The strongest cement brand. Which cement is better? Proportions of components for concrete

The durability of a structure directly depends on the reliability of its foundation. The cost of laying the foundation of buildings is up to a fifth of all construction costs. Long-term operation of the structure, without unexpected repair work, can be ensured by the correct choice of cement brand.

The importance of the foundation during construction

The correct creation of foundation substrates is based on several criteria, these are:

- soil type and characteristics;

- freezing depths;

- groundwater rise level;

- weight and design features of the structure.

Having considered the set of parameters, a method of constructing the foundation that best meets safety requirements, its type and the appropriate grades of cement are selected.

Types of foundations

Building structures of foundations:

- tape;

- pile or columnar;

- from a monolithic slab.

In each type of base of a building structure, appropriate concrete mixing technologies are used. For each technology, cement grades that best meet the task are used.

Cement grades used in construction

The basis of cement mixtures is limestone and natural clay or carbonate rocks. Clinker is prepared from these components, processed in a special way, and cement is obtained by grinding. The addition of additives shapes the properties of the mixture:

- curing time;

- frost resistance;

- moisture resistance;

- corrosion stability;

- durability;

- elasticity;

- mobility.

Indexes and grades of cement determine in what proportions the main components are taken and what plasticizing additives are added to the composition.

Designation of cement grades

Grades of cement mixtures indicate the amount of pressure per 1 cm² of area sufficient to destroy hardened concrete. Numbers from 100 to 700 show the pressure value in kilograms.

In addition to marking in numbers, indices are used in the designation of mixtures:

- mixtures without additives are designated by the index – D0;

- compositions with additives are designated as the percentage volume of inclusions - D5.

Letter values of additives:

- mixtures with a high setting speed - B;

- resistant to low temperatures - PL;

- Portland cement - PC;

- compositions resistant to salt solutions - SS;

- Portland cement with a slag component - ShPC;

- mixtures are plastic and resistant to low temperatures and water - GF;

- non-water-absorbing, expanding cement - VRC;

- white cement for decorative works - BC.

Features of the structure of the supporting part of households

To avoid premature destruction of a building, you should take a responsible approach to the choice of its design and building materials.

Technologically accessible, popular and relatively inexpensive type of foundation. Regardless of the type of soil, a trench is built under all the supporting structures of the building; the depth of the trench depends on the mass of the building, and its width is taken slightly larger than the dimensions of the tape.

The width of the foundation strip is taken within 0.5-0.8 m, depending on the thickness of the walls. To maintain the shape of the strip foundation, a frame is made and reinforced with reinforcement strapping. Increasing the strength of the base is achieved by adding crushed rubble stone or coarse crushed stone.

When constructing heavy buildings on soils prone to freezing or with a high groundwater level, it is recommended to make a concrete footing 10-15 cm thick. The same work must be done when arranging basements in the building. In such cases:

- cements M100, M200 are used for the cushion;

- for foundation tape M500, M600.

In building projects without basements and with light walls, this type of foundation will be justified. The construction of concrete pillars significantly reduces the construction time of a building and reduces its final price.

Foundation pillars are placed at significant nodes of the building and at least 2 m apart around the perimeter. The concrete mixture is prepared from M300 or M400 cement, reinforced with crushed stone, and poured into prepared formwork, tied with reinforcement. The base of the pillars, in area, should be at least 2 times the cross-section of the column. Beams are laid on top of the constructed pillars.

On loose soils subject to erosion, it is recommended to build slab foundations. This kind of foundation is also called “floating”.

A simple manufacturing sequence, at the same time, takes much more time and requires significant investment. But such a monolithic substrate can easily withstand both vertical and horizontal soil displacements.

A monolithic reinforced concrete slab requires high strength concrete and a grade of cement not lower than M500, M600.

Dependence of concrete strength in kg/cm² on water-cement ratio (graph)

Selecting a cement grade (Table)

| Type of foundation | Soil type | Features of the structure being built | Brand cement |

| Tapemonolithic | Heaving, clayey, with a high rise in groundwater. | Prefabricated panel, brick up to two floors. | M400 |

| Sandy, gravel. | Prefabricated panel, block one-story. | M300 | |

| Columnarmonolithic | With a groundwater height of up to 100 cm from the surface. | М400М300 | |

| Slabmonolithic | Clayey-sandy with groundwater rise less than 100 cm from the surface, subsidence, mobile. | Frame, cobblestones, chopped. | М500М600 |

Having determined which cement is best for the foundation of a structure, you need to pay attention to the manufacturer of the binding material, the shelf life of the mixture and find out the storage conditions before purchasing the product.

