearance of your fabulous summer cottage garden.

In magazines and newspapers, countless drawings, projects and ready-made solutions for wooden sun loungers have accumulated. The sizes of the homemade sun loungers are identical to the industrial models.

A folding sun lounger is much more comfortable than a regular one. It is easy to move around the territory, and in winter it can be folded and removed, even cloudy weather will not create any obstacles.

Preparation and manufacture of a sun lounger

Parts purchased in advance for the structures of the future chaise longue must be processed, we impregnate the wood with an antiseptic and an anti-corrosion compound. We grind the surface to a perfectly smooth state. We put the resulting details aside and proceed to study the drawing.

If you turn to the latter, you will notice that the crossbars are fixed to the lower part of the legs. They allow you to fix the back in the desired position. When installing only one strip, it is first necessary to make cuts at the installation sites of the strips with a step of 5 cm, starting from 20 centimeters.

The backrest frame should have bolt attachment points, we retreat from the edge on each side by 41 centimeters, and at the very base of the seat - 43 centimeters indent from above.

First you need to assemble the backrest frame. The main load will be transferred to the 20 x 60 x 610 mm bar, so pay special attention to securing it. It should be recorded as efficiently as possible. It is customary to leave a distance of 1 centimeter between the slats. It will be needed to secure the fabric in the future.

Using the instructions described above, we assemble the main frame. Then, we connect 2 frames together - the back and the seat. Pay attention to the backrest frame, it is necessary to drill a hole on it from 2 sides, the distance is 41 centimeters for the backrest and 43 centimeters for the seat. Screw the two pieces together using nuts and bolts.

Attention! During regular use of the chair, the nuts may gradually loosen and loosen. To avoid this trouble completely, tighten the locknuts. For better fixing of the nuts, "Moment" or ordinary paint can be used.

To determine the degree of free play, first tighten the nut firmly, and then gradually loosen it. We give the paint and glue to finally set.

The next step is to mount the back support. The planks are secured with bolts and washers. Choose only thick fabric for the seats; tarpaulin, canvas and jeans are the best choices.

The fabric blank is folded in 2 times and stitched with an indent of 1.5 centimeters. After that, it must be turned out. We bend a piece of fabric on one side so that you can insert the rod and stitch it. We do it in a similar way on the other side.

We push each of the ends of the folded fabric between the planks and insert a rod into it. We will get a tightly fixed seat, and at the same time dismantling to wash it will not cause any problems.

Photo of sun loungers with your own hands

A do-it-yourself sunbed or chaise lounge is easy enough to make. Such a homemade uncomplicated garden accessory is not only functional, but will also become a real decoration of the local area. Such peculiar clamshells differ not only in size, but also in appearance.

Sun loungers and sun loungers for summer cottages: main types

Chaise longue (Сhaise lоngue) is a popular folding light armchair for relaxation in a reclining position. Such beach structures are easily transformed. A simple wooden accessory can be a great option not only for the beach and outdoor pools, but often used as garden furniture replacing a comfortable and practical chair on open verandas or terraces. There are both adult and children's versions of the sun lounger, for the manufacture of which solid wood, durable plastic, durable aluminum or synthetic fabric are used.

Depending on the design characteristics, there is the following conditional classification of such products:

- monolithic armchairs represented by components that are rigidly connected to each other, with a high level of strength and designed to withstand significant loads. The special feature is safety. The disadvantages include the impossibility of folding the structure and making changes to the angle of inclination of the backrest, which complicates the process of storage and transportation;

- monolithic armchairs with special inserts, characterized by very high decorative properties. They have additional fragments made of various materials, which can negatively affect the level of reliability and strength of such a structure;

- portable models, characterized by the presence of special mechanisms, make it easy and simple, without much hassle, to change the position of such a rest chair. There is also a great opportunity to change the angle of inclination on the footrest and headrest. The foldable model is very compact and suitable for transportation in a regular passenger car.

Varieties of sun loungers (video)

Models with a metal base are extremely rarely made on their own and are distinguished by the presence of aluminum or steel frames with fixed fabric durable canvases. The advantages of such chairs include low weight and mobility., as well as a high degree of operating comfort. Among other things, modern materials are distinguished by a high level of resistance to various adverse external factors, as well as contamination that can be obtained during operation.

How to make a wooden deck chair with your own hands: drawings and stages of work

The drawing and diagrams for the manufacture of a wooden deck chair are presented in large quantities, but to independently perform such a design, you can also use a simple step-by-step instruction.

Kentucky Chair Making Workshop

A very original model is the Kentucky version, completely assembled from wooden blocks. This chair can be folded, it is very convenient to store. For self-production, you will need to purchase:

- galvanized wire with a diameter of 0.4 cm;

- galvanized staples in the amount of sixteen pieces;

- hammer and nippers;

- fine-grained sandpaper;

- wooden bars with dimensions of 50x33 mm;

- antiseptic composition and varnish for wood, as well as a brush.

It is not difficult to assemble the structure on your own. In the bars, holes are drilled with a diameter of one and a half millimeters larger than the thickness of the wire used. If necessary, you can replace the staples and wire with galvanized pins, the edges of which are fixed with nuts and washers.

A simple option for making a sun lounger made of wood for tanning yourself

This option is easy to manufacture, but rather cumbersome and does not allow changing the position of the backrest. Before you start making your own, you need to decide on the dimensions of the structure. The best is considered to be the length of the lounger of two meters with a width of 0.6 m.