Views: 12012 2015-04-10

6 rules for choosing cement. Good cement - learn to buy correctly + VIDEO

Cement- an irreplaceable building material. Currently, there is a large assortment and different types on the market. The construction season is at the start. You just need to know not only which one to buy, but also how to choose cement Right. Let's take care of the durability and quality of our work together and learn how to shop correctly.

So, we invite you to read and learn 6 rules how to choose cement:

1. Rule - look at all the symbols on the packaging. You should be primarily interested in compliance with international quality standards (GOST, ISO-9000).

2. The rule is to examine the packaging itself. It's not that important buy cement wholesale or retail, each package must be examined for defects and inconsistencies. Material - 4-layer paper. All layers are either stitched or glued, the neck is tightly closed. Bag of cement must be absolutely sealed, without signs of tampering. Note that if you did not use all of the cement, then it must be stored hermetically sealed, away from water.

3.

The rule is how to choose cement Right. Now we check the packaging date and verify information about the properties. The date is not mandatory information on the packaging (GOST does not require this), however, there is an expiration date. Don’t be lazy to ask the seller for documents, because the production date of cement is the main factor influencing its quality. Thus, experts note that cement cakes after just six months and loses its activity by a third.

3.

The rule is how to choose cement Right. Now we check the packaging date and verify information about the properties. The date is not mandatory information on the packaging (GOST does not require this), however, there is an expiration date. Don’t be lazy to ask the seller for documents, because the production date of cement is the main factor influencing its quality. Thus, experts note that cement cakes after just six months and loses its activity by a third.

4. The rule is what cement to choose(manufacturer and brand). Research the manufacturers before making a purchase. In the store, read the information on the packaging. It must have not only markings cement, but also the weight of the material, manufacturer, addresses and telephone numbers. If all this is not there, then it is better to put bag of cement back, it doesn’t bode well.

Let's talk separately about what cement to choose: domestic or imported. A domestic manufacturer has one significant advantage - you can make a claim without any problems, if something happens. As for imports, please note that cement from Iran or Turkey is not designed for long-term construction and frost resistance of different regions. Moreover, often imported cement They are transported by sea and not hermetically packaged, which leads to its spoilage long before it appears on the store counter.

Which cement is better?The answer will depend on where and how it will be used. Cement brands There are different ones, we can talk about them a lot and for a long time. Let's dwell on a few points:

Which cement is better?The answer will depend on where and how it will be used. Cement brands There are different ones, we can talk about them a lot and for a long time. Let's dwell on a few points:

Rapid-hardening cement is marked “B”, normal-hardening cement is marked “N”.

SS is brand of cement, which resists salt water well.

PC - simple Portland cement.

ShPC, a type of Portland cement with additives of no more than 20%.

BC is white cement, which is often used for finishing work.

Waterproof brand of cement is marked “VRTs”, this cement sets very quickly (4-10 minutes).

Frost-resistant brand of cement- PL.

Plastic and frost-resistant cement that does not absorb water for up to 5 minutes is marked “GF”.

And there is also cement brands 400, 500 (indicates the maximum load in kg per sq.m. that it can withstand cement), are used under certain conditions.

5. Rule: If you're not sure, just take it as a test. Take 1 bag, see if it suits you. At the same time, take a look at the appearance. Good cement, in most cases, gray with slightly darker shades. No greenish or very dark color! If you take it in your hand, then cement will slip through your fingers and will not form lumps.

6. Rule how to choose cement Right - cement price. Mostly, cement price matches its quality. If it is greatly underestimated, this only means one thing - too many additives were added to the material, such as granite dust or ash. Can't decide by color, but the quality of this cement will let you down a lot. The price of cement also decreases due to lower transportation costs and storage costs. There is only one conclusion: don’t chase cheap cement, it will cost you more.

Search cement? Need a good one? Interested cement prices? -CALL - 067-702-43-26!

Conclusion: 6 rules, how to choose cement. Good cement- learning to buy correctly. Low cement price, lack of appropriate labeling, non-compliance with storage conditions and damaged packaging can significantly affect the quality of your future design, incl. and screeds for laminate flooring, its strength and durability.

VIDEO how to choose cement

VIDEO which cement to choose

More Articles

Another participant in the annual construction exhibition InterBuildExpo, the company Creaton, which offers a wide range of roofing and facade finishing materials, decided to please the domestic building materials market with new products - Easyton fiber cement tiles.

Laminate door windows They are standard PVC or metal products covered with a laminated film on top. .The process of creating this product takes place on a high-speed machine. The door leaf or window profile is heated to the required temperature, after which it is covered with a layer of special glue. A decorative film is glued onto the treated surface by thermal activation using pressure rollers.

Famous brand Сersanit- this is a real challenge to repair as such. Сersanit offers a complete solution for bathrooms, something that will provide comfort, guarantee high quality and highlight your style. Trademark Сersanit offers tiles, porcelain tiles, vanities, shelving, bathtubs, toilets and much more.

Ceiling tiles have become a favorite material for ceiling decoration. And not surprisingly, low price, wide range, ease of installation and the ability to hide minor defects, and even the height of the ceiling will not be lost. Today we will tell you how to glue (glue) ceiling tiles with your own hands. This work is not particularly difficult, but you still have to follow a few rules.

The foundation, being the basis of any structure, must be poured from a material whose technical characteristics correspond to its mass and the nature of the soil of the site. Otherwise, already in the first year of operation of the structure, its partial or complete destruction is possible.

Brand of concrete for pouring the foundation

In fact, there are only two criteria for choosing a brand of cement for pouring a foundation:

- The brand of cement will depend on the brand of concrete that will be used to build the foundation. The grade of concrete, in turn, depends on the mass of the structure and the characteristics of the soil;

- Which brand of cement can be purchased in your area.

Let's look at these two factors in more detail. In accordance with building regulations and practical experience, the following recommendations can be given on the grade of concrete for the foundation, on which in turn (and not vice versa) the factor under consideration depends - what brand of cement is needed for the foundation:

- Concrete M150 is suitable for pouring light-loaded foundations of courtyard buildings, light garages, fences and small wooden and foam concrete houses;

- Concrete M200, being the most common grade in low-rise construction, can be used for the construction of foundations for small residential buildings with light floors;

- Concrete M250, M300 or 350 is capable of withstanding significant loads from “heavy” private houses with a height of more than one floor, up to five-story cottages;

- Concrete grades M400, M450, M500 and higher are rarely used in private housing construction, due to the significant unreasonable increase in construction costs. As a rule, these grades of concrete are used for pouring foundations for multi-story buildings, overpasses, bridge crossings and other heavily loaded structures.

- Depending on the nature of the soil, it is recommended to use the following grades of concrete. In case of rocky or dry sandy soil, concrete M200 or M250 will be sufficient to fill the foundation for any low-rise building; for the more common “heaving” loam or clay in Russia with close standing groundwater, concrete should be used at least M250, preferably M300 or M350.

Which cement to choose?

Having considered the question of the possibility of using one or another brand of concrete for pouring a foundation, let’s move on to the main factor under consideration: “What kind of cement is needed for pouring a foundation?”

In accordance with the theoretical and practical data that you will receive from various sources, for the preparation of the above grades of concrete, you can use Portland cement grade M300 for concrete grades from M100 to M200 and Portland cement M400, M500 and M600 for concrete grades from M250 to M600. In other words, according to theory and practice, Portland cement grades can be used to fill the foundation: M300, M400, M500 and M600.

M300 cement can be ignored. This brand of cement has practically been discontinued, so it is extremely difficult to purchase this cement. Mostly, packaged cement-sand mixtures of the M300 brand, the so-called “sand concrete”, consisting of M400 cement and sand, go on retail sale. In other words, we can say that the M300 cement grade does not exist in nature.

When buying cement, many of us know very little about this building material. As a result, the brickwork, foundation and mortar screeds are of poor quality and crack under the influence of load, frost and groundwater.

Ignorance of the specifics of using different types of cement, its grades and characteristics leads to excessive consumption of this material.

Untimely use and improper storage lead to damage and loss of investment.

In order to confidently navigate when choosing cement for repairs, landscaping or new construction, let’s take a closer look at its classification, as well as strength and price indicators.

Cement is a powdered building material consisting of a binder base - clinker, filler and modifying additives. Upon contact with water, it turns into a plastic mass called cement paste. When hardened, it turns into a durable stone.

Unlike other binders (gypsum, lime), all types of cement harden and gain the necessary strength not only in air, but also in water.

The main characteristic of any cement is its brand. This is a digital designation of its strength in the solid state, expressed in kg/cm2. The grade is determined in accordance with GOST standards by testing samples for bending and compression after 28 days of exposure. Rapid-hardening types of cement are tested for strength 3 days after preparing the solution.

Brands of this group of binding materials are designated in numbers from 100 to 900(in increments of 100 or 50 kg/cm2). Today, cement grades below 300 are not produced. The most popular on the market are M400 and M500. High-quality cements (from M600 and above) are used in military, mine, airfield and hydraulic engineering construction.

When buying a bag of cement in a store, you will see on it not only the brand designation, but also other abbreviations, the meaning of which we will now explain. In the retail network, Portland cement is most often sold, marked with the letters - PTs.

To regulate the setting speed, increase frost resistance and water permeability, special additives are introduced into the cement composition. They are designated by the letter D, after which the percentage of additives is indicated (0, 5, 10 or 20%). For example, Portland cement grade 400 with 20% chemical additives is labeled as follows: PC 400 D20.

Slag Portland cement

In addition to Portland cement, Portland slag cement is used in construction. In addition to clinker, granulated blast furnace slag is added to it in an amount of 30–65% of the total weight.

It is marked with the letters ШПЦ and differs from Portland cement in several important parameters:

- resistant to soft river and aggressive sulfate groundwater;

- low resistance to low temperatures;

- gains strength slowly over the first 4 weeks;

- Withstands high temperatures (from +600 to +800 C) without reducing strength.

The listed technical characteristics of cement using slag allow us to draw two important conclusions: it should not be used to make concrete that will be used at low temperatures or subject to periodic freezing and thawing.

In the cold season, it is better to use it for preparing mortars and concrete laid in heated rooms, and to use it for open work in the summer.

The light shade of Portland slag cement allows it to be used for preparing decorative mortars, saving on the purchase of expensive alkali-resistant dyes.

An important advantage of cement based on blast furnace slag is the low rate of loss of activity. Therefore, it can be stored longer than ordinary Portland cement.

The beginning of setting (hardening) for this cement occurs 3.5 hours after preparing the solution, and ends after 6 hours (air temperature +18 - +22C). By this time, the solution loses its plasticity, and any mechanical impact on it leads to irreversible destruction of the cement stone. With ordinary Portland cement, the setting process ends after about 2 hours.

Special types of cements

Since cement is used in all sectors of the construction industry, there are many varieties of this binder.

The most famous of them are:

- Rapid hardening Portland cement, abbreviated as BTC. It gains 60% of brand strength within 3 days and is used for high-speed construction;

- Sulfate-resistant cement (SSPC) used for massive foundations that experience the destructive effect of sulfate groundwater (dams, piers, breakwaters);

- Cement using surfactants. If an additive is introduced into the composition that improves the plasticity and workability of the mortar, then the cement marking contains the letters PL. To reduce water permeability, a hydrofibizing substance is added, and the letters GF are added to the marking;

- Portland cement cement. Used to isolate boreholes from groundwater penetration.

- Waterproof Expanding Cement. Denoted by the letters VRTs. It has a very high density and is used for sealing cracks in reinforced concrete structures, waterproofing water pipes and mine structures;

- White (BC) and colored cements. They are used for the preparation of decorative concretes and mortars used for laying facade and facing bricks.

The cost of this material depends on its brand and type. In addition, the final price of cement is influenced by the reputation of the manufacturer (brand).

The price of one bag of Portland cement grade 500 (weight 50 kg) that does not contain additives (PTs M500-D0) ranges from 200 to 250 rubles.

Cement with additives is slightly cheaper. A 50-kilogram bag (M500, 20% additives) will cost you from 190 to 220 rubles.

A standard bag of M400 cement from different manufacturers costs from 160 to 190 rubles.

Prices for domestically produced white cement M500 start at 390 rubles. Turkish white cement M600 D0 (50 kg) is significantly more expensive. Its cost ranges from 540-570 rubles.

Consumption rates

When answering the question of how much cement is needed per cube of concrete, you need to take into account its brand and the required structural strength. The release date is also of great importance, since this type of binder loses activity over time and is very sensitive to storage conditions.

Practice shows that it is more profitable to buy cement of a higher grade, since to prepare concrete or mortar of the same strength, it can be taken 15-20% less than low-grade cement.

For example, the cement consumption per 1 m3 of mortar of the “three hundredth” grade is: M500 - 500 kg, and M400 - 600 kg. To prepare one cubic meter of M200 concrete, you need to buy 400 kg of M500 cement or half a ton of M400 Portland cement.

To simplify the calculation of the composition of concrete or mortar, you can use the following formula: for structures that do not bear a large load (paths, floor screed, plaster), a ratio of M500 cement to sand of 1:5 is sufficient.

For foundations, floors and other critical structures, the proportion should be 1:2. For tub mortars, a ratio of 1:4 is usually used.

Deciding for yourself which cement is better to choose, remember that the date of its release is no less important than the brand. Even if all storage conditions are met, it loses about 10% of its activity every 30 days. This means that if 3 months have passed since the date of manufacture, then instead of the M500 you will buy the M350.

If the cement has been in the warehouse for six months, then its grade will not exceed 200 kg/cm2. It is unrealistic to make a high-quality solution, much less durable concrete, using such material. Therefore, before purchasing, ask the seller for a document that clearly indicates the date of manufacture.

The requirements for the binder when preparing concrete for pouring or assembling a foundation are high: the cement must have the correct strength grade, be suitable for reinforced concrete structures, be fresh and of high quality. Much depends on the type and weight of the building; for the foundations of residential buildings, PC M400 is considered the minimum; for temporary and lighter ones, a reduction in requirements is allowed. Checking the certificate and expiration date is mandatory in any case; preference is given to cement produced no later than 3 months; the material is not purchased in advance. Important technology standards include precise adherence to proportions, preparation and correct sequence of loading components into the mixer, and compaction of concrete after pouring.

Preference is given to Portland cement; concretes with it have the necessary strength and resistance to external influences. The choice of brand for foundations directly depends on the type and purpose of the building composition being mixed. To fill the drainage base, it is allowed to use cement with a low strength grade (the final concrete is from M75 to M150), in all other cases the rule applies: the grade of binder must be twice as high as the expected grade of the concrete mixture. Taking into account the minimum allowable for foundation structures M200, the solution is mixed with Portland cement with a strength of M400 (about this brand of cement).

The maximum proportion of foreign impurities in the binder is 20%; their introduction reduces the cost, slightly reducing frost and water resistance. As a result, suitable types of cement for pouring a foundation include:

- PC M400 D0 – can withstand loads of up to 400 kg/cm2 after curing, providing good durability, water resistance and frost resistance. Concrete based on it can withstand low temperatures, contact with ground and atmospheric moisture and exposure to aggressive environments. Cement M400 D0 is suitable for any type of foundation, including reinforced and prefabricated (it is used for mixing masonry mortar).

- PC M400 D20 - combining fairly good resistance to moisture and freezing and a reasonable price. The best option for constructing foundations for light residential buildings in the absence of serious soil requirements.

- PC M500 D0 is recommended to be chosen when constructing critical objects; this brand consists only of cement clinker, the share of foreign additives (in this case, gypsum) does not exceed 1%. This has a positive effect on frost and moisture resistance; the variety is considered elite. Its use when mixing concrete for the foundation will pay off economically during construction in problem areas (in particular, flooded ones).

- PC M500 D20 is a similar brand of cement to the previous one, slightly inferior in terms of resistance to moisture and freezing (but not in strength), but in its characteristics it still surpasses M400.

Slag or pozzolanic based cements withstand the effects of sulfates dissolved in ground moisture well, but for laying monolithic or prefabricated foundations it is better to choose a different type. The main reason is the slow development of strength and low frost resistance. As a result, their use is permissible only on the recommendation of professionals and with the adoption of additional measures to protect foundation structures from frost heaving of soils. If there is the slightest doubt, it is better to choose Portland cement without impurities or specialized brands:

- B is a fast-hardening binder, which is recommended for limited work periods.

- PL is a plasticized variety with increased frost resistance. Its introduction allows you to save up to 8-10% of cement, but it is important to remember that it cannot be used with any other types except PC.

- SS – special sulfate-resistant PCs.

- NC – tensile cement. Concrete based on it has a compacted structure after hardening, preventing moisture from entering. NC is recommended to be chosen when laying the foundation of a house with a basement or erecting a monolith on flooded soils. They are also well suited for repairing and restoring existing structures.

Cements below M400 are allowed to be used in the construction of bathhouses and light panel or wooden one-story buildings on dry and stable soils. To eliminate mistakes, they start from the grade of concrete; when selecting it, they must take into account such criteria as the expected weight load (weight of load-bearing structures, including the foundation itself, roofing system, snow cover and objects in the house) and soil parameters (level of freezing, rising water, structural composition and soil homogeneity), timing of filling and hardening conditions.

Cooking proportions

The minimum acceptable grade of concrete for pouring a foundation is considered to be M200 (more is better); when concreting the foundations of residential buildings within 1-2 floors, M250 is most often chosen. The recommended proportions of components when preparing the M250 solution are 1:3:5 (cement, sand, gravel or granite crushed stone, respectively). The W/C ratio does not exceed 0.65, it depends on the expected grade of concrete: the higher it is, the lower the volume of introduced water, minimum 0.4.

| Concrete grade | Ratio (C:P:SH) | Volumetric composition per 10 liters of cement for sand and crushed stone, l | Concrete yield per 10 liters of cement, l |

| PC M400 | |||

| M100 | 1:4,1:6,1 | 41:61 | 78 |

| M150 | 1:3,2:5 | 32:50 | 54 |

| M200 | 1:2,5:4,2 | 25:42 | 64 |

| M250 | 1:1,9:3,4 | 19:34 | 43 |

| M300 | 1:1,7:3,2 | 17:32 | 41 |

| M400 | 1:1,1:2,4 | 11:24 | 31 |

| M450 | 1:1:2,2 | 10:22 | 29 |

| When using PC M500 | |||

| M100 | 1:5,3:7,1 | 53:71 | 90 |

| M150 | 1:4:5,8 | 40:58 | 73 |

| M200 | 1:3,2:4,9 | 32:49 | 62 |

| M250 | 1:2,4:3,9 | 24:39 | 50 |

| M300 | 1:2,2:3,7 | 22:37 | 47 |

| M400 | 1:1,4:2,8 | 14:28 | 36 |

| M450 | 1:1,2:2,5 | 12:25 | 32 |

The indicated proportions are relevant when using the correct components: clean and dry quartz sand with a fraction size of at least 2 mm, washed and dried crushed stone with a strength grade of at least M1200. The activity of the binder plays an important role, reviews in this regard are clear: for the foundation of a house it is better to take cement no earlier than 1-2 weeks before the start of work, checking the release date and certificate is mandatory. Fresh powder has no lumps and is easily passed through your fingers.

If you doubt the integrity of the supplier, it is worth checking the quality of the material in advance: the correct cement sets well within 45 minutes.

In addition to using components of the required quality, the sequence of their loading into the concrete mixer is observed. Recommended scheme: 80% of the total share of water → crushed stone → sifted cement and sand → the rest of the water in small portions. Most plasticizers or hardeners are added at the end with strict adherence to proportions. These include liquid soap (added along with the main portion of water), specialized factory additives, fiber, inhibitors, substances that affect the setting time of concrete. Their use requires caution; exceeding their proportion worsens the structure of the artificial stone.

Material cost

Products are sold in bags, big bags and in bulk; wholesale purchases are the cheapest. The prices in this case are:

| Cement marking | Manufacturer | Price for 1 ton, rubles | |

| With delivery within Moscow by cement truck | pickup | ||

| PC M500 D0 | JSC Lipetskcement CJSC Belarusian Cement Plant |

4500 | 4250 |

| PC M500 D20 | JSC Maltsovsky Portland Cement | 4350 | 4100 |

| PC M500 D0B (fast-hardening) | |||

| PC M500 D0N (standardized clinker) | 4650 | 4450 | |

| PC M400 D0 | JSC Maltsovsky Portland Cement JSC Mikhailovcement JSC Lipetskcement |

4300 | 4150 |

| PC M400 D20 | 4200 | 3950 | |

When building a foundation on your own and delivering it using your own transport, it is more convenient to use bags (the proportions are easier to adjust to the measured weight). High-quality cement is offered by many domestic factories and manufacturers of dry building mixtures: Novgorod Central Plant, Borshchevsky Central Plant (Lafarge), Mikhailovcement, Maltsovsky Portland Cement, OJSC Voskresenskcement, Mordovcement, Sebryakovcement, Rusean. The cost when purchasing it in packaged form is.

DIY brick foundation: strip and columnar

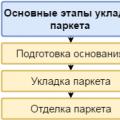

DIY brick foundation: strip and columnar How to lay parquet: methods, necessary tools and step-by-step process for proper installation

How to lay parquet: methods, necessary tools and step-by-step process for proper installation How to lay parquet: methods, necessary tools and step-by-step process for proper installation

How to lay parquet: methods, necessary tools and step-by-step process for proper installation