The main stages of making a model of a sunbed made of wood for tanning are as follows:

- making a frame base of a lounger from four sidewalls, a pair of which are two meters long, and two are 60 cm long;

- sheathing of the outer part of the frame with polished boards, 2.5 cm wide;

- fixation on the long sidewalls of four legs with an indent from the edge of the structure 80 mm using galvanized self-tapping screws;

- it is best to use stable 100 mm long wooden blocks for making the legs of the lounger.

At the next stage, the grille is assembled, which is the main part of the outdoor lounger. Using an electric wooden board, it is necessary to cut boards with dimensions of 10x60 cm. All jaggedness and roughness on wooden blanks must be removed with fine sandpaper. The finished boards are fixed with galvanized self-tapping screws on the frame base of the chaise longue and with a gap of one and a half centimeters, which will allow you to get a convenient and attractive product.

Somewhat less often, models with a comfortable adjustable back are made. In this case, the lattice should be divided into a couple of parts, one of which is used directly as a lounger, and the other part serves as a comfortable headboard. The two parts are installed on the connecting boards, and standard door hinges of the required dimensions are used to hold the lattice elements together. To fix the headboard in a certain position, a transverse bar is used, which is installed on the inner edge of the frame base of the structure. The headboard support post is fixed to such a bar with the help of galvanized self-tapping screws. The finished structure must be carefully sanded, and then the surface must be coated with varnish-based compositions or special varnishes.

How to make a sun lounger from solid wood (video)

How to DIY a folding fabric sun lounger

One of the most convenient and easy-to-make options is presented by a fabric seat on a frame base. Such a model is quite mobile and can be carried from place to place, as well as easily folded to an almost flat state. The materials used in the manufacture are presented:

- furniture bolts and nuts D-8mm;

- two wooden battens of a circular cross-section 65 cm long;

- two wooden slats of circular cross-section 50 cm long;

- slats of rectangular section 65 cm long with a section of 25x60 mm;

- a piece of durable and water-repellent fabric measuring 200 x 50 cm.

You will also need to purchase a round file and fine sandpaper, as well as PVC glue. Experts recommend giving preference to slats obtained from wood species such as oak or birch. As a strong and reliable fabric, types are used that are maximally resistant to abrasion and are distinguished by increased strength indicators. Mattress teak, as well as tarpaulin, denim and camouflage fabrics, and canvas have proved to be the best.

Folding fabric model manufacturing technology:

- cutting laths of standard length and carefully sanding their surface with emery paper;

- with a distance of 0.7 and 0.4 m from the corners, holes are drilled, after which they are sanded with a round file;

- so that during operation the position of the back changes, with a distance of 8.0 cm, you need to make three or four cuts;

- with a sufficient distance from the two ends of the wooden slats, holes are drilled to equip the seat;

- the end part of the round wooden slats are lubricated with PVA glue and installed in the drilled holes.

The assembly of the frame ends with the installation of a fabric seat. The sewing of the seat is carried out after measuring the finished frame. The crossbars are wrapped with a cut edge and fixed with standard furniture nails. Loop fastening of the fabric seat to the crossbars is also allowed.

We buy a ready-made chaise lounge: characteristics of the types and selection criteria

Today a chaise longue is a very popular and demanded product, mainly as a comfortable and beautiful garden furniture. All modern sun loungers or sun loungers are divided according to the material used in the manufacturing process. A significant number of models are made from reliable and high-quality plastic, but there are products from processed wood and modern metals. Various combination models are especially popular., in which the frame base is made of wood or steel pipes, and the seat is made of wood or fabric. Some loungers have woven fabrics based on artificial or natural fibers.

Factory products made of modern plastics of different colors are resistant to negative external influences, including ultraviolet light, precipitation and wind. Wooden factory products are characterized by surfaces that have undergone a three-stage treatment, represented by a primer, subsequent painting and decorative finishing, which makes it possible to operate such a chaise lounge in high humidity conditions, in the open air.

All manufactured products are subdivided into folding and non-folding models. and also have a rising or falling foot and headboard. As a rule, the position of the backrest is changed by means of grooves located on the supporting frame. For example, the Lucca chaise lounge from a German manufacturer is made on the basis of aluminum and modern textiles, and the position of the back can be adjusted without getting up by loosening the locking levers located in the access zone.

In recent years, owners of suburban real estate increasingly prefer a comfortable and very original type of sun lounger - duchess breeze. This modern model is a very spacious and deep armchair with a comfortable side stool that can be placed next to the main body or fixed by fastening. The lounger can be foldable, transforming into a comfortable chair or chair that is convenient for transportation. The most modern models have a raised and lowered footrest, a retractable sunscreen, convertible armrests, and spacious storage compartments for various accessories.

How to make a deck chair from a barrel (video)

Wooden sun loungers or sun loungers are not only very convenient for summer vacations, but, of course, can become an adornment of any backyard area. Despite the fact that the cost of such a product is quite affordable, in recent years, the owners of suburban real estate are increasingly making sun loungers on their own, which allows you to get a bright and stylish, very individual and durable design with minimal time and effort.

Edith Piaf: biography, best songs, interesting facts, listen to the story of Edith Piaf

Edith Piaf: biography, best songs, interesting facts, listen to the story of Edith Piaf Blackcurrant jelly

Blackcurrant jelly How many times a day should an adult pee - pee?

How many times a day should an adult pee - pee